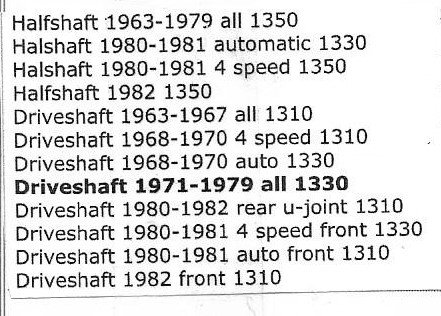

http://www.dennysdriveshaft.com/c976_combination_universal_joints.html69vette427 said:Replacing the u joints on the drive shaft. I can put 1 clip in ok. But the space on the other side is too small for the clip.

If I try to force it in the u joint doesn't move.Using MOOG 369 u joint. any suggestions?

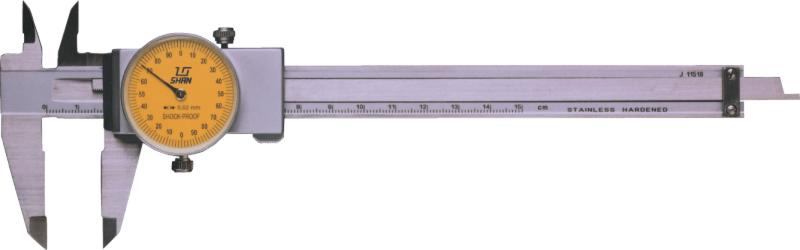

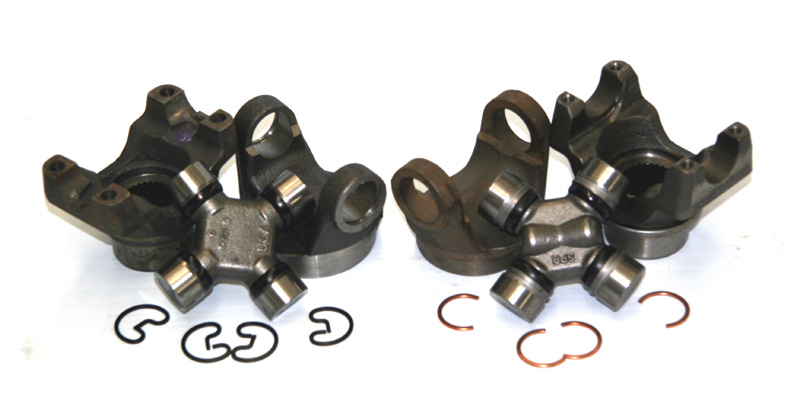

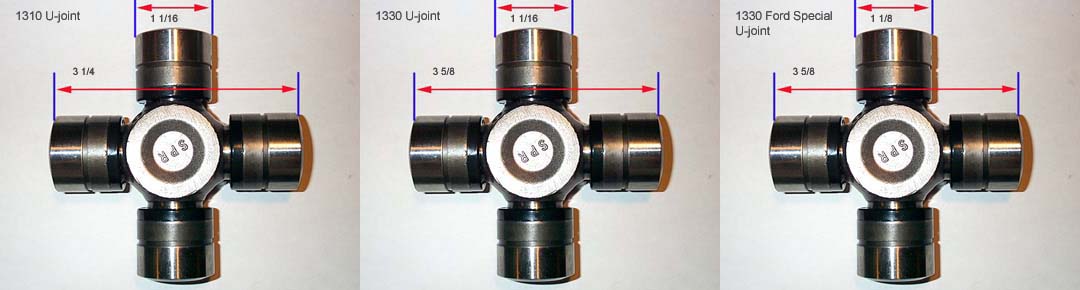

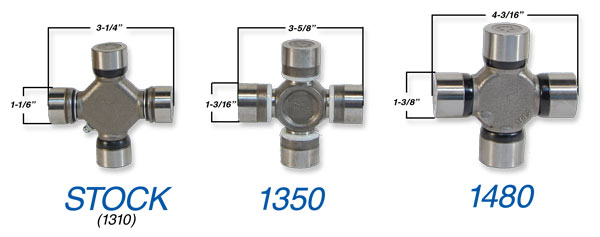

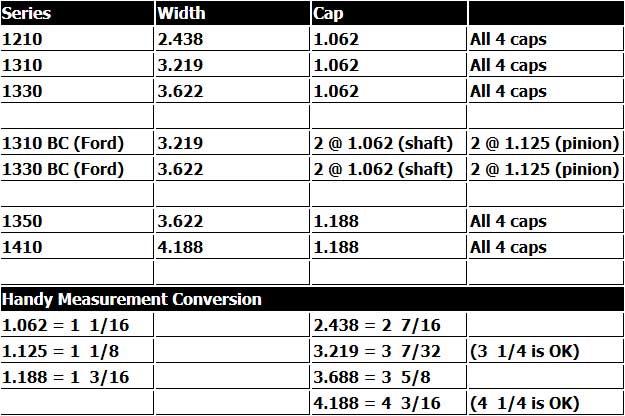

Obviously youll want to verify that the u-joint your using is the correct one and if you use a caliper you should be able to measure the space in the drive shaft yoke the u-joint that it seats in and the u-joint with the caps seated,obviously they should match.If they don,t ID suggest pulling both caps off and very carefully inspecting the roller bearing pins, in the caps, because its very common for one to slip and get located under the trunnion end cap during its instal if your not very careful , and of course it needs to be well greased, a press must be used to re-assemble the u-joints if you try to beat them into place you almost always dislodge the roller bearings

RELATED INFO

viewtopic.php?f=33&t=80&p=38597&hilit=u+joints#p38597

http://garage.grumpysperformance.co...nsion-related-links-and-info.1025/#post-67816

http://garage.grumpysperformance.co...asuring-for-a-new-drive-shaft.478/#post-67321

http://garage.grumpysperformance.com/index.php?threads/trans-slip-yoke-problem.8765/#post-53682

the inner roller bearings must be carefully placed in the outer cup wall and covered with the correct grease before assembly

some use either inner c-clips or outer expansion clips to retain the u-joints

some use a retention step to retain the u-joint

http://www.actionmachineinc.com/slipyoke.aspx

http://www.driveshaftspecialist.com/Tra ... 0yoke.html

TWISTED SPLINES

KEY OR INDEXED SPLINE

http://www.circletrack.com/drivetrainte ... _delivery/

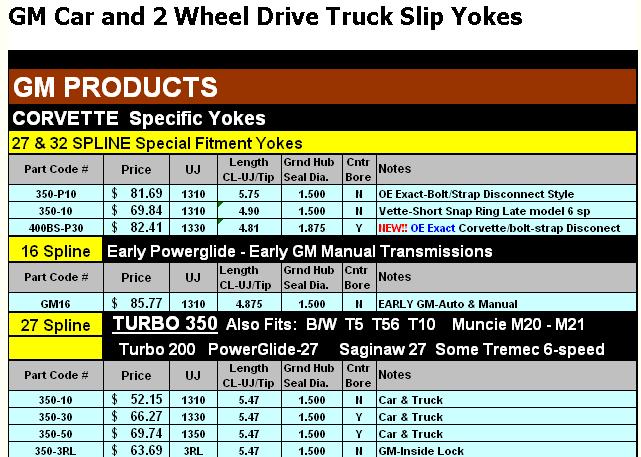

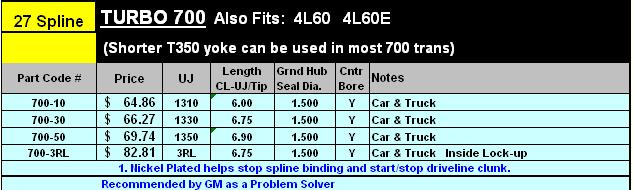

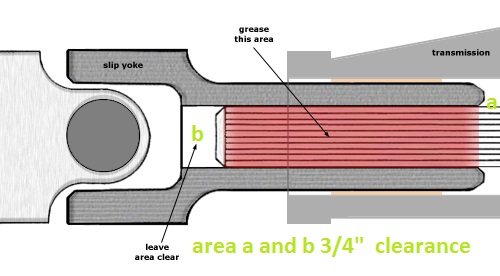

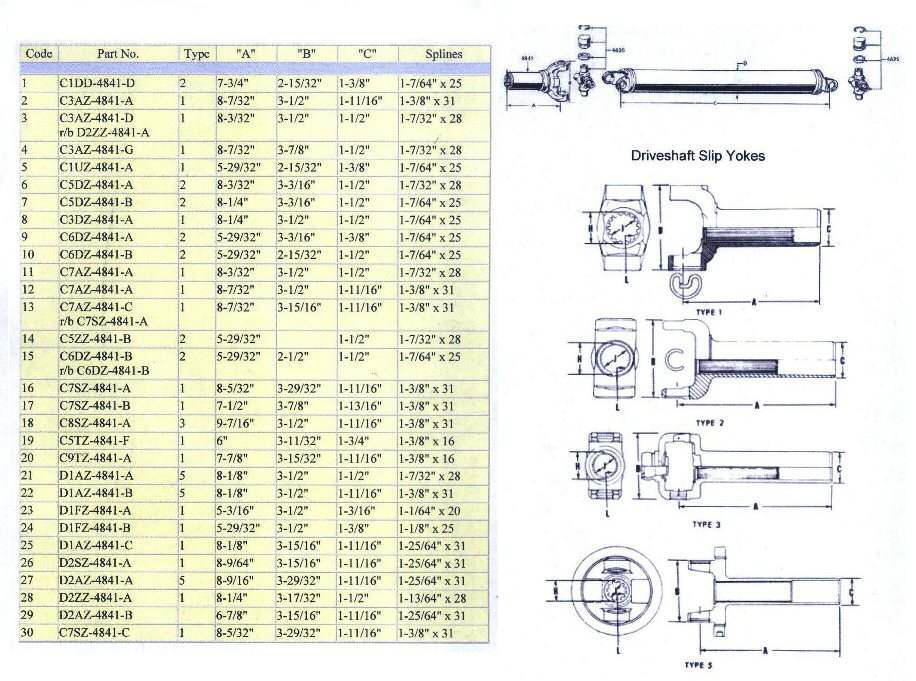

I thought this diagram above covered yoke length requirements fairly well, obviously you might require a different length drive shaft or the yoke you use might need to be cut a bit shorter in some applications , but remember the yoke needs to move in and out freely without binding and the u-joint should be fairly close to the rear of the transmission as excessive extra yoke length provides leverage that can cause damage if a u-joint fails

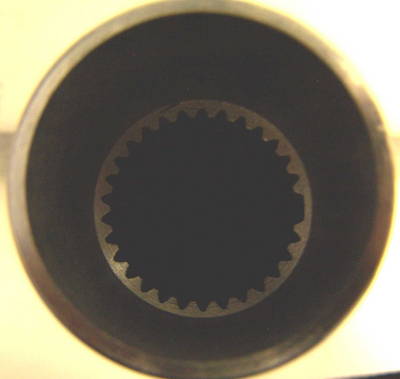

you obviously must know the spline count and shaft diameter, but these are fairly standard, the yoke length is not, you simply slide the yoke into the trans tail till it bottoms outdraw a line on the spined yokes outer surface,then back it out 1" and draw a new line,remove the yoke,there should ideally be about 3" or a bit more from the second line to the end of the yoke, insuring good spline contact , there should be less than 2" from the first mark drawn to the u-joint saddle, in an ideal world, but obviously your drive shaft u-joint spacing length comes into play here!

OK, if you don,t have a spline yoke to fit the trans yet ,just slide a strait stiff soda straw in between the spline shaft and the inner trans tail, measure the depth it will slide in and you can use that depth measurement, lets say it slides in 4.7", if so you want a spline yoke at least 3.5- 4"contacting the splines with 1" of possible movement without contact,or bottoming out in the trans, so about 5.5" would be ideal,so you could get 3.7" of spline engaged and 1.8" before the u-joint,would in theory contact the trans tail shaft, (yes it bottoms out in the trans before that could happen), lets say your choices are 3.5" and 7.5" 3.5" is too short

you would buy the 7.5" and have a machine shop cut it to the ideal length AFTER you measure the drive shaft length and spline engagement

Last edited by a moderator: