brad.arcova

Member

Not sure what to do next.

0. ran a compression test when new; all about 180.

1. engine now has 7500 mile, ran compression test and found 1-8: 175, 149, 90, 174, 173,170, 183, 166

2. pulled head and found that #3 exhaust valve wouldn't seal. could see light through the valve seat by shining flash light through exhaust port.

3. with the #3 exhaust valve spring removed, found .020 front to rear motion on valve stem; side to side only about .007. When holding valve in a certain position, it seals by the light test but with the spring reinstalled it won't seal.

4. can't find a spec for this test but #5 exhaust valve motion is only .005 front to rear and .003 side to side and the valve seals, no light.

5. its pretty obvious the #3 exhaust valve guide is worn badly. haven't pull the right side head to check #2 cyl yet.

6. The engine and heads have only 7500 miles on them. They are no-name vortec style, cast iron.

7. The rocker arms are stamped steel self-aligning.

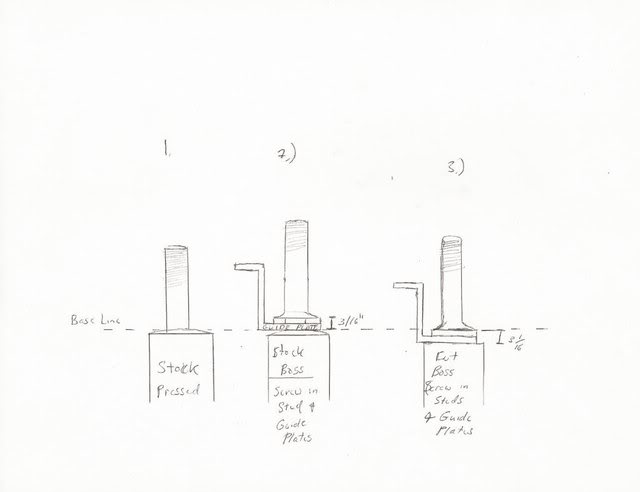

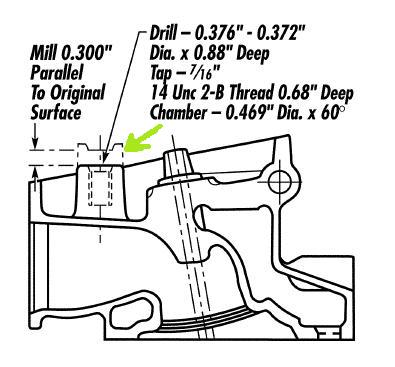

8. The valve springs don't stand up straight; I've read that off-square springs can cause excessive wear but don't know if "standing up straight" is the right test.

9. no lubrication problems, lots of pressure and lots of flow.

10. Engine under warranty; what should I ask for? New heads?

11. If the builder won't honor the warranty how should I fix this? new valve guide liners?

12. What's causing this? How can I keep it from recurring?

Brad

0. ran a compression test when new; all about 180.

1. engine now has 7500 mile, ran compression test and found 1-8: 175, 149, 90, 174, 173,170, 183, 166

2. pulled head and found that #3 exhaust valve wouldn't seal. could see light through the valve seat by shining flash light through exhaust port.

3. with the #3 exhaust valve spring removed, found .020 front to rear motion on valve stem; side to side only about .007. When holding valve in a certain position, it seals by the light test but with the spring reinstalled it won't seal.

4. can't find a spec for this test but #5 exhaust valve motion is only .005 front to rear and .003 side to side and the valve seals, no light.

5. its pretty obvious the #3 exhaust valve guide is worn badly. haven't pull the right side head to check #2 cyl yet.

6. The engine and heads have only 7500 miles on them. They are no-name vortec style, cast iron.

7. The rocker arms are stamped steel self-aligning.

8. The valve springs don't stand up straight; I've read that off-square springs can cause excessive wear but don't know if "standing up straight" is the right test.

9. no lubrication problems, lots of pressure and lots of flow.

10. Engine under warranty; what should I ask for? New heads?

11. If the builder won't honor the warranty how should I fix this? new valve guide liners?

12. What's causing this? How can I keep it from recurring?

Brad