Transmission over temp

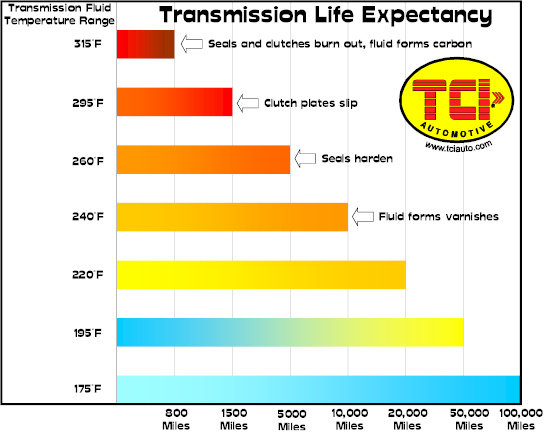

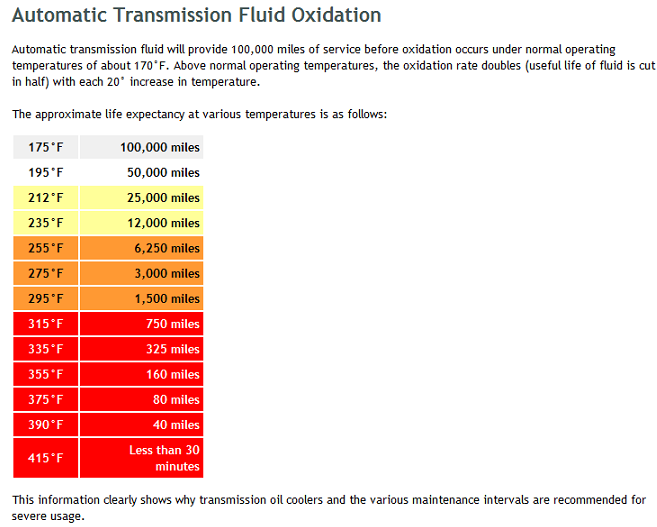

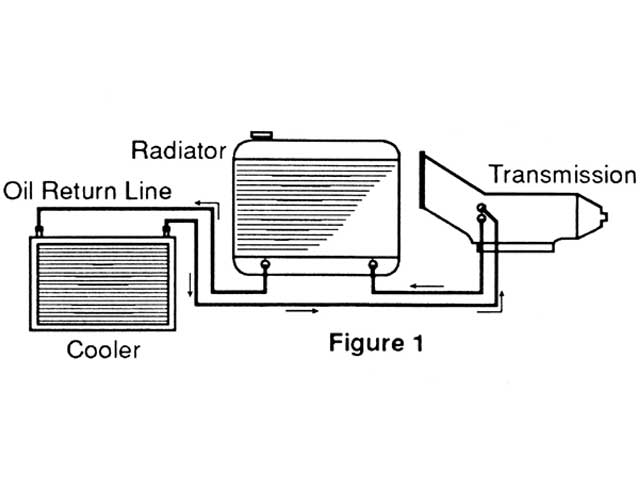

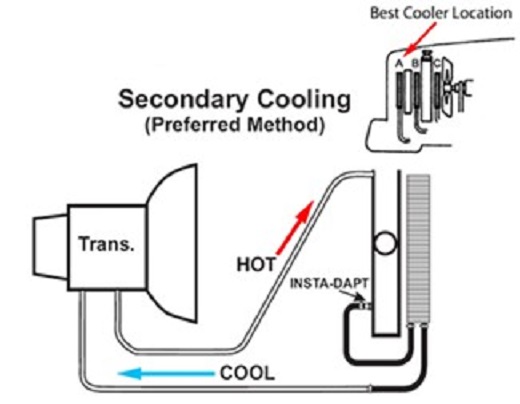

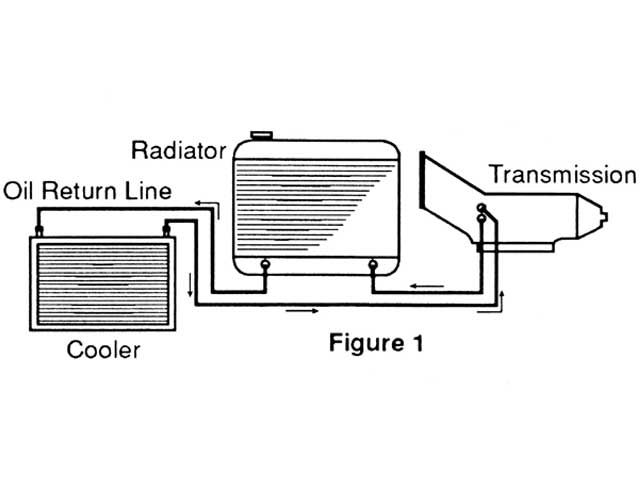

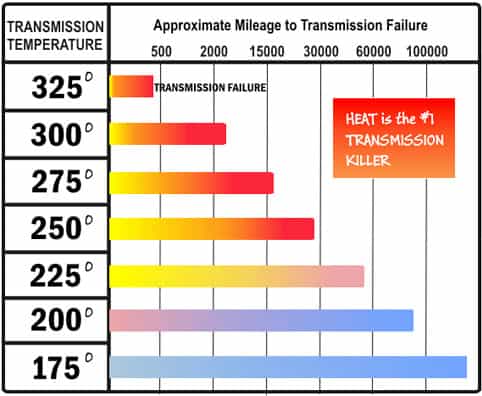

as trans fluid temps go up transmission durability drops rapidly your stock trans fluid cooler in the lower radiator has never been designed to cope with performance stress loads, youll NEED an added cooler if your going to beat on the car

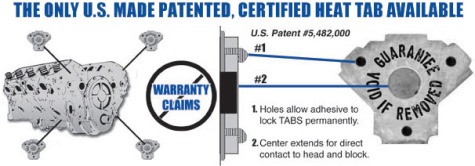

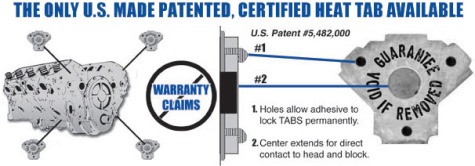

BTW you may find freeze plugs that look like this on blocks and cylinder heads, especially from engine rebuilder machine shops, the "exterior outside BUTTONs are made from a very special low melt metal like bismuth thats specifically designed too melt and distort if the blocks coolant temp reaches about 250-260F indicating and proving beyond question that you over heated the engine and voided your warranty

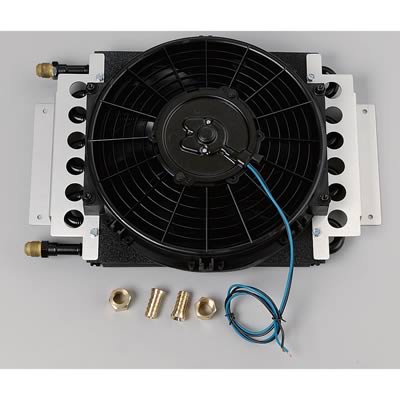

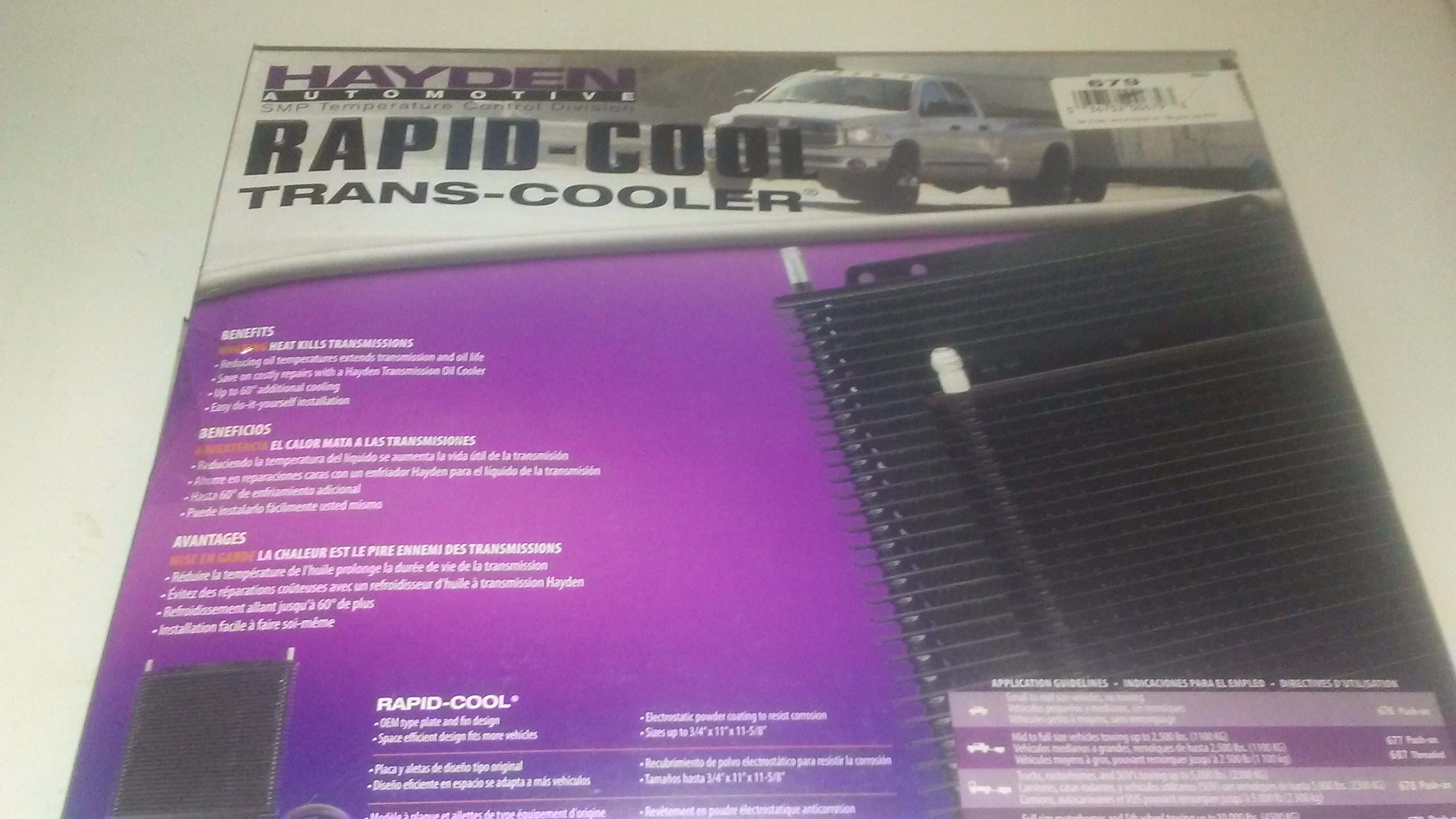

I don,t remember, where I purchased most of the oil/trans fluid coolers Ive used ,

but I've purchased and installed several oil and trans fluid coolers

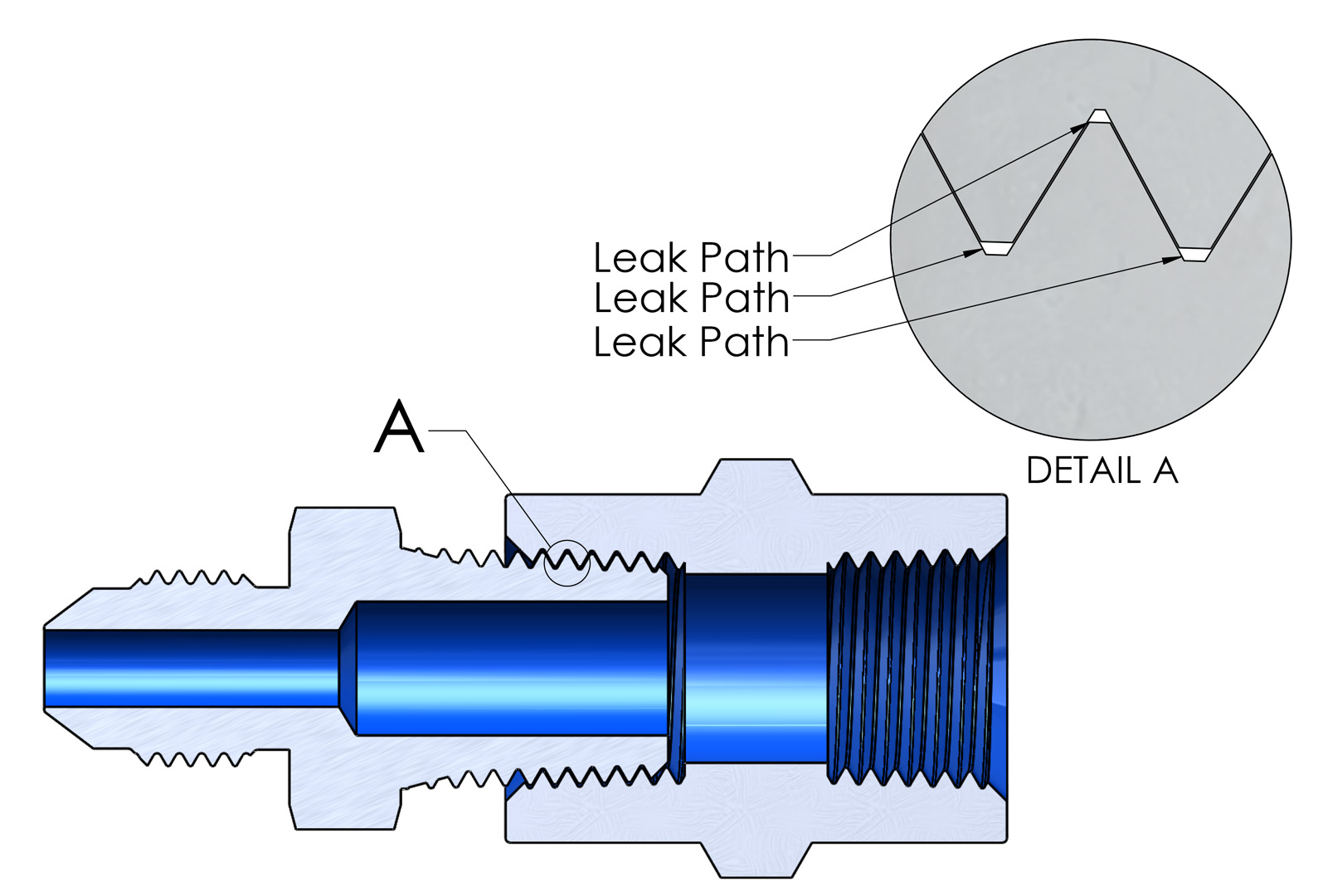

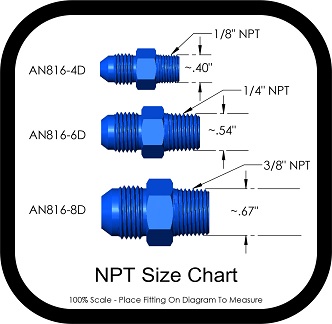

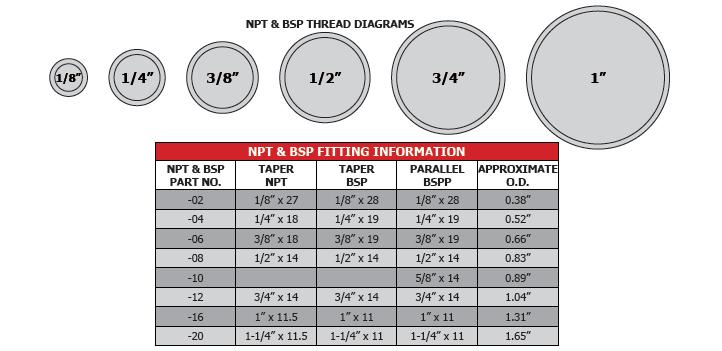

over the decades, almost all were used 1/2" or an#8 connections and were purchased from summit or jegs

as always read carefully,

and measure accurately, remembering you must be leaving room for the hot oil or trans fluid hose and connections

and access to get the cooler in and mounted and connections made too it!

you would certainly not be the first or last guy to buy a cooler that will not fit in the space you though it would,

due to the connections and hoses required or forgetting about the thickness or lack of easy access.

https://www.summitracing.com/parts/der-15820

https://www.summitracing.com/search...rtOrder=Ascending&keyword=oil cooler with fan

https://www.jegs.com/i/Derale/259/15850/10002/-1

https://www.jegs.com/webapp/wcs/sto...&submodel=&engine=&Nrpp=&No=&persistYmm=false

http://www.silver-seal.com/category/shop.1_cylinder_head_rebuilding.2_heat_tabs/

http://www.engineheattabs.com/products

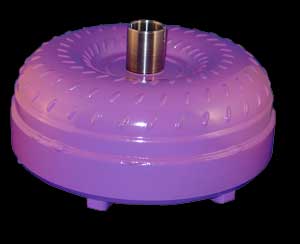

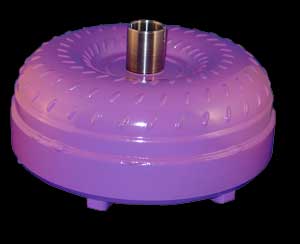

btw torque converters are frequently painted with a very special paint that changes color at a specific temperature for the exact same reason, proof you voided the warranty and failed to run the transmission fluid thats supposed to act as a lubricant and coolant within the designed temperature range, they did not select the pink or purple because they like the color, its done to reduce warranty cost issues , if you over heat the converter its waranty is void

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...n-cooler-info-and-derale-trans-cool-pans.662/

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-12335

Transmission over temp warning comes on when I'm at the track. It takes about 10 minutes of hard use for it to come on. Granted it's Florida and it's been 90 plus degrees. I've been trying to find a system schematic to think of what might be going on. Anyone have any knowledge of the 2007 Z06 tranny system? Does it have a thermostat? An electrical or mechanical pump? Does it always send fluid through the cooler? Etc etc.....Thx!

as trans fluid temps go up transmission durability drops rapidly your stock trans fluid cooler in the lower radiator has never been designed to cope with performance stress loads, youll NEED an added cooler if your going to beat on the car

BTW you may find freeze plugs that look like this on blocks and cylinder heads, especially from engine rebuilder machine shops, the "exterior outside BUTTONs are made from a very special low melt metal like bismuth thats specifically designed too melt and distort if the blocks coolant temp reaches about 250-260F indicating and proving beyond question that you over heated the engine and voided your warranty

I don,t remember, where I purchased most of the oil/trans fluid coolers Ive used ,

but I've purchased and installed several oil and trans fluid coolers

over the decades, almost all were used 1/2" or an#8 connections and were purchased from summit or jegs

as always read carefully,

and measure accurately, remembering you must be leaving room for the hot oil or trans fluid hose and connections

and access to get the cooler in and mounted and connections made too it!

you would certainly not be the first or last guy to buy a cooler that will not fit in the space you though it would,

due to the connections and hoses required or forgetting about the thickness or lack of easy access.

https://www.summitracing.com/parts/der-15820

https://www.summitracing.com/search...rtOrder=Ascending&keyword=oil cooler with fan

https://www.jegs.com/i/Derale/259/15850/10002/-1

https://www.jegs.com/webapp/wcs/sto...&submodel=&engine=&Nrpp=&No=&persistYmm=false

http://www.silver-seal.com/category/shop.1_cylinder_head_rebuilding.2_heat_tabs/

http://www.engineheattabs.com/products

btw torque converters are frequently painted with a very special paint that changes color at a specific temperature for the exact same reason, proof you voided the warranty and failed to run the transmission fluid thats supposed to act as a lubricant and coolant within the designed temperature range, they did not select the pink or purple because they like the color, its done to reduce warranty cost issues , if you over heat the converter its waranty is void

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

https://www.paintwithpearl.com/shop-custom-paint/temperature-changing-paint/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...n-cooler-info-and-derale-trans-cool-pans.662/

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-12335

Last edited: