once your engines hp and torque levels start to significantly exceed the factory levels its not at all uncommon for the engines twisting movement in the frame to start stressing the factory motor mounts, this can result in difficult shifts due to linkage geometry changes or jammed throttles etc.

On the motor mounts, the driver side is under extension or stretching and the passenger is under compression, as the engine torque increases with shifts etc. so the load is on the driver side. This is the reason for the solid driver mount most guys use is to limit engine movement,. As far as the trans goes, I like having something to absorb any vibes in the car so Ive generally used the hard plastic/ or POLY trans mounts. The weaker part is the aluminum trans case

many guys go to the stronger aftermarket poly motor mounts or add a short section of chain from the drivers side cylinder head to the drivers side frame to limit the shock loads on the motor mounts that speed shifts, high stall speed converters, higher rear gears and slicks, and much higher torque loads impart to the factory mounts, the first time you bust an engine mount and the throttle jams wide open , you might see the advantages

many guys simply bolt a short section of chain or an adjustable strap with heim joint ends,between the left side car frame and some solid location like a bolt on the the left engine cylinder head that has just a bit of slack so as the engine torque increases stress on the motor mounts it tightens up as the distance between the left cylinder head and frame increases and significantly reduces the load on the motor mount.

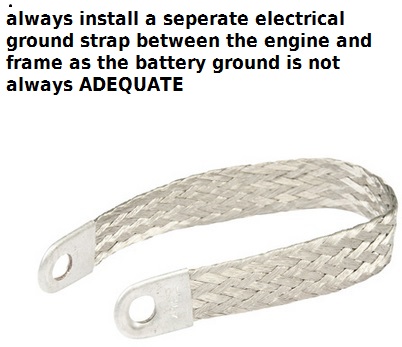

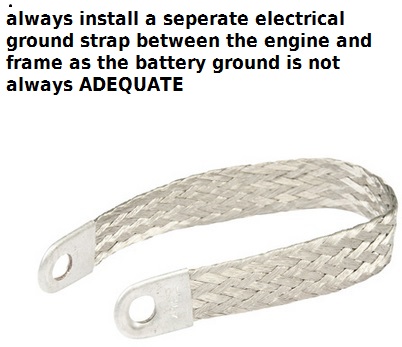

ALWAYS run a good separate electrical ground strap between the engine and frame , transmission and motor mounts are notoriously bad electrical ground connections to the frame.

www.zoro.com

clean the battery terminals and replace the two cables, make sure you use similar to factory cables, and connect to starter and frame or as factory installed.

www.zoro.com

clean the battery terminals and replace the two cables, make sure you use similar to factory cables, and connect to starter and frame or as factory installed.

buy and correctly install TWO ground straps

be sure you clean metal contact areas and once install spray with good corrosion barrier

install

1 engine to frame

1- transmission to frame

run the battery neg to the frame also

http://garage.grumpysperformance.co...urrent-flow-grounds-and-more.3504/#post-54625

http://garage.grumpysperformance.co...hooting-tip-for-electronics.11317/#post-51557

starter support brackets can be helpful

396588 = BB or Caddy

3965589 = 168 tooth SB '66-'91

354353 = 153 tooth '66-'91

3851294 = '64-'69 Vette

3816511 = '62-'68 SB

Attachment: brackets.jpg (53.42 KB) 4 View(s)

Attachment: brackets.jpg (53.42 KB) 4 View(s)

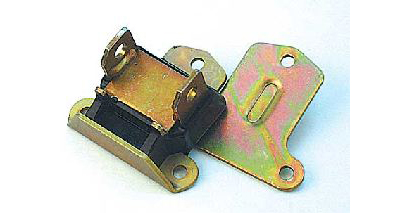

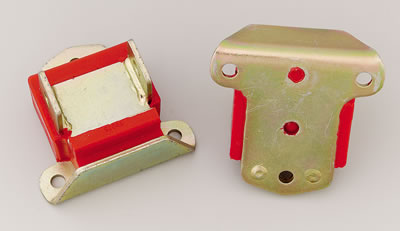

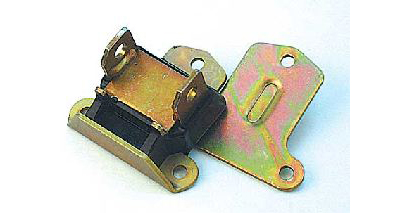

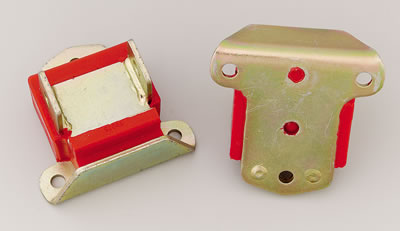

POLY MOTOR MOUNTS and a decent grade 8 set of mount bolts, with loc-tite on the threads will help , check the bolt length, diameter and thread pitch carefully.

3/8 mount to block and or -7/16" bolt about 3.5" long is the common solution,to broken stock motor mount in a high stress application,

btw on some motor mounts the bolt holes either don,t line up exactly or the holes a bit under sized so a bit of drill bit time might be required to get the thru bolt to clear easily, so don,t get crazy, test fit the bolt before you install the mounts

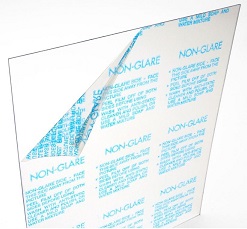

when planing on fabricating a large bracket like that engine mount plate its frequently a good idea to buy , cut and test fit

a pattern made from dirt cheap clear plastic before starting on rather expensive steel or aluminum, to get all the necessary mods and clearances worked out, the huge advantage of clear plastic is you can easily see where you need bolt holes or some item that moves during operation (like suspension) or more easily let you recognize early in the fabrication process that theres always a compromise some place to be considered, parts like STARTERS , OIL FILTERS AND HEADERS that might become nearly impossible to work on if the brackets in place

http://www.homedepot.com/p/11-in-x-14-in-Non-glare-Styrene-Sheet-1S11143A/202771350

if youve built a real torque monster solid mid plate mounts might be a good idea

http://stores.channeladvisor.com/Summit ... s/CEE-4031

http://garage.grumpysperformance.co...ng-engine-accessory-brackets.8523/#post-29916

http://garage.grumpysperformance.co...ng-engine-accessory-brackets.8523/#post-29916

http://www.kmjent.com/cart/product.php?productid=1047

http://www.kmjent.com/cart/product.php? ... 602&page=1

IF your having trouble getting motor mounts to line up correctly ,you do realize that chevy motor mounts come in several styles and heights

1- 11/16"

1- 3/4"

2 -1/8"

2- 3/8"

2 -9/32"

theres also spacers for motor mounts

Part # Description

62535 Motor Mount Shim Kit

1/16", 1/8", and 3/16" thick, 2 ea.

Standard Chevrolet bolt pattern

Works great with Chevy Motor Mounts 62500, 62510, 62515, & 62530

Used to make slight adjustments to engine height to compensate for minor oil pan, linkage, and header interference

Great addition to engine swap kits

Part # Description

http://www.moroso.com/eb/catalog/naviga ... =main.menu

theres far more than just these designs

viewtopic.php?f=71&t=545&p=684&hilit=engine+mounts#p684

viewtopic.php?f=50&t=704&p=1573&hilit=engine+mounts#p1573

viewtopic.php?f=38&t=879&p=1377&hilit=engine+mounts#p1377

viewtopic.php?f=87&t=783&p=4910&hilit=engine+mounts#p4910

viewtopic.php?f=50&t=44&p=103&hilit=engine+mounts#p103

viewtopic.php?f=38&t=200&p=235&hilit=engine+mounts#p235

http://www.speedwaymotors.com/m/405_Eng ... -Kits.html

http://www.racecarparts.com/Big_Block_Chevy.html

http://www.eficonnection.com/eficonnection/58x.aspx

http://www.tperformance.com/street_rod_ ... or_mounts/

http://www.brokenkitty.com/xj/xjv8.htm

http://www.highangledriveline.com/unlti ... system.htm

http://www.highangledriveline.com/toy_flange.html

http://www.mrdriveshaft.com/U-Joint%20P ... 20U-Joints

http://www.pirate4x4.com/tech/billavist ... ndex4.html

https://sdp-si.com/eStore/Direct.asp?GroupID=574

http://www.billshotrodcompany.com/673/5301.html

http://www.speedhound.com/lsxswap.html

http://www.billetspecialties.com/assets/pdf/747.pdf

http://kwikperf.com/

http://www.progressiveautomotive.com/motor.htm

http://chucker54.stores.yahoo.net/enginemounts.html

http://www.sachserodshop.com/pdf/5.pdf

http://www.tdperformance.com/categories/?id=3102

http://www.hotrodsusa.com/store/bills.html

http://www.campbellenterprises.com/motorplates.htm

http://www.alangrovecomponents.com/

http://chucker54.stores.yahoo.net/enginemounts.html

http://garage.grumpysperformance.com/index.php?threads/bolts-a-bit-of-useful-info.4868/#post-13372

http://competitionengineering.com/catal ... Code=11025

http://engine-swaps.com/frames/frame_Torquestrap.html

http://www.carcraft.com/techarticles/po ... index.html

http://www.fordmuscle.com/archives/2000/04/quicktips/

while hardly high tech,

adding a simple length of 3/8" chain from the drivers side frame to a bolt in the drivers side cylinder head will prevent a great deal of torque damage to motor mounts

and yes a commercial version looks better but its not significantly more effective

mark Bradley posted this info on a torque strap tp limit engine movement ,

to help the fan not hit the fan shroud

http://competitionengineering.com/catal ... Code=10029

if you want to get fancy and do a really nice job you can fabricate custom, adjustable length torque straps with HEIM joint swivel ends,and heavy wall stainless or chrome moly steel tubing and weld a lower bracket to the frame

http://www.pacificnorthwestbearing.net/ ... _info.html

https://www.speedwaymotors.com/shop/heim-joints-and-rod-ends~14-16-578-31189

https://www.barnes4wd.com/Heim-Joints-Enduro-Joints-and-Hardware_c_7.html

https://www.ruffstuffspecialties.com/catalog/RODENDS.html

On the motor mounts, the driver side is under extension or stretching and the passenger is under compression, as the engine torque increases with shifts etc. so the load is on the driver side. This is the reason for the solid driver mount most guys use is to limit engine movement,. As far as the trans goes, I like having something to absorb any vibes in the car so Ive generally used the hard plastic/ or POLY trans mounts. The weaker part is the aluminum trans case

many guys go to the stronger aftermarket poly motor mounts or add a short section of chain from the drivers side cylinder head to the drivers side frame to limit the shock loads on the motor mounts that speed shifts, high stall speed converters, higher rear gears and slicks, and much higher torque loads impart to the factory mounts, the first time you bust an engine mount and the throttle jams wide open , you might see the advantages

many guys simply bolt a short section of chain or an adjustable strap with heim joint ends,between the left side car frame and some solid location like a bolt on the the left engine cylinder head that has just a bit of slack so as the engine torque increases stress on the motor mounts it tightens up as the distance between the left cylinder head and frame increases and significantly reduces the load on the motor mount.

ALWAYS run a good separate electrical ground strap between the engine and frame , transmission and motor mounts are notoriously bad electrical ground connections to the frame.

Grote Ground Strap Braided, 18 In 84-9465 | Zoro

Order Grote Ground Strap Braided, 18 In, 84-9465 at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or sign up for an account.

buy and correctly install TWO ground straps

be sure you clean metal contact areas and once install spray with good corrosion barrier

install

1 engine to frame

1- transmission to frame

run the battery neg to the frame also

http://garage.grumpysperformance.co...urrent-flow-grounds-and-more.3504/#post-54625

http://garage.grumpysperformance.co...hooting-tip-for-electronics.11317/#post-51557

starter support brackets can be helpful

396588 = BB or Caddy

3965589 = 168 tooth SB '66-'91

354353 = 153 tooth '66-'91

3851294 = '64-'69 Vette

3816511 = '62-'68 SB

POLY MOTOR MOUNTS and a decent grade 8 set of mount bolts, with loc-tite on the threads will help , check the bolt length, diameter and thread pitch carefully.

3/8 mount to block and or -7/16" bolt about 3.5" long is the common solution,to broken stock motor mount in a high stress application,

btw on some motor mounts the bolt holes either don,t line up exactly or the holes a bit under sized so a bit of drill bit time might be required to get the thru bolt to clear easily, so don,t get crazy, test fit the bolt before you install the mounts

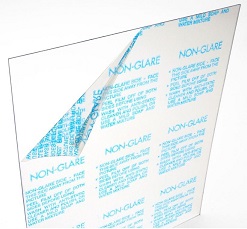

when planing on fabricating a large bracket like that engine mount plate its frequently a good idea to buy , cut and test fit

a pattern made from dirt cheap clear plastic before starting on rather expensive steel or aluminum, to get all the necessary mods and clearances worked out, the huge advantage of clear plastic is you can easily see where you need bolt holes or some item that moves during operation (like suspension) or more easily let you recognize early in the fabrication process that theres always a compromise some place to be considered, parts like STARTERS , OIL FILTERS AND HEADERS that might become nearly impossible to work on if the brackets in place

http://www.homedepot.com/p/11-in-x-14-in-Non-glare-Styrene-Sheet-1S11143A/202771350

if youve built a real torque monster solid mid plate mounts might be a good idea

http://stores.channeladvisor.com/Summit ... s/CEE-4031

http://garage.grumpysperformance.co...ng-engine-accessory-brackets.8523/#post-29916

http://garage.grumpysperformance.co...ng-engine-accessory-brackets.8523/#post-29916

http://www.kmjent.com/cart/product.php?productid=1047

http://www.kmjent.com/cart/product.php? ... 602&page=1

IF your having trouble getting motor mounts to line up correctly ,you do realize that chevy motor mounts come in several styles and heights

1- 11/16"

1- 3/4"

2 -1/8"

2- 3/8"

2 -9/32"

theres also spacers for motor mounts

Part # Description

62535 Motor Mount Shim Kit

1/16", 1/8", and 3/16" thick, 2 ea.

Standard Chevrolet bolt pattern

Works great with Chevy Motor Mounts 62500, 62510, 62515, & 62530

Used to make slight adjustments to engine height to compensate for minor oil pan, linkage, and header interference

Great addition to engine swap kits

Part # Description

http://www.moroso.com/eb/catalog/naviga ... =main.menu

theres far more than just these designs

viewtopic.php?f=71&t=545&p=684&hilit=engine+mounts#p684

viewtopic.php?f=50&t=704&p=1573&hilit=engine+mounts#p1573

viewtopic.php?f=38&t=879&p=1377&hilit=engine+mounts#p1377

viewtopic.php?f=87&t=783&p=4910&hilit=engine+mounts#p4910

viewtopic.php?f=50&t=44&p=103&hilit=engine+mounts#p103

viewtopic.php?f=38&t=200&p=235&hilit=engine+mounts#p235

http://www.speedwaymotors.com/m/405_Eng ... -Kits.html

http://www.racecarparts.com/Big_Block_Chevy.html

http://www.eficonnection.com/eficonnection/58x.aspx

http://www.tperformance.com/street_rod_ ... or_mounts/

http://www.brokenkitty.com/xj/xjv8.htm

http://www.highangledriveline.com/unlti ... system.htm

http://www.highangledriveline.com/toy_flange.html

http://www.mrdriveshaft.com/U-Joint%20P ... 20U-Joints

http://www.pirate4x4.com/tech/billavist ... ndex4.html

https://sdp-si.com/eStore/Direct.asp?GroupID=574

http://www.billshotrodcompany.com/673/5301.html

http://www.speedhound.com/lsxswap.html

http://www.billetspecialties.com/assets/pdf/747.pdf

http://kwikperf.com/

http://www.progressiveautomotive.com/motor.htm

http://chucker54.stores.yahoo.net/enginemounts.html

http://www.sachserodshop.com/pdf/5.pdf

http://www.tdperformance.com/categories/?id=3102

http://www.hotrodsusa.com/store/bills.html

http://www.campbellenterprises.com/motorplates.htm

http://www.alangrovecomponents.com/

http://chucker54.stores.yahoo.net/enginemounts.html

http://garage.grumpysperformance.com/index.php?threads/bolts-a-bit-of-useful-info.4868/#post-13372

http://competitionengineering.com/catal ... Code=11025

http://engine-swaps.com/frames/frame_Torquestrap.html

http://www.carcraft.com/techarticles/po ... index.html

http://www.fordmuscle.com/archives/2000/04/quicktips/

while hardly high tech,

adding a simple length of 3/8" chain from the drivers side frame to a bolt in the drivers side cylinder head will prevent a great deal of torque damage to motor mounts

and yes a commercial version looks better but its not significantly more effective

mark Bradley posted this info on a torque strap tp limit engine movement ,

to help the fan not hit the fan shroud

To limit the engine rotation under heavy acceleration I built an adjustable torque bar/strap.

I purchased the parts from Speedway Motors.

PartNo, Description, Price

175-6045-LH, 6pc 1/2x20 Jam nut LH, 2.99

175-6045-RH, 6pc 1/2x20 Jam nut RH, 2.99

910-34212-7, 7” Swedged tube, 11.99

175-0305, 1/2” LH heim joint, 5.99

926-10896, Sway bar end link kit, 7.99

I created a plate/arm that bolts to the front of the drivers side cylinder head and extends past the p/s pump. The heim joint connects there and runs directly down to a bracket on the engine cross member. The lower bracket connects with bushings for a sway bar end.

http://competitionengineering.com/catal ... Code=10029

if you want to get fancy and do a really nice job you can fabricate custom, adjustable length torque straps with HEIM joint swivel ends,and heavy wall stainless or chrome moly steel tubing and weld a lower bracket to the frame

http://www.pacificnorthwestbearing.net/ ... _info.html

https://www.speedwaymotors.com/shop/heim-joints-and-rod-ends~14-16-578-31189

https://www.barnes4wd.com/Heim-Joints-Enduro-Joints-and-Hardware_c_7.html

https://www.ruffstuffspecialties.com/catalog/RODENDS.html

Last edited by a moderator: