4doorscooter

Active Member

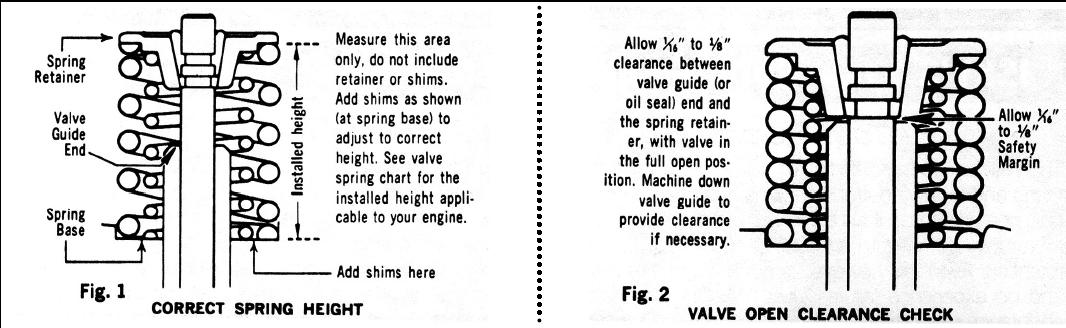

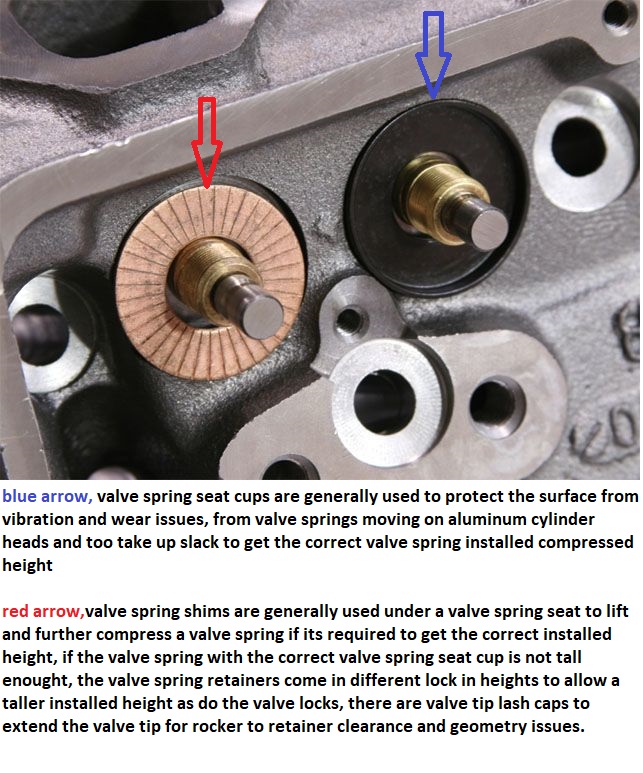

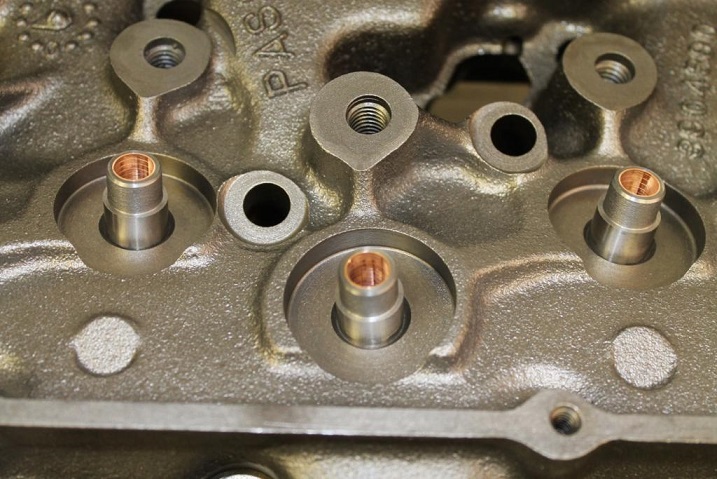

I am in the process of installing the required springs recommended for my cam on my vortec heads. My first question is, on a cast iron head do I need to add a hardened steel shim to every spring pocket to protect the head or can I install a spring directly against the spring cup if the installed height is correct? my second question is can i use a snap gauge and a dial caliper to measure installed height as I am on a budget and I would like to save the 50 bucks a spring mic would cost me? Thanks in advance for the help everyone!