those oil pans generally work out well...

IF the front cross member allows the required clearance for the pans installation

be aware theres

right and left dipsticks

and thick and thin front seals,

and one and two piece rear seals

ONE PIECE OIL PAN GASKETS

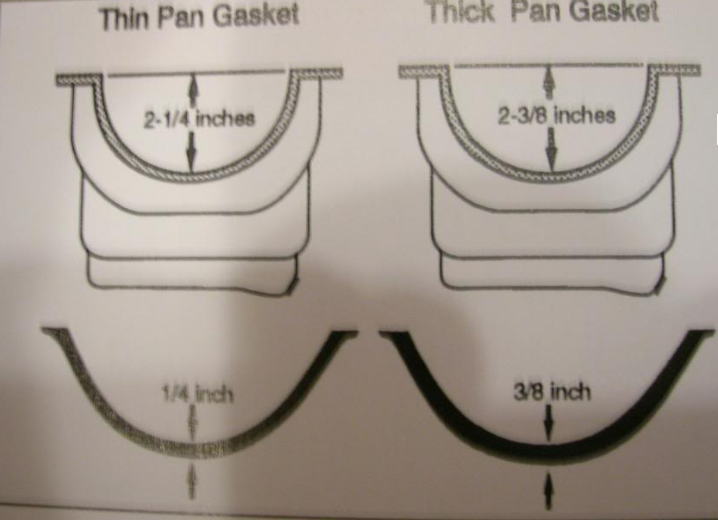

1974 and earlier pans had a shallower/thinner front gasket opening where the pan meets the timing chain cover and 1975 and later used a deeper/thicker pan gasket in this area, the 1985 and some other blocks used the right hand dip stick further complicating things

theres two common gasket thickness measurements,Put a straight edge across the front of the oil pan and measure down to the lowest part of where the seal rests directly centered under the crank,the distance from the strait edge to the lower front oil pan is the measurement you need,. It's the oil pan that determines thick or thin seal, not the timing cover.

IVE GENERALLY HAD THE BEST RESULTS WITH ONE PIECE OILPAN GASKETS AND USING STUDS

http://www.summitracing.com/parts/mor-38360

http://www.summitracing.com/parts/mor-38350

2-1/4" = thin seal

2-3/8" = thick seal

HERES A BASIC LIST

(SBC)

SMALL BLOCK FELPRO

Fel Pro #375-OS34510T

Replacement Oil Pan Gasket

PermaDryPlus

1975-85 SBC 262-400

Right-hand dipstick

this while deal is not that difficult

youll obviously need a damper puller tool

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-53706

http://garage.grumpysperformance.com/index.php?threads/damper-honing.4975/#post-13912

http://www.jegs.com/i/JEGS-Performance-Products/555/W89711/10002/-1

Fel Pro #375-1880

H/P Oil Pan Gasket

PermaDryPlus

1975-79 SBC 262-400 (side rails cut for Strokers)

9/64" thick

Thick Front Seal

Left-hand dipstick

Fel Pro #375-1881

H/P Oil Pan Gasket

PermaDryPlus

1980-85 SBC 262-400 (side rails cut for Strokers)

9/64" thick

Thick Front Seal

Right-hand dipstick

Fel Pro #375-1882

H/P Oil Pan Gasket

PermaDryPlus

SB-Chevy & race blocks with straight side rails

9/64" thick

Thick Front Seal

Fel Pro #375-1885

H/P Oil Pan Gasket

PermaDryPlus

1957-74 SBC 262-400

9/64" thick

Thin Front Seal

Left-hand dipstick

Fel Pro #375-OS-34509T

Replacement Oil Pan Gasket

PermaDryPlus

1957-74 SBC 262-400

Thin Front Seal

Left-hand dipstick

Fel Pro #375-OS34500R

Replacement Oil Pan Gasket

Rubber-coated/steel core

1986-99 SBC 305-350

Fel Pro #375-OS34510T

Replacement Oil Pan Gasket

PermaDryPlus

1975-85 SBC 262-400

Right-hand dipstick

HERES A BASIC LIST

(BBC)

Fel Pro #375-1884R

H/P Oil Pan Gasket

PermaDryPlus

1965-90 BBC 396-454

3/32" thick

Fel Pro #375-OS34407R

Replacement Oil Pan Gasket

Rubber-coated/steel core

1991-2000 BBC 454

Fel Pro #375-1893 (THREE PIECE)

H/P Oil Pan Gasket

Rubber-coated/steel core

1965-90 BBC 396-454

1991-Up BBC 454-572

Side rails cut to clear rods

Fel Pro #375-1863

Replacement Oil Pan Gasket

Rubber-coated multipiece

Donovan-Merlin blocks

BIG BLOCK MOPAR

Fel Pro #375-1834

H/P Oil Pan Gasket

Rubber-coated/steel core

1958-79 361-440 & Hemi

3/32" thick

http://www.jegs.com/webapp/wcs/stores/s ... 4_-1_10197

http://www.jegs.com/i/Milodon/697/41000/10002/-1

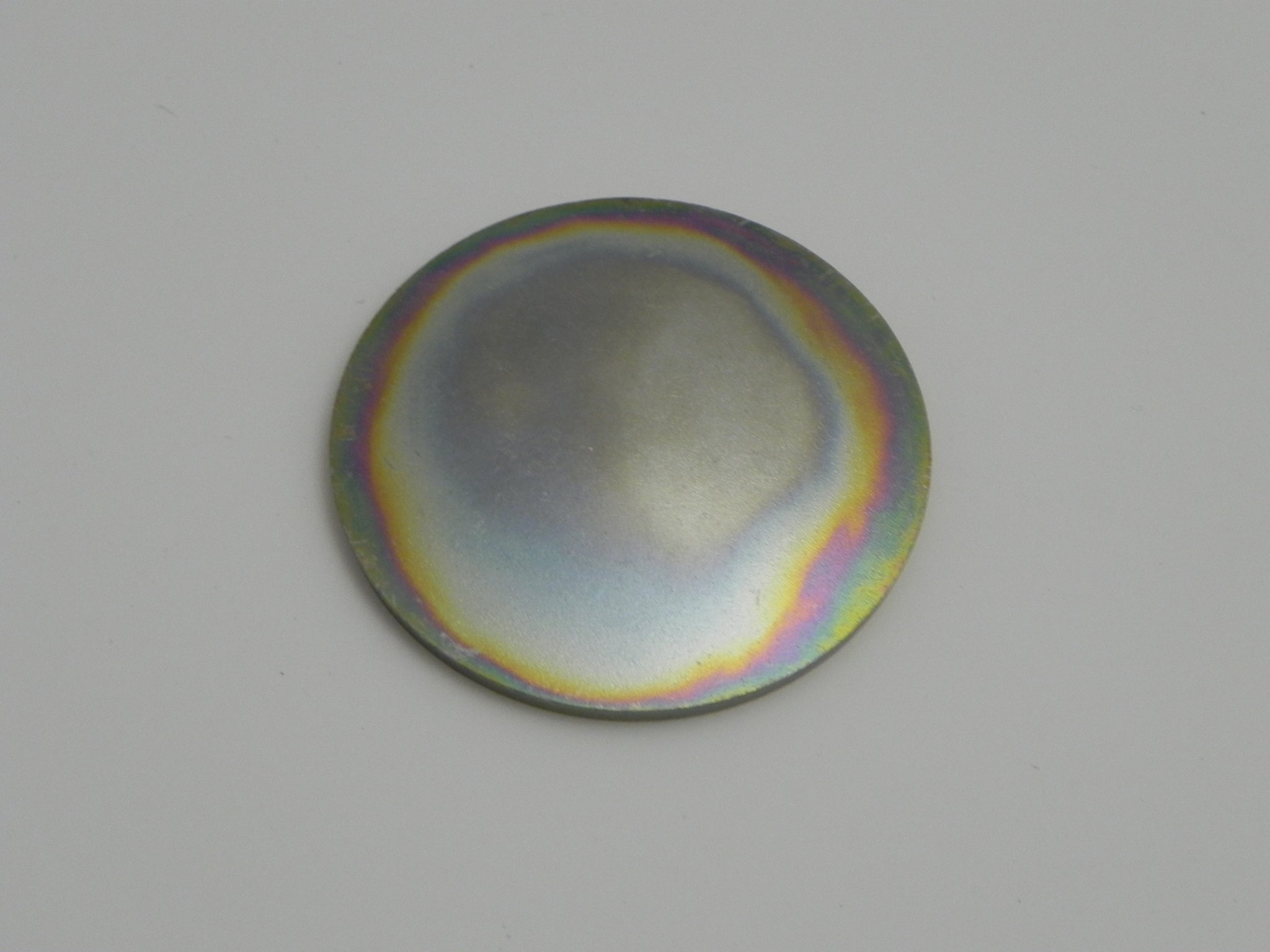

TWO PIECE REAR SEAL

OS34509T: Thin seal

OS34510T: Thick seal

BOTH LEFT HAND DIPSTICK

looks like you need the #OS34509T: Thin seal,if you need a thin front seal

but that only comes in left hand

so you might be forced to use

the older 4 piece design if you need a thin seal and right hand dip stick

Right-hand dipstick

375-1818

have the Felpro catalog and they show 5 SBC one piece gasket part numbers:

PN1881 1980-85 thick front seal RH dipstick; side rails trimmed for strokers

PN1880 1975-79 thick front seal LH dipstick; side rails trimmed for strokers

PN1885 1957-74 thin front seal LH dipstick

PN1882 Thick front seal straight side rails; side rails trimmed for strokers

PN1886 1986-97 thick front seal, one 1pc rear main seal GM bowtie short deck block

________

per jegs #'s FEL-PRO SMALL BLOCK CHEVY

1957-1975 1 piece 37.99 #1885

1986-1997 1 piece 39.99 #1886

MR.GASKET SMALL BLOCK CHEVY

1975-1985 1 piece 27.99 #6560

1986-1996 1 piece 27.99 #6561

http://www.jegs.com/webapp/wcs/stores/s ... 2_47050_-1

one-piece main seal blocks use this one:

OS34500R

Which type you use is dependent on your oil pan, not the block or timing cover.

BBC LISTED ALSO

http://www.jegs.com/webapp/wcs/stores/s ... 4_-1_10197

http://store.summitracing.com/egnsearch ... 5&y=8&x=43

http://garage.grumpysperformance.co...main-seal-in-a-gen-i-chevy-v8.1718/#post-4257

keep in mind on big blocks theres mark IV, mark V and MARK VI oil pan gaskets

Grumpy, what should you torque the bolts to and in what pattern?

this should help, (I generally snug the bolts up on the oil pan by feel and don,t over tighten them, and I generally use a small 1/4" drive ratchet to do so, not a tq wrench, (I think its 14-15 ft lbs or 165-170 inch lbs if you want to get technical) Im sure theres a specification, your supposed to use but Ive seldom had any problems just snugging them up by the feel with a short 1/4" drive ratchet.) I generally tighten in stages and constantly circle the pattern, I think the main problem occur when guys OVER TIGHTEN and crush the gaskets, snug but not tight works, if the gaskets being squished out noticeably between the block and pan lip, your more than likely over tightening the bolts, heres where experience comes into play, if your not sure use a inch rated tq wrench at 170 inch lbs

http://www.digitalcorvettes.com/forums/showthread.php?t=81323

http://www.small-block-chevy.com/assemblyspec.html

http://www.gmpartsdirect.com/performanc ... D=968.html

http://www.sallee-chevrolet.com/oilsystem/index.cfm

http://garage.grumpysperformance.co...epair-leaking-oil-pan-drain.13652/#post-70344

BTW oil pan rails are flimsy on some oil pans

ID check the oil pan rails are not bent/warped and if you need to use some black silicone sealant, but Ive never yet had that be necessary, most leaks are the result of EITHER the gasket not being seated correctly or over tightening the bolts bending oil pan.

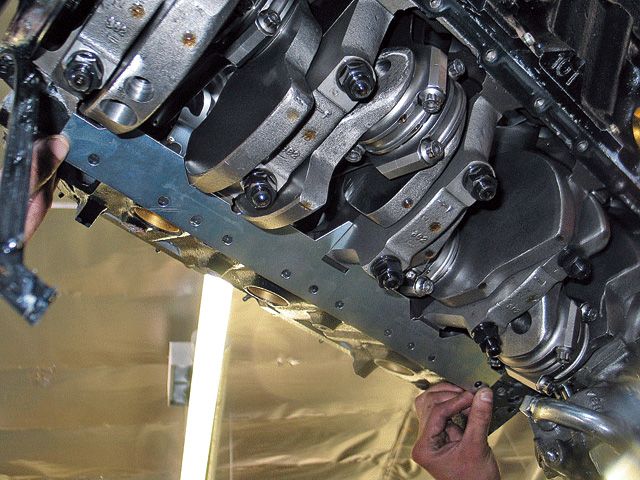

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

always use the manufacturers suggested installation instructions, as some applications or gasket types REQUIRE different lubes or sealants but heres a rough guide, you need to carefully clean and degrease any contact areas where sealants are to be used.

heres a rough guide to help select the correct sealants

yes any component needs to be properly installed, I've seen something similar happen a few times in the past, (persistent slow oil leaks) when guys were using a crank scraper sandwiched between the oil pan gasket and the block,

when guys simply forgot to spray both of the crank scraper surfaces and the block and gasket surface with some sealant like copper coat. hot oil is DESIGNED and formulated to seep into and through small cracks , and if there's no sealant blocking that hot liquid penetrating oil, it will eventually find its way through micro cracks in the area between two metal surfaces, so you,ll want to coat both sides of the gasket and crank scraper with a thin coat of spray sealant just prior to oil pan assembly

If you find you have an oil leak from the front of a chevy engine don,t assume its the front cover or lower timing cover seal leaking, be damn sure thats where the actual oil leak is, your oil pan and front cover and oil pan gasket being used, may not be properly matched to each other causing the leak, its very easy to buy a universal chevy sbc oil pan that may not match your year block or indicated fron seal but I find in many cases, its the front crank seal OR that common oil leak, from a lose or missing bolt, in the block ( read through all the links) and don,t ignore the fuel pump to block gasket as a potential oil leak point or valve cover of front intake rail gasket

this while deal is not that difficult

youll obviously need a damper puller tool

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-53706

http://garage.grumpysperformance.com/index.php?threads/damper-honing.4975/#post-13912

http://www.jegs.com/i/JEGS-Performance-Products/555/W89711/10002/-1

http://garage.grumpysperformance.com/index.php?threads/tracking-down-an-oil-leak.1430/#post-3168

http://garage.grumpysperformance.co...l-pan-gasket-still-small-leak.3084/#post-8194

http://garage.grumpysperformance.com/index.php?threads/oil-pan-gaskets.206/#post-390

http://garage.grumpysperformance.co...ain-seal-in-a-gen-i-chevy-v8.1718/#post-11956

http://garage.grumpysperformance.co...stalling-the-intake-manifold-distributor.464/

http://garage.grumpysperformance.co...pans-that-fit-the-c4-corvette.3071/#post-8131

http://garage.grumpysperformance.co...ece-oil-pan-gasket-thickness.4578/#post-12188

http://garage.grumpysperformance.com/index.php?threads/oil-pan-gaskets.206/#post-1154

http://forum.grumpysperformance.com/viewtopic.php?f=51&t=1718&p=4257&hilit=+rear+seal#p4257

http://garage.grumpysperformance.co...ain-seal-in-a-gen-i-chevy-v8.1718/#post-33369

http://garage.grumpysperformance.co...-pan-gasket-still-small-leak.3084/#post-11971

http://garage.grumpysperformance.co...ling-an-oil-pump-pick-up-tube.1800/#post-4597

http://garage.grumpysperformance.co...oving-gaskets-the-wrong-way.10464/#post-43934

http://garage.grumpysperformance.com/index.php?threads/which-sealant-goes-where.700/#post-43768