Thanks so much Dorian !!!Thanks Gents...

Man, Rick !!! You pics are always so stunning. Could almost eat lunch off of them or perform surgery with them and still not risk infection...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Force Awakens...

- Thread starter DorianL

- Start date

Lay it on a somewhat flat surface, then roll the push rod. It will be easy to see it wobble if it's bent.then I'll yank the push rod and check it against a straight edge.

Interesting. These heads look like they have been rebuilt very recently. They look very clean. No wear pattern on the valve tips. The rocker studs are the screw-in type; that’s not what is supposed to be on 882 heads.

I put a vacuum gauge on the running engine and got a very stable 17 inches. With the engine running, I could see the pushrods spinning. Though #8 exhaust was spinning slightly slower.

Pushrod #8 exhaust is bent, but slightly. Spinning it in a drill one can see a slight wobble that the pushrod right next to it does not have.

Nonetheless (and bear with me) I do not think this is enough to explain the lack of lift. Hmmm. I’ll have to see if I can find a dial gauge somewhere this weekend. That or I may pull the intake and eyeball the bottom of the lifter direc

I put a vacuum gauge on the running engine and got a very stable 17 inches. With the engine running, I could see the pushrods spinning. Though #8 exhaust was spinning slightly slower.

Pushrod #8 exhaust is bent, but slightly. Spinning it in a drill one can see a slight wobble that the pushrod right next to it does not have.

Nonetheless (and bear with me) I do not think this is enough to explain the lack of lift. Hmmm. I’ll have to see if I can find a dial gauge somewhere this weekend. That or I may pull the intake and eyeball the bottom of the lifter direc

I tried that but it’s slight and my eyes aren’t very goodLay it on a somewhat flat surface, then roll the push rod. It will be easy to see it wobble if it's bent.

I’d say there is 1/32 to 1/16 deflection

Yes. Just get it running without sinking too much $$$ in it. Best to explore a crate engine at this point.Hmm. If that is a rounded off lobe, I’m not too sure what the most cost effective thing to do is to get this running while I save up my nickels and dimes for a rebuild or a crate engine.

http://www.herbertcams.com/dhp383-dhp-383-chevrolet-small-block-engine-stroker-400-hp/

http://www.ohiocrank.com/chev_sb_shortb.html

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/upgrading-sbc-crate-engine-heads.13041/

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.com/index.php?threads/bits-of-dart-component-info.13263/#post-69135

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.com/index.php?threads/82-cfi-crate-motor.12472/#post-62639

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/a-high-torque-406.12184/#post-68415

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-71932

http://garage.grumpysperformance.com/index.php?threads/tweaking-a-350-383.13087/#post-68195

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...-or-upgrading-too-a-383-sbc.11408/#post-54984

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://www.ohiocrank.com/chev_sb_shortb.html

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/upgrading-sbc-crate-engine-heads.13041/

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.com/index.php?threads/bits-of-dart-component-info.13263/#post-69135

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.com/index.php?threads/82-cfi-crate-motor.12472/#post-62639

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/a-high-torque-406.12184/#post-68415

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-71932

http://garage.grumpysperformance.com/index.php?threads/tweaking-a-350-383.13087/#post-68195

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...-or-upgrading-too-a-383-sbc.11408/#post-54984

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

Last edited:

Loves302Chevy

"One test is worth a thousand expert opinions."

Hmmmm, I have a nagging suspicion this might be a bent pushrod. The engine seems to be in too reasonable condition for it to be something so catastrophic.

First I'll put my vacuum gauge on this, then I'll yank the push rod and check it against a straight edge.

Just roll it on a glass table top. If it clicks when it rolls, it's not straight.

Loves302Chevy

"One test is worth a thousand expert opinions."

Let's see if I can save you some work. The magnet above is strong enough to pull the lifters out of their bores - without removing the intake manifold. This assumes that the lifters do not have a huge varnish build-up or a burr from being collapsed and are now concave. I have changed entire sets of lifters using this magnet in this manner. You don't even have to drain any coolant.

You said the problem is #8, which is right next to the distributor hole, so you can do everything through that hole. If you were doing other cylinders, then use the holes between each pair of pushrods - assuming they are large enough for the magnet to fit through.

Pull the distributor and fold up a paper towel or rag and stuff it over/into the hole in the lifter valley where the distributor engaged the oil pump drive shaft.

Loosen the rockers for any pushrods you wish to remove. Use the magnet to remove your suspect lifters. Do 1 at a time, or mark them, so they don't get mixed up. They must go back where they came from!

To re-install the lifter, use the magnet the same way. Get the lifter over the hole you want to put it in and use a long wooden dowel through the pushrod slot to push it in the hole. Don't forget to remove the rag or paper towel when finished.

If you happen to have the Harbor Freight Inspection Camera https://www.harborfreight.com/digital-inspection-camera-61839.html, you could use it to inspect the cam lobe in question.

Good morning Gentlemen,

Thank you for your invaluable feedback. Really.

Ha, I had forgotten I had an inspection camera or endoscope.

There's an expression in French which roughly translates as: the night brings good counsel.

Having slept on this, I think the best course of action is to pull the engine. One reason is of course to be able to carefully swap out the cam, flush then engine and ensure a leak-free reassembly. I HATE leaking engines !!!!!

The other reasons include:

- timing tab needs to be properly mounted. I may have to helicoil a bolt hole; it will be safer and easier to do that with the engine out;

- There is an intake bolt missing front passenger side;

- I have a power-brake conversion kit to install, it will be easier with the engine out;

- wiring I can clean up;

- clean up and inspect the engine bay;

- possibly swap in a borgeson while I am at it. It probably will be much easier to do like this...

This evening I will pull the intake (an open plenum Torker first generation which I do not think is appropriate for the street). I will pull and inspect the lifters individually. If they are fine - no biggie, I'll swap in a better intake... If they are not... I pull the engine.

I also need to determine what caused the cam lobe to wipe.

I will limit my work to cleaning up, a new cam with lifters and a new timing chain. I'd rather get this back on the road fast and save up for a the expense of a crate later on.

Thank you for your invaluable feedback. Really.

Ha, I had forgotten I had an inspection camera or endoscope.

There's an expression in French which roughly translates as: the night brings good counsel.

Having slept on this, I think the best course of action is to pull the engine. One reason is of course to be able to carefully swap out the cam, flush then engine and ensure a leak-free reassembly. I HATE leaking engines !!!!!

The other reasons include:

- timing tab needs to be properly mounted. I may have to helicoil a bolt hole; it will be safer and easier to do that with the engine out;

- There is an intake bolt missing front passenger side;

- I have a power-brake conversion kit to install, it will be easier with the engine out;

- wiring I can clean up;

- clean up and inspect the engine bay;

- possibly swap in a borgeson while I am at it. It probably will be much easier to do like this...

This evening I will pull the intake (an open plenum Torker first generation which I do not think is appropriate for the street). I will pull and inspect the lifters individually. If they are fine - no biggie, I'll swap in a better intake... If they are not... I pull the engine.

I also need to determine what caused the cam lobe to wipe.

I will limit my work to cleaning up, a new cam with lifters and a new timing chain. I'd rather get this back on the road fast and save up for a the expense of a crate later on.

Cam opinions on these:

https://www.summitracing.com/search...7+4294876856+4294876851+4294844512+4294797962

https://www.summitracing.com/search...7+4294876856+4294876851+4294844512+4294797962

if your simply looking for a replacement cam in the existing engine that potentially provides you with a bit more power than stock

either cam will work reasonably well.

http://www.pbm-erson.com/Catalog/Erson/Camshafts/Hydraulic Flat Tappet_E/ERSE110028

https://www.summitracing.com/parts/sum-k1103/overview/

either cam will work reasonably well.

http://www.pbm-erson.com/Catalog/Erson/Camshafts/Hydraulic Flat Tappet_E/ERSE110028

https://www.summitracing.com/parts/sum-k1103/overview/

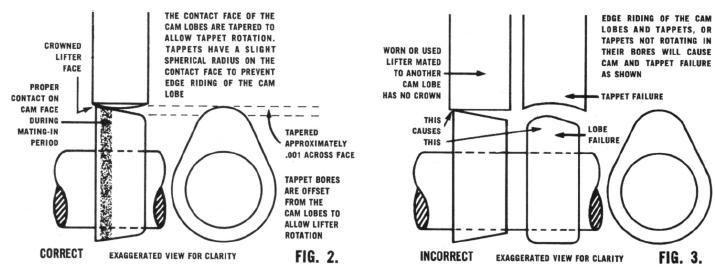

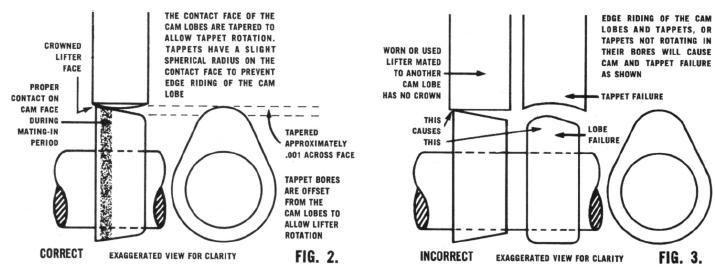

yes that cupped concave lifter base indicates a badly worn lifter and cam lobe

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

Last edited:

Interestingly, everything else looks in reasonably good shape.yes that cupped concave lifter base indicates a badly worn lifter and cam lobe

I have no idea how long it has been in this condition.

What could have caused this??? I'd rather not screw the next cam up.

A buddy over here has a new stock cam. My guess is the stick is very affordable, he has had it for a while and will discount it. Shall I stab the one in there in the meantime?

yeah! Id get the broken bolt removed

http://garage.grumpysperformance.co...studs-bolts-rusted-in-place.11410/#post-52306

and if the cam your buddies got is NEW not used, ID install it with NEW LIFTERS,

personally, Id rather carefully select and pay for a new cam that I knew the specs on ,

rather than install a unknown "stock" cam.

(even if that stock cam were free)

the engine looks to be clean, that cams been that way for hundreds of miles

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/cam-install-info.1246/#post-2666

http://garage.grumpysperformance.com/index.php?threads/breaking-in-a-cam.798/#post-1160

http://garage.grumpysperformance.com/index.php?threads/break-in-oil-quality-tested.11145/#post-52505

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-67562

http://garage.grumpysperformance.co...ectly-and-get-it-to-last-cam-install-info.90/

http://garage.grumpysperformance.com/index.php?threads/chain-vs-gear-drive-cam.781/#post-72280

read through the links above

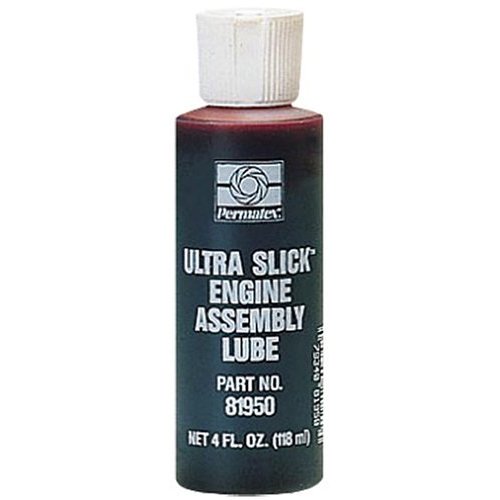

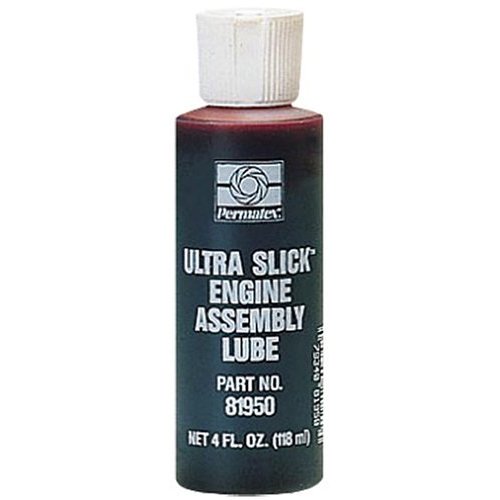

coat the cam lobes and lifter bases with this moly lube and check clearances, and Id use the new cam drive timing set

http://garage.grumpysperformance.co...studs-bolts-rusted-in-place.11410/#post-52306

and if the cam your buddies got is NEW not used, ID install it with NEW LIFTERS,

personally, Id rather carefully select and pay for a new cam that I knew the specs on ,

rather than install a unknown "stock" cam.

(even if that stock cam were free)

the engine looks to be clean, that cams been that way for hundreds of miles

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/cam-install-info.1246/#post-2666

http://garage.grumpysperformance.com/index.php?threads/breaking-in-a-cam.798/#post-1160

http://garage.grumpysperformance.com/index.php?threads/break-in-oil-quality-tested.11145/#post-52505

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-67562

http://garage.grumpysperformance.co...ectly-and-get-it-to-last-cam-install-info.90/

http://garage.grumpysperformance.com/index.php?threads/chain-vs-gear-drive-cam.781/#post-72280

read through the links above

coat the cam lobes and lifter bases with this moly lube and check clearances, and Id use the new cam drive timing set

Last edited: