hey grumpyvette,

noticed the pressure in my BBC seemed low on the way home, and it kept dropping. Now it sits at 24psi at a 650rpm idle, dips to 15psi at 1500rpm, bottoms out at 11psi beyond 2500rpm, then creeps back slightly to about 13psi if I hold it around 4000rpm, at which point I think I can detect lifter noise, though not much. Here're some particulars:

- use 15w-40 Delo w/blue STP treatment, K&N filter w/red filter mag

- bottom end has around 50,000 miles on an 11 yr. old rebuild

- after top end rebuild, saw 35psi at idle, up to 70psi over 4000rpm

- runs great, no strange noises (though Summit billet distributor makes more racket than I remember the HEI making)

- changed the oil and filter for giggles, no difference after

- did notice I could produce light "swirls" in the old oil with my finger. Haven't cut the filter open.

- tested electric pressure gauge against mechanical tester, appears accurate. Currently referencing the mechanical gauge.

Any wisdom, ideas, thoughts, etc.? Thanks.

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

BTW THATS NOT TOTALLY TRUE! YOU STILL HAVE SOME OIL PRESSURE BUT MOST OF THE OIL BYE_PASSES THE OIL FILTER

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a gauge

http://cvrproducts.com/oil-pressure-test-kit/

when your rpms go up but the oil pressure drops its frequently an indicator that the oil pump pick-up screen on the oil pump is restricted, this is comonly caused from EITHER crud like bits of silicone and gaskets clogging part of the oil pump pick-up screen surface resticting oil flow into the pump, like when old nylon coated timing gears start to fail, OR more comonly the oil pan floor too, oil pump pick-up distance being under 3/8"

this is comonly the result of ADDING a high volume pump without carefully verifying the pumps pick-up to oil pan floor clearance issues OR having a pressed in oil pump pick-up tube vibrate enought so it slips lower in the pan OR the end of the oil pump pick-up screen breaking off, allowing the pump to suck air as the rpms build up.....in either case removing the oil pan is required to verify and correct the condition.

BRAZING THE OIL PUMP PICK-UP to the oil pump body IN THE CORRECT LOCATION TO MAINTAIN the correct floor clearance is generally a good idea

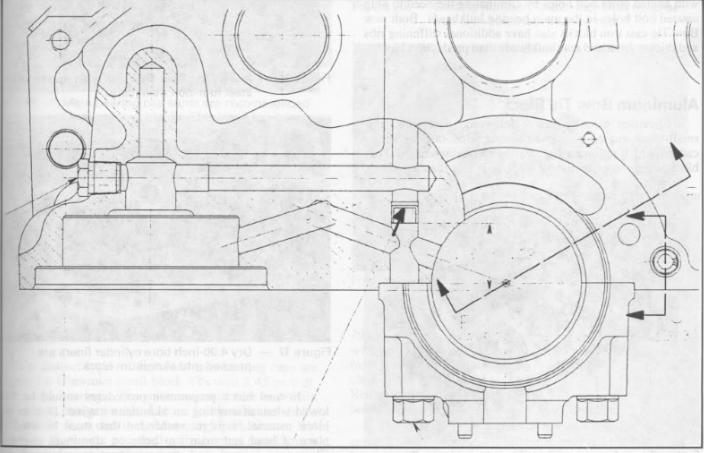

little tack welds seldom last, look carefully at the angle of this pumps pick-up screen, theres no way its indexed parralel to the oil pan floor. and its certianly not brazed correctly to the pumps body

BRAZING DOES WORK

links and info well worth reading

http://www.babcox.com/editorial/ar/ar10180.htm

http://www.mellingselectperformance.com ... -guide.pdf

http://www.mellingselectperformance.com ... charts.pdf

viewtopic.php?f=54&t=52

http://www.chevyhiperformance.com/techa ... index.html

http://www.aa1car.com/library/us1097.htm

viewtopic.php?f=54&t=938

viewtopic.php?f=27&t=26&p=2761#p2761

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=615

this info might help

btw anytime your tracking down an oil pressure problem step one is verify the oil pressure with a different mechanical oil pressure gauge. oil pressure sensors go bad frequently.

next oil pumps MUST have th oil pan floor to oil pump pick-up distance in the 3/8"-1/2" range and the pick-up needs to be mounted parallel to the oil pan floor.

verify the byepass piston and spring assembly move freely and move far enought to uncover the byepass port, shimming the spring is a bad idea, use the proper spring and REMOVE it durring the brazing of the oil pump pick-up to the pump body AFTER verifying clearance with modeling clay between the pick-up and oil pan floor.

the pressure relief spring has no effect at all untill the pressure exceeds the springs resistance and at that point all it does is limit the oil pressures INCREASE! a normal spring starts to bypass oil at about 65-70 psi a high pressure spring starts to bypass at 75-80 psi, below those pressures the springs have no effect (NONE)

there are 3 major factors in how fast your engine builds oil pressure

(1) the sweep volume of the pump (here is where a high volume pump has an advantage with larger rotor gears)

(2)engine clearances and oil viscosity, the larger the clearances and the thinner the oil the harder it will be to build back-pressure due to the resistance to oil flow necessary to build that resistance

(3) engine rpm, the faster you spin the engine the more oil the pump can move if the system has been set up with minimal restrictions

btw the most common mistake is placing the oil pump pickup too close to the bottom of the oil pan and/or not brazing the pickup to the pump so that it moves down restricting the intake opening or falls off and starts sucking air!

your bye-pass spring controls the pressure at which the pump starts to bleed off excess oil pressure, if it reaches 65 psi and then drops to 50 psi its NOT the pumps bye-pass circuit, as it will close at pressures below 65 psi, and shimming the spring will only effect the peak pressure you reached, before it opens,... below that point it has no effect, on the pressure the pump puts out ,you must keep the pumps pick-up covered in a significant level of oil in the sump, a running engine can keep 2 or more quarts in the upper engines, lifter gallery and heads, if the oil drains are not clear or the spinning cranks preventing drain back, into the sump. the fact that its dropping pressure at high rpms indicates an oil supply or control issue, in most cases its a control issue if you have at least a 7-8 quart baffled oil pan and a properly installed windage screen, if your running a 5-and in some cases a 6 quart factory style oil pan, without baffles and a windage screen, its potentially a problem with the supply.

if the oil pump pick up is mounted to close to the oil pan floor it can cause a restriction at higher rpms, if the oil doesn,t drain back to the pan because its rotating with the crank assembly, as its dragged around, or if your not running a pan and windage screen that allows the spinning crank assembly to sweep returning oil into the sump for re use,it is a potential problem.

a quick test is adding one-two more quarts of oil to the sump, if the oil pressure curve changes with the extra oil and doesn,t drop at the same rpm point you've proved its a supply or control issue, if it remains exactly consistent with the current set up, it could be a control issue if you don,t have the baffled pan and windage screen,but its unlikely to be a supply issue

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=615

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=64&p=1394#p1394

noticed the pressure in my BBC seemed low on the way home, and it kept dropping. Now it sits at 24psi at a 650rpm idle, dips to 15psi at 1500rpm, bottoms out at 11psi beyond 2500rpm, then creeps back slightly to about 13psi if I hold it around 4000rpm, at which point I think I can detect lifter noise, though not much. Here're some particulars:

- use 15w-40 Delo w/blue STP treatment, K&N filter w/red filter mag

- bottom end has around 50,000 miles on an 11 yr. old rebuild

- after top end rebuild, saw 35psi at idle, up to 70psi over 4000rpm

- runs great, no strange noises (though Summit billet distributor makes more racket than I remember the HEI making)

- changed the oil and filter for giggles, no difference after

- did notice I could produce light "swirls" in the old oil with my finger. Haven't cut the filter open.

- tested electric pressure gauge against mechanical tester, appears accurate. Currently referencing the mechanical gauge.

Any wisdom, ideas, thoughts, etc.? Thanks.

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

BTW THATS NOT TOTALLY TRUE! YOU STILL HAVE SOME OIL PRESSURE BUT MOST OF THE OIL BYE_PASSES THE OIL FILTER

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a gauge

http://cvrproducts.com/oil-pressure-test-kit/

when your rpms go up but the oil pressure drops its frequently an indicator that the oil pump pick-up screen on the oil pump is restricted, this is comonly caused from EITHER crud like bits of silicone and gaskets clogging part of the oil pump pick-up screen surface resticting oil flow into the pump, like when old nylon coated timing gears start to fail, OR more comonly the oil pan floor too, oil pump pick-up distance being under 3/8"

this is comonly the result of ADDING a high volume pump without carefully verifying the pumps pick-up to oil pan floor clearance issues OR having a pressed in oil pump pick-up tube vibrate enought so it slips lower in the pan OR the end of the oil pump pick-up screen breaking off, allowing the pump to suck air as the rpms build up.....in either case removing the oil pan is required to verify and correct the condition.

BRAZING THE OIL PUMP PICK-UP to the oil pump body IN THE CORRECT LOCATION TO MAINTAIN the correct floor clearance is generally a good idea

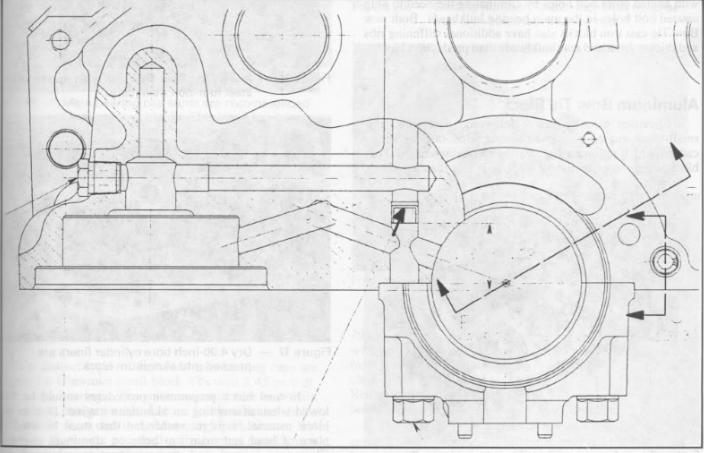

little tack welds seldom last, look carefully at the angle of this pumps pick-up screen, theres no way its indexed parralel to the oil pan floor. and its certianly not brazed correctly to the pumps body

BRAZING DOES WORK

links and info well worth reading

http://www.babcox.com/editorial/ar/ar10180.htm

http://www.mellingselectperformance.com ... -guide.pdf

http://www.mellingselectperformance.com ... charts.pdf

viewtopic.php?f=54&t=52

http://www.chevyhiperformance.com/techa ... index.html

http://www.aa1car.com/library/us1097.htm

viewtopic.php?f=54&t=938

viewtopic.php?f=27&t=26&p=2761#p2761

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=615

this info might help

btw anytime your tracking down an oil pressure problem step one is verify the oil pressure with a different mechanical oil pressure gauge. oil pressure sensors go bad frequently.

next oil pumps MUST have th oil pan floor to oil pump pick-up distance in the 3/8"-1/2" range and the pick-up needs to be mounted parallel to the oil pan floor.

verify the byepass piston and spring assembly move freely and move far enought to uncover the byepass port, shimming the spring is a bad idea, use the proper spring and REMOVE it durring the brazing of the oil pump pick-up to the pump body AFTER verifying clearance with modeling clay between the pick-up and oil pan floor.

the pressure relief spring has no effect at all untill the pressure exceeds the springs resistance and at that point all it does is limit the oil pressures INCREASE! a normal spring starts to bypass oil at about 65-70 psi a high pressure spring starts to bypass at 75-80 psi, below those pressures the springs have no effect (NONE)

there are 3 major factors in how fast your engine builds oil pressure

(1) the sweep volume of the pump (here is where a high volume pump has an advantage with larger rotor gears)

(2)engine clearances and oil viscosity, the larger the clearances and the thinner the oil the harder it will be to build back-pressure due to the resistance to oil flow necessary to build that resistance

(3) engine rpm, the faster you spin the engine the more oil the pump can move if the system has been set up with minimal restrictions

btw the most common mistake is placing the oil pump pickup too close to the bottom of the oil pan and/or not brazing the pickup to the pump so that it moves down restricting the intake opening or falls off and starts sucking air!

your bye-pass spring controls the pressure at which the pump starts to bleed off excess oil pressure, if it reaches 65 psi and then drops to 50 psi its NOT the pumps bye-pass circuit, as it will close at pressures below 65 psi, and shimming the spring will only effect the peak pressure you reached, before it opens,... below that point it has no effect, on the pressure the pump puts out ,you must keep the pumps pick-up covered in a significant level of oil in the sump, a running engine can keep 2 or more quarts in the upper engines, lifter gallery and heads, if the oil drains are not clear or the spinning cranks preventing drain back, into the sump. the fact that its dropping pressure at high rpms indicates an oil supply or control issue, in most cases its a control issue if you have at least a 7-8 quart baffled oil pan and a properly installed windage screen, if your running a 5-and in some cases a 6 quart factory style oil pan, without baffles and a windage screen, its potentially a problem with the supply.

if the oil pump pick up is mounted to close to the oil pan floor it can cause a restriction at higher rpms, if the oil doesn,t drain back to the pan because its rotating with the crank assembly, as its dragged around, or if your not running a pan and windage screen that allows the spinning crank assembly to sweep returning oil into the sump for re use,it is a potential problem.

a quick test is adding one-two more quarts of oil to the sump, if the oil pressure curve changes with the extra oil and doesn,t drop at the same rpm point you've proved its a supply or control issue, if it remains exactly consistent with the current set up, it could be a control issue if you don,t have the baffled pan and windage screen,but its unlikely to be a supply issue

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=615

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=64&p=1394#p1394

Last edited by a moderator: