NOT A TA

reliable source of info

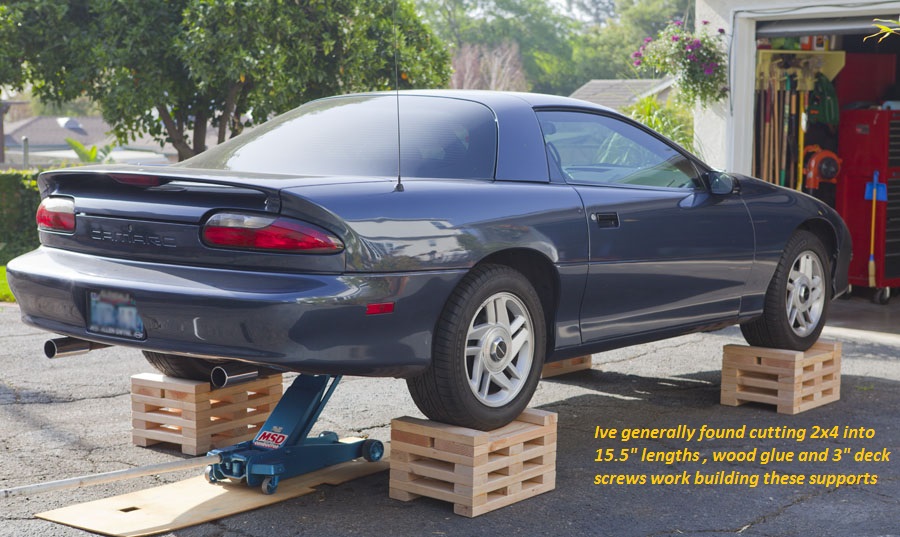

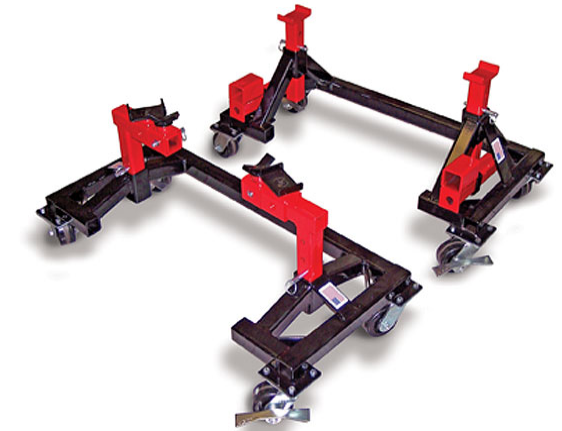

I use wheel cribs, wheel dollys, and go jacks a lot. I have about a hundred of the cribs and leave them on jobs building cars until I finish. The wheel dollys in the pics of the red car are rated for 1000 lbs each and with no drive train or front end the car only weighs maybe 1500 in the pics so 3 dollys is double whats needed.

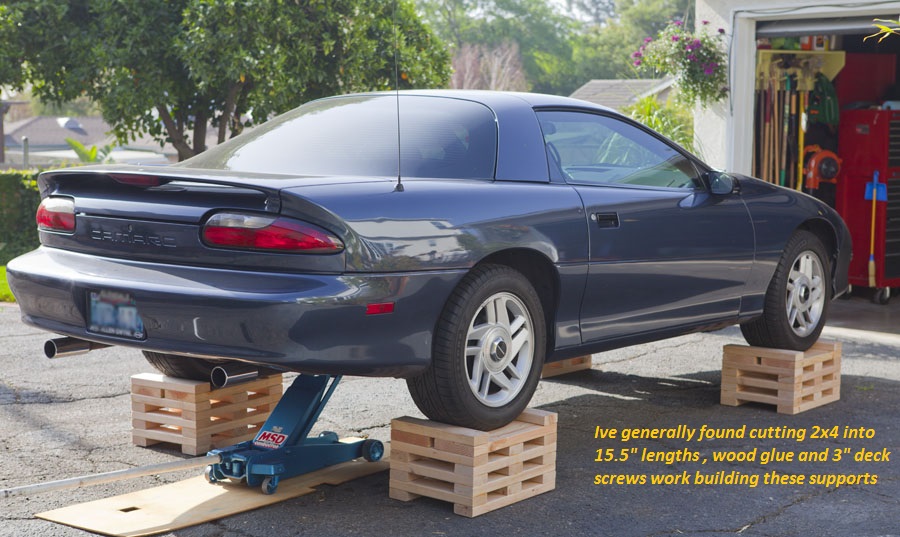

The wheel cribs used on the truck above aren't ideal for the use pictured. They aren't long enough for the diameter of the tire so the tire doesn't sit down enough between the 2X4's. Another thing is without a flat surface for the tire to sit on the cribs want to tilt on the opposite end of the vehicle when raising the vehicle more than a couple cribs high because of the arc the floor jack makes as you pump it up. If you're going to put the car up high you have to raise each end in stages. While jacking the wheels on the opposite end need to roll a bit so a flat top longer than the contact patch is better.

I would not build rolling cribs with the above mentioned 6" wheels from Harbor Freight (or any of their castor wheels). They are crap. I examined them closely as a possible replacement for all the wheels on the rotisserie after we broke a couple of the stock ones. They have cheap bearings, a pressed pivot point, and the rubber wheels make it hard to get the wheels to turn together on concrete as opposed to the smooth tile floors they're marketed toward.

I also use wheel cribs a lot on cars without wheels. I like them more than jackstands.

The wheel cribs used on the truck above aren't ideal for the use pictured. They aren't long enough for the diameter of the tire so the tire doesn't sit down enough between the 2X4's. Another thing is without a flat surface for the tire to sit on the cribs want to tilt on the opposite end of the vehicle when raising the vehicle more than a couple cribs high because of the arc the floor jack makes as you pump it up. If you're going to put the car up high you have to raise each end in stages. While jacking the wheels on the opposite end need to roll a bit so a flat top longer than the contact patch is better.

I would not build rolling cribs with the above mentioned 6" wheels from Harbor Freight (or any of their castor wheels). They are crap. I examined them closely as a possible replacement for all the wheels on the rotisserie after we broke a couple of the stock ones. They have cheap bearings, a pressed pivot point, and the rubber wheels make it hard to get the wheels to turn together on concrete as opposed to the smooth tile floors they're marketed toward.

I also use wheel cribs a lot on cars without wheels. I like them more than jackstands.