Maniacmechanic1

solid fixture here in the forum

Ok.I'm calling B.S. on that one.

Grumpy has a thread related to the situation in the rotating section.

Page 3 half way down titled "

how to install a 2piece rear seal crank in 1 piece block

B.S. it is.

Never seen that ever.

No one here has ever done it here.

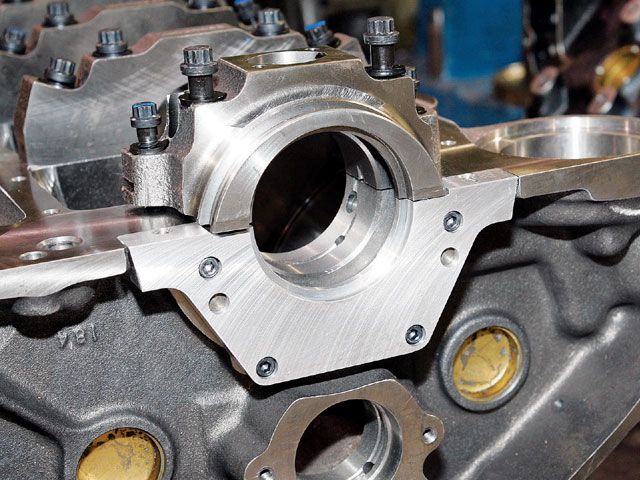

Billet split adapter.

Have to machine up an alignment tool.

Multiple Leakage points potential present.

How much is that M.OF.O. ?

FREE ?

LIKELY NOTTA.

LOOKS LIKE $$$.

Gotta fix that GM Race block yet too.

Dart Little M with China wall blem & end mill error facing on freeze plug surface lot better than present deal (s).