It's been a while since I posted. Seems I forgot my password. LOL

Anyhow...

Over the years, I have been able to get the 0-60mph time down to 5 seconds flat. Here was the set up that got me to 5 seconds-

Oh- and this was on OEM smog-era, stock heads. I also left the OEM air pump in place to retain the sleeper look (although the actual hoses were not linked up to the exhaust).

My goal is to get it just under 5 seconds on its 0-60mph time... specifically, high 4s. It's not a drag car- its just supposed more responsive than stock. I want to be able to sneak up on the late model muscle cars. Not to out accelerate them- but rather to give them a good scare.

I've kept the car as stock looking as possible from inside & out. It has a restored interior and show car level paint. The bottom line is to keep it looking period correct but with modern running gear and significantly improved performance. Obviously, when the key rolls over and it starts... the facade of "stock" falls apart quickly. Until then, it's just ho-hum crossfire.

So, here's the latest round of mods...

The car sounds amazing and has a lot of throttle response. Over the next couple of weeks I will walk the tune in and get it optimized for the adjustments I have made to it (a la EBL & the WUD). Unfortunately, I needed the real estate for the fuel lines and VAFPR, so I had to remove the air pump this go round of changes.

Grumpy suggested the rockers a few years ago and now just getting around to making the upgrade.

Anyhow...

Over the years, I have been able to get the 0-60mph time down to 5 seconds flat. Here was the set up that got me to 5 seconds-

- TBs bored to 1.95"

- 454 truck injectors (PN# 5235231)

- GM Marine TBI pressure regulator modded into a VAFPR

- TPI fuel pump

- DCS Renegade intake

- Erson .465" / .488" cam 224/234 @.05 with 112 LC

- Built 700R4 with the governor set to 5.4k rpm shifts

- 2k rpm stall

- 3.73 gears

- Dynamic EFI EBL with wideband O2 integrated into an ADC port

- Added an IAT & upgraded to a 1990 Caprice 350 engine code N knock sensor

- Hooker headers

- True duals

- Magnaflows

- Eliminated the trap door on the fresh air chamber & plugged the heat riser snorkel- set up to breath exclusively through the fresh air chamber (similar to using a ram air set up like on the LS1 Fbodies).

Oh- and this was on OEM smog-era, stock heads. I also left the OEM air pump in place to retain the sleeper look (although the actual hoses were not linked up to the exhaust).

My goal is to get it just under 5 seconds on its 0-60mph time... specifically, high 4s. It's not a drag car- its just supposed more responsive than stock. I want to be able to sneak up on the late model muscle cars. Not to out accelerate them- but rather to give them a good scare.

I've kept the car as stock looking as possible from inside & out. It has a restored interior and show car level paint. The bottom line is to keep it looking period correct but with modern running gear and significantly improved performance. Obviously, when the key rolls over and it starts... the facade of "stock" falls apart quickly. Until then, it's just ho-hum crossfire.

So, here's the latest round of mods...

- AFR 180cc Eliminator heads with 65cc chambers

- Upgraded the valve train with 1.6 roller rocker on the intake and 1.52 on the exhaust (should push total lift to the .496 / .495 range)

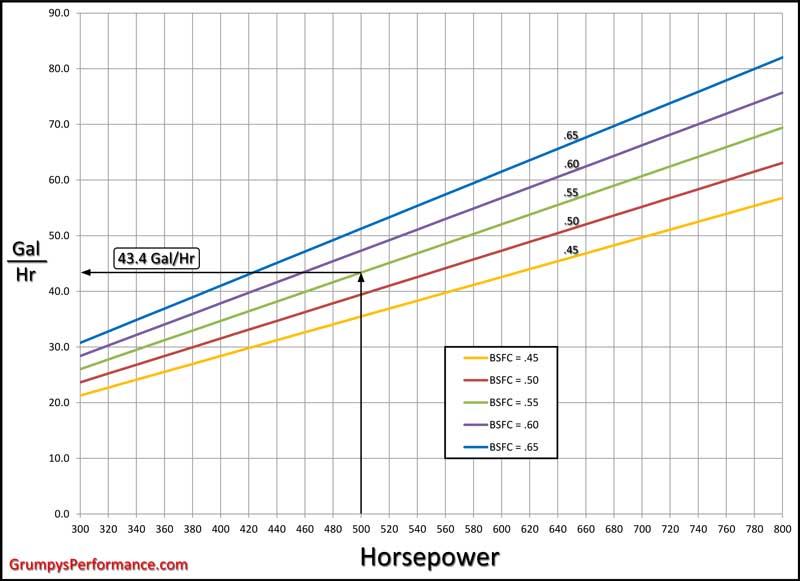

- Parallel plumbed the fuel delivery with an Aeromotive 13301 VAFPR set at 25psi (key-on)

The car sounds amazing and has a lot of throttle response. Over the next couple of weeks I will walk the tune in and get it optimized for the adjustments I have made to it (a la EBL & the WUD). Unfortunately, I needed the real estate for the fuel lines and VAFPR, so I had to remove the air pump this go round of changes.

Grumpy suggested the rockers a few years ago and now just getting around to making the upgrade.

Attachments

Last edited: