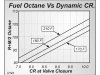

from what Ive seen working on and tuning engines ,those charts are depicting about the ideal maximum compression ratio to run,in your basically stock engine, giving you a bit of a hedge for detonation resistance, and they pretty much assume a 14.7:1 f/a mix ratio to minimize emissions.

detonation can destroy an engine but its frequently caused by more than just a bit of compression ratio increase in relation to the octane of the fuel alone, get the heat transfer rates out of the combustion chamber and ignition curves and fuel/air ratios correct and you can run a bit higher ratio that the charts depict.

A great deal of how well your engine runs will be determined by its state of tuning,if you run a non-emission friendly 12.5-13.1:1 fuel/air ratio where you maximize the engines power curve and play with the ignition timing advance curve to get the best torque ,you can frequently boost the effective compression ratio by about .2-.3 and not only get away with it but make noticeably better power.

now IM not saying you can ignore the graph, but in the real world its not like if the graph says that if your engines compression ratio is at 9:1 your, engine combo instantly self destructs the point you put 89 octane in the tank,or at 9.1:1 compression, if you mis-calculated,or that if the pump says your getting 91 octane, your not occasionally getting 89,90, or 92 octane.

get the quench down in the .040-.042 range , polish the combustion chambers and keep the coolant temps below about 190F and run a good oil control system with an oil cooler and you would be AMAZED at how far you can push the limits.....push NOT IGNORE!

you can add a bit of chamber volume and reduce the potential hot spots that help cause detonation by opening and blending and smoothing the combustion chamber