Chevy 4 Life said:Good morning Grumpy,

I really appreciate and respect the advice that you have given me and other on CT over the last year or so that I have been a member. I was duped into buying a rebuilt 68 350 with 882 smogger heads, and over cammed, even though I was told it was a built motor. The motor does run well though, just no low end TQ for the street and my 4000lb impala. I would like to install aluminum heads to lower the front weight. I am looking for reliable 375+hp, and over 400tq in the Idle-4500 range. It currently has 280h cam, performer intake, 882 heads with z28 springs, 1406 600 carb, long tubes, and 2 1/2" exhaust. 700r4 with 2200 stall,3.70s and 27" tires. My budget is 2k for parts, and do you think that I should stay flat tappet or roller. Rollers are pricey and I do like to lean towards the old school flat tappet route. Thanks for the help in advance.

with a 4000 lb car and a basically stock 350 short block youll want all the torque you can get in the lower and mid rpm bands, torque is the result of efficiently using cylinder pressure, great flowing heads are mandatory for max potential power and better heads tend to partially compensate for a slightly milder than ideal cam, but the current cams a bit too large in duration and the heads are restrictive ,given the budget limitations and reluctance to totally rebuild it as a 383 stroker config, and Id bet the reluctance to go with a flat tappet solid lifter cam, Id suggest going this route.(parts listed below)

the old chevy smogger 882 heads are very old and restrictive technology

even the more modern and fairly reasonable priced rhs heads flow much better

GM 882

Valve Exhaust Exhaust Open

Intake Lift w/ pipe

0.050 39 34 34

0.100 58,59,70

0. 200 125 108 109

0. 300 175 135 136

0.400 204 141 143

0.500 205 142 144

0. 600 206 142 145

E/I 69% 70%

http://www.competitionproducts.com/Short-Blocks-Chev-SB/departments/1224/

http://www.strokerengine.com/SBCHeadsFlow.html

READ THESE LINKS

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0701-chevy-cylinder-heads/

http://www.chevelles.com/forums/showthread.php?t=370311

I doubt youll quite reach 400 hp but youll darn sure have a more streetable combo with noticeably better low and mid rpm torque over the rpm band your using 90% of the time.

going with a roller cam and lifters would cost enough, of that $2K budget, to exclude the purchase of better heads and the heads are more critical to boosting operformance.

heads (low cost but noticeably better than current 882 heads)

http://www.summitracing.com/parts/sum-162109

SPEND A BIT MORE and get better heads (personally I think $240 extra,very well spent)

http://www.jegs.com/i/Brodix/158/1021004/10002/-1?parentProductId=760699#moreDetails

or

http://www.profilerperformance.com/racing/cylinderheads/sbc-23-degree

milder crower cam

http://www.summitracing.com/parts/cro-00240

rhoads lifters

http://www.summitracing.com/parts/rhl-8178/overview/

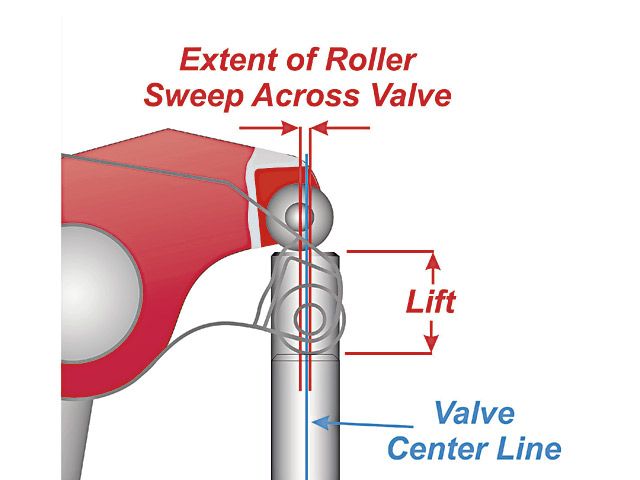

1.6:1 erson rockers

http://www.ebay.com/itm/like/291431719883?lpid=82&chn=ps

RELATED INFO

youll learn a good deal by reading through

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-46582

http://garage.grumpysperformance.co...rocker-ratios-and-the-effects.126/#post-38478

http://garage.grumpysperformance.com/index.php?threads/breaking-in-a-cam.798/#post-1160

http://garage.grumpysperformance.co...lifter-to-increase-oil-flow.11152/#post-49968

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

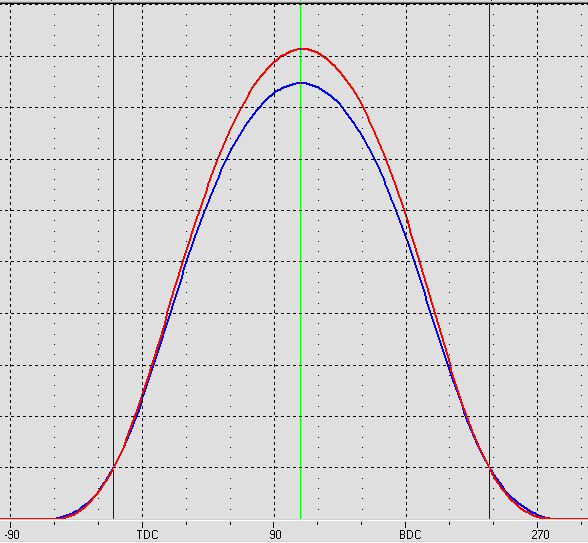

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

Last edited: