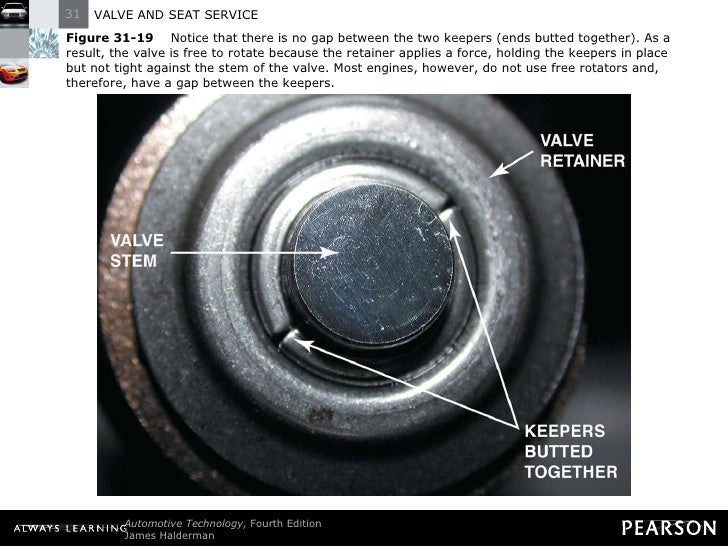

bob said:"grumpy, I started to adjust my valves today and found a valve retainer lock lying loose in the cylinder head, stuck to one of those magnets that you suggested I install in the oil drain on the rear of the head, I then carefully inspected all the valve spring locks and found two more sticking up higher than they should...any ideas here as to the cause?"

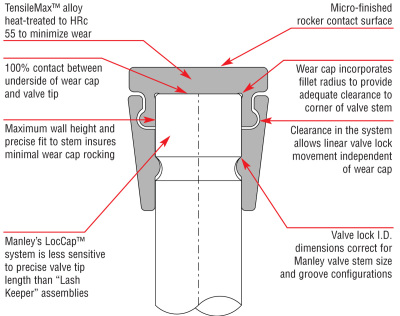

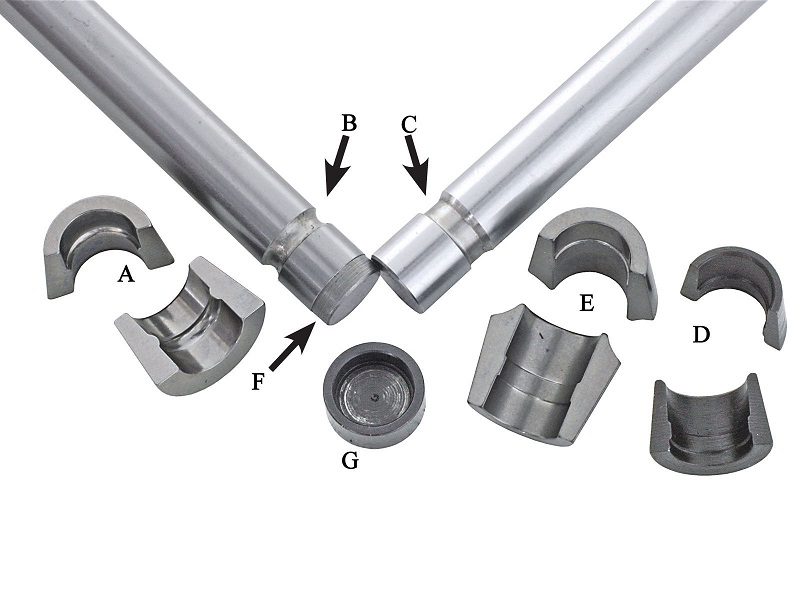

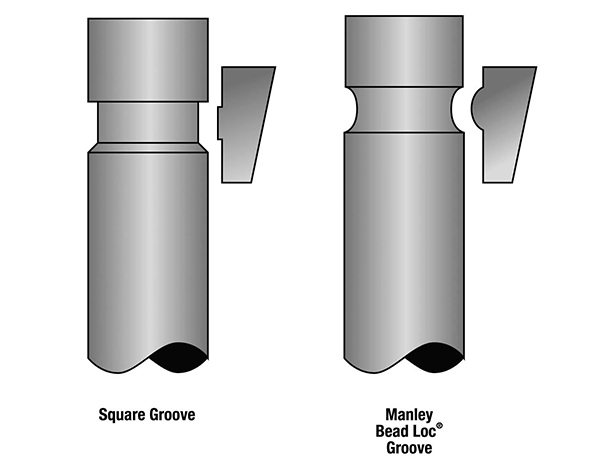

valve locks come in 7 and 10 degree designs and obviously in sizes and diameters, and groove spacing to match the valve stem locking grooves on the valves and tapered holes in valve retainers.

you left out NEEDED info

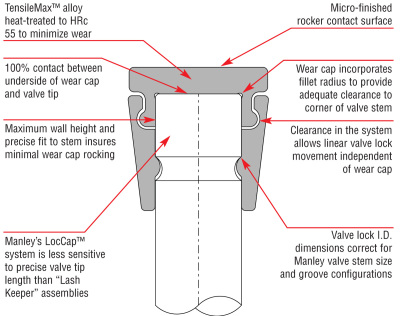

Ive used lash caps to protect valve stem tips on lots of engines , but Id pint out that you really need to verify several things before you use them, obviously the first point is you have the required length of valve stem tip extending above the retainer and the correct valve lash cap design to fit your particular application.

but be aware theres several different designs and sizes available and valve spring retainer and rocker arm designs vary a great deal, making checking clearances and geometry through the full arc the rocker moves mandatory

when ordering this infos NEEDED

valve stem diameter?

3/8"?

8MM?

11/32"?

5/16"?

0.310"?

0.3415"?

0.342 " ?

0.372"?

STEEL?

TITANIUM?

2 groove?

single groove?

.050 offset?

no off set?

COMP Cams

Lunati

Howards Cams

Manley

K-Motion

Trick Flow Specialties

Trick Flow Specialties

so verify your parts match correctly. and yes that magnet may have prevented more extensive damage.

thankfully you caught this before dropping a valve which gets expensive very quickly, so don,t just stick a new valve lock on, and start driving, find the source of your problem before things get really expensive, theres a good chance the valve lock, valve spring retainer or notches in the valve stem are worn, so check carefully before reassembly

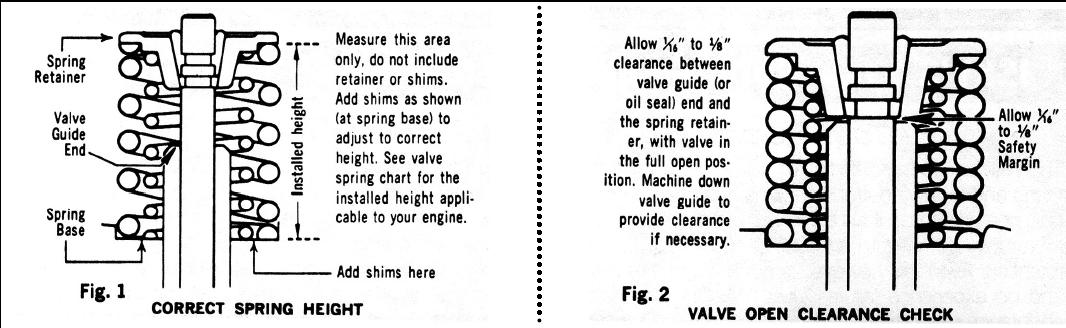

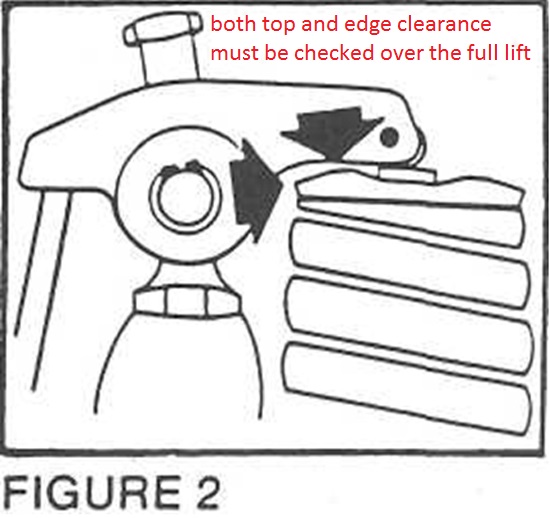

the most common cause of them coming loose is either mis-matched components or running the engine up into valve float rpms where erratic valve control can allow them to get loose, but there's two other common mistakes in clearancing an engine that can be a contributing factor, ones not checking to verify the rocker arm clears the edge of the retainer at all lifts and the second is the retainer getting close too or getting into spring bind or the retainer touching the valve seal at near full valve lift/

VERIFY YOUR ROCKER TO RETAINER CLEARANCES, if the retainer touches the rocker it puts significant stress on the valve locks, you might need a different length push rod or valve lash caps

the locks and valve spring retainers usually come in either 7 degree and 10 degree, and you obviously need the locks to be used with the matching retainer size and lock angle, and valve stem diameter with the correct grooves and grove locations, the locking ridge can be standard or offset either upwards or lower on the valve stem to change the valve spring installed height and type of valve notches , be sure to carefully verify valve spring loads and clearances and installed height, and parts compatibility.

use the wrong valve stem/retainer locks or retainers and its just a matter of time before you drop a valve and have serious repair issues

break a valve spring or rocker and metallic trash starts moving around your engine, an excellent reason to use magnets and shrapnel screen to limit the areas those hard sharp and at times very destructive parts, or chunks of debris can reach.

THIS is a good example of what happens to bearings if the oil passages are allowed to push small metallic debris, from wear like rockers,valve tips,cam and lifter wear thru the engine, use of a few small magnets, and shrapnel screens helps reduce or eliminate this

If your not sure about the proper installed spring height,spring load rates,valve shims ,valve spring seat and required clearances,why not have the machine shop suggest what would match your current needs after telling them the clearance requirements and cam lift.

remember longer valves generally require longer push rods and getting the rocker geometry correct is critical to durability, shims & spring seats can easily be used to shorten installed spring heights,they also make .050 off set valve keepers and .050 off set spring retainers so you can adjust installed height over a full .200 with the same valve length.

a .100 longer valve gives you more clearance and should be fully adequate, but remember load rates have a good deal to do with both the spring and its installed height.

adding some magnets to trap loose metallic debris, from broken or worn parts helps reduce potential problems

http://www.magnet4sale.com/samarium-cobalt-discs/

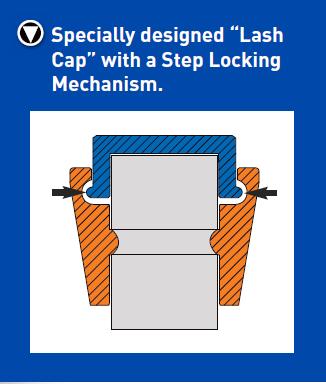

properly installed lash caps protect the tip of the valve stem from wear, and can protect the valve keepers from wear and movement on the valve stem, and properly installed lash caps can add a bit to the length of the valve extending above the valve retainer, this can be useful if you need retainer to rocker clearance , or adjust the rocker push-rod geometry

If the valve springs are to be removed with the heads still on the car,

the last thing you want is too remove a valve spring and have the valve to drop into the cylinder,

if you use air the crank tends to want to spin the crank to BDC, youll want to verify TDC ,

and make sure the flywheels temporarily prevented from turning from that the TDC position,

Ive used both methods both work,you can put 6 ft of rope in the cylinder while its in BDC then turn it to TDC, Ive used both with zero issues,

If you use the compressor youll want to keep it at 120 psi and constantly feeding pressurized air to keep the valves held in place,

and theres a small chance the compressor pushes enough moisture to allow water to accumulate in the cylinders,

so be sure you spin the engine with the starter with the spark plugs removed several times before you re-install plugs.

if you use the rope, theres a very low chance that the rope will tangle and form a knot that makes removal difficult,

in either case be sure the pistons locked at tdc,

before removing the valve springs, on each cylinder.

IF THE ROCKER BEARS ON THE EDGE OF THE RETAINER it causes the valve locks to shift on the valve stem constantly, this results in worn valve locks and a worn valve stem, and depending on how long the condition continues and the extent of the contact, frequently results in a dropped valve and a VERY expensive repair or a trashed engine due to over looking this issue!

lash caps, can be used to lengthen the valve slightly and protect the tip of the valve from excessive wear

It is some what likely that you can run the same length push-rod with the lash caps installed as you can run without them, but you obviously need to verify clearances and valve train geometry. The caps work great for guys who have high spring pressures ,they can give you some extra clearance from underneath the rocker arm to the valve spring retainer.

you might find that lash caps IMPROVE the geometry or you might find they throw it so far out new push rods are required, you need to verify not guess,THERE'S MORE THAN THREE TYPES. AND THE MOST COMMON JUST SNAP OVER THE VALVE TIP WITH A SLIGHT FRICTION FIT, the tip of the rocker prevents them from riding up on the valve stem, and coming loose

most sit on the tip like this picture

you are aware you need the lash caps to be the same diameter as the valve stem diameter??

THEY COME IN different heights and diameters

http://www.summitracing.com/search/part ... ash%20caps

http://www.competitionproducts.com/searchprods.asp

http://www.enginebuildermag.com/Article ... signs.aspx

thinking about putting roller rockers on my 327.

IM seriously considering/ thinking about putting roller rockers on my 327.do i have room to put 1.6 ratio or just stay with 1.5s http://garage.grumpysperformance.com/index.php?threads/louis-tool-swapping-to-1-6-1-ratio-rockers.14761/...

garage.grumpysperformance.com

THERE ARE COMBO LASH CAPS/KEEPERS, and locking lash caps

http://www.competitionproducts.com/Mant ... 603751-16/

rocker body rubbing retainer BEFORE lash cap installed

rocker body clearance preventing its rubbing retainer AFTER lash cap installed

the advice earlier in the thread on checking push rod length should be re-read if in doubt

Because today's racing engines run at higher and higher rpm levels and the cam profiles are extremely harsh, the tip of the valve stem is subjected to a tremendous amount of pounding. These engines always run just on the brink of valve float-one of the most severe conditions that can exist. The best solution to this problem is the use of quality Lash Caps. These lash caps are precision machined and ground perfectly flat to maintain accuracy of valve train adjustment.They fit the valve stems well and can be removed with relative ease because of a tiny hole to relieve the suction created when removing the lash cap. The Chrysler "Hemi" engine has benefitted greatly from this design. A special version is available to accommodate the very short tip on these valves. For the ultimate in strength and reliability, you will not find a better part than the COMP Cams® Lash Cap. A must for titanium valves.

http://www.jegs.com/p/Comp-Cams/Comp-Ca ... 5/10002/-1

http://www.jegs.com/i/Crane-Cams/271/99 ... Id=1354633

http://www.pauter.com/RockerInst.htm

http://garage.grumpysperformance.co...2/&page=6&q=corvette+heads+restrictive&o=date

obviously valve float and improper lash clearance can cause problems but in some cases, lash caps can reduce wear

in most cases when you see valve tip damage like this its the result of valve float or a weak valve spring or improperly adjusted valves alowing the rocker to bounce on the valve tip., in many cases youll need to swap to a higher spring load rate and new springs to prevent or reduce this damage

related INFO

viewtopic.php?f=52&t=9613&p=35611&hilit=valve+keepers#p35611

viewtopic.php?f=52&t=181

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

Last edited by a moderator: