now IDEALLY youll be working with the engine out of the car and the cylinder heads on a bench, and you'll need a few decent tools and some concept of what your looking at, and what your trying to do.

many guys prefer to remove the inner dual spring (if your heads are so equipped) during the cam break-in process to reduce the cam lifter contact loads and reduce the potential for the cam lobes and lifter bases to wear excessively, until the parts are lapped into a smooth mated surface.

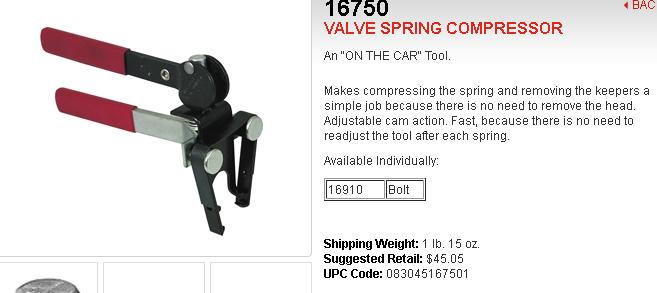

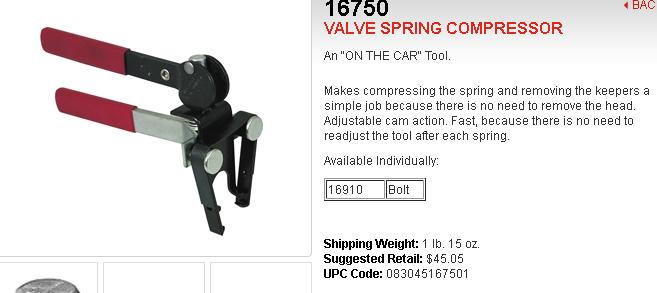

now its fare easier to work on the heads if they are off the engine but obviously youll need the type of spring compressor that works with the heads mounted on the engine to re-install the inner springs later.

obviously youll want to coat the cam lobe and lifter bases with a good moly cam lube

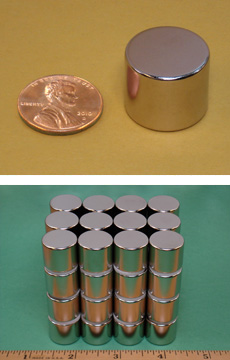

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out

youll need to read thru these threads

but the basic idea is that youll need to know the installed height, the coil bind height, the clearances and spring load rates, and install the springs to match the manufacturers intended load rates and clearances for the application,thus at least partly insuring the valve train components can stabilize the valve train at the intended rpm band,and control valve float. any spring that fails to meet specks by more than about 7% in load rates should be replaced, and you need to be sure the clearances are correct and the rocker geometry is set up to place the majority of the pressure during the rockers arc in the center of the valve to limit side loads and wear on the valve guides.

http://store.summitracing.com/partdetai ... toview=sku

heads off the car

http://store.summitracing.com/partdetai ... toview=sku

heads on the car

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

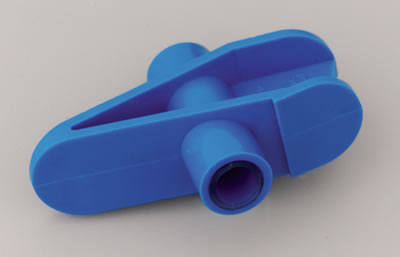

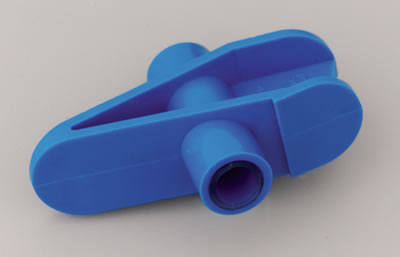

Proper push rod length is absolutely critical for peak performance—minimizing bent or broken valve stems, guide wear, and energy-wasting valve side-loading friction.

With the lifter located on the round base circle, position the Push Rod length Checker (make sure you have the Checker with the proper diameter hole) over the stud. Ideally the Checker should contact the top of the push rod and the valve tip evenly at the same moment, should the Checker contact the push rod first, measure the gap between the front of the checker and the valve tip, and purchase a shorter push rod of the correct length. Should the Checker contact the valve tip first, measure the gap between the back of the Checker and the top of the push rod, and purchase a longer push rod

you can change installed height of valve springs thru, machining the valve spring seat depth deeper,or the use of SHIMS under the valves, to shorten the height or different valve spring retainers, even different spring dia.and coil sizes and different valve keepers and even different length valves.

Hey grumpy, my cars engine started running like crap, and the valve springs on two valves started ticking ,

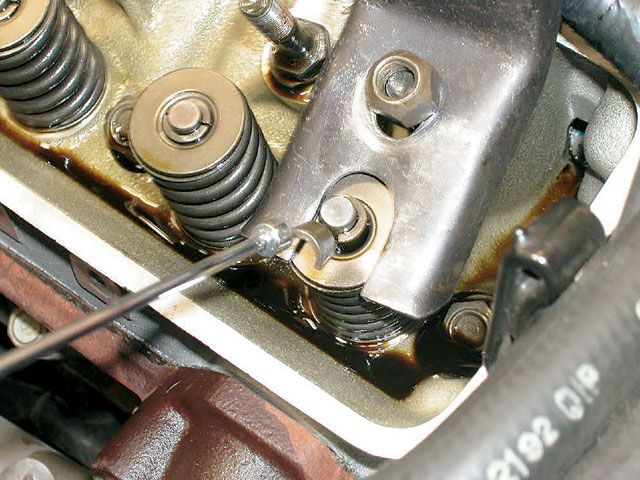

( I pulled this picture off the internet, its not my engine) but it looks very similar to my engines valve springs

so obviously, Ill need to be removing,and replacing the valve springs,

removing,and replacing the valve springs,

testing and replacing valve springs can be done with the heads on the car, but its far easier to do correctly with the heads off the car.

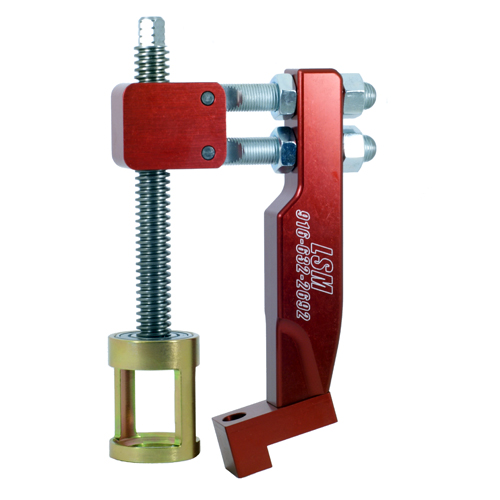

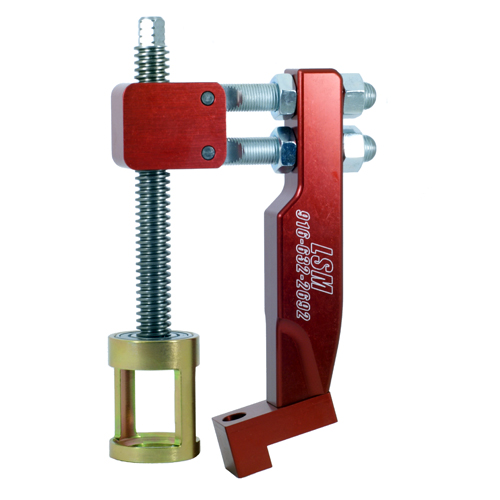

youll eventually find a need to replace valve springs on any car that you either race or replace a cam in its engine so youll need the correct valve spring compressor tool

http://www.lislecorp.com/divisions/prod ... category=6

THIS TOOL WORKS OK ON SINGLE SPRINGS BUT NOT DUAL VALVE SPRINGS

http://www.summitracing.com/parts/otc-4573/media/images

http://www.summitracing.com/parts/wmr-w ... dia/images

THIS TOOL IS A BIT FLIMSY BUT WORK ON MOST HEADS WITH STOCK SPRINGS BUT ONLY WITH THE HEADS OFF THE ENGINE

http://www.summitracing.com/parts/sum-9 ... dia/images

THIS TOOL WORKS ON SOME HEADS BETTER THAN OTHERS, WITH THE HEADS ON OR OFF THE ENGINE

http://www.summitracing.com/parts/pro-6 ... dia/images

these links should help you understand the subject

viewtopic.php?f=50&t=903&p=10020&hilit=change+valve+springs#p10020

viewtopic.php?f=52&t=4957&p=13739&hilit=spring+bind#p13739

viewtopic.php?f=52&t=181&p=19783&hilit=change+valve+springs#p19783

viewtopic.php?f=52&t=6237&p=19552&hilit=change+valve+springs#p19552

viewtopic.php?f=52&t=4962&p=13780&hilit=change+valve+springs#p13780

youll generally do that too get the correct clearances and load rates

removing the inner springs for the first hour of run time will tend to help

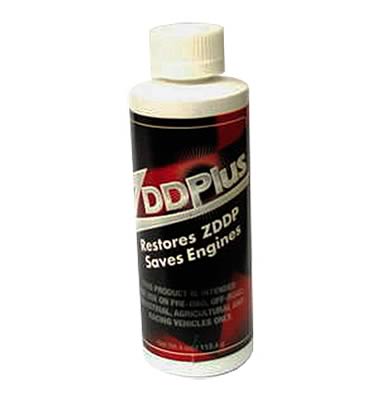

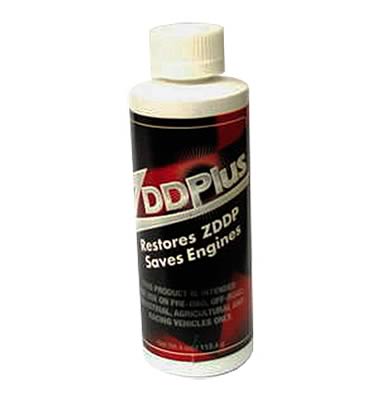

adding a ZddP additive will also

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=1191&p=4497&hilit=+break+moly#p4497

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=16&p=1173&hilit=rope+adapter#p1173

viewtopic.php?f=54&t=2187

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=456&p=8844&hilit=break+in+moly#p8844

READ THE SUB LINK INFO POSED ABOVE IN THIS THREAD

many guys prefer to remove the inner dual spring (if your heads are so equipped) during the cam break-in process to reduce the cam lifter contact loads and reduce the potential for the cam lobes and lifter bases to wear excessively, until the parts are lapped into a smooth mated surface.

now its fare easier to work on the heads if they are off the engine but obviously youll need the type of spring compressor that works with the heads mounted on the engine to re-install the inner springs later.

obviously youll want to coat the cam lobe and lifter bases with a good moly cam lube

changing valve springs on the car

now most shops will rotate the cylinder to TDC and install an adapter for an air hose and pump a steady 100-130psi into the cylinder to hold the valves closed, but theres frequently clearance problems with headers and the adapters or hose and since you need to wack the valve retainer with a...

garage.grumpysperformance.com

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out

youll need to read thru these threads

but the basic idea is that youll need to know the installed height, the coil bind height, the clearances and spring load rates, and install the springs to match the manufacturers intended load rates and clearances for the application,thus at least partly insuring the valve train components can stabilize the valve train at the intended rpm band,and control valve float. any spring that fails to meet specks by more than about 7% in load rates should be replaced, and you need to be sure the clearances are correct and the rocker geometry is set up to place the majority of the pressure during the rockers arc in the center of the valve to limit side loads and wear on the valve guides.

http://store.summitracing.com/partdetai ... toview=sku

heads off the car

http://store.summitracing.com/partdetai ... toview=sku

heads on the car

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

Proper push rod length is absolutely critical for peak performance—minimizing bent or broken valve stems, guide wear, and energy-wasting valve side-loading friction.

With the lifter located on the round base circle, position the Push Rod length Checker (make sure you have the Checker with the proper diameter hole) over the stud. Ideally the Checker should contact the top of the push rod and the valve tip evenly at the same moment, should the Checker contact the push rod first, measure the gap between the front of the checker and the valve tip, and purchase a shorter push rod of the correct length. Should the Checker contact the valve tip first, measure the gap between the back of the Checker and the top of the push rod, and purchase a longer push rod

you can change installed height of valve springs thru, machining the valve spring seat depth deeper,or the use of SHIMS under the valves, to shorten the height or different valve spring retainers, even different spring dia.and coil sizes and different valve keepers and even different length valves.

Hey grumpy, my cars engine started running like crap, and the valve springs on two valves started ticking ,

( I pulled this picture off the internet, its not my engine) but it looks very similar to my engines valve springs

so obviously, Ill need to be removing,and replacing the valve springs,

removing,and replacing the valve springs,

testing and replacing valve springs can be done with the heads on the car, but its far easier to do correctly with the heads off the car.

youll eventually find a need to replace valve springs on any car that you either race or replace a cam in its engine so youll need the correct valve spring compressor tool

http://www.lislecorp.com/divisions/prod ... category=6

THIS TOOL WORKS OK ON SINGLE SPRINGS BUT NOT DUAL VALVE SPRINGS

http://www.summitracing.com/parts/otc-4573/media/images

http://www.summitracing.com/parts/wmr-w ... dia/images

THIS TOOL IS A BIT FLIMSY BUT WORK ON MOST HEADS WITH STOCK SPRINGS BUT ONLY WITH THE HEADS OFF THE ENGINE

http://www.summitracing.com/parts/sum-9 ... dia/images

THIS TOOL WORKS ON SOME HEADS BETTER THAN OTHERS, WITH THE HEADS ON OR OFF THE ENGINE

http://www.summitracing.com/parts/pro-6 ... dia/images

these links should help you understand the subject

viewtopic.php?f=50&t=903&p=10020&hilit=change+valve+springs#p10020

viewtopic.php?f=52&t=4957&p=13739&hilit=spring+bind#p13739

viewtopic.php?f=52&t=181&p=19783&hilit=change+valve+springs#p19783

viewtopic.php?f=52&t=6237&p=19552&hilit=change+valve+springs#p19552

viewtopic.php?f=52&t=4962&p=13780&hilit=change+valve+springs#p13780

youll generally do that too get the correct clearances and load rates

removing the inner springs for the first hour of run time will tend to help

adding a ZddP additive will also

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=1191&p=4497&hilit=+break+moly#p4497

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=16&p=1173&hilit=rope+adapter#p1173

viewtopic.php?f=54&t=2187

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=456&p=8844&hilit=break+in+moly#p8844

READ THE SUB LINK INFO POSED ABOVE IN THIS THREAD

Last edited by a moderator: