You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Force Awakens...

- Thread starter DorianL

- Start date

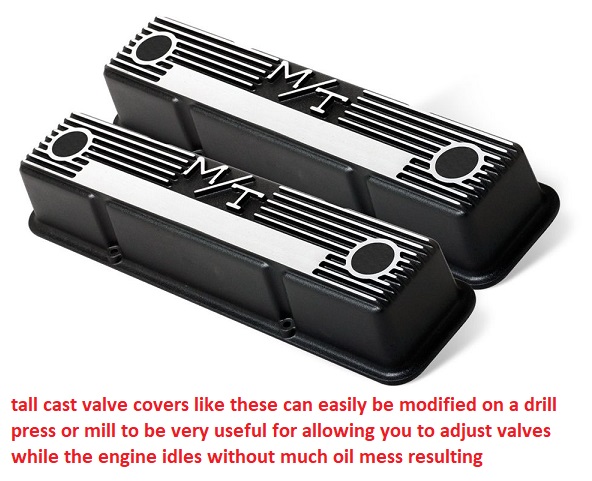

the the tall cast valve covers I fabricated/modified for valve adjustment is taller and has a smaller open area,By the way. That opened valve cover worked extremely well. NO oil mess at all.

but yes the basic concept of having a valve cover modified to adjust valves at idle works very effectively,

I bought a used set like these to modify and drilled 8 -2 1/8" diameter round holes centered on the rocker studs (yes the holes overlap)

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/

Last edited:

Yes. I was very pleased with the results of setting the valve lash this way.

The engine seems to sag in power at 2500 plus rpm. It vibrates as well and shudders.

On the timing light idle seems fine and up to 2200 rpm the mark looks good. Pushing above 2500 rpm and you can feel the engine doesn’t like it. The timing mark comes and goes and sometimes seems to pop up quite retarded.

This is an HEI but not GM. Some aftermarket thing with a mechanical tach drive. It looks about new. Cap and rotor look pristine. As do the cables.

I’m going to:

- check the gaps

- check the resistance on the HT leads (as the Brits call them)

- give direct full battery to the ignition instead of running through the firewall connector. I have a small length (a few inches) of the original wire there... but that was originally for points... I’m wondering if there is some resistance there...

Beyond that, I suppose it’s the coil or the module.

The engine seems to sag in power at 2500 plus rpm. It vibrates as well and shudders.

On the timing light idle seems fine and up to 2200 rpm the mark looks good. Pushing above 2500 rpm and you can feel the engine doesn’t like it. The timing mark comes and goes and sometimes seems to pop up quite retarded.

This is an HEI but not GM. Some aftermarket thing with a mechanical tach drive. It looks about new. Cap and rotor look pristine. As do the cables.

I’m going to:

- check the gaps

- check the resistance on the HT leads (as the Brits call them)

- give direct full battery to the ignition instead of running through the firewall connector. I have a small length (a few inches) of the original wire there... but that was originally for points... I’m wondering if there is some resistance there...

Beyond that, I suppose it’s the coil or the module.

Are you using the push button start still or have you removed it?

Any chance there are still some wires associated with the push button or key start that need further inspection?

I rewirded it to a free IGN spade on the fuse panel. I do here the solenoid snapping every time. Nonetheless, you are right, I’ll try giving an alternate source to see if that changes anything

I do here the solenoid snapping every time.

Does it snaps once or clicks over and over until the key is released?

If the solenoid clicks every time, then the push button must be good. What's the voltage at the

starter with the button pushed and the solenoid energized ?

If you suspect a worn cam lobe, checking the cams lobe lift with a dial indicator on the valve spring retainer vs the other lobes would certainly provide useful related info.

knowing vs guessing helps in making decisions wisely

http://www.summitracing.com/parts/pro-66830/overview/

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=indicator+stand

knowing vs guessing helps in making decisions wisely

http://www.summitracing.com/parts/pro-66830/overview/

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=indicator+stand

Time for a little update...

I put a relay on both the line to the coil/distributor and to the starter solenoid and that seems to have cleared things up dramatically. The starter no longer seems to hang and spins nice and fast. No more detectable high RPM misses.

I took the corvette out for a series of test drives and, it seems that I have a sticky thermostat: temp spikes and slow or erratic behavior. I'll replace that within the next few days taking care to drill some holes in the thermostat flange.

Soon I will start looking into tuning what I have... which isn't much: 882 heads, headers, who-knows-what cam, Torker intake and 750CFM Performer carb. I have good compression and oil pressure; I am happy about that.

The idle quality is good - I'll check this weekend how many inches of vacuum I am getting. But from experience, I'd say at least 15. I don't know if it is the cam or the burble of the twin Flowmasters that give the car a feeling of vibration at 2500-3000 rpm. The sound might be misleading me. It almost feels like the rotating assembly was not properly balanced. I'll need to focus my senses the next time I take this for a drive (after I swap the thermostat.)

I rebuilt the carb; it has the original Performer tuning on it. The ignition curve, I still have to check. I am going to double-check TDC. (Anyone have a tutorial on converting a spark plug into a piston stop?)

There is significant bogging when I get on the gas. Peak torque feels around 2800-3000 rpm. Beyond that is seems to run out of steam.

Once I get the basics done, I will take it down to a dyno. I also have a dual wideband O2 sensor... I just need to get a couple of bungs welded in. We shall see what I can find out there.

I also have to remember that I have at least one cam lobe that is worn... that might be a factor; number 8 intake barely rocked over when setting lash.

I put a relay on both the line to the coil/distributor and to the starter solenoid and that seems to have cleared things up dramatically. The starter no longer seems to hang and spins nice and fast. No more detectable high RPM misses.

I took the corvette out for a series of test drives and, it seems that I have a sticky thermostat: temp spikes and slow or erratic behavior. I'll replace that within the next few days taking care to drill some holes in the thermostat flange.

Soon I will start looking into tuning what I have... which isn't much: 882 heads, headers, who-knows-what cam, Torker intake and 750CFM Performer carb. I have good compression and oil pressure; I am happy about that.

The idle quality is good - I'll check this weekend how many inches of vacuum I am getting. But from experience, I'd say at least 15. I don't know if it is the cam or the burble of the twin Flowmasters that give the car a feeling of vibration at 2500-3000 rpm. The sound might be misleading me. It almost feels like the rotating assembly was not properly balanced. I'll need to focus my senses the next time I take this for a drive (after I swap the thermostat.)

I rebuilt the carb; it has the original Performer tuning on it. The ignition curve, I still have to check. I am going to double-check TDC. (Anyone have a tutorial on converting a spark plug into a piston stop?)

There is significant bogging when I get on the gas. Peak torque feels around 2800-3000 rpm. Beyond that is seems to run out of steam.

Once I get the basics done, I will take it down to a dyno. I also have a dual wideband O2 sensor... I just need to get a couple of bungs welded in. We shall see what I can find out there.

I also have to remember that I have at least one cam lobe that is worn... that might be a factor; number 8 intake barely rocked over when setting lash.

as long as its easy to drive, I would not spend a great deal of effort ,time and cash on any engine,

you know for a fact has a seriously worn cam lobe as its kind of wasted effort.

that worn cam lobe and matched lifter,has puked fine metallic trash all over the current engines internal parts and bearing surfaces

Id just concentrate on building its replacement

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/#post-61283

you know for a fact has a seriously worn cam lobe as its kind of wasted effort.

that worn cam lobe and matched lifter,has puked fine metallic trash all over the current engines internal parts and bearing surfaces

Id just concentrate on building its replacement

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/#post-61283

Last edited:

Thanks - that is the advice I needed to hear.as long as its easy to drive, I would not spend a great deal of effort ,time and cash on any engine,

you know for a fact has a seriously worn cam lobe as its kind of wasted effort.

that worn cam lobe and matched lifter,has puked fine metallic trash all over the current engines internal parts and bearing surfaces

Id just concentrate on building its replacement

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/#post-61283

Last edited by a moderator:

its only a mater of time before that metallic trash causes other moving component wear issues

this is one reason changing oil filters, rather frequently (at least every 7-8K miles)

(IDEALLY the long versions with extra surface area)

and having previously installed several high temp magnets in an engine, you build,

is rather critical too preventing similar damage in any future engine builds

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/#post-61283

http://garage.grumpysperformance.co...filters-wix-vs-royal-purple.12988/#post-67560

this is one reason changing oil filters, rather frequently (at least every 7-8K miles)

(IDEALLY the long versions with extra surface area)

and having previously installed several high temp magnets in an engine, you build,

is rather critical too preventing similar damage in any future engine builds

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/#post-61283

http://garage.grumpysperformance.co...filters-wix-vs-royal-purple.12988/#post-67560

Loves302Chevy

"One test is worth a thousand expert opinions."

(Anyone have a tutorial on converting a spark plug into a piston stop?)

Simple answer. Cut or grind the ground electrode off. Smash the porcelain off and out. Determine what thread the ID will accept for the center bolt.

Tap the new threads. Install bolt. Done.

This is what I made.

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-33#post-23374

.

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-33#post-23374

.

Hmmmm, I have a nagging suspicion this might be a bent pushrod. The engine seems to be in too reasonable condition for it to be something so catastrophic.

First I'll put my vacuum gauge on this, then I'll yank the push rod and check it against a straight edge.

First I'll put my vacuum gauge on this, then I'll yank the push rod and check it against a straight edge.

you also might want to swap out those older stock stamped rocker arms for new ones when you do a compression test, they may be excessively worn and they don,t cost much to replace.

in fact swapping to a set of the stamped 1.6:1 ratio stamped rockers is a cheap and usually effective upgrade, if you keep it simple and check clearances carefully you could rather easily gain 10-12 hp from the increased valve lift and usually more consistent ratio, quality control on the parts dimensions.(stock stamped chevy rockers are supposed to be 1.5:1 ratio but they rather frequently actually measure closer to 1.4:1-1.44:1

https://www.summitracing.com/parts/sum-g6801/overview/make/chevrolet

(BE DAMN SURE you check clearances , especially on the push-rods to cylinder head guide slots)

http://garage.grumpysperformance.co...swap-in-1-6-1-ratio-rockers.10671/#post-46039

http://garage.grumpysperformance.co...rocker-ratios-and-the-effects.126/#post-37621

http://garage.grumpysperformance.co...-rocker-ratio-help-your-combo.2632/#post-6790

in fact swapping to a set of the stamped 1.6:1 ratio stamped rockers is a cheap and usually effective upgrade, if you keep it simple and check clearances carefully you could rather easily gain 10-12 hp from the increased valve lift and usually more consistent ratio, quality control on the parts dimensions.(stock stamped chevy rockers are supposed to be 1.5:1 ratio but they rather frequently actually measure closer to 1.4:1-1.44:1

https://www.summitracing.com/parts/sum-g6801/overview/make/chevrolet

(BE DAMN SURE you check clearances , especially on the push-rods to cylinder head guide slots)

http://garage.grumpysperformance.co...swap-in-1-6-1-ratio-rockers.10671/#post-46039

http://garage.grumpysperformance.co...rocker-ratios-and-the-effects.126/#post-37621

http://garage.grumpysperformance.co...-rocker-ratio-help-your-combo.2632/#post-6790

Last edited: