http://www.powerperformancenews.com/for ... q-635.html

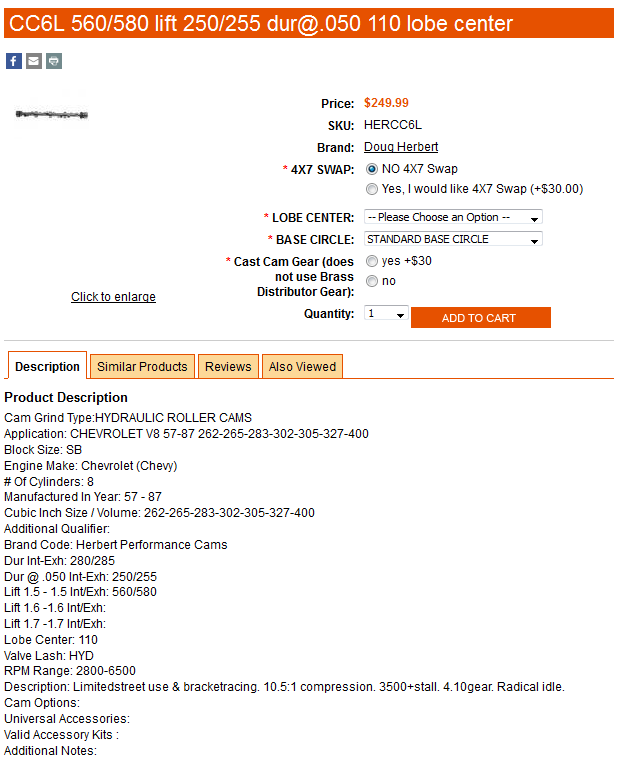

http://www.herbertcams.com/560-580-lift-250-255-dur-050-110-lobe-center/

theres some rather significant advantages in ordering a cam that closely matches the engines

requirements, and after building dozens of similar engines youll notice some trends and you may want to tweak the cam timing, this of course requires both a good understanding of what your trying to change or accomplish and what the changes you intend to make are likely to do to engine performance.

heres a cam thats rather well known for producing good power in a 10.7:1 compression 406 SBC combo.

(use mostly for racing in a light weight car like a cobra replica)

Ive built several times in the past, it really requires the following matched components

210-230cc port heads, 5" scat rods on a forged crank, a 3600-3800rpm stall converter, a 4.11:1-4.56:1 rear gear and an automatic trans that shifts at 6300rpm under full load race acceleration.

a good single plane intake like the edelbrock VIC series, an 850 cfm carb, long tube 1 3/4" headers 1.6:1 roller rockers and a rocker stud girdle

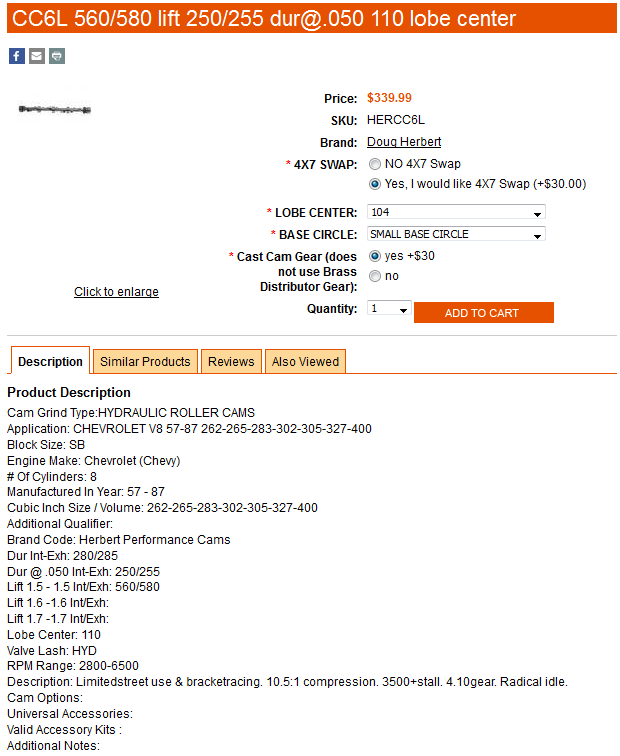

heres the came basic cam, but with a few mods that provide about 20 extra horse power, but at the cost of a noticeably rougher lope in the idle

notice the tighter LSA and its a 4/7 swap cam version on a smaller base circle

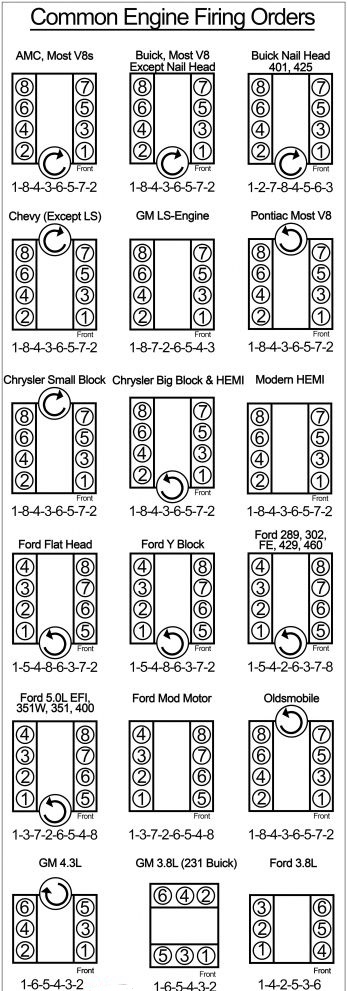

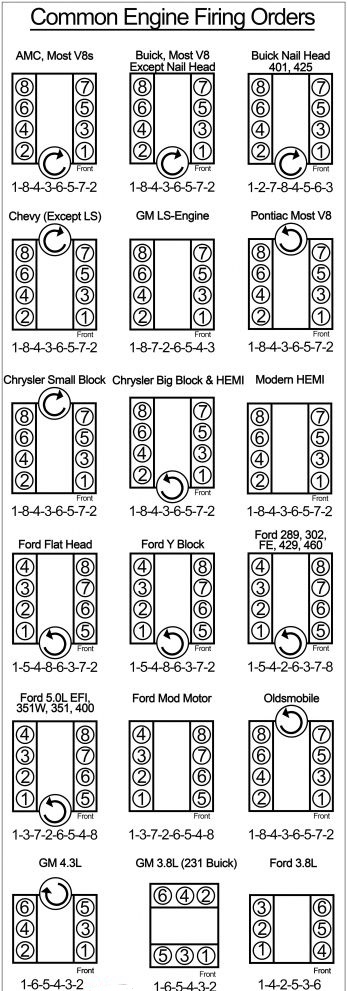

1. A typical 4 & 7 FOS (firing order swap) seems to be fairly common today. Why is this firing order change beneficial?

There are three basic issues that engine builders or developers try to address through a firing order change. Here are three considerations:

A) Hot spots in the head and block – With a common pin V8 crankshaft, it is impossible to eliminate having adjacent cylinders (paired next to each other) fire subsequent to one another in the sequence (which we call a hot spot). While this is unavoidable on a four counterweighted throw crankshaft, you do have some choice as to which pair(s) fire together. The 4 & 7 firing order moves that hot spot from the 5 & 7 cylinders up to the 4 & 2 cylinders which is more desirable as the front pair of cylinders are easier to keep cool with a front mounted water pump.

B) Main bearing issues – Most engine builders see better bearing life and less scuffing indicators with the 4 & 7 swap camshaft. In the case of the LS firing order (which utilizes the 4 & 7 swap plus an additional 2 & 3 swap), there may be a bearing life benefit. Again, we are talking about pairs of rods firing together, keeping the force of the adjacent crank main bearings in the same pin. Moving this “hot spot†to the back of the engine seems to be a good idea because the drive train is much better able to dampening these forces in this case rather than with a small mass on the front of the crankshaft. When we consider the power that can be gained with lighter weight, lower viscosity oils, bearing life becomes not only question of durability, but of power as well.

C) Fuel distribution – Changing the firing order is one of the best ways to change the cylinder-to-cylinder fuel and air distribution in the engine. Just like the forces experienced by the bottom end with hot spots where cylinders fire together next to each other, when this occurs with an engine, the same happens in the manifold with ports that are next to each other. This creates a very dynamic system in the manifold plenum where pressure waves of air (and also fuel in a wet manifold) are moving from the front to the back and side-to-side. Changing the firing order definitely changes how the ports interact. Depending on the configuration, this can be a big plus or minus for an engine builder, so changing the firing order is a critical question.

2. In what type of motorsports application is a firing order swap most helpful (drag racing, oval track, road race, etc.)?

We have certainly seen engine builders benefit from firing order swaps in a wide variety of applications. By the numbers more drag racing and road racing engine builders are using this change than oval track builders, but that is probably a function of the sanctioning body rules over builder choice. Certainly, OEMs competing in NASCAR try various firing orders before submitting a new engine configuration to NASCAR because they know this configuration will be locked down to certain restrictions if it is accepted.

3. I’m told that a firing order swap (4 & 7 or the LS swap of 4 & 7 and 2 & 3) results in reduced crankshaft and main bearing deflection. Is this true? Can you further explain how/why this occurs?

As noted in part B of question #1 above, but deflection has to do with neighboring cylinders firing subsequently. This condition creates force pulses due to the firing sequence affecting deflection within the engine and specifically, the crankshaft.

4. As far as I am aware, FOS (firing order swap) cams for Small and Big Block Chevy engines including the 4 & 7 swap and the LS firing order swap are popular. Are there any different firing order swaps that are used in other make engines (Ford, Chrysler, etc.)? Are these same swaps applicable to all domestic V8 engines?

On any even fire, common pin, 90-degree V8 application, a cam can be made to swap any of the cylinders that are four positions apart in the firing order. What may be the third most common order is called a “Bank-Bank†where you fire all the cylinders on one side of the engine, and then fire the cylinders on the other side. Simply swapping 2 & 3 (w/o 4 & 7) will result in the firing order of 1-8-4-2-6-5-7-3 with each bank’s cylinders firing all four cylinders before jumping to the other side. Some engine builders believe this helps traction limited and/or restricted applications.

5. Can you provide detailed information of what occurs (in terms of valve operation) with a 4 & 7 swap and with a 4 & 7 and 2 & 3 swap?

We have not measured a change in valve duration that we can absolutely trace to a firing order change.

6. How does an FOS cam benefit engine horsepower and/or torque?

An engine’s power and torque varies depending on the intake manifold, fuel delivery and exhaust system, along with a host of other considerations. A one to three percent improvement is actually quite common. If you experience changes greater than three percent, it is probably due to either creating or eliminating a major distribution problem that could have been addressed in another way (the manifold is commonly the culprit here).

7. I assume that all FOS cams are machined from billet stock instead of starting with a casting…true or false?

Actually COMP Cams® does offer cast iron flat tappet cores to make flat tappet 4 & 7 swap camshafts for Small Block and Big Block Chevys. For Small Block Fords there are two firing order swaps available: one for the standard 302 versus the later 351W (5.0 HO) firing order. In essence, the 351 engine firing order is basically Ford’s version of the Cadillac/LS1/4 & 7 + 2 & 3 GM firing order change. There are also two billet steel cores available off the shelf from COMP Cams® for the most common Chevy and Ford firing order engines. Most of the other firing orders require more expensive custom cores.

http://www.smokemup.com/tech/ls1.php

5.7L V8 LT1

Type:90 Degree V

Longitudinal 5.7 V8 350ci

Firing Order:1-8-4-3-6-5-7-2 ;

Left Bank:1-3-5-7;

Right Bank:2-4-6-8

Compression Ratio: 10.5:1

http://www.herbertcams.com/560-580-lift-250-255-dur-050-110-lobe-center/

theres some rather significant advantages in ordering a cam that closely matches the engines

requirements, and after building dozens of similar engines youll notice some trends and you may want to tweak the cam timing, this of course requires both a good understanding of what your trying to change or accomplish and what the changes you intend to make are likely to do to engine performance.

heres a cam thats rather well known for producing good power in a 10.7:1 compression 406 SBC combo.

(use mostly for racing in a light weight car like a cobra replica)

Ive built several times in the past, it really requires the following matched components

210-230cc port heads, 5" scat rods on a forged crank, a 3600-3800rpm stall converter, a 4.11:1-4.56:1 rear gear and an automatic trans that shifts at 6300rpm under full load race acceleration.

a good single plane intake like the edelbrock VIC series, an 850 cfm carb, long tube 1 3/4" headers 1.6:1 roller rockers and a rocker stud girdle

heres the came basic cam, but with a few mods that provide about 20 extra horse power, but at the cost of a noticeably rougher lope in the idle

notice the tighter LSA and its a 4/7 swap cam version on a smaller base circle

1. A typical 4 & 7 FOS (firing order swap) seems to be fairly common today. Why is this firing order change beneficial?

There are three basic issues that engine builders or developers try to address through a firing order change. Here are three considerations:

A) Hot spots in the head and block – With a common pin V8 crankshaft, it is impossible to eliminate having adjacent cylinders (paired next to each other) fire subsequent to one another in the sequence (which we call a hot spot). While this is unavoidable on a four counterweighted throw crankshaft, you do have some choice as to which pair(s) fire together. The 4 & 7 firing order moves that hot spot from the 5 & 7 cylinders up to the 4 & 2 cylinders which is more desirable as the front pair of cylinders are easier to keep cool with a front mounted water pump.

B) Main bearing issues – Most engine builders see better bearing life and less scuffing indicators with the 4 & 7 swap camshaft. In the case of the LS firing order (which utilizes the 4 & 7 swap plus an additional 2 & 3 swap), there may be a bearing life benefit. Again, we are talking about pairs of rods firing together, keeping the force of the adjacent crank main bearings in the same pin. Moving this “hot spot†to the back of the engine seems to be a good idea because the drive train is much better able to dampening these forces in this case rather than with a small mass on the front of the crankshaft. When we consider the power that can be gained with lighter weight, lower viscosity oils, bearing life becomes not only question of durability, but of power as well.

C) Fuel distribution – Changing the firing order is one of the best ways to change the cylinder-to-cylinder fuel and air distribution in the engine. Just like the forces experienced by the bottom end with hot spots where cylinders fire together next to each other, when this occurs with an engine, the same happens in the manifold with ports that are next to each other. This creates a very dynamic system in the manifold plenum where pressure waves of air (and also fuel in a wet manifold) are moving from the front to the back and side-to-side. Changing the firing order definitely changes how the ports interact. Depending on the configuration, this can be a big plus or minus for an engine builder, so changing the firing order is a critical question.

2. In what type of motorsports application is a firing order swap most helpful (drag racing, oval track, road race, etc.)?

We have certainly seen engine builders benefit from firing order swaps in a wide variety of applications. By the numbers more drag racing and road racing engine builders are using this change than oval track builders, but that is probably a function of the sanctioning body rules over builder choice. Certainly, OEMs competing in NASCAR try various firing orders before submitting a new engine configuration to NASCAR because they know this configuration will be locked down to certain restrictions if it is accepted.

3. I’m told that a firing order swap (4 & 7 or the LS swap of 4 & 7 and 2 & 3) results in reduced crankshaft and main bearing deflection. Is this true? Can you further explain how/why this occurs?

As noted in part B of question #1 above, but deflection has to do with neighboring cylinders firing subsequently. This condition creates force pulses due to the firing sequence affecting deflection within the engine and specifically, the crankshaft.

4. As far as I am aware, FOS (firing order swap) cams for Small and Big Block Chevy engines including the 4 & 7 swap and the LS firing order swap are popular. Are there any different firing order swaps that are used in other make engines (Ford, Chrysler, etc.)? Are these same swaps applicable to all domestic V8 engines?

On any even fire, common pin, 90-degree V8 application, a cam can be made to swap any of the cylinders that are four positions apart in the firing order. What may be the third most common order is called a “Bank-Bank†where you fire all the cylinders on one side of the engine, and then fire the cylinders on the other side. Simply swapping 2 & 3 (w/o 4 & 7) will result in the firing order of 1-8-4-2-6-5-7-3 with each bank’s cylinders firing all four cylinders before jumping to the other side. Some engine builders believe this helps traction limited and/or restricted applications.

5. Can you provide detailed information of what occurs (in terms of valve operation) with a 4 & 7 swap and with a 4 & 7 and 2 & 3 swap?

We have not measured a change in valve duration that we can absolutely trace to a firing order change.

6. How does an FOS cam benefit engine horsepower and/or torque?

An engine’s power and torque varies depending on the intake manifold, fuel delivery and exhaust system, along with a host of other considerations. A one to three percent improvement is actually quite common. If you experience changes greater than three percent, it is probably due to either creating or eliminating a major distribution problem that could have been addressed in another way (the manifold is commonly the culprit here).

7. I assume that all FOS cams are machined from billet stock instead of starting with a casting…true or false?

Actually COMP Cams® does offer cast iron flat tappet cores to make flat tappet 4 & 7 swap camshafts for Small Block and Big Block Chevys. For Small Block Fords there are two firing order swaps available: one for the standard 302 versus the later 351W (5.0 HO) firing order. In essence, the 351 engine firing order is basically Ford’s version of the Cadillac/LS1/4 & 7 + 2 & 3 GM firing order change. There are also two billet steel cores available off the shelf from COMP Cams® for the most common Chevy and Ford firing order engines. Most of the other firing orders require more expensive custom cores.

http://www.smokemup.com/tech/ls1.php

5.7L V8 LT1

Type:90 Degree V

Longitudinal 5.7 V8 350ci

Firing Order:1-8-4-3-6-5-7-2 ;

Left Bank:1-3-5-7;

Right Bank:2-4-6-8

Compression Ratio: 10.5:1

Last edited by a moderator: