I got the new 383 installed and she runs. But It is very hard to start.

I had installed the TPI system before the rebuild and everything worked fine and started right up.

Now it has to crank over for 10 to 15 seconds before it will start. And then it's like only on a few cylinders then all catch.

Yesterday my wife took it to go to the store. It died on her 3 times. The gas gauge said 1/4 tank left but she filled it up anyways.

Only took 9 gallons to fill it. So I know that the gauge is messed up.

I'm thinking its either a fuel pump or that cheap distributor I got. I've had a new chip burned and it didn't change anything.

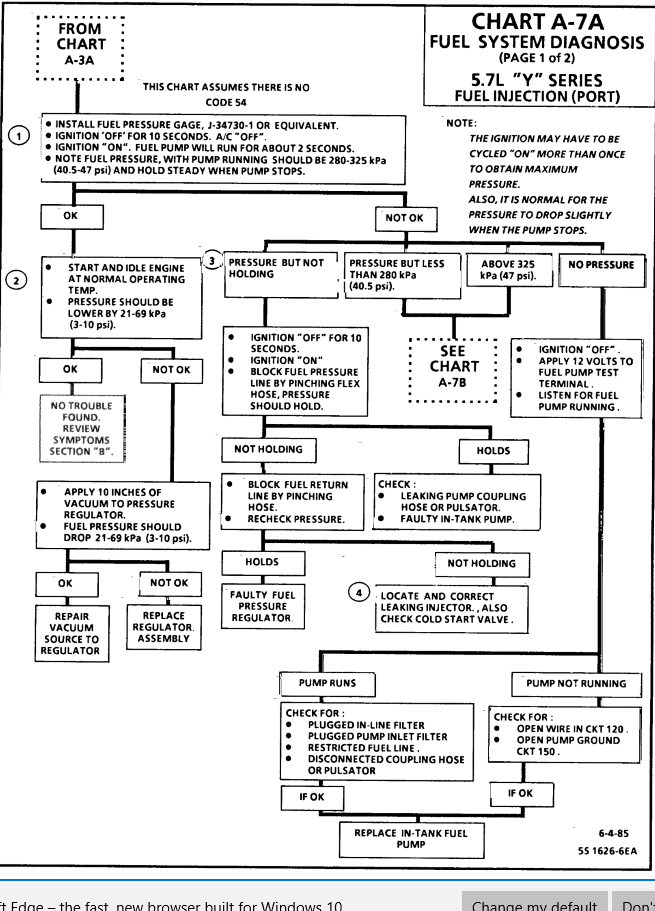

Any ideas as to where to look? I'm checking the fuel pressure tonight.

verify your fuel pressure is at least 37 psi,

your oil pressure is at least 10 psi

and theres zero vacuum leaks

Id be very sure to verify the fuel pressure regulator is functioning correctly

Id be pulling trouble codes and verify all the sensors , (like engine heat , FUEL PRESSURE, oil pressure and o2 sensors etc.work correctly)

change your fuel filter

Measured Value

Engine Coolant Temperature Sensor. 185 Ohms @ 210F, 3400 Ohms @ 68F, 7,500 Ohms @ 39 F.

Engine Oil Temperature Sensor. (lower sensor above oil filter) 185 Ohms @ 210 F, 3400 Ohms @ 68 F, 7,500 Ohms @39 F.

some early c4 vettes have the gauge and oil pressure switch on an adapter near the distributor base into the block

to add something to this that is often over looked regarding MAF codes, so here it is, a direct quote from my 87 FSM which is probably the same for 85,86,88,89.

Second paragraph on both code 33 and 34...interestingly not on code 36.

Code 33 page 6E3-A-42

"The oil pressure switch or the ECM, through control of the fuel pump relay, will provide 12 volts for the MAF power relay which provides the 12 volts needed by the MAF sensor".

I personally know a few guys who cured their MAF problem simply by either replacing the FP relay or repairing the wires going into the FP relay...these wires over time may have had the insulation shrink back (mine were bare 1-2 inches, and touching) not only dangerous , but can cause all types of problems.

Oil Pressure Sender/Switch. (top sensor in picture above) 1 Ohms @ 0 PSI, 43 Ohms @ 30 PSI, 86 Ohms @ 60 PSI.

Fuel Quantity Sender. 0 Ohms @ Empty, 45 Ohms @ 1/2 Full, 90 Ohms @ Full.

MAT (Manifold Absolute Temperature Sensor). 185 Ohms @ 210 F, 3400 Ohms @ 70 F,

BTW it generally helps if you post the city and state your in,

as theres at least some chance a local member,

may want to stop by and help you diagnose,

and maybe help rectify the issue if your LOCAL

below youll find several links, and sub links,

that may take you several hours to read through,

but it will save you a great deal of time and money to do so carefully.

read through all the linked info it contains a good deal of related info youll need to look through and understand to boost the TPI engines power effectively.

Knowing what your dealing with, what the stock parts can do, and what should be modified or replaced, and what you can do to enhance , increase and broaden, the power is 1/2 the battle here.

(take notes and ask questions)

C4 Corvette Start Sequence for L-98 Engines

When starting an L-98 Corvette engine, a sequence of events take place that precedes the engine running. Knowing these sequences will help you troubleshoot no start issues with your C4 Corvette.

- Fuel Rail Pressurization

- C4 Corvette Start Sequence begins when you first turn the key to the “on” position, the fuel pump will run for 2 seconds pressurizing the fuel rails. There is a Schrader valve on the passenger side fuel rail near the rear of the engine and proper fuel pressure after the pump runs should be between 40-42 pounds of pressure. The reading will drop to 38-40 pounds after the engine is running.

- Initial C4 Corvette Start Action: Once rotating the key to the start position if the anti-theft system has not disabled the starter the engine will rotate.

- Once the oil pressure has reaches 4 PSI, the oil pressure switch contacts will close allowing the fuel pump to run. Note that you should have a black color oil pressure switch/sender. This sender is mounted behind the distributor on the driver’s side. If its not replace it with one that's only black. If the car fires then stalls replace this switch.

- The distributor outputs rotational frequencies to the ECM (Engine Control Module) as a result of the engine being rotated by the starter. This frequency continues as long as the engine turns (both starting and running) if no frequency output is present the engine will not run.

- ECM Outputs : Once the ECM sees oil pressure greater than 4 PSI and the reference frequency from the distributor the ECM will command the injector drivers which will begin pulsing the injectors open for 4 ms (milliseconds) periods. (The L98 injectors all fire on one side of the engine at the same time followed by all injectors on the other side firing at the same time. The LT-1 fires the injectors individually per the firing order).

- Brainiac Fact for C4 Corvette Start Sequence! The ECM also pulls the fuel pump relay which makes the contacts and parallel's it electrically with the oil pressure switch. This way if the fuel pump relay fails you can still normally get the car to run. This will only happen if you make at least 4 PSI oil pressure. This “limp home mode” feature was put in place to allow for a fuel pump relay failure.

- The ECM requires an input from the TPS (Throttle Position Sensor which is mounted on the throttle body assembly) required voltage is .54 volts DC. Greater than 0.54 volts the ECM will assume the engine is flooded. This logic is triggered by the driver when pressing the accelerator pedal to the floor. The flooded condition would clear as a result of restricted fuel flow. The output of . 54 volts during start and idle from the TPS is very important in both starting and run performance. Its important to have a good voltmeter to troubleshoot something with such low voltage. Poor quality voltmeters can be inaccurate up to .2 volts.

- Assuming the ignition module has spark of sufficient intensity to ignite the air-fuel mixture the engine will start.

- C4 Corvette Start Sequence of Engine "Initial Start" for 1985 through 1989 L-98: When the engine initially starts, the MAF sends a signal to the ECM reporting that air is flowing at "XXXX" hertz frequency through it and into the intake manifold. The ECM refers to its Airflow Table for ECT conditions of the amount of air being consumed and adjusts the injector pulse width to around 2.2 ms this supplies a proper air/fuel mixture for combustion. For information on the 1990 and 1991 L-98 see below.

Engine Running

- Note 1990 and 1991 L-98 : The MAF was eliminated from the engine in favor of a speed/density system. This system uses a sensor called the MAP sensor which measures the Manifold Absolute Pressure (hence the name MAP) and compares it with the atmospheric pressure outside the intake manifold. This information, coupled with the Manifold Air Temperature, Engine Coolant Temperature and Engine RPM is used by the ECM to determine the amount of air entering the cylinders. It is a different way of reaching the desired 14.7:1 air-fuel mixture ratio but functionally is like the MAF system in that the ECM uses the feedback to control the "on time" for the injectors.

- GM used this approach in the 1990 and 1991 L-98 engines and in the 1992 and 1993 LT-1 engines. With the 1994 model C4, they went back to the MAF system. Note that MAF based systems are far more accurate since they measure air flow directly whereas the MAP system calculates air flow indirectly. Errors and vacuum leaks can throw the calculation off and Corvette returned to the MAF system beginning with the 1994 C4 (with a MAP backup). From a troubleshooting standpoint, the MAP operation comes into the sequence the same place that the MAF does.

- Initial engine idle speed of should be around 900-1100 RPM and then slowly decay to around 600-700 RPM unless the air conditioner is on at which case it will run at around 800-1000 RPM depending on pressure altitude. If this does not happen, the Idle Air Mixture Valve or IAC may be plugged or faulty. You could also have an intake manifold leak or another vacuum leak. Check for vacuum leaks.

C4 Corvette Start Problem Summary

- ECM Open Loop Mode: In "Open Loop" mode the ECM is controlling the air/fuel mixture by referencing generic values stored in the ECM Flash memory. These values do not benefit from from the O2 sensor monitoring and lean rich correcting factors.

- After the C4 Corvette Start Sequence is finished the Oxygen Sensor (mounted in the exhaust pipe) indirectly is considered to have reached operating temperature of several hundred degrees when the Manifold Air Temperature (MAT) sensor shows an intake air temperature of more than 140 degrees and the Engine Coolant Temperature (ECT) is 160 degrees. This would be a Boolean logic type of result. In simple terms X+X+X= Output "Y" The computer then switches to "closed loop" mode meaning the Oxygen sensor’s output is being referenced and being used along with the MAT and ECT outputs for the ECM to adjust the injector pulse widths (more “ms longer” or less “ms shorter”) to maintain a 14.7:1 air/fuel mixture.

If you have a no start condition or if your C4 Corvette starts and then dies, check the above items in sequence to see if all the events are occurring as stated.

Having the proper tools make this job much easier and are highly recommended for troubleshooting these sorts of problems.

read the links and sub links

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.co...ard-starting-tpi-crossfire-or-lt1-vette.1401/

http://garage.grumpysperformance.co...uble-shooting-flow-chart-info.11536/#post-783

http://garage.grumpysperformance.com/index.php?threads/l98-start-sequence.330/#post-404

http://garage.grumpysperformance.co...asic-trouble-shooting-on-the-c4.302/#post-367

http://garage.grumpysperformance.com/index.php?threads/sources-for-tpi-parts-and-info.590/#post-1074

http://garage.grumpysperformance.com/index.php?threads/fuel-injector-resistance.607/#post-806

http://garage.grumpysperformance.co...p-after-running-out-of-fuel.11309/#post-51444

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-54562

http://garage.grumpysperformance.com/index.php?threads/locating-vacume-leaks.882/#post-45944

http://garage.grumpysperformance.com/index.php?threads/c4-hesitation.10451/#post-43633

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/

Last edited: