A few charts and a bit of math go a LONG WAY towards answering a few basic questions, and I'm frequently asked why a certain combination once its built does not live up to the car owners expectations.

I've constantly seen trends over the years and while I'm all too aware most of us build on a very limited budget and because that restricts access to all the components we would like to have in our builds it makes the process far longer and more difficult, yet I also see a STRONG tendency for guys to select components based more on price than part compatibility to the intended goal. in fact at times I get the distinct impression that the parts being bolted together , were almost a random selection of components with the only requirement in their selection being the physical ability too have the parts bolt together.

the fact is that a well planed selection of matched quality components will almost always perform far more effectively that the random mix of bargain priced parts many cars are built from.

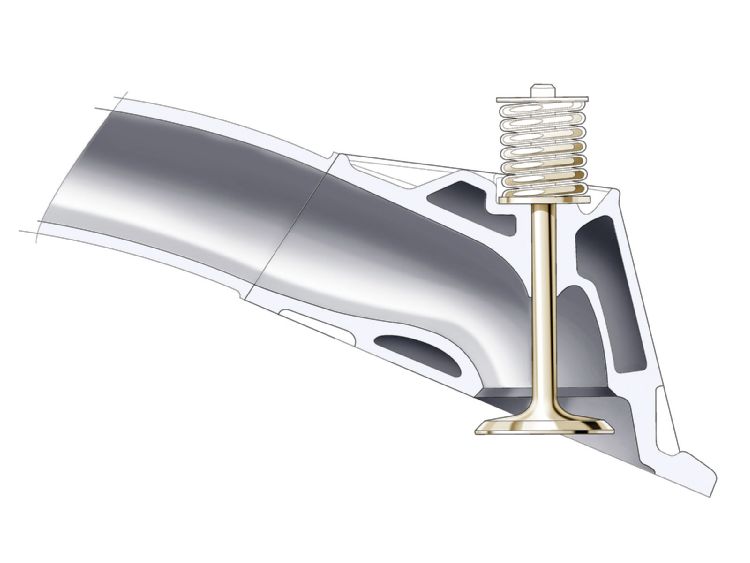

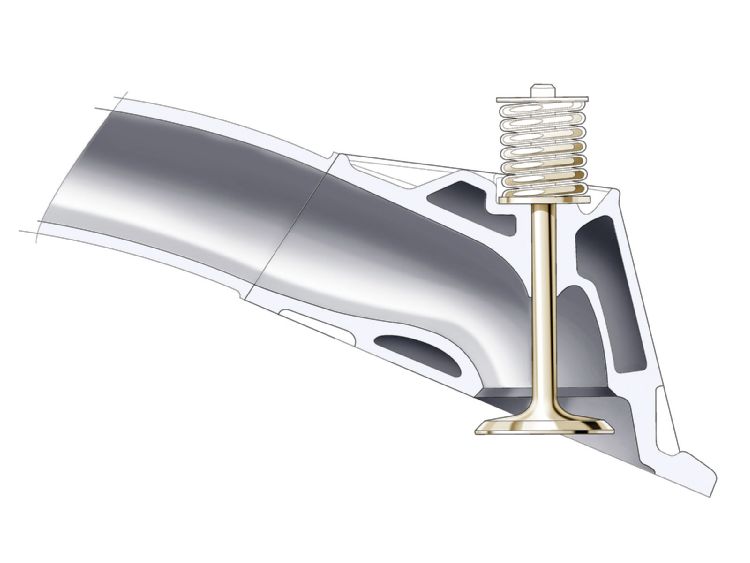

a simple choice made while planing the engine, like selecting a bit less duration on a tighter LSA in a cam, or actually accurately measuring the valve train clearances and valve spring load rates can and does make a huge difference in the finished engines durability and power curve!

Id also point out that your vehicles drive train, rear gear, transmission gearing and tire diameter can have a very pronounced effect on how your engine will function

EXAMPLE one of the local guys has a son that started out in this hobby like most of us do, buy buying some ones half finished project car and a wide assortment of parts from friends cast offs and the idea that simply bolting them together , with the help of several enthusiastic but usually equally in-experienced friends,would some how result in a fast car.

YEAH! I'll freely admit I went through a sharp learning curve due to starting out on a similar manor but unlike many guys I've always had a strong tendency to step back and say to myself "WELL CRAP! THAT DIDN,T WORK WORTH A SHIT!" when I screw something up royally, but unlike many or most guys I want to know EXACTLY WHY IT DID NOT WORK!, AND WHAT I COULD DO TO MAKE THE CAR MORE DURABLE, FASTER, OR LESS EXPENSIVE OR EASIER TO WORK ON, OR WHAT TOOL CAN I USE TO DO THAT WITH A GREAT DEAL LESS EFFORT.

theres been hundreds of times where I read through some magazine article, explaining how too do some modification,and think, this guy forgot to mention you can,t do that... without doing ..#$%^&*, or that this guys SKIPPING OVER THE FACT THAT, if you did some other minor modification, the first modification would be far more efficient or more durable.

one of the local guys built a older 1968 camaro with a low compression 454 big block, engine he pulled from a donor motor home, he installed a rather aggressive roller cam in place of the original STOCK roller cam with no thought to the non-adjustable valve train, and the woefully inadequate valve spring load rates and clearances. that engine was also severely compromised, because the original 307 sbc exhaust system in the car, was designed for a small block engine that would have strangled the engines performance once the engine rpms went much past about 4000 rpm.

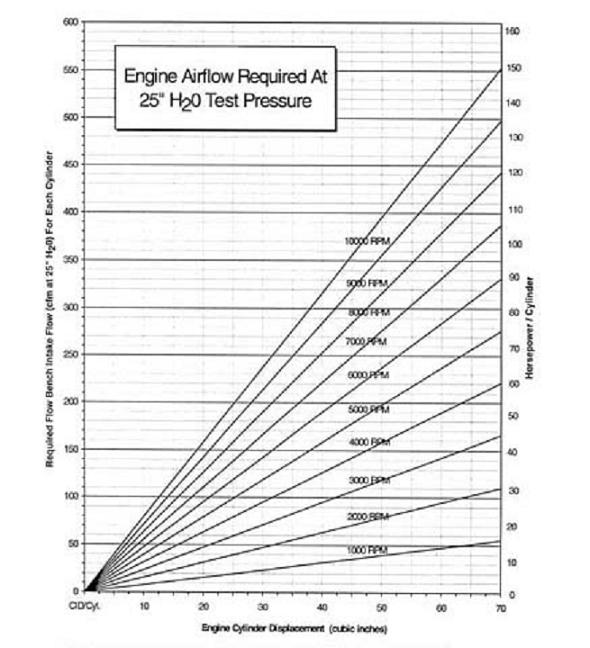

look at the chart below

now assume your BBC has 2.06 diameter intake valves, and displaces 454 cubic inches ,like this example did, a 454 big block chevy, thats 56.75 cubic inches per cylinder divided by 2.06 equals 27.55

looking at the chart it should be rather obvious that a much tighter LSA than the 114 LSA that was selected in this case, would have potentially enhanced the engines ability to efficiently fill the cylinders and the very restrictive exhaust was obviously used to save money but would be a very obvious and measurable problem area restricting the engines power potential.

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

USE THE CALCULATORS, YOULL, QUICKLY FIND THE LIMITATIONS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

related info, that you might need

http://garage.grumpysperformance.co...heads-for-small-block-chevys.3293/#post-26213

http://garage.grumpysperformance.com/index.php?threads/what-are-these-heads.4702/#post-12742

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-26322

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.co...ads-tuned-intake-turbulence.12998/#post-67611

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

Last edited: 1 minute ago

related threads

viewtopic.php?f=52&t=10705

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=181

viewtopic.php?f=71&t=741

http://www.maliburacing.com/patrick_budd_article.htm

viewtopic.php?f=56&t=495

viewtopic.php?f=56&t=1166

viewtopic.php?f=56&t=3155

viewtopic.php?f=71&t=555

viewtopic.php?f=52&t=8460

viewtopic.php?f=52&t=3802

viewtopic.php?f=52&t=480

I've constantly seen trends over the years and while I'm all too aware most of us build on a very limited budget and because that restricts access to all the components we would like to have in our builds it makes the process far longer and more difficult, yet I also see a STRONG tendency for guys to select components based more on price than part compatibility to the intended goal. in fact at times I get the distinct impression that the parts being bolted together , were almost a random selection of components with the only requirement in their selection being the physical ability too have the parts bolt together.

the fact is that a well planed selection of matched quality components will almost always perform far more effectively that the random mix of bargain priced parts many cars are built from.

a simple choice made while planing the engine, like selecting a bit less duration on a tighter LSA in a cam, or actually accurately measuring the valve train clearances and valve spring load rates can and does make a huge difference in the finished engines durability and power curve!

Id also point out that your vehicles drive train, rear gear, transmission gearing and tire diameter can have a very pronounced effect on how your engine will function

EXAMPLE one of the local guys has a son that started out in this hobby like most of us do, buy buying some ones half finished project car and a wide assortment of parts from friends cast offs and the idea that simply bolting them together , with the help of several enthusiastic but usually equally in-experienced friends,would some how result in a fast car.

YEAH! I'll freely admit I went through a sharp learning curve due to starting out on a similar manor but unlike many guys I've always had a strong tendency to step back and say to myself "WELL CRAP! THAT DIDN,T WORK WORTH A SHIT!" when I screw something up royally, but unlike many or most guys I want to know EXACTLY WHY IT DID NOT WORK!, AND WHAT I COULD DO TO MAKE THE CAR MORE DURABLE, FASTER, OR LESS EXPENSIVE OR EASIER TO WORK ON, OR WHAT TOOL CAN I USE TO DO THAT WITH A GREAT DEAL LESS EFFORT.

theres been hundreds of times where I read through some magazine article, explaining how too do some modification,and think, this guy forgot to mention you can,t do that... without doing ..#$%^&*, or that this guys SKIPPING OVER THE FACT THAT, if you did some other minor modification, the first modification would be far more efficient or more durable.

one of the local guys built a older 1968 camaro with a low compression 454 big block, engine he pulled from a donor motor home, he installed a rather aggressive roller cam in place of the original STOCK roller cam with no thought to the non-adjustable valve train, and the woefully inadequate valve spring load rates and clearances. that engine was also severely compromised, because the original 307 sbc exhaust system in the car, was designed for a small block engine that would have strangled the engines performance once the engine rpms went much past about 4000 rpm.

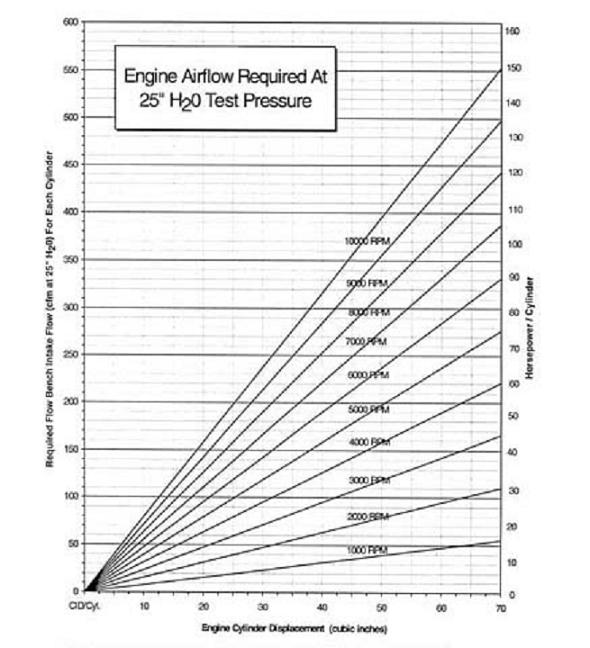

look at the chart below

now assume your BBC has 2.06 diameter intake valves, and displaces 454 cubic inches ,like this example did, a 454 big block chevy, thats 56.75 cubic inches per cylinder divided by 2.06 equals 27.55

looking at the chart it should be rather obvious that a much tighter LSA than the 114 LSA that was selected in this case, would have potentially enhanced the engines ability to efficiently fill the cylinders and the very restrictive exhaust was obviously used to save money but would be a very obvious and measurable problem area restricting the engines power potential.

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

USE THE CALCULATORS, YOULL, QUICKLY FIND THE LIMITATIONS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

related info, that you might need

http://garage.grumpysperformance.co...heads-for-small-block-chevys.3293/#post-26213

http://garage.grumpysperformance.com/index.php?threads/what-are-these-heads.4702/#post-12742

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-26322

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.co...ads-tuned-intake-turbulence.12998/#post-67611

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

Last edited: 1 minute ago

related threads

viewtopic.php?f=52&t=10705

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=181

viewtopic.php?f=71&t=741

http://www.maliburacing.com/patrick_budd_article.htm

viewtopic.php?f=56&t=495

viewtopic.php?f=56&t=1166

viewtopic.php?f=56&t=3155

viewtopic.php?f=71&t=555

viewtopic.php?f=52&t=8460

viewtopic.php?f=52&t=3802

viewtopic.php?f=52&t=480

Last edited by a moderator: