clampdaddy

Member

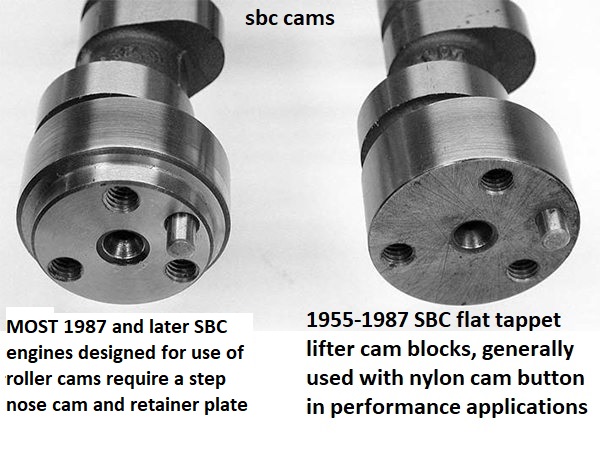

What have you all found to be the best way to put a nice, square face on a nylon cam button? I do have access to a lathe where I work, which I will be using tomorrow to turn down the big end a little bit so it will fit in the timing gear hole, and to buzz the bulk of the material off the other end, but do you have any tricks that might help me when I'm back home doing the final fitting?