http://www.raceone85.com/

http://garage.grumpysperformance.co...ne-running-a-turbo-s-on-e85.10990/#post-48520

http://marksullense85carburetors.com/

viewtopic.php?f=55&t=613

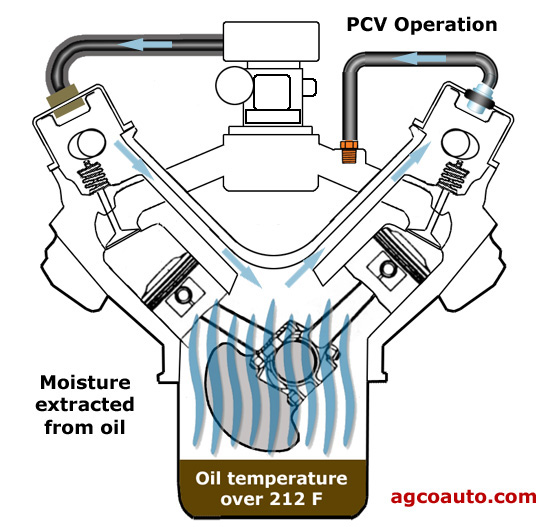

KEEP IN MIND WHEN READING THRU THIS INFO THAT E85 IS SLIGHTLY CORROSIVE AND ATTRACTS MOISTURE, and requires about 12.5:1-13:1 compression and about 30% higher flow rates ,minimum to burn effectively and see power gains compared to standard pump gas. has anyone else noticed the fuel you get from the local gas stations is causing problems?

I,m seeing a good deal more rust and oxidized metal causing carburetor problems,EVEN WITH E10,

Ive seen several guys having rather,obvious corrosion issues in the carburetors of muscle cars that don,t get driven a great deal with the current fuel, and Ive had to replace my weed trimmers, carburetor for similar issues , it seem s that much of the current fuel is less stable over the longer term, its probably that 10%-15% ethanol but its beginning to show up as a suspected cause in a lot of the tuning issues I see, at a far higher frequency that the older fuel caused, especially when I disassemble and inspect carburetors.

its looking as though the fuel separates over time, into a semi corrosive mix.

as long as your constantly adding fresh fuel and your driving the car regularly and changing the filters and oil regularly, and provided you add some of the corrosion inhibitor and lubricant additives to the fuel any time the car sits for a few days you can LOWER the corrosive effects on the engine

BTW alcohol in fuel tends to cause aluminum to oxidize over time

http://video.foxbusiness.com/v/2000862202001/

Due to the instability of gas containing alcohol, shelf life is less than 3 months according to the fuel manufacturers, this is a HUGE issue with engines that don,t get used constantly like lawn equipment, or rarely driven muscle cars

yes if your willing to make several changes to your fuel supply system, e85 fuel has a higher resistance to detonation and can make good hp,

theres several additives that are supposed to make use of ethanol laced fuel far less corrosive,

if you find a really good additive that works 100% let me know , we have ETHANOL FUEL LACED GAS AND ITS KILLS SMALL ENGINES LIKE LAWN MOWER CARBS AND PRESSURE CLEANER CARBS, in the mean time heres a list of gas vendors that only sell alcohol free fuel

ETHANOL FREE FUEL

http://www.buyrealgas.com/

BTW IF YOU WANT TO AVOID ETHANOL LACED FUEL

http://pure-gas.org/

http://www.raceone85.com/

viewtopic.php?f=55&t=613&p=1379&hilit=octane+booster#p1379

Q & A About E85:

Q: Why should I switch to E85?

A: E85 is a renewable fuel source that is also environmentally friendly. Its performance is comparable to race gas at a fraction of the cost. Your engine will run cooler and your ETs will be less affected by atmospheric changes. E85 is not corrosive like methanol and does not leave carbon deposits like gas so maintenance is reduced across the board. With the proper tune-up your oil stays looking like new.

Q: What is the difference in ethanol and methanol?

A: Both fuels have an excellent intake air charge cooling effect. Ethanol (grain or ethyl alcohol) is a biofuel made through the distillation of renewable resources like corn, sugar cane and switch grass. Yes, this is the same process they use to make alcoholic beverages like liquor. Fuel ethanol is 180 proof when produced. 15% regular 87 octane gasoline is added to E100 to add a little lubricant as well as ease the initial cold startup. Methanol (wood alcohol) is produced through a chemical process. By its nature methanol is more corrosive and provides 35% less energy then E85 so you have to burn 35% more of it to make comparable power. E85 cost the same or less then regular unleaded gasoline, methanol cost $4.00 - $5.00 a gallon.

Q: What type of performance can I expect from making the switch to E85?

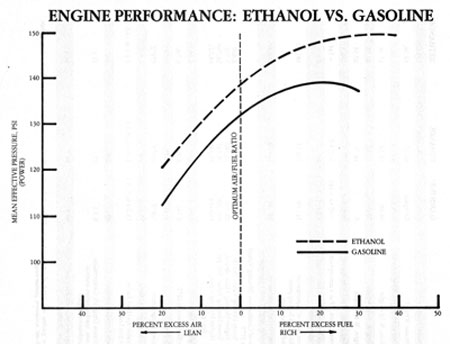

A: It has been our experience that

E85 with its 105 octane rating and high tolerance to detonation is superior to premium pump gas and equal to and in most cases better than 110 octane race gas. We picked up a tenth of a second and 2 to 3 miles per hour in the eighth mile after switching to E85 from 110 race gas and our engine runs 20 degrees cooler.

Q: Don’t I have to replace all the “rubber” in my fuel system so it want be eaten up by the alcohol in E85?

A: NO!!! We started out on this journey with a complete gasoline system. We upped the flow 30% to compensate for the lower heat energy output of ethanol and left everything else the same just to see the effects. We switched to E85 at the end of the 2006 racing season and to date we have found zero deterioration or corrosion anywhere in our fuel system. We leave it in the system all the time. We don’t drain anything between races or use any type of fuel lube.

Q: How much compression can I run with E85 fuel just the way it comes out of the pump at my local station?

A: This is one question I don't have a concrete answer for. We are running it in engines up to 14.5:1 naturally aspirated and some fairly high boost forced induction applications with great results. I have seen charts that draw the line at 16:1 but there again I just don’t have the data yet of a failure directly due to the compression limit of pump grade E85 being reached.

Q: Where can I find E85 in this area?

A: You can find E85 in any area by logging onto

http://www.e85fuel.com and just click on your state for a list of stations that carry it.

1. No matter what type of fuel system you are running you must increase flow (volume) by roughly 30% over a (gas) setup. This is more than just increasing the main jets (in a carburetor) by 30%. Flow must be increased throughout the whole system and fuel curve. Generally speaking one jet size represents a 4.5% change in a Holley type main jet.

2. Start out with your total timing the same as on gas then adjust for best mph.

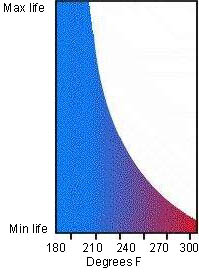

3. Water temp. needs to be 140 - 150 degrees when you pull into the water box and at least 160 degrees when you stage. Your jetting is close when you gain about 10 degrees in the 1/8th and about 20 degrees in the quarter.

4. If you have the luxury of tuning with a wide band air/fuel ratio meter we have found that it is very easy to use the lambda scale. We tune for 1 at idle and .82 to .83 @ WOT for best (safe) power. If you use an EGT meter to tune with you know that ideal temps. will vary greatly from one combination to another. It has been our finding that if you keep it below 1500 degrees while you are sorting out your tune up you don't have to worry about hurting anything in the process. We have found that most naturally aspirated combinations end up making best power around 1250 degrees on E85. Forced induction applications usually run 100 to 200 degrees hotter. If you need a good "inexpensive" EGT meter check out

http://www.ifamilysoftware.com/8307.html

5. E85 has a high resistance to knock but lights off easy so it is susceptible to pre-ignition. A non protruding tip plug is recommended. Autolite Racing plugs with the cut back strap work well for us. We run AR-133 with the blower, this is a little cooler then you would need for natural aspiration. When reading your plugs look for them to be real clean with a little tan color down inside the threads on the porcelain. If no color appears after the first couple of runs, jet up until some starts to show then adjust jetting for best mph from there. Here is a helpful cross reference chart.

http://www.autolite.com/pdf/RacingCrossRef.pdf

http://www.hotrod.com/techarticles/hrdp ... ewall.html

viewtopic.php?f=55&t=613&p=6025&hilit=toluene#p6025

viewtopic.php?f=54&t=10500&p=44355&hilit=bearing+clearances#p44355

http://prometh.com/collections/all?gclid=CMj-kpXXyc8CFZSEaQodeBwJ7A

http://www.bosch-mobility-solutions...njection/?WT.mc_id=bosch_oe_oe_wo_portal_0002

https://www.summitracing.com/parts/...se1-_-holley&gclid=CNPw4MvXyc8CFQMMaQodBQYEsw

https://www.summitracing.com/parts/...s-express-nx&gclid=CLSTkN_Xyc8CFYcCaQodNyYMZA

http://garage.grumpysperformance.com/index.php?threads/octane-boosters.613/#post-12677

http://sohiperformance.com/i-2152421.aspx?gclid=CO_UkYTYyc8CFQ6taQodfTMP6A

http://sohiperformance.com/i-2152421.aspx?gclid=CPOjzprYyc8CFQIEaQodVroDkg

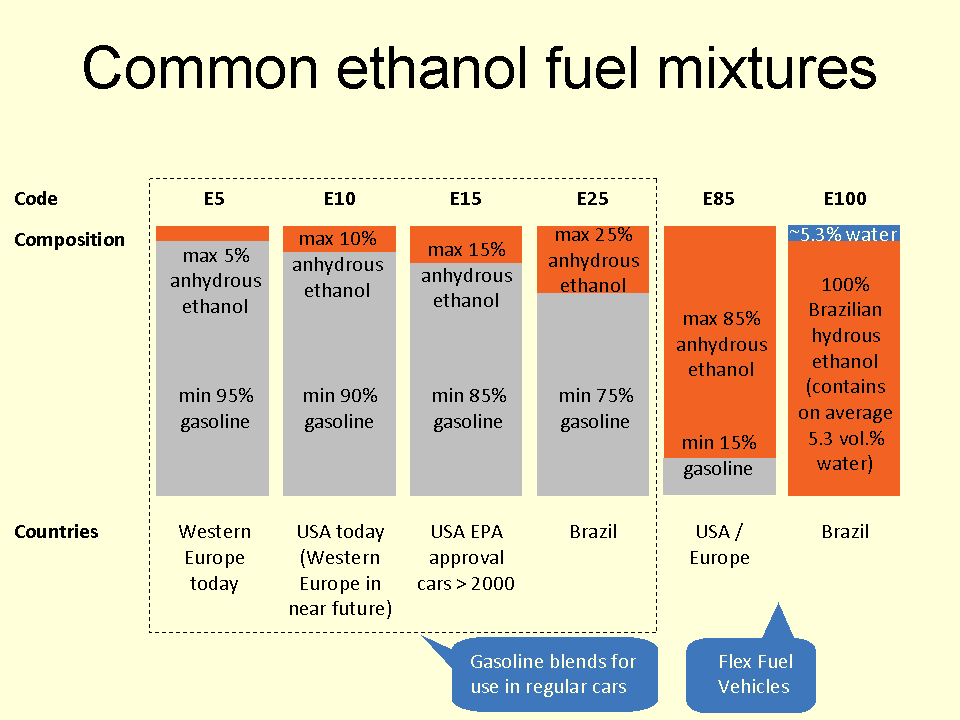

Technical facts about the mentioned fuels:

E85 requires 42% more fuel to reach stoich,

even if that is not what you may come up with when doing calculations, based on the table below.

This is because the injector flow is slightly different when using E85 among many other things.

I can´t really think of at this time (will be added at a later time).

Fuel ........................

AFRst ........

FARst .......

Equivalence Ratio ...

Lambda

Gas stoich ................ 14.7 .......... 0.068 ................ 1 ................... 1

Gas max power rich ....

12.5 .......... 0.08 ................. 1.176 .............. 0.8503

Gas max power lean .... 13.23 ........ 0.0755 .............. 1.111 ............. 0.900

E85 stoich .................. 9.765 ....... 0.10235 ............ 1 ................... 1

E85 max power rich ......

6.975 ....... 0.1434 .............. 1.40 ............... 0.7143

E85 max power lean ..... 8.4687 ...... 0.118 ............... 1.153 .............. 0.8673

E100 stoich ................ 9.0078 ...... 0.111 ............... 1 .................... 1

E100 max power rich ....

6.429 ........ 0.155 .............. 1.4 .................. 0.714

E100 max power lean .... 7.8 .... ...... 0.128 .............. 1.15 ................ 0.870

The term AFRst refers to the Air Fuel Ratio under stoichiometric, or ideal air fuel ratio mixture conditions. FARst refers to the Fuel Air Ratio under stoichiometric conditions, and is simply the reciprocal of AFRst.

Equivalence Ratio is the ratio of actual Fuel Air Ratio to Stoichiometric Fuel Air Ratio; it provides an intuitive way to express richer mixtures. Lambda is the ratio of actual Air Fuel Ratio to Stoichiometric Air Fuel Ratio; it provides an intuitive way to express leanness conditions (i.e., less fuel, less rich) mixtures of fuel and air.

When driving purely on E85 you can blend it with up to 25% gasoline in case you want to raise the AFR number used to produce max. power. In that case you can raise the boost even further since the volume of fuel needed to reach the desired lambda is decreased.

hy·gro·scop·ic

ˌhīɡrəˈskäpik/

adjective

(of a substance) tending to absorb moisture from the air.

water combined with

ethanol is highly corrosive if left in contact with most metals over long time periods

the ability of gasoline to quickly and easily vaporize tends to degrade over time making it significantly less easily ignited as its the vapor not the liquid component of the fuel that burns the most efficiently, normally heat helps rapidly atomize and vaporize the fuel, but as fuel ages the easily vaporized components tend to be lost to evaporation, leaving a less easily ignited and usually DARKER COLORED LIQUID.

mixing the remaining old gas with new fuel will generally help but not cure the issue!

I use STA-BIL marine fuel additive in my lesser used engines, but reading the info on various site the LONGEST listed time frame it seems to work for as designed was about 2 years, if I had gas over 2 years old ID personally drain the tank, add stabil, plus a name brand fuel system cleaner and a fresh fuel filter,add fresh non-alcohol laced fuel, and flush the fuel rail and or car fuel bowls, before using the car or engine,

Id probably use the old fuel I drained to clean parts or ignite a trash pile, yeah you might be able to mix it with fresh fuel and use it but the chances of it having absorbed moisture, separated into various less than ideal for use as a fuel,components while sitting for over two years,or causing issues with the engine that might damage it,would just not be worth the risk in my opinion.

http://www.goldeagle.com/tips-tools/top ... s-debunked

the common 10% or greater ethanol content causes the o-rings too deteriorate

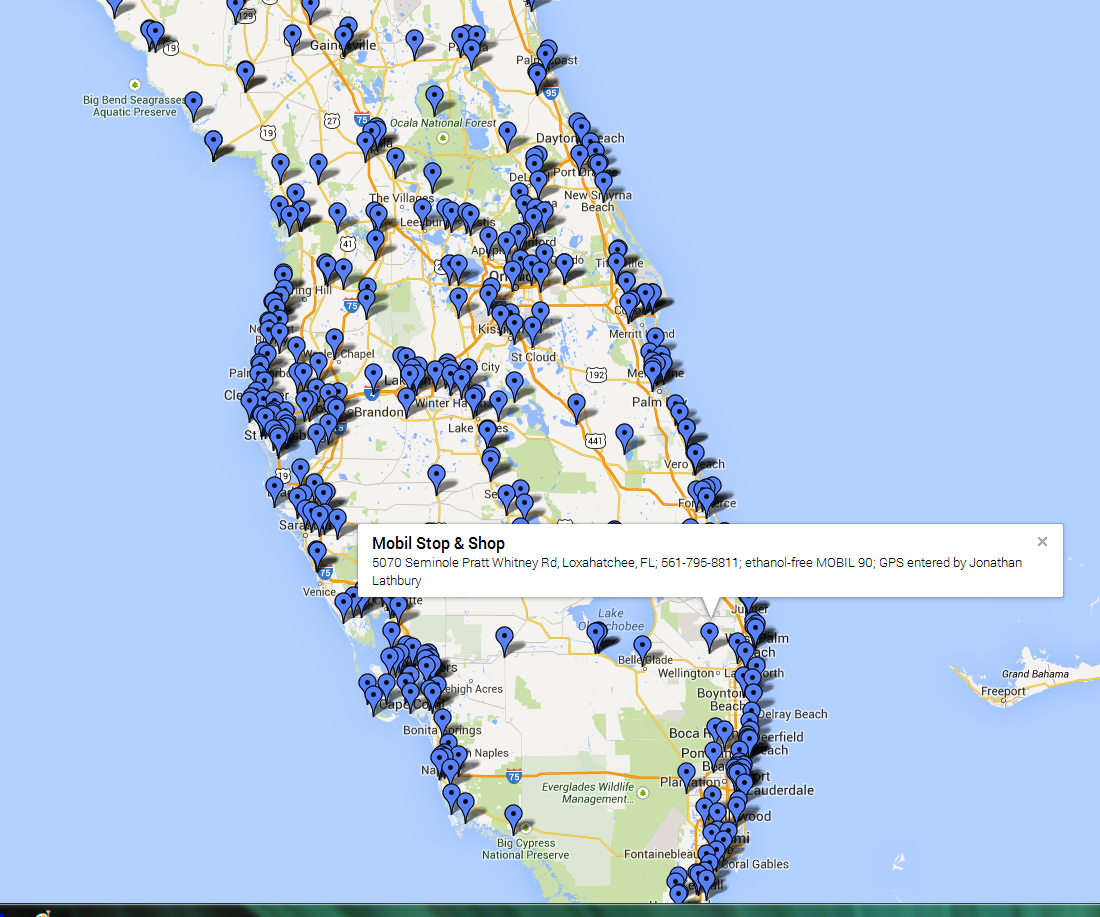

there are gas stations that sell non-ethanol laced fuel

http://pure-gas.org/extensions/map.html

http://www.sta-bil360.com/how-it-works

there ARE ETHANOL FREE GAS STATIONS LISTED, when you NEED TO FILL A MUSCLE CAR TANK, HERES MY LOCAL STATION, yes it costs more short term, easily an extra 70-80 cents a gallon, but you don,t run nearly the same risk of trashing your muscle cars engine and fuel delivery systems

http://pure-gas.org/extensions/map.html