Home ::

Fuel Pumps/Regulators/Fuel Filters :: Fuel Pumps

Fuel Pumps

Belt Driven Fuel Pumps for Alcohol and Gas

Alcohol has become a very popular race fuel to use with a Holley® carburetor. The big problem is the fuel supply requirement using alcohol. The fuel requirement is twice the amount needed with gasoline. A 700 HP engine consumes 700 pounds of fuel an hour when operating at full throttle. Simple math tells you that no electric and/or mechanical fuel pump will handle this requirement. The electric and 6 valve mechanical pumps have excessive high idle fuel pressure which can cause flooding and rich conditions at idle and part throttle but they cannot keep up with full throttle fuel demand. The solution to the problem is a fuel pump where the pressure is low (3-5 psi) at idle then increases with engine RPM and the pressure is fully adjustable to your needs.

These pumps have become very popular on Drag Race engines using gasoline as well as alcohol. The fuel pressure

is low when doing a water burn out and staging and does not have the high fuel pressure spike that is common with electric pumps. With an 800 HP engine it takes less than 1 HP to operate this pump. Also, there is no drain on the battery.

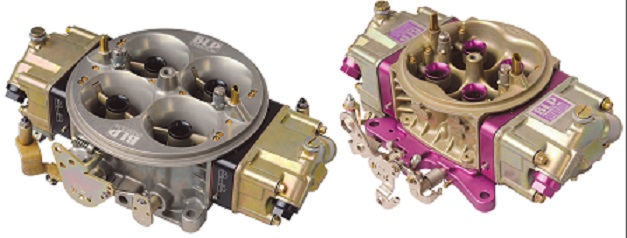

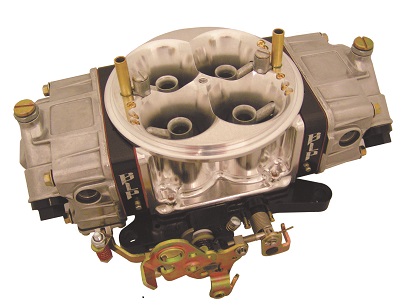

At BLP Racing Products we have developed 2 versions of belt driven fuel pumps. One features an internal fuel by-pass system that enables the user to regulate and adjust the fuel pressure without having to use a separate by-pass valve and a return line to the tank. The second version is a fuel pump with no internal regulator and can be used with a BLP 7491 fuel by-pass regulator or the installer can use their own by-pass system.

Doug Learned and his staff at Intercity Manufacturing Incorporated manufacture the pump component parts. BLP then assembles and tests the pumps in-house. The pumps are available in 4 different gear sizes .400”, .500”, 600”, and .700” thick gears. By using different thickness gear wear plates the same body can be used for all 4-size gears. This gives us the option of changing pump volumes by just changing the gears and wear plates.

Features:

• The adjusting arm can be rotated a full 360° without having to disassemble the pump

• Pump can be used with or without a return line

• All billet construction

• Available in 4 volume sizes

• Available for right or left hand mounting

• Can be serviced in the field

• Easily mounted with simple plumbing

• 1 full year warranty including parts and labor

WHICH FUEL PUMP IS BEST?

In our opinion it is always best to use a –8 return line with a belt driven fuel pump. This type fuel return system handles fuel spikes better than an internal by-pass type pump. It also keeps the fuel cooler when using gasoline. However, having said that, BLP builds and sells more adjustable, internal by-pass fuel pumps than we do the return line style fuel pumps. The reason for that is they are simple to plumb and easy to adjust. Used in the right application and maintained properly they are virtually trouble free.

External return Fuel Pumps

Providing that you use the proper return regulator these fuel pumps can be used in any application.

Features:

• They handle fuel spike much better when you back off the throttle. This is very important in circle track racing to prevent fuel from loading up in the corners

• You can have a lower idle pressure and a larger spread between idle and full throttle pressure

NOTE:

• Must use a –8AN return line (cannot use a –6AN)

• Must use a quality and regularly maintained return regulator

Internal By-Pass Fuel Pumps

These fuel pumps by-pass the excess fuel internally to the low-pressure side of the fuel pump. The pressure is adjustable at the fuel pump. No regulators of any kind are required or recommended.

Features:

• Easy to install and does not require a return line

• Easy to adjust and maintain

MUST:

• You cannot use the high volume .700 wide gear pump when internally regulated

• Do not use in circle track application when using gas. It works fine with alcohol in any heat condition, but vapor lock can occur when using gas as a fuel.

The keys to successfully using the internal by-pass fuel pump is to use our recommendation and do the following:

• Size the pump correctly and do not use any larger pump than necessary. Bigger is not better.

• The internal by-pass type pump has to have the fuel inlet line lower than the pump. For example, if you run a modified that has to run the fuel line up high on the chassis then you need to run an external by-pass pump.

Fuel Pump Volumes

The validity of advertised fuel pump volumes is only as accurate as the method used for testing. In other words, a fuel pump will show more volume if it is gravity fed with no outlet restriction than if the pump had to lift the fuel and maintain a constant pressure. This holds especially true with a mechanical fuel pump.

Example: a mechanical pump may pump 108 gallons per hour at 1 pound of pressure but only 60 gallons per hour if it had to maintain 5 pounds of pressure. We test and flow our pumps in a real world environment. To simulate racing conditions we lift the fuel 18”, pump it through a 1/2” line and maintain race condition fuel pressure.

BLP Fuel Pump driven at 50% of Engine Speed with A Fixed Pressure

.400 Thick gear pump

1800 Pump RPM at 50 PSI flows 81 GPH

3500 Pump RPM at 10 PSI flows 98 GPH

4000 Pump RPM at 11 PSI flows 113 GPH

.500 1800 Pump RPM at 50 PSI flows 108 GPH

3500 Pump RPM at 10 PSI flows 120 GPH

4000 Pump RPM at 11 PSI flows 139 GPH

.600 Thick gear pump

1800 Pump RPM at 50 PSI flows 120 GPH

3500 Pump RPM at 10 PSI flows 148 GPH

4000 Pump RPM at 11 PSI flows 170 GPH

.700 Thick gear pump

1800 Pump RPM at 50 PSI flows 138 GPH

3500 Pump RPM at 10 PSI flows 170 GPH

4000 Pump RPM at 11 PSI flows 192 GPH

FUEL PUMP SIZE APPLICATION

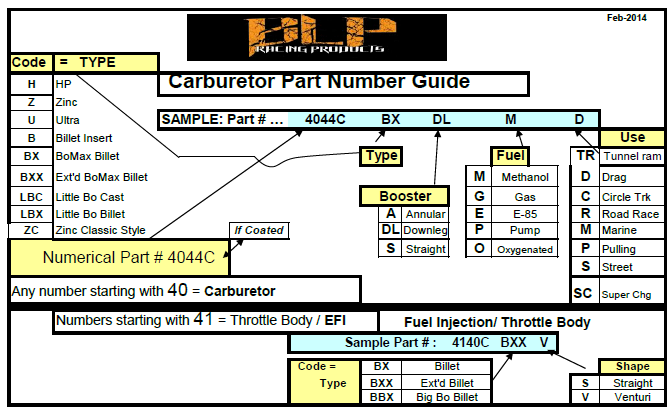

We classify our fuel pumps by the gear thickness and we have (4) different gear sizes to choose from. If you compare the BLP fuel pump to a typical fuel injection pump such as a Hilborn or Enderle then use this as a volume comparison.

BLP FUEL PUMP TYPICAL FUEL INJECTION PUMP

.400 wide gear No comparison

.500 wide gear 0 Pump

.600 wide gear ½ Pump

.700 wide gear 1 Pump

A BLP .500 wide gear pump will handle most carburetor fuel volume needs. Installing the correct volume fuel pump is very important. Bigger is not always better and if the pump has to by-pass too much fuel then you will have problems with fuel spike. Contact BLP for the correct fuel pump application.