You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve Seat Runout

- Thread starter Indycars

- Start date

Maniacmechanic1

solid fixture here in the forum

.002" is production valveseat Run Out by GM Chevrolet and Pontiac V8.

Race you want .000".

Only can be done by the best.

To repeat is hard.

A few Pros still do by hand with old School stone valve grinding gear.

I can hit .000" and repeat.

Key is your pilots used.

Race you want .000".

Only can be done by the best.

To repeat is hard.

A few Pros still do by hand with old School stone valve grinding gear.

I can hit .000" and repeat.

Key is your pilots used.

Maniacmechanic1

solid fixture here in the forum

Can lap.

Too much destroys the valvejob.

Too much destroys the valvejob.

obviously dealing with a machine shop known to do quality and consistent high quality, 3 angle valve jobs is the first step in this process,

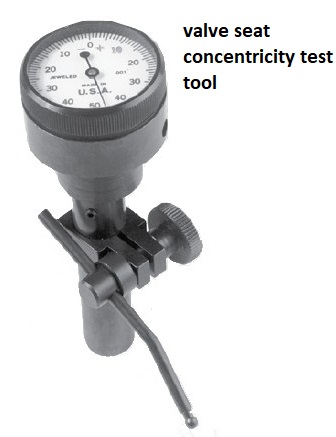

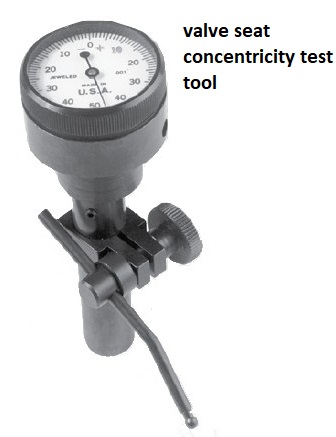

Yes ,Ive generally found you will need to disassemble and check run-out yourself and yeah,

that requires you purchase a few tools to do it accurately.

https://www.cylinderheadsupply.com/kl8545.html

you can generally verify valve seat seal with simply pouring alcohol into the intake or exhaust ports with what ever port your testing vertical and watching for solvent or alcohol seepage in the combustion chamber ,

alcohol will seep past a marginal valve seat seal contact far faster than water will due to its lack of surface tension, so its a better test fluid. hand lapping the valve seats tends to help.

hand lapping valve seats can be done reasonably easily and greatly increases valve seat seal.

https://www.enginebuildermag.com/2013/10/cautioning-on-valve-seat-concentricity/

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-78724

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

Yes ,Ive generally found you will need to disassemble and check run-out yourself and yeah,

that requires you purchase a few tools to do it accurately.

https://www.cylinderheadsupply.com/kl8545.html

you can generally verify valve seat seal with simply pouring alcohol into the intake or exhaust ports with what ever port your testing vertical and watching for solvent or alcohol seepage in the combustion chamber ,

alcohol will seep past a marginal valve seat seal contact far faster than water will due to its lack of surface tension, so its a better test fluid. hand lapping the valve seats tends to help.

hand lapping valve seats can be done reasonably easily and greatly increases valve seat seal.

https://www.enginebuildermag.com/2013/10/cautioning-on-valve-seat-concentricity/

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-78724

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

Last edited:

Ernest Shaw

Retired machinist

When doing measurements of this nature, in all fairness as far as repeatability goes the stylus on the instrument should also be taken into consideration. You can have a reading taken with a larger diameter stylus and it will read completely different than a smaller one.

true, I've generally found you'll need to disassemble and hand lap the valve seats to the valves, and then carefully and totally clean all surfaces, on any set of heads you get back from the machine shop ,

as many machine shops don't do a decent job of cleaning micro trash out of the valve bowl and valve seat areas , or for that mater the rest of the cylinder heads valve spring seats, guides etc.

once I started to get parts back from machine shops and had the knowledge and the precision measuring tools and valve train disassembly tools.

it became all too apparent that most shops had done crap, quality slop shod work or at least the minimum they thought they could get away with and cleaning micro trash from machined areas was very low on the too-do list

if you just assume that the machine shop must have cleaned the parts they worked on carefully...

http://store.summitracing.com/partdetai ... toview=sku

related info

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...tched-valve-spring-required.13774/#post-77425

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...ring-installation-questions.12833/#post-66378

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-54091

http://garage.grumpysperformance.co...u-buy-bare-or-assembled-heads.534/#post-81754

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-59253

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.co...mpressors-and-checking-springs.903/#post-1465

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/#post-28127

as many machine shops don't do a decent job of cleaning micro trash out of the valve bowl and valve seat areas , or for that mater the rest of the cylinder heads valve spring seats, guides etc.

once I started to get parts back from machine shops and had the knowledge and the precision measuring tools and valve train disassembly tools.

it became all too apparent that most shops had done crap, quality slop shod work or at least the minimum they thought they could get away with and cleaning micro trash from machined areas was very low on the too-do list

http://store.summitracing.com/partdetai ... toview=sku

related info

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...tched-valve-spring-required.13774/#post-77425

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...ring-installation-questions.12833/#post-66378

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-54091

http://garage.grumpysperformance.co...u-buy-bare-or-assembled-heads.534/#post-81754

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-59253

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.co...mpressors-and-checking-springs.903/#post-1465

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/#post-28127

Last edited:

Ernest Shaw

Retired machinist

Another thing that you can do when working on parts that can become magnetized is degauss them so there isn't as much tendency to trap particulate matter. Sometimes all the solvent cleaning in the world won't alleviate the problem. This is another step that's over looked by a lot of shops.

Another thing that you can do when working on parts that can become magnetized is degauss them so there isn't as much tendency to trap particulate matter. Sometimes all the solvent cleaning in the world won't alleviate the problem. This is another step that's over looked by a lot of shops.

A quick look and it seems this is not something the average enthusiast would be able to do. Does it

take specialized equipment?

Maniacmechanic1

solid fixture here in the forum

I have an electro magnetic Sine Plate.Another thing that you can do when working on parts that can become magnetized is degauss them so there isn't as much tendency to trap particulate matter. Sometimes all the solvent cleaning in the world won't alleviate the problem. This is another step that's over looked by a lot of shops.

Bought it around 2001.

Used it to mount Pontiac V8 iron cylinder heads in a VERTICLE mill Bridgeport.

Holds real tight.

Flip the lever and AC 60 cycle current demagnatizes or Deguasses.

From the 1960s.

Replaced the OZ2 Argon gas rectifier tube with a Full wave bridge rectifier.

In my basement now.

Think I paid $400 for it.

Maniacmechanic1

solid fixture here in the forum

Yes. It's an investment.A quick look and it seems this is not something the average enthusiast would be able to do. Does it

take specialized equipment?

True Love for Hotrod Race.

Takes lots of practice and skill.

Going to screw up the 1st time and times after.

Till good enough for your own Race Engine.

Loves302Chevy

"One test is worth a thousand expert opinions."

Rick, have you ever erased a cassette tape? Do you remember that Radio Shack had a gadget for doing that?A quick look and it seems this is not something the average enthusiast would be able to do. Does it

take specialized equipment?

Demagnetized a screwdriver? It's just a matter of running whatever metallic object through an AC current field.

The words degauss and demagnetize can be interchanged. Brian gives a good example with his electromagnetic sine plate. Run DC through it and it's a strong electromagnet. Turn it off and I'm sure it would retain some residual magnetism. That's why the need for the AC to demagnetize it.

Now if I only could figure out how my pushrods in my 334 SBC got magnetized. I'm never gonna figure that one out.

Maniacmechanic1

solid fixture here in the forum

Possibly occurred when the RC .080 Pushrods were made Mike.Rick, have you ever erased a cassette tape? Do you remember that Radio Shack had a gadget for doing that?

Demagnetized a screwdriver? It's just a matter of running whatever metallic object through an AC current field.

The words degauss and demagnetize can be interchanged. Brian gives a good example with his electromagnetic sine plate. Run DC through it and it's a strong electromagnet. Turn it off and I'm sure it would retain some residual magnetism. That's why the need for the AC to demagnetize it.

Now if I only could figure out how my pushrods in my 334 SBC got magnetized. I'm never gonna figure that one out.

Swaged rolled formed ends on high quality 1- piece pushrods.

They use a die pressed against with a pushrod turning in a lathe or mill machine.

Recall seeing on Smith Brothers racing pushrods website in past.

They are in Washington state.

Made pushrods for Isky

Found about them from Pontiac racers and engine builders.

Maniacmechanic1

solid fixture here in the forum

Friction under right conditions magnetizes iron and steel.

Loves302Chevy

"One test is worth a thousand expert opinions."

They are Trick Flow brand. They weren't magnetized when I first put the engine together, but were when it came apart. Mystery.

Maniacmechanic1

solid fixture here in the forum

Heat & Friction ?They are Trick Flow brand. They weren't magnetized when I first put the engine together, but were when it came apart. Mystery.

Dry start maybe Mike. Only the best oils will remain cling to pushrod tips after a few days to several years later on engine startup.

Just know Castrol GTX will.

Other good oils too out there.

But John Force used Castrol GTX also.

Maybe a Nuclear War took place already.

EMP dropped also.

Magnetize all iron & steel likley.

They Turned on Stargate Time Machine & reset the Clocks.

Your Trickflow Pushrods the only evidence left of what really occured.

Ernest Shaw

Retired machinist

You fellas are right in assuming the friction is what causes the magnetization of your steel parts. What I do with my parts is take them to a facility we have that rebuilds aircraft engines to have them degaussed. Pushrods will become magnetized when they rotate against a lifter or from rubbing against guide plates. Some guide plate manufacturers used to use a phenolic (plastic/UHMW material) insert in the guide area. The magnetization isn't a huge problem, it's just nice to be aware of it when you get parts back that have been machined, so you can try to clean up some of those hidden areas. Another thing racers will do is epoxy magnets close to drain holes in the block to catch particulates. I've also seen blocks prepared with paint for electrical applications to aid in the drain back of oil also.

related threads

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.com/index.php?threads/magnets.120/#post-76617

http://garage.grumpysperformance.co...akes-particles-in-oil.13330/page-2#post-69990

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-54398

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-37266

http://garage.grumpysperformance.co...-rockers-and-the-pushrods-rub.198/#post-34140

http://garage.grumpysperformance.co...am-lobe-rod-or-bearings-fail.2919/#post-26436

http://garage.grumpysperformance.com/index.php?threads/valve-train-shrapnel-screens.1458/#post-22845

http://garage.grumpysperformance.com/index.php?threads/magnets.120/#post-76617

http://garage.grumpysperformance.co...akes-particles-in-oil.13330/page-2#post-69990

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-54398

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-37266

http://garage.grumpysperformance.co...-rockers-and-the-pushrods-rub.198/#post-34140

http://garage.grumpysperformance.co...am-lobe-rod-or-bearings-fail.2919/#post-26436

http://garage.grumpysperformance.com/index.php?threads/valve-train-shrapnel-screens.1458/#post-22845

Last edited:

Ernest Shaw

Retired machinist

I about forgot, you can epoxy screens over the drain back holes to catch bits from the valve train when it comes apart also.

Loves302Chevy

"One test is worth a thousand expert opinions."

I'll buy that!Heat & Friction ?

Maybe a Nuclear War took place already.

EMP dropped also.

Magnetize all iron & steel likley.

They Turned on Stargate Time Machine & reset the Clocks.

Your Trickflow Pushrods the only evidence left of what really occurred.

And I did screens, paint, and magnets this time around.

Maniacmechanic1

solid fixture here in the forum

LOL.I'll buy that!

And I did screens, paint, and magnets this time around.

Me too Mike.