read thru these links and sub links

viewtopic.php?f=27&t=26

http://www.classicperform.com/TechBook/ ... eshoot.htm

viewtopic.php?f=71&t=3556&p=9442&hilit=fluid+brake#p9442

http://auto.howstuffworks.com/auto-part ... brake5.htm

BTW its ALWAYS a good idea to completely replace old brake fluid and NEVER mix old and new brake fluid if it can be avoided simply because old brake fluid can contain moisture and might not be compatible with the new brake fluid

some of the newer synthetic brake fluids are far less prone to absorb moisture and boil at much higher temps that the OEM brake fluids

http://www.speedwaymotors.com/AFCO-6691 ... 65622.html

http://www.speedwaymotors.com/Wilwood-2 ... ,1386.html

BTW banjo fittings require a seal washer on both sides

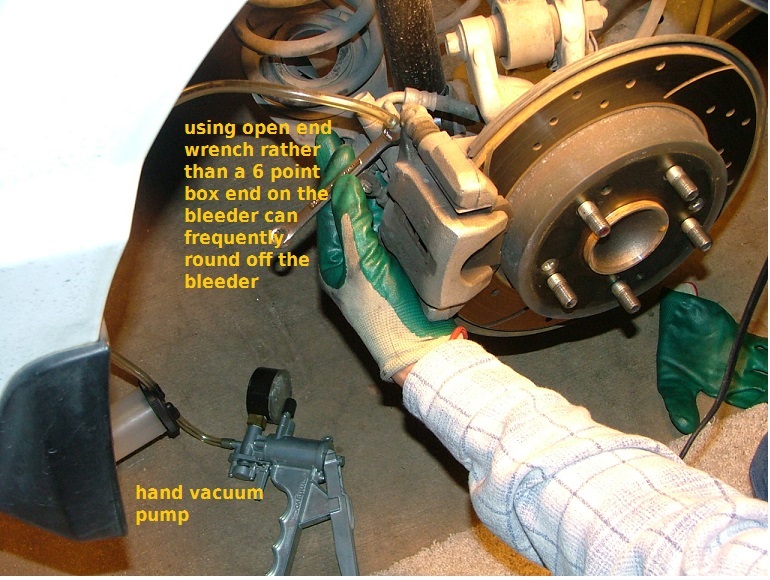

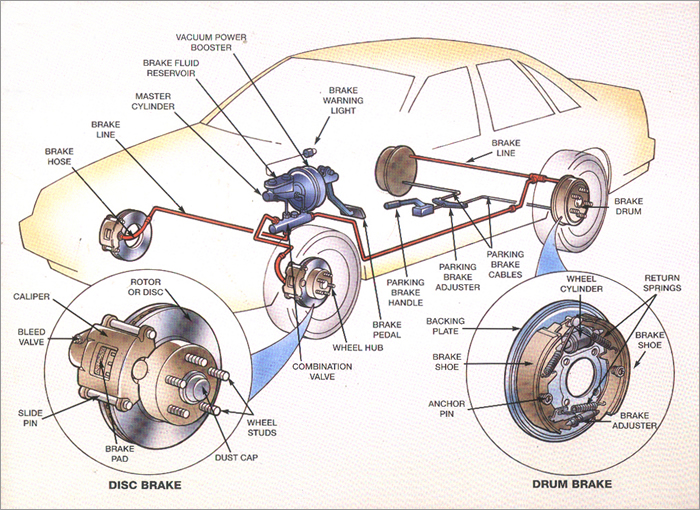

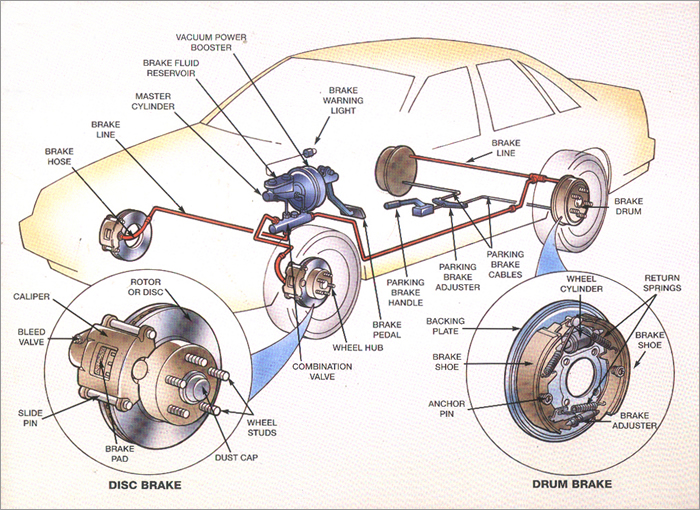

If your not getting full functioning brakes your obviously not getting full caliper or slave cylinder movement on the rear drums or calipers, somethings busted, clogged or corroded, or your low on brake fluid or somethings out of adjustment or badly worn, locating the cause won,t be difficult if you attack the problem logically and understand how the systems designed to function, and how to dis-assemble and inspect and posiably replace defective or worn, components, as a start point Id strongly suggest bleeding the brakes on all four wheels and replacing all the brake fluid with new DOT 4 , get a couple quarts and

read the links

having a lift or at least 4 good jack stands , which make working on brakes far easier once the cars frame is supported and the wheels are easily accessed.(don,t forget the brake the lug nuts loose before raising the car off the ground if you don,t have a lift or air impact gun)

and a decent floor jack helps a great deal, knowing what your looking at and how to make adjustments helps and having a friend help is a huge plus.

BTW don,t forget to put ANTI-SEIZE on the lug threads before re-installing the lug nuts

http://www.classicperform.com/TechBook/ ... eshoot.htm

http://autorepair.about.com/od/troubles ... brakes.htm

http://www.classicperform.com/TechBook/ ... eshoot.htm

http://www.consumerreports.org/cro/cars ... /index.htm

http://www.aa1car.com/library/pwrsteer.htm

http://www.afcoracing.com/tech_pages/shoot.shtml

http://www.popularmechanics.com/automot ... 13448.html

http://www.stoptech.com/tech_info/wp_bedintheory.shtml

http://www.stoptech.com/tech_info/wp_bedinstock.shtml

http://home.att.net/~m.prendergast-alli ... AKCHRT.htm

http://www.sjdiscounttools.com/fow72-234-223.html

http://auto.howstuffworks.com/auto-part ... brake5.htm

http://www.clarks-garage.com/shop-manual/ts-07.htm

http://www.pjwauto.com/troubleshooting- ... lems.shtml

http://www.ehow.com/topic_3454_car-brak ... guide.html

http://www.fordf150.net/howto/brakerepair.php

http://www.lbfun.com/warehouse/tech_inf ... Brakes.pdf

viewtopic.php?f=27&t=26

http://www.classicperform.com/TechBook/ ... eshoot.htm

viewtopic.php?f=71&t=3556&p=9442&hilit=fluid+brake#p9442

http://auto.howstuffworks.com/auto-part ... brake5.htm

BTW its ALWAYS a good idea to completely replace old brake fluid and NEVER mix old and new brake fluid if it can be avoided simply because old brake fluid can contain moisture and might not be compatible with the new brake fluid

some of the newer synthetic brake fluids are far less prone to absorb moisture and boil at much higher temps that the OEM brake fluids

http://www.speedwaymotors.com/AFCO-6691 ... 65622.html

http://www.speedwaymotors.com/Wilwood-2 ... ,1386.html

BTW banjo fittings require a seal washer on both sides

If your not getting full functioning brakes your obviously not getting full caliper or slave cylinder movement on the rear drums or calipers, somethings busted, clogged or corroded, or your low on brake fluid or somethings out of adjustment or badly worn, locating the cause won,t be difficult if you attack the problem logically and understand how the systems designed to function, and how to dis-assemble and inspect and posiably replace defective or worn, components, as a start point Id strongly suggest bleeding the brakes on all four wheels and replacing all the brake fluid with new DOT 4 , get a couple quarts and

read the links

having a lift or at least 4 good jack stands , which make working on brakes far easier once the cars frame is supported and the wheels are easily accessed.(don,t forget the brake the lug nuts loose before raising the car off the ground if you don,t have a lift or air impact gun)

and a decent floor jack helps a great deal, knowing what your looking at and how to make adjustments helps and having a friend help is a huge plus.

BTW don,t forget to put ANTI-SEIZE on the lug threads before re-installing the lug nuts

http://www.classicperform.com/TechBook/ ... eshoot.htm

http://autorepair.about.com/od/troubles ... brakes.htm

http://www.classicperform.com/TechBook/ ... eshoot.htm

http://www.consumerreports.org/cro/cars ... /index.htm

http://www.aa1car.com/library/pwrsteer.htm

http://www.afcoracing.com/tech_pages/shoot.shtml

http://www.popularmechanics.com/automot ... 13448.html

http://www.stoptech.com/tech_info/wp_bedintheory.shtml

http://www.stoptech.com/tech_info/wp_bedinstock.shtml

http://home.att.net/~m.prendergast-alli ... AKCHRT.htm

http://www.sjdiscounttools.com/fow72-234-223.html

http://auto.howstuffworks.com/auto-part ... brake5.htm

http://www.clarks-garage.com/shop-manual/ts-07.htm

http://www.pjwauto.com/troubleshooting- ... lems.shtml

http://www.ehow.com/topic_3454_car-brak ... guide.html

http://www.fordf150.net/howto/brakerepair.php

http://www.lbfun.com/warehouse/tech_inf ... Brakes.pdf