Philly, when I get my finances in better shape I think we need to talk about the potential of building a 496 big block twin turbo set up to produce a reliable, 900-1000hp , now I know that can be done, and Ive always preferred building high durability rather than trying for big bragging numbers

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

turbo maps, and related turbo info

- Thread starter grumpyvette

- Start date

philly

solid fixture here in the forum

an update grumpy for your big block turbo build... i think we may soon be embarking on that endeavor here only on a much more junk yard grenade status... however i came across this from crower:

http://www.crower.com/chevy-396-454-tur ... -4595.html

we will probably be sliding this in our junkyard 454tt setup... if we actually go through with it... i think we are going to end up using the gt45 knockoffs on ebay with larger than i would like rear housings, in the hopes that we can keep traction issues out of the hole to a minimum.

expect a gotech ecu to control that action and atleast 1200 wheel horsepower... 2700 ish pound car with driver

im not sure if the build is even gonna happen but we saw some scary fast cars last night and realized we need to step up are game if we are going to ever get out of the kiddie pool and swim with the big fish.

http://www.crower.com/chevy-396-454-tur ... -4595.html

we will probably be sliding this in our junkyard 454tt setup... if we actually go through with it... i think we are going to end up using the gt45 knockoffs on ebay with larger than i would like rear housings, in the hopes that we can keep traction issues out of the hole to a minimum.

expect a gotech ecu to control that action and atleast 1200 wheel horsepower... 2700 ish pound car with driver

im not sure if the build is even gonna happen but we saw some scary fast cars last night and realized we need to step up are game if we are going to ever get out of the kiddie pool and swim with the big fish.

JUST FOR A POINT OF DISCUSSION HERE

THAT CAM YOU LINKED TOO HAD THIS TIMING

Duration @ .050" Lift: Intake / Exhaust 226 / 212

Lobe Lift: Intake / Exhaust .300 / .288

Rocker Ratio: Intake / Exhaust 1.7 / 1.7

Gross Valve Lift: Intake / Exhaust .510 / .490

why would you not select a cam with a bit more or less lift or duration,

THAT CAM YOU LINKED TOO HAD THIS TIMING

Duration @ .050" Lift: Intake / Exhaust 226 / 212

Lobe Lift: Intake / Exhaust .300 / .288

Rocker Ratio: Intake / Exhaust 1.7 / 1.7

Gross Valve Lift: Intake / Exhaust .510 / .490

why would you not select a cam with a bit more or less lift or duration,

philly

solid fixture here in the forum

grumpyvette said:JUST FOR A POINT OF DISCUSSION HERE

THAT CAM YOU LINKED TOO HAD THIS TIMING

Duration @ .050" Lift: Intake / Exhaust 226 / 212

Lobe Lift: Intake / Exhaust .300 / .288

Rocker Ratio: Intake / Exhaust 1.7 / 1.7

Gross Valve Lift: Intake / Exhaust .510 / .490

why would you not select a cam with a bit more or less lift or duration,

i saw that cam as a cheap way to slide a decent turbo cam in the car, if we do the deed with our junkyard 454 price is a major factor is parts selection. the low exhaust duration matched with small primaries on the header (if we do this we will use a tri-y setup) will keep velocity of the gasses high and the cheap and oversized turbos spinning. i am running off of assumtions that the motor is gonna be a low compression pig since we dont have a motor yet but the 049 big block heads dont flow alot more in stock ish form with more than a .500 lift as it is. that is to say the difference in flow from .500 lift to say .800 lift isnt going to net us the gains to justify the loss of bottom end grunt. and we arent going to spin the motor very high in the name of longevity.

8

87vette81big

Guest

With $$ tight for all of us Phil I think I would choose a

5.3 Liter LS Chevy Truck Engine.

Twin Turbo charge it.

You can find a used 5.3 L V8 for around $200-300 around me.

Buy the entire truck for $500-700.

Strip it down & sell what you can.

Scrap the rest.

I think you can easily double or triple your purchase price.

And have the 6-bolt main LS 5.3 V8.

They run strong as is.

Not much less torque than the 5.7 & 6.0.

Turbo charging will add another 500-800 Ft/lbs in powerband everywhere.

5.3 Liter LS Chevy Truck Engine.

Twin Turbo charge it.

You can find a used 5.3 L V8 for around $200-300 around me.

Buy the entire truck for $500-700.

Strip it down & sell what you can.

Scrap the rest.

I think you can easily double or triple your purchase price.

And have the 6-bolt main LS 5.3 V8.

They run strong as is.

Not much less torque than the 5.7 & 6.0.

Turbo charging will add another 500-800 Ft/lbs in powerband everywhere.

philly

solid fixture here in the forum

any truck motor will do... but the voltures down here where im at have driven the price up to between 500 (long block) to as high as 1800 (motor tranny wiring harness) for the 4.8's and 5.3's.... a 6.0 or bigger? add atleast another 50-100% on top those prices. in a small car like 3000 pounds or less, the 4.8 is where its at... you get more useable rpm band without sacrificing the torque if you use the right cam and turbo size.

now admittedly, I have limited experience building turbo charged engines, having only helped on several of my friends cars , mostly building the engines or partial engines to match agreed upon configurations.

and yes theres a great deal of related info posted earlier in this thread to help.

but we may as well get a discussion about the basic strategy, and parts selections.

you guys with more experience can and should post info WITH REFERENCE LINKS , diagrams and pictures to back up any suggestions as that will be useful

1) how do you select a basic displacement, bore & stroke combo and compression ratio

2)how do you select the cylinder heads, port size.

3)what rotating assembly, crank ,rods, pistons, rings ETC.(obviously forged) but related info on set-up and clearances, ring gaps, heat coating, is welcome

4) Header design, Size and construction

5) Crossover tube design, size and construction

6) How do you choose the correct turbocharger make and model/flow map,and boost range

7) Exhaust system basics feeding the turbo and leaving the turbo to exit the car

8) Waste gate selection ,installation and optimal performance

9)intake manifold and throttle body selection

10) injector size and type selection

11) heat shielding

12)intercoolers

13) engine cooling & lube system designs

14) turbo lube supply

15) cams designed for turbo tend to have equal or lower duration on the exhaust to keep exhaust gas speed high and a

112-116 lsa to limit intake flow of fuel/air pressure exiting the exhaust

16) the fuel lines and injectors will need to be calculated at near 85% duty cycle and BSFC of near 65%

17) AN#8 fuel lines and 200 GPH, or larger fuel pumps at 40-60 PSI are normal

18) how to select rearing and converter stall speeds

19) solid copper head gaskets and ARP head studs are suggested as cylinder pressures are noticeably higher than N/A

20) BLOW OFF VALVES, bov, settings and size and location

viewtopic.php?f=55&t=1200

viewtopic.php?f=55&t=2718&p=35581&hilit=octane+booster#p35581

viewtopic.php?f=86&t=9078

viewtopic.php?f=53&t=4516&p=11935#p11935

viewtopic.php?f=86&t=4402&p=11579&hilit=intercooler#p11579

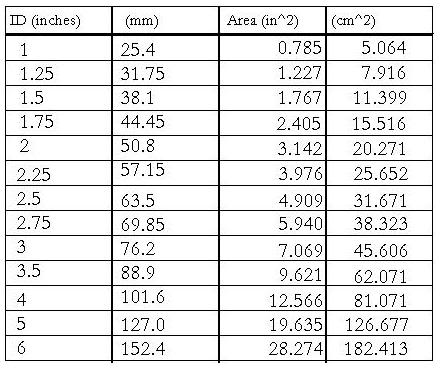

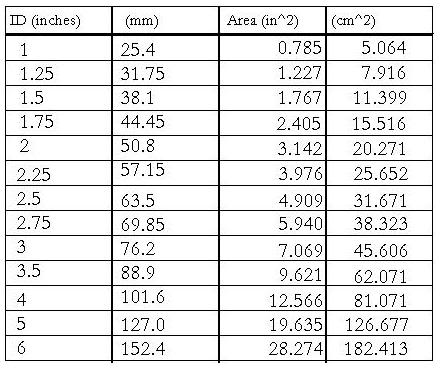

from an engineering perspective on the exhaust side feeding the turbo, a 1.75" -to-2" exhaust port in a typical cylinder head,would need a primary header tube that would ideally feed a collector of about twice its cross sectional area too maintain high exhaust gas speeds, so in theory all four cylinders should feed a 2.75" exhaust collector feeding the turbo input, on a dual turbo set-up, obviously you cant fit 4 2" pipes into a 2.75" collector but you can use a collector and reducer to maintain exhaust gas velocity

on the intake side thats pressurized you'll want less flow restriction ,so fairly large intake runner cross section in that manifold and a throttle body thats not a restriction and head ports and tubing feeding any inter-cooler would be almost mandatory, but keep in mind as the pressure differential changes so does the flow numbers, a throttle body that may be rated at 1000cfm at 1.5" of mercury may flow 2500cfm at 15 psi of boost

http://www.burnsstainless.com/321sstubing-5.aspx

http://www.burnsstainless.com/mc4-188-dst-321.aspx

321SS stainless

OK a few tips I have found to start,

the exhaust headers feeding the turbo must be constructed from heat resistant stainless

header primary should ideally be short, fairly close to equal length and have the inside diam. cross sectional area just large enough to not block the exhaust port exit.

header flanges should be a minimum of 3/8" to ideally 1/2" thick to reduce warping

AS ALWAYS A BIT OF RESEARCH WON"T HURT

http://users.erols.com/srweiss/calchpb.htm

http://users.erols.com/srweiss/calcplv.htm

http://www.gnttype.org/techarea/turbo/turboflow.html

https://www.rbracing-rsr.com/calcboost.html

http://www.rbracing-rsr.com/intercoolers.htm

http://www.turbobygarrett.com/turbobyga ... %20103.pdf

http://www.turbofast.com.au/turbomap.html

http://www.turbofast.com.au/javacalc.html

http://www.stainlessheaders.com/flanges

http://www.stainlessheaders.com/turboheader

http://www.jegs.com/i/Stainless-Works/8 ... Id=1197917

http://www.lovehorsepower.com/joomla/in ... &Itemid=88

http://www.amazon.com/Maximum-Boost-Tur ... nk22192-20

http://www.amazon.com/Turbochargers-HP4 ... o+charging

http://www.amazon.com/Turbocharging-Per ... o+charging

and yes theres a great deal of related info posted earlier in this thread to help.

but we may as well get a discussion about the basic strategy, and parts selections.

you guys with more experience can and should post info WITH REFERENCE LINKS , diagrams and pictures to back up any suggestions as that will be useful

1) how do you select a basic displacement, bore & stroke combo and compression ratio

2)how do you select the cylinder heads, port size.

3)what rotating assembly, crank ,rods, pistons, rings ETC.(obviously forged) but related info on set-up and clearances, ring gaps, heat coating, is welcome

4) Header design, Size and construction

5) Crossover tube design, size and construction

6) How do you choose the correct turbocharger make and model/flow map,and boost range

7) Exhaust system basics feeding the turbo and leaving the turbo to exit the car

8) Waste gate selection ,installation and optimal performance

9)intake manifold and throttle body selection

10) injector size and type selection

11) heat shielding

12)intercoolers

13) engine cooling & lube system designs

14) turbo lube supply

15) cams designed for turbo tend to have equal or lower duration on the exhaust to keep exhaust gas speed high and a

112-116 lsa to limit intake flow of fuel/air pressure exiting the exhaust

16) the fuel lines and injectors will need to be calculated at near 85% duty cycle and BSFC of near 65%

17) AN#8 fuel lines and 200 GPH, or larger fuel pumps at 40-60 PSI are normal

18) how to select rearing and converter stall speeds

19) solid copper head gaskets and ARP head studs are suggested as cylinder pressures are noticeably higher than N/A

20) BLOW OFF VALVES, bov, settings and size and location

viewtopic.php?f=55&t=1200

viewtopic.php?f=55&t=2718&p=35581&hilit=octane+booster#p35581

viewtopic.php?f=86&t=9078

viewtopic.php?f=53&t=4516&p=11935#p11935

viewtopic.php?f=86&t=4402&p=11579&hilit=intercooler#p11579

from an engineering perspective on the exhaust side feeding the turbo, a 1.75" -to-2" exhaust port in a typical cylinder head,would need a primary header tube that would ideally feed a collector of about twice its cross sectional area too maintain high exhaust gas speeds, so in theory all four cylinders should feed a 2.75" exhaust collector feeding the turbo input, on a dual turbo set-up, obviously you cant fit 4 2" pipes into a 2.75" collector but you can use a collector and reducer to maintain exhaust gas velocity

on the intake side thats pressurized you'll want less flow restriction ,so fairly large intake runner cross section in that manifold and a throttle body thats not a restriction and head ports and tubing feeding any inter-cooler would be almost mandatory, but keep in mind as the pressure differential changes so does the flow numbers, a throttle body that may be rated at 1000cfm at 1.5" of mercury may flow 2500cfm at 15 psi of boost

http://www.burnsstainless.com/321sstubing-5.aspx

http://www.burnsstainless.com/mc4-188-dst-321.aspx

321SS stainless

OK a few tips I have found to start,

the exhaust headers feeding the turbo must be constructed from heat resistant stainless

header primary should ideally be short, fairly close to equal length and have the inside diam. cross sectional area just large enough to not block the exhaust port exit.

header flanges should be a minimum of 3/8" to ideally 1/2" thick to reduce warping

AS ALWAYS A BIT OF RESEARCH WON"T HURT

http://users.erols.com/srweiss/calchpb.htm

http://users.erols.com/srweiss/calcplv.htm

http://www.gnttype.org/techarea/turbo/turboflow.html

https://www.rbracing-rsr.com/calcboost.html

http://www.rbracing-rsr.com/intercoolers.htm

http://www.turbobygarrett.com/turbobyga ... %20103.pdf

http://www.turbofast.com.au/turbomap.html

http://www.turbofast.com.au/javacalc.html

http://www.stainlessheaders.com/flanges

http://www.stainlessheaders.com/turboheader

http://www.jegs.com/i/Stainless-Works/8 ... Id=1197917

http://www.lovehorsepower.com/joomla/in ... &Itemid=88

http://www.amazon.com/Maximum-Boost-Tur ... nk22192-20

http://www.amazon.com/Turbochargers-HP4 ... o+charging

http://www.amazon.com/Turbocharging-Per ... o+charging

8

87vette81big

Guest

Its the only affordable way for all us Grumpy to massive torque curves, High Hp that makes anyone smile.

Make same as Hellcat & surpass.

Question is how far we can push usual parts used.

And how far can BBC & TALL DECK BE PUSHED.

Pontiac pretty well documented by diehards like me on the net.

Piston speeds can be kept at 4,000 feet per minute.

I have no fear at 4,900 feet per minute.

But 4300 enough usually.

Make same as Hellcat & surpass.

Question is how far we can push usual parts used.

And how far can BBC & TALL DECK BE PUSHED.

Pontiac pretty well documented by diehards like me on the net.

Piston speeds can be kept at 4,000 feet per minute.

I have no fear at 4,900 feet per minute.

But 4300 enough usually.

grumpyvette said:3" stainless components

the first time you think about doing this I,m sure you'll have dozens of questions and probably realize you don,t know most of the tricks or have some of the tools required, obviously having access to a lift and welding equipment is a huge advantage, the good part about building your first few exhaust systems is that in most cases, most of the welding is not all that easy to inspect while the cars being driven so if your just learning to weld a a few less than skilled welds won,t be a huge eye sore on your car.

remember youll want to complete the project in a reasonably short time (usually a weekend) so make sure you have all the tools and components before you start, because finding something like a extra 3" stainless (X) or (S) bend on a weekend can be a royal P.I.T.A. at times.

BUT USE A MINIMUM 16GA, and 321 stainless as its formulated to with stand heat better, 18 GA is too THIN, FOR STAINLESS HEADERS OR EXHAUST PIPE, AND DON,T FORGET TO PURGE the pipe close off the ends with duct tape if its not hot or thick aluminum foil and a thin wire wrap if its hot ,THE BACK GAS WHEN WELDING IS MANDATORY IF YOU WANT TO AVOID A SUGAR LIKE WELD ON THE INSIDE SURFACE THAT WOULD OTHER WISE EXPOSED TO AIR

just remember the old carpenters rule of MEASURE carefully TWICE before CUTTING ONCE!, and take the time to think thru the route the exhaust pipes, must take, any clearance issues and muffler to suspension or frame clearance, etc.

lay it all out before you permanently weld any connection, between sections or components and make sure you make allowances for the future temporary dis-assembly, at some point, if the mounted exhaust blocks access to the drive train.

use vibration or rubber damper strap mounts to prevent annoying harmonics or vibrations .

remember stainless welds must have the back of the weld area shielded so both ends of the pipe covered with aluminum duct tape and fill the pipe with a flush of shield argon gases is a good idea, mig or tig works (I vastly prefer TIG) but remember to use stainless mig wire or tig fill rods and argon tends to work ok as a shield gas.

we have a welding tips section you might want to browse thru

viewforum.php?f=60

http://www.youtube.com/watch?v=4TIQYEv1 ... ure=fvwrel

http://www.youtube.com/watch?v=ANFXXKMR ... re=related

http://www.youtube.com/watch?v=zzvy3Rd0 ... re=related

http://www.youtube.com/watch?v=DzNcHI7r ... re=related

http://www.youtube.com/watch?v=KdaVNRcy ... re=related

http://www.youtube.com/watch?v=8KrApq04 ... re=related

http://www.youtube.com/watch?v=02U0H15_ ... re=related

CRISS POSTED THIS INFO

"You can mig stainless just fine. I use stainless wire, the mix isn't really that important, C25, tri mix etc. The best results are with 100% Argon or a Argon/Helium mix.

What IS more important is the back side of the weld, you should use either a shielding gas on the backside or solar flux B which is a powder you mix with rubbing alcohol and coat the back of the weld to prevent oxygen contamination. Without the coating you will get black crystals or sugar in the weld on the backside that makes the weld weak.

Tig welding is really the best way to weld stainless, but mig welding it is very doable as well. "

IF YOU WELD STAINLESS EXHAUST PIPE without a back flush you can get weld crystallizing or SUGARING , an ARGON back flush and taping both ends to exclude oxygen helps reduce this significantly as will tig paste

http://www.solarflux.com/Pages/Productinfo.html

http://www.stainless-specialties.com/products2a.htm

http://www.magnaflow.com/wideopen/wideopen.asp

http://www.spiderautomotive.com/benttubing.html

http://www.stainlessworks.net/cart/inde ... 66a68a046a

http://www.pypesexhaust.com/accessories.html#03

http://www.weldingtipsandtricks.com/wel ... steel.html

http://www.pypesexhaust.com/xpipes.html

http://www.classictube.com/products_exhaust.asp

http://www.gowelding.org/TIG_Welding.html

http://www.weldingtipsandtricks.com/wel ... steel.html

http://www.discountexhaustsystems.com/

http://www.autoanything.com/exhausts-mu ... 3A0A0.aspx

8

87vette81big

Guest

I have a few vintage Turbo articles I picked up recent Grumpy.

Scan and post them. Internet is down till tommarow night.

Could use stock exhaust manifolds initial.

Real poor man's layout.

But will work OK.

Something to chew on for ideas.

Get them up ASAP.

Scan and post them. Internet is down till tommarow night.

Could use stock exhaust manifolds initial.

Real poor man's layout.

But will work OK.

Something to chew on for ideas.

Get them up ASAP.

philly

solid fixture here in the forum

i've never built purpose driven race cars, just street cars so alot of the finer R&D points that have developed over the past 5-8 years (which parallels the amount of advancement in microprocessors) is lost on me. but i'll tell you how we basically deal with a street car that wants to go fast.

ill add some links and pictures to this tomorrow i need to shower and get some shuteye

for alot of good general turbo related info and specifically running a turbocharged gen III/IV chevy look no further than denmah and the sloppy mechanics blog

the sloppy mechanics team has built atleast a dozen single digit cars all with genIII/IV junkyard motors and transmissions, alot of fox platforms swapped, currently working on a nissan 240sx. they do all the work themselves including fabrication and they tune the cars either thru a hptuners or a microsquirt. they have combinations on pump gas and on e85 and theres some nuggets on that blog about methanol injection, its purpose and its use. very few of their cars cost more then 10k to build INCLUDING THE COST OF THE CAR so believe me when i tell you they are a very budget minded group

https://sites.google.com/site/sloppywik ... ardturbols

grumpyvette said:1) how do you select a basic displacement, bore & stroke combo and compression ratio

unless we are building a class specific race car, or have an unlimited budget, its basically a run what you brung deal. dynamic compression ratio is the only real factor to consider and that can be played with thru the cam. iskendarian has been spec'ing fast turbo cams for a long time and they have a long lengthy history with camshafts and turbocharging.

2)how do you select the cylinder heads, port size.

some consideration needs to be taken for port size as it relates to expected power output. so it isnt a bad idea to get a larger port than you would in an NA application since port speed is affected differently when the manifold is pressurized. also as it relates to cylinder head flow, having a big bore is important for valve shroud reasons we talked about in another thread. valves and valve springs are very important, hollow stem valves will break with any real power, sodium filled valves seem to handle the stresses much better and are still very light. obviously it would be nice to get titanium wherever we can in the valvetrain, but sometimes those parts dont exist for the application or they are simply too expensive. on the exhaust side, again, with an unlimited budget i would use inconel valves in everything but sometimes its either impractical or out of budget. stainless steel at least.

3)what rotating assembly, crank ,rods, pistons, rings ETC.(obviously forged) but related info on set-up and clearances, ring gaps, heat coating, is welcome

most applications have a wider gap in the top two rings than you would expect in the NA world, the high heat from the extra air and fuel causes the usual gaps to close and then we have busted rings, pistons, and all around catastrophe. or you could use a gapless ring setup and not worry about it, but a certain amount of blowby probably saves more motors than it hurts. if ordering custom pistons its a good idea to have the top ring lower in the cylinder than a typical NA motor (something like you would for a big shot of nitrous) to add some clout to the top of the pistons. ive seen alot of people use coatings both on the piston face and in the combustion chamber to great effect. but i subscribe to the school of thought that if you rely on those coatings, when stuff inevitably breaks, you have alot of extra down time sending parts out for coating than just slapping your combination back together.

4) Header design, Size and construction

turbo headers on a street car are dictated way more than 75% by packaging. there are very successful turbo combinations that use factory cast iron manifolds with some sort of crossover tube setup for singles. also, theres a big market for turbo headers right now and theres alot of people making nice entry level setups for small block and big block ford and chevy of most generations that you can use as a building block to fit your application.

5) Crossover tube design, size and construction

a quick note about crossover pipes. a 2.25" crossover tube is good to atleast 900hp before it gets to be a restriction, so dont go crazy with a huge tube, its just gonna slow down the exhaust gas and cause lag my buddy had a great idea to use the wonderbar on c4 corvettes as a crossover tube and mount the turbo flange right on the square bar with the two headers low and straight forward into the bar. food for thought i know alot of us on here have c4's and packaging in that engine bay aint easy.

6) How do you choose the correct turbocharger make and model/flow map,and boost range

theres basically three methods, you can call a turbo company and take heir recomendation, use the software that we went over earlier in this thread, or you can use a turbo that someone else is using and hope it works with your cam, head, converter, and gear combo

7) Exhaust system basics feeding the turbo and leaving the turbo to exit the car

every time a moving gas or liquid has to make a turn in a tube, its a restriction. the turbines efficiency is greatly dictated by its ability to evacuate the gases that spin it. so have a very free flowing exhaust is IMPORTANT. theres alot of charts and tables here that correlate inside diameter of exhaust pipe to horsepower capacity, size accordingly and keep in mind oversizing (after the turbo) has no horsepower penalty.

8) Waste gate selection ,installation and optimal performance

if you want to run low boost pressures (14psi or less) on a large displacement motor that means alot of exhaust has to run out the wastegate instead of thru the turbine to keep boost levels down. therefore we need a larger diameter wastegate to control that large amount of exhaust gas. a smaller wastegate could possibly do the job at lower rpms but as exhaust gas volume increases, the smaller wastegates flow capability will be pegged and boost creep will happen.

9)intake manifold and throttle body selection

i really dont see anything working better than a single plane in any v8 application. it just moves the most air with the least restrictions, its the easiest to port, and most applications already have an efi version if you want to go that route so yea. single plane wherever packaging allows.

10) injector size and type selection

based on expected power output same as any other setup. figure for 85% duty cycle and add atleast 30% volume capability vs regular gas to your fuel system if running e85

11) heat shielding

i like to run a blanket on the turbine side at a minimum, it genuinely keeps underhood temps down and looks cool too. turbine housings get ugly like all the other cast iron parts on a car that reach cherry red glowing levels of heat. so a blanket insulates them and protects stuff from getting heat soaked and protects your eyes from looking at that crusty hunk of metal. i didnt mention it in the header section because i dont have enough experience with it but i havent seen a ceramic coating in person that can withstand the abuse of a regularly driven and raced turbo car. so header wrap would be a worthy investment on cast iron manifolds, however i wouldnt use the wrap on tubular headers for the same reason i wouldnt do it in an NA application, it ruins the headers and drastically reduces their lifespan.

12)intercoolers

we went over this before but briefly here, water to air is the best efficiency, but in a street car it isnt very practical. air to air works great but again in a street car you really have to make due with what you ot for space and packaging. guys with a/c probably feel it even more in the space department because of the condensor taking up room ou there by the front of the car.

13) engine cooling & lube system designs

same as any other high horsepower application, no special considerations different from NA in regards to operating temps or anything like that. the cars gonna make more power so expect it to generate more heat. both in the engine and under the hood

14) turbo lube supply

theres lots of ways to skin a cat and every application is different but basically tapping a pressurized part of the block typically near the oil pump outlet or after the oil filter and feeding that into he top of the cartridge (usually thru a restrictor orifice in a fitting like a banjo bolt or a nitrous jet with an orifice to turbo manufacturers specification) and the return of that is gravity, lord willing and packaging permiting, if gravity return is impossible youll need to utilize a scavenger pump of some sort. good luck with that

15) cams designed for turbo tend to have equal or lower duration on the exhaust to keep exhaust gas speed high and a

112-116 lsa to limit intake flow of fuel/air pressure exiting the exhaust

traditionally thats true and it definitely works. but theres alot of people who are using big NA style cams too as a way of maintaining performance while in vacuum or at the starting line. theres alot thats still developing every day in the world of camshafts and turbochargers.

16) the fuel lines and injectors will need to be calculated at near 85% duty cycle and BSFC of near 65%

17) AN#8 fuel lines and 200 GPH, or larger fuel pumps at 40-60 PSI are normal

some people running alot of boost pressure (like 50 psi or more) run very high fuel pressure to combat reversion thru the injectors. something to consider.

18) how to select rearing and converter stall speeds

turbo cars run a numerically lower gearing to build load and come into boost faster, the fat torque carries them thru the rpm's very quickly still. in a 240z i helped build when i was younger, with a 3.36 gear, the turbo came on hot and it felt like a bad ass NA car with 4.56's. as soon as you let the clutch out in first it was time to shift to second. as for converters hughes performance and PTC have alot of experience with converter for turbo cars i would trust their experts

19) solid copper head gaskets and ARP head studs are suggested as cylinder pressures are noticeably higher than N/A

20) BLOW OFF VALVES, bov, settings and size and location

on an automatic car i wouldnt even run a blow off valve. ive seen enough evidence to say that its really not necessary unless you have a manual transmission where you are going to be letting the throttle slam shut multiple times per pass... even then with the new antisurge technology thats out in turbochargers today its really more of a "i like the way it sounds so ill run one" type of deal

ill add some links and pictures to this tomorrow i need to shower and get some shuteye

for alot of good general turbo related info and specifically running a turbocharged gen III/IV chevy look no further than denmah and the sloppy mechanics blog

the sloppy mechanics team has built atleast a dozen single digit cars all with genIII/IV junkyard motors and transmissions, alot of fox platforms swapped, currently working on a nissan 240sx. they do all the work themselves including fabrication and they tune the cars either thru a hptuners or a microsquirt. they have combinations on pump gas and on e85 and theres some nuggets on that blog about methanol injection, its purpose and its use. very few of their cars cost more then 10k to build INCLUDING THE COST OF THE CAR so believe me when i tell you they are a very budget minded group

https://sites.google.com/site/sloppywik ... ardturbols

8

87vette81big

Guest

Pontiac V8's have 1/2" diameter headbolts & blind headbolt holes.

Super Strong headgasket clamping force seal even with stock headbolts.

Headbolts work to 13.0:1 static compression ratio.

13.0:1 Used in the 1963 SD 421 420HP Version that actually put out 550 HP N/A Flyhweel power.

Isky cams and boost history dates back to 1959-60 with Mickey Thompson & His 4-engine Pontiac V8 streamliner that ran 406 mph on the saltflats. Hit 420 mph return road.

Ed Iskenderian made the Camshafts for Mickey.

Supercharged & 30% Nitromethane mix fuel used.

I have Titanium Intake & Exhaust valves in the Trans Am.

Ti Tetainers & Ti valvelocks.

It revs like a Stihl Chainsaw on steroids.

Orange High Temp spec Manley Ti material.

Custom made for me.

The 427 Tall deck BBC I have has forged pistons stock

4-bolt mains.

Super Strong headgasket clamping force seal even with stock headbolts.

Headbolts work to 13.0:1 static compression ratio.

13.0:1 Used in the 1963 SD 421 420HP Version that actually put out 550 HP N/A Flyhweel power.

Isky cams and boost history dates back to 1959-60 with Mickey Thompson & His 4-engine Pontiac V8 streamliner that ran 406 mph on the saltflats. Hit 420 mph return road.

Ed Iskenderian made the Camshafts for Mickey.

Supercharged & 30% Nitromethane mix fuel used.

I have Titanium Intake & Exhaust valves in the Trans Am.

Ti Tetainers & Ti valvelocks.

It revs like a Stihl Chainsaw on steroids.

Orange High Temp spec Manley Ti material.

Custom made for me.

The 427 Tall deck BBC I have has forged pistons stock

4-bolt mains.

8

87vette81big

Guest

Have ARP Head Studs on T/A Also Phil.

8

87vette81big

Guest

It comes down to budget and parts on hand Phil.

Also no one here has ever flogged a 427 Tall Deck BBC like I have sitting put away with Turbos.

Unknown if it can take it or not.

If I follows Grumpys ultimate 496 ci combo only the Block gets reused.

Its different in Pontiac V8 land I come from.

Block, crankshaft, Rods, Heads, ect can or gets reused.

Still works. Actually save $$.

Did the math & debated many nights.

Pontiac 455 actually better value if you can find one complete as I did.

87 Vette will stay Chevy Power.

Also no one here has ever flogged a 427 Tall Deck BBC like I have sitting put away with Turbos.

Unknown if it can take it or not.

If I follows Grumpys ultimate 496 ci combo only the Block gets reused.

Its different in Pontiac V8 land I come from.

Block, crankshaft, Rods, Heads, ect can or gets reused.

Still works. Actually save $$.

Did the math & debated many nights.

Pontiac 455 actually better value if you can find one complete as I did.

87 Vette will stay Chevy Power.

Strictly Attitude

solid fixture here in the forum

Hopefully the whole ls rush frees some out of hiding cheap they were crazy money 16 years ago and junk yards wanted big money if they would part with their treasure.

8

87vette81big

Guest

I found the 1971 GTO 455 on Craigslist Chicago.Strictly Attitude said:Hopefully the whole ls rush frees some out of hiding cheap they were crazy money 16 years ago and junk yards wanted big money if they would part with their treasure.

It was actually in Wisconsin about 1 hour driving time North.

I paid less for it than bare block used 455's are selling for today.

Going rate of used bare block 455 Pontiac is $600-900 2-bolt.

4-bolts sell for $2-4k . 1973 SD455 With factory machined rear cam driven dry sump oil system intact can bring up to $8k.

Deals to be had. Keep searching.

philly

solid fixture here in the forum

i would get some MLS headgaskets and some arp hardware for your heads rods and mains, regap your rings and boost the shit out of that 427 brian. if it takes a shit build your tall boy 496 all forged and titanium the way you want to. but in the mean time enjoy the fucking car before its too late.

8

87vette81big

Guest

No Phil.philly said:i would get some MLS headgaskets and some arp hardware for your heads rods and mains, regap your rings and boost the shit out of that 427 brian. if it takes a shit build your tall boy 496 all forged and titanium the way you want to. but in the mean time enjoy the fucking car before its too late.

Both sets of Crpwer Rods are for Pontiac V8 I have.

One Set is Custom made Forged. Rated to 1200 HP @ 8,500.

Other set is Custom made 6AL4V Titanium rated to 2,000HP @8,500.

NEITHER SET OF RODS WILL FIT A TALLDECK BBC

.

ONLY TALL DECK BBC PARTS I HAVE IS THAT ENGINE COMPLETE ITSELF.