heres one for you guys that insist on building a 7500rpm 302 sbc

http://www.superchevy.com/technical/eng ... ewall.html

Those loyal readers who follow Super Chevy will remember our two-part Legendary Small-Blocks dyno series. It included such great names as the L76, the LT-1 and the Z/28's 302. We followed up part one with their hydraulic-cammed counterparts, namely the L79, L46 and L82 last month.

Though any of the original small-blocks would be a welcome addition to the engine bay of a Chevy street machine, one in particular caught our eye. We certainly understand that cubic inches rule the world and the only thing better than a mouse displacing 350 ci is one sporting 400 ci. When it comes to powering a street Chevy, the torque that accompanies displacement is always welcome. As much as we like a good stroker motor, there is something almost hypnotic about a high-rpm screamer like the DZ302 tested in part one. If the 383 stroker is that wholesome cheerleader, think of the DZ302 as a leather-clad biker chick. She's not exactly Miss Right, but she makes one hell of a Miss Right Now. Sure, the 350 and 383 cheerleaders of the world will always make more torque, but the sweet symphony of a high winding 302 is worth the price of admission on sound alone. Nothing beats the aural gratification of an 8,000 rpm solid-lifter SBC running at full song. Besides, think what your family and friends will say when you roll up with Miss Biker Chick.

302 Engine Buildup Four Bolt Cylinder Block

Loyal readers will remember that our 302 started out life with a four-bolt block from Demo

The original 302 sprung to life as a result of the 5.0L displacement limit imposed by the SCCA for its Trans-Am road racing series. Still, the 302 was plenty successful at the drag strip as well. Right from the factory, the little 302 was the perfect candidate for high-rpm duty, starting with the original bore and stoke. By combining the 4.00-inch bore offered by the 327 block with the 3.00-inch stroke of the 283, the 302 offered a rare combination of a big bore for breathing and a short stroke for increased engine speed. To ensure that its 5.0L small-block was plenty powerful, Chevy applied all the hardware originally designed for the larger 365hp L76 327 to the smaller 302. The list included a Duntov 30-30 cam, big-valve fuelie heads and a high-rise aluminum intake topped with a Holley 780 carb.

302 Engine Buildup 283 Crank

The block was stuffed with a small-journal, steel 283 crank using bearing inserts to adapt

Testing in part one of our Legendary Small-Blocks proved that the original 290hp rating by Chevrolet was somewhat shy of the real power output, as our replica produced 357 hp and 333 lb-ft of torque. Our motor was run sans accessories and with long-tube headers, but 357 hp is still a far cry from the 290hp rating.

As impressive as the 302 was in stock trim, the factory heads, cam and intake only hinted at the power available from the big bore/short stroke combination. With a forged steel crank, forged rods (ours came from Pro Comp) and forged pistons (from Probe Racing), the DZ short-block was ready and willing to run well past the 7,000 rpm limit we used when testing the motor in stock trim (peak power came at 6,700 rpm). Basically we were looking for a reason to build a high-winding small-block and this 302 provided the perfect opportunity. Given that our short-block was primed and ready for action, we set about changing the other components required to allow it to safely run near 8,000 rpm. By shifting the torque curve higher in the rev range, we could unleash a ton of extra horsepower.

The key elements in power production have always been the heads, cam and intake, and we quickly ditched the stock Duntov cam, fuelie heads and dual-plane, high-rise intake for even higher-rpm counterparts. In addition to the major, power-producing components, we also improved the all-important oiling system, valvetrain and carburetion. When you go looking to exceed 7,000 rpm, care must be taken to ensure plenty of lubrication. Stuffing a big roller cam in an otherwise stock motor isn't going to get the job done, you need to address every possible problem associated with making big power at elevated engine speeds. Our goal with the build up was to take our 350hp 302 and transform it into a 500hp screamer.

Except under extreme circumstances, you don't usually find 150 hp by bolting on a single component like a new carburetor or even a wilder cam profile. This is especially the case if you are starting with a motor that is already producing nearly 1.2 hp per cubic inch. To reach our goal of 500 hp, the little 302 would need to exceed 1.65 hp per cubic inch, a serious number in anyone's book. Reaching that specific output meant replacing not one but all of the major power producing components, starting with the Duntov 30-30 cam. The factory solid flat-tappet cam was both outdated and insufficient in terms of lift and duration to meet our needs. Though a modern equivalent to the Duntov cam would be worth an easy 20-25 hp over the original, our lofty power goal required swapping out the flat-tappet design for a serious roller profile. Comp Cams supplied the custom roller cam that offered a 0.640/0.621 lift split, a 256/260-degree duration split (at 0.050) and a tight 107-degree lobe separation angle. The custom roller offered super aggressive ramp rates to maximize not only peak power but power production throughout the useable rev range. Comp Cams also supplied the matching roller lifters, hardened pushrods and 1.52 ratio roller rockers.

302 Engine Buildup

Here is our completed 302 short-block assembled and ready to receive the new AFR 210cc Eli

With our cam needs met, we turned our attention to some deep breathing exercises. Back in the day, the fuelie heads were the hot set up for a 302, but time and technology marched on. Given the relatively small displacement (most heads are designed for 350 or more cubic inches), we'd normally look for port volumes on the small end of the scale. But this high-rpm build up was anything but normal, so we stepped right up to a set of heads offering 210cc intake port volumes.

With peak power scheduled to occur somewhere near 7,500 rpm, our buzzy little small-block could take full advantage of the airflow offered by the sizable port volume. Airflow Research supplied a set of its 210cc Eliminator heads. Since we wanted to maximize peak power numbers, we opted for the "competition" version that featured additional port work to increase the intake/exhaust flow rates from 299/222 cfm to 311/237 cfm.

302 Engine Buildup Intake Ports

The AFR Eliminator heads featured full CNC porting to produce the 210cc intake ports that

In addition to the 210cc intake ports, the AFR Eliminator heads also featured a lightweight (8mm) 2.08/1.60 valve package, full CNC combustion chambers and 80cc raised exhaust ports. Additional features included 3/4-inch head deck surfaces and dual valve cover bolt patterns. These heads represented a huge step up the performance ladder compared to the original fuelie heads.

With the head flow taken care of, we turned our attention to the intake manifold and carburetor. Given our head and cam choice, peak power was going to be well past 7,000 rpm, so we chose an intake manifold accordingly. The natural choice was a single-plane manifold, which was designed to optimize power production higher in the rpm range. Since most of the intake manifolds are designed with 350 ci in mind, the intake would allow our 302 to effectively rev even higher. All things being equal, an increase in displacement will mean a drop in where the motor makes peak power. If a 350 produces peak power at 7,000 rpm with a given combination of heads, cam and intake, employing the same components on a smaller 302 will result in peak power somewhere north of 7,000 rpm. We saw this when we ran our Legendary Small-Block series, as the 327 and 302 were equipped with the same heads, cam and intake and the 302 produced peak power 500-600 rpm higher. We chose a ProComp single-plane, high-rise intake and Holley 750 HP series carburetor to top our 302. The combination offered plenty of airflow and the proper resonance tuning to optimize top-end power production. It would have been fun to try a dual-carb tunnel ram on this high-rpm screamer, but we couldn't get our hands on one in time for testing. A huge thanks goes out to Westech's Steve Brule for building this motor and curing a few minor issues we had during testing.

As much as we highlight the big three power producers, the mill simply would not run without a host of other important components, including proper oiling, ignition and cooling systems. Since elevated engine speeds were in the cards, we stepped up the stock oiling system run previously on the stock 302 to a complete small-block system from Moroso. Moroso supplied not only a new oil pan but an oil pump, pickup and even integrated windage tray for our little Chevy. It is possible to get by with a factory pump, pan and pickup on a stock small-block, but when you go testing the rpm limits of the internal components, you'd better make sure everything is well lubed. The oiling system from Moroso ensured our high-rpm engine always had plenty of oil, while the windage tray helped free up some additional power.

The ignition system included a Pro Comp billet distributor and matching wires feeding an MSD Digitial 7 ignition amplifier. Denso plugs were responsible for eventually lighting the fire. We finished off the 302 for dyno use with an electric water pump from Meziere and a set of Hooker long-tube headers feeding 18-inch collector extensions. Since the motor was run previously, there was no need to run it through a break-in procedure and we filled the Moroso pan with Lucas 5W-30 synthetic oil using a K&N oil filter.

302 Engine Buildup Electric Water Pump

The 302 was run on the engine dyno with a Meziere electric water pump and 1 3/4-inch long

With our motor installed on the dyno, all that was necessary was to get everything up to temperature, check for leaks and proceed with the tuning. Initial pulls were made with 35 degrees of total timing but we quickly found out that the combination of the short stroke and high-dome pistons wanted significantly more ignition timing. The power climbed with each successive increase in timing until we reached a total of 41 degrees. Next we dialed in the air/fuel mixture, as the previous runs made to dial in the ignition timing were still a tad on the rich side. After pulling a few jets out, we were finally rewarded with a nice steady air/fuel mixture of 13.0:1 at the power peak.

302 Engine Buildup Dyno Test

After dialing in the air/fuel mixture and ignition timing, we tightened up the lash and replaced the conventional oil with Lucas 5W-20 synthetic. Our fine-tuning eventually netted us peak power numbers of 519 hp at 7,400 rpm and an even 400 lb-ft at 6,300 rpm. This compares to 357 hp and 333 lb-ft from the stock 302.

302 Engine Buildup Dyno Test

After dialing in the air/fuel mixture and ignition timing, we tightened up the lash and re

Since we were looking to extract every last ounce of power out of the 302, we applied a number of speed secrets to fine tune the combination, including tightening up the lash, swapping a series of carb spacers and even lightweight (5W-20) Lucas synthetic oil. After exhausting all of the tricks in the book, we not only managed to reach our goal of 500 hp, but exceed it by a significant margin with peak power numbers of 519 hp at 7,400 rpm and an even 400 lb-ft of torque at 6,300 rpm. These new power numbers represented gains of 162 hp and 67 lb-ft of torque over our original 302. Making the power numbers even more impressive was the fact that these gains came with no change in the 302 short-block. Now we can't help but wonder what it might take to get this little screamer to 600 hp?

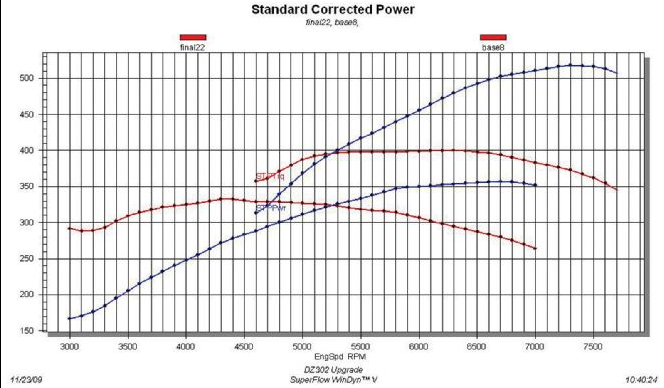

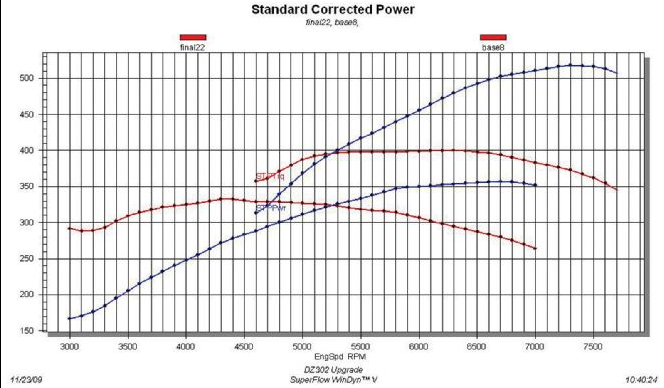

302 Engine Buildup Dyno Chart

302: Stock vs Modified

This graph represents that power curves from the stock and modified 302 Chevy. What is clearly evident from these curves is that the modifications resulted in not only a sizable hike, but also a serious shift in the torque curve. Where the stock DZ302 produced peak torque at 4,400 rpm, the roller-cammed, AFR-headed motor produced peak torque at 6,300 rpm. The significant shift in the torque curve resulted in a jump in peak power, from 357 hp at 6,700 rpm to 519 hp 7,400 rpm. 500hp 383s are considered powerful combinations, but we managed to exceed that figure do it with eighty less cubic inches. Leather-clad biker chicks need love too!

YES 500 plus HP from a 302 is damn impressive,.....yet the part many of the guys who prefer the high rpm small block combos hate to admit is that if you used similar parts but used a 3.75" stroke crank, 6" connecting rods and a cam with about 5 degrees more duration and a tight 106 LSA with 210cc heads , and a good intake on a 383 vs that 302, the resulting combo would leave the 302 looking at tail lights if both are geared correctly , in the same weight cars ,simply because the larger displacement engine when properly built has a very noticeable increase in torque and tends to produce that higher torque faster and over a slightly wider rpm band. theres just no way to ignore that fact that an extra 80 cubic inches of displacement produces more power if its properly set up to do so

viewtopic.php?f=52&t=266