the idea behind the use of under drive pulleys, is that they reduce the water pump and accessory induced drag,on the engine by reducing the water pump and accessory operating rpm slightly, this usually also reduces the coolant flow, and reduces alternator out put rather drastically in some applications , which tends to make the engine idle hotter and can lower the alternator voltage out put, which can effect the electrical system and ignition , for at best small hp gains, in the upper rpm ranges, but keep in mind youll rarely see time at peak rpms and far more frequently spend time at just above idle to about 4000rpm on a street car.. in most cases its not a great trade off, but its also not going to hurt much if your cars basically running decent to begin with, IF YOU SELECT A CORRECTLY DESIGNED PULLEY, FROM A QUALITY MANUFACTURER that bolts to a decent damper or a SMALLER diam. damper designed with the smaller pulley machined into its outer rim..manual transmissions tend to have much more frequent and more abrupt changes in rpms so they tend to be harder on belts and tend to throw belts from the smaller diam. pulleys slightly more often

there's several different designs and suppliers so do some research.

keep in mind cruising speed forces air thru the radiator and aids cooling at speed so slowing the water pump may not noticeably reduce the cars cooling at speed but it may at idle, or in traffic. and if you've got electric fans you may want to get a different alternator pulley to speed up the alternator to compensate.

http://www.marchperf.com/underdrive2.html

http://www.chevelle.com/Crank-Pulleys-C687.aspx

http://www.marchperf.com/csb_pulleys.html

http://www.marchperf.com/csb_pulleys.html#pulleysbb

http://www.corvetteguys.com/bbk-ls1-sfi ... ulley.html

http://www.ecklers.com/product.asp?pf_i ... pt_id=1768

http://www.ws6.com/mycar.htm

http://www.steedafusion.com/store/Engin ... _info.html

heres a dyno test

http://www.ws6.com/mod-2.htm

http://www.summitracing.com/parts/SLE-M10007/

http://en.wikipedia.org/wiki/Underdrive_pulleys

http://www.machv.com/tip11cranpul.html

THIS THREAD ( BELOW ) MIGHT ALSO BE OF INTEREST

viewtopic.php?f=32&t=258&p=313#p313

QUOTE

Tip 11: Crank Pulleys

We've had lots of questions about crank pulleys lately, so here's all we know.

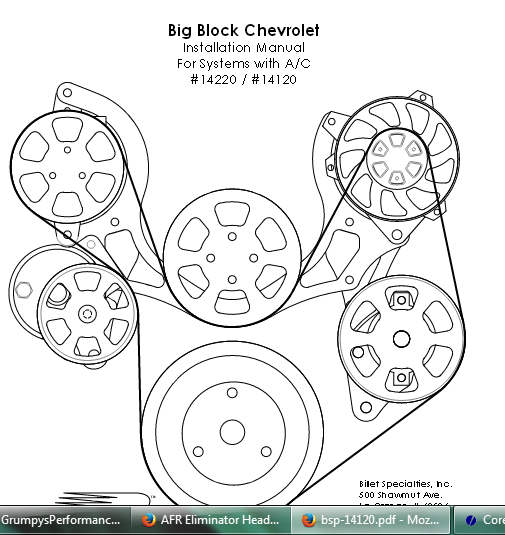

First, the crank pulley is the main pulley on the end of the crank (duh) that drives the accessories -- alternator, water pump, and air conditioning compressor.

An "underdrive" crank pulley is a pulley with a smaller diameter. The result is that it drives the accessories more slowly, and with greater mechanical leverage. It's like pedaling a bicycle up a hill with the smallest sprocket engaged on the crank. The goal of the underdrive pulley is to reduce drag from the accessories on the motor. Of course, if the accessories are turning more slowly, they will also be that much less effective, but life is all about compromises.

Does an underdrive pulley really add horsepower? The pulley manufacturers say they do, and we've seen tests in magazines that seemed to indicate signficant gains. But you could get the same sort of gains during a drag race WITHOUT an underdrive pulley by removing the belt from your alternator. (The motor can run solely off the battery for a short time.)

The other benefit of aftermarket pulleys is to reduce rotating mass. Here the simple aluminum crank pulley has a big advantage over the heavy stock pulley, but there's a reason it's so much lighter: It's missing the harmonic dampener. The reduction in rotating mass may be worth a couple of horsepower. But removing the dampener seems like a bad idea to us.

The factory crank pulley has a built-in harmonic dampener, in the form of a split design, with a thick rubber pad sandwiched between two steel sheels. The dampener is designed to absorb torsional and vertical vibrations from the crank. MOST underdrive crank pulleys (with the exception of the Buschur Racing model) do not have a harmonic dampener at all.

Torsional vibration is a twisting vibration caused by the pulses of each combustion event. The force of the piston causes the crank to deflect ever so slightly in the direction of the force, and when that force goes away the crank ever-so-slightly springs back. At certain frequencies the crank can resonate, making the vibration much worse. This is where the harmonic dampener comes into play.

Although many DSM owners have removed the harmonic dampener crank pulley without incident, doing so almost certainly increases crank bearing wear, and COULD lead to early failure of the crank or crank bearings. Just how much the life of these parts is shortened is unknown.

We do have one piece of first-hand experience, to offer, though. We know of ONE instance of crank failure on the 4G63 motor. It was a 2.3-liter motor that belong to an employee of ours. The crank cracked in two -- the only time we have ever seen this happen. That block had an un-dampened crank pulley on it.

On a race motor, increased risk of bearing or crank problems is in-signficant next to the risk of, say, detonation in the cylinder that could blow up the motor. So for a race block, we heartily endorse lightweight un-dampened crank pulleys.

But for a street-driven car, one that you might want to last a couple of hundred thousand miles, we do not recommend using a pulley without a harmonic dampener.

One last note: The rubber in the OEM crank pulley gets old and weak over time, and it's not uncommon on high-mileage motors to see the crank pulley completely come apart. This can be a serious problem if the accessory belts wind their way into the timing belt area. The moral of the story: Inspect your crank pulley the next time you're working on the car, and replace it if it shows any signs of looseness or wobbling.

there's several different designs and suppliers so do some research.

keep in mind cruising speed forces air thru the radiator and aids cooling at speed so slowing the water pump may not noticeably reduce the cars cooling at speed but it may at idle, or in traffic. and if you've got electric fans you may want to get a different alternator pulley to speed up the alternator to compensate.

http://www.marchperf.com/underdrive2.html

http://www.chevelle.com/Crank-Pulleys-C687.aspx

http://www.marchperf.com/csb_pulleys.html

http://www.marchperf.com/csb_pulleys.html#pulleysbb

http://www.corvetteguys.com/bbk-ls1-sfi ... ulley.html

http://www.ecklers.com/product.asp?pf_i ... pt_id=1768

http://www.ws6.com/mycar.htm

http://www.steedafusion.com/store/Engin ... _info.html

heres a dyno test

http://www.ws6.com/mod-2.htm

http://www.summitracing.com/parts/SLE-M10007/

http://en.wikipedia.org/wiki/Underdrive_pulleys

http://www.machv.com/tip11cranpul.html

THIS THREAD ( BELOW ) MIGHT ALSO BE OF INTEREST

viewtopic.php?f=32&t=258&p=313#p313

QUOTE

Tip 11: Crank Pulleys

We've had lots of questions about crank pulleys lately, so here's all we know.

First, the crank pulley is the main pulley on the end of the crank (duh) that drives the accessories -- alternator, water pump, and air conditioning compressor.

An "underdrive" crank pulley is a pulley with a smaller diameter. The result is that it drives the accessories more slowly, and with greater mechanical leverage. It's like pedaling a bicycle up a hill with the smallest sprocket engaged on the crank. The goal of the underdrive pulley is to reduce drag from the accessories on the motor. Of course, if the accessories are turning more slowly, they will also be that much less effective, but life is all about compromises.

Does an underdrive pulley really add horsepower? The pulley manufacturers say they do, and we've seen tests in magazines that seemed to indicate signficant gains. But you could get the same sort of gains during a drag race WITHOUT an underdrive pulley by removing the belt from your alternator. (The motor can run solely off the battery for a short time.)

The other benefit of aftermarket pulleys is to reduce rotating mass. Here the simple aluminum crank pulley has a big advantage over the heavy stock pulley, but there's a reason it's so much lighter: It's missing the harmonic dampener. The reduction in rotating mass may be worth a couple of horsepower. But removing the dampener seems like a bad idea to us.

The factory crank pulley has a built-in harmonic dampener, in the form of a split design, with a thick rubber pad sandwiched between two steel sheels. The dampener is designed to absorb torsional and vertical vibrations from the crank. MOST underdrive crank pulleys (with the exception of the Buschur Racing model) do not have a harmonic dampener at all.

Torsional vibration is a twisting vibration caused by the pulses of each combustion event. The force of the piston causes the crank to deflect ever so slightly in the direction of the force, and when that force goes away the crank ever-so-slightly springs back. At certain frequencies the crank can resonate, making the vibration much worse. This is where the harmonic dampener comes into play.

Although many DSM owners have removed the harmonic dampener crank pulley without incident, doing so almost certainly increases crank bearing wear, and COULD lead to early failure of the crank or crank bearings. Just how much the life of these parts is shortened is unknown.

We do have one piece of first-hand experience, to offer, though. We know of ONE instance of crank failure on the 4G63 motor. It was a 2.3-liter motor that belong to an employee of ours. The crank cracked in two -- the only time we have ever seen this happen. That block had an un-dampened crank pulley on it.

On a race motor, increased risk of bearing or crank problems is in-signficant next to the risk of, say, detonation in the cylinder that could blow up the motor. So for a race block, we heartily endorse lightweight un-dampened crank pulleys.

But for a street-driven car, one that you might want to last a couple of hundred thousand miles, we do not recommend using a pulley without a harmonic dampener.

One last note: The rubber in the OEM crank pulley gets old and weak over time, and it's not uncommon on high-mileage motors to see the crank pulley completely come apart. This can be a serious problem if the accessory belts wind their way into the timing belt area. The moral of the story: Inspect your crank pulley the next time you're working on the car, and replace it if it shows any signs of looseness or wobbling.

Last edited by a moderator: