Ok, here gos!

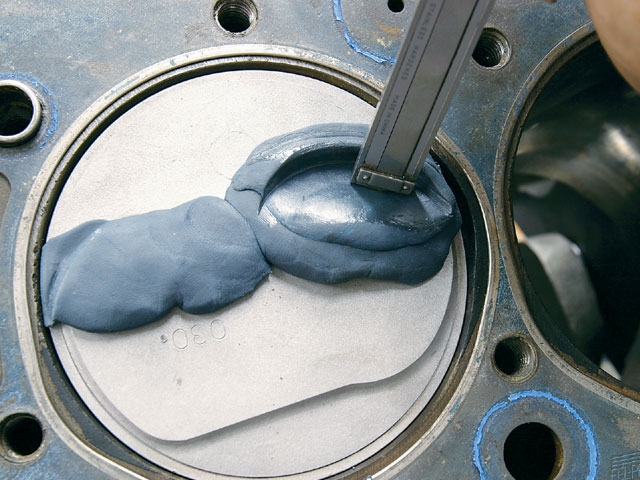

being I have the hydraulic roller lifters and need to make sure the piston to valve clearances are acceptable (min .037) does it make a difference checking them with out oil in them?

I guess what I'm asking is do they build pressure that would make the clearance between the piston and valve different or is that what the .037 is for?

another question is "if" when I check this I dont have the min amout of .037 how do I get the clearance I need with keeping the quench right?

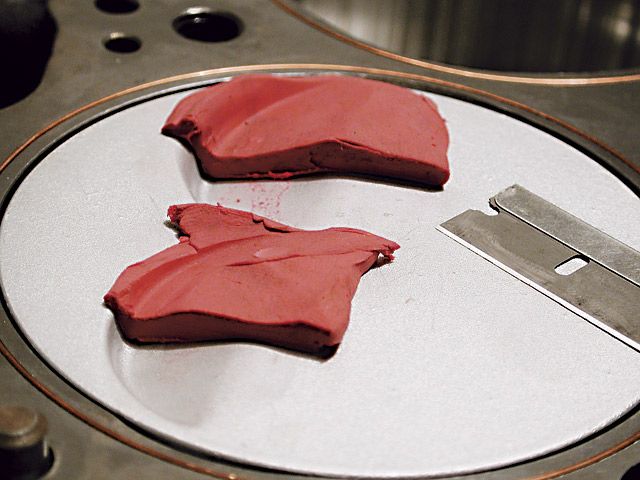

being I have the hydraulic roller lifters and need to make sure the piston to valve clearances are acceptable (min .037) does it make a difference checking them with out oil in them?

I guess what I'm asking is do they build pressure that would make the clearance between the piston and valve different or is that what the .037 is for?

another question is "if" when I check this I dont have the min amout of .037 how do I get the clearance I need with keeping the quench right?