AFTER youve welded up a decent exhaust system coating it with a decent galvanized paint will extent the expected life span, ( YES EVEN ON STAINLESS STEEL) you need to get it on while the steels clean and dry after welding and it won,t hurt to soak the welds, anything with a high zinc content that also tends to exclude moisture helps, remember the coating tends to allow the steel to retain heat slightly longer so it dries better and while it will still rust from the inside out it tends to take longer

http://www.clearcoproducts.com/cold_...e_primers.html

http://www.porcupinepress.com/_bending/segmentbends.htm

http://www.zoro.com/i/G0999047/?utm_sou ... gQodHoIAWA

READ THESE RELATED THREADS ALSO

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=961

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=1166

http://forum.grumpysperformance.com/viewtopic.php?f=60&t=72&hilit=stainless+welding

http://forum.grumpysperformance.com/viewtopic.php?f=60&t=1108&p=2185&hilit=stainless+welding#p2185

viewtopic.php?f=56&t=495

BTW standard aluminized steel exhaust systems are one area of welding where ,in the hands of a guy with some decent experience, a good oxy- acetylene torch or a 110 volt mig welder can do every bit as well as the higher amp 220 volt migs, but while a good tig welder may take longer it generally produces a superior weld in skilled hands

just keep in mind if you weld outside in a fully exposed area with a steady breeze the exposure is FAR lower than you get inside a closed garage

The fumes contain carcinogenic hexavalent chromium, sometimes written as CR(VI).

Respirator Procedures for Welding Stainless Steel exhausts

When you are welding stainless steel, wear a 1/2 facepiece respirator with a filter that has a “100″ rating.

If you are working within 10 feet of welding, or if you are grinding or sweeping, wear a “95″ rated disposable respirator or 1/2 facepiece respirator.

The dust is much less toxic than fumes but should be treated with care. Burning and smoking it should be done with caution.

Recognize that the bother respirators cause is worth it. They keep scratchy throats and lung cancer away. They can be slightly uncomfortable. It is difficult to be heard when speaking through a disposable respirator and you have to really speak up to be heard through a 1/2 facepiece respirator.

Always work in an area with excellent ventilation. Outside is best. If not possible, open windows & doors, push (or pull) fumes outdoors with a fan or fume extractor.

Alert people nearby what you are welding and of the danger. If indoors, alert everyone in the building and suggest they wear “95″ rated respirators.

After being near welding for a long time, be sure to shower when you get home to get the particles off you. Keep your work clothes separate from your other clothes. Do not eat your work clothes.

Get your own disposable and 1/2 facepiece respirators. They will fit better, you’ll know that they’ve been cared for, and they won’t smell of someone else’s copious sweat and snot.

When you’re not using them, keep your respirators in a plastic bag. “OV†filters will slowly degrade if left in the open air, decreasing their effectiveness. Also, the plastic bag will keep potentially toxic shop dusts out of the insides.

Replace the filter in your respirator if you detect a funny taste or smell through it or if it becomes difficult to breathe through. Those are signs that it’s useful life is over. There aren’t any hard and fast rules about this but you should get 4-40 hours of actively breathing through the respirator.

About Respirators

You must use at least an “N95″ or better respirator to protect yourself from stainless steel dust and fumes. It’s a very good idea to use a better respirator because the better fit and filtering will ensure safer working, especially for people that are less experienced (like myself!) with such work environments. The literature from 3M and OSHA says that a 95 rated respirator should be enough to protect you from dangerous levels of CR(VI). Scientists simply haven’t figured out exactly why people in the welding professions have higher lung cancer rates."

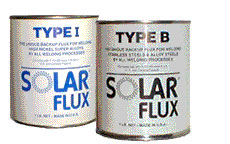

IF YOU WELD STAINLESS EXHAUST PIPE without a back flush you can get weld crystallizing or SUGARING , an ARGON back flush and taping both ends to exclude oxygen helps reduce this significantly as will tig paste

http://www.solarflux.com/Pages/Productinfo.html

SOLAR FLUX is a complex chemical compound in the form of a very fine powder – finer even than a lady's face powder. SOLAR FLUX, is mixed with alcohol (methanol/methyl acohol preferred) and brushed on the back of the weld joint. It is formulated to shield the BACK of the weld joint from oxygen, dissipate heat and unwanted oxides, and to clean the surface of the metal. It will aid in the flow of filler metal over base metal and form a protective barrier to prevent re-oxidation and heat scale

now having a decent MIG or TIG welder is a HUGE advantage in building exhaust systems,

BACK FILLING THE EXHAUST WITH SHIELD GAS, AND USE OF PROTECTIVE SHIELD WELDING PASTE,

HELPS KEEP THE WELD QUALITY HIGH

you can do excellent work on EXHAUST SYSTEMS with a little 110 volt mig like this

http://www.welders-direct.com/merchant2 ... ode=907335

but this mig below would be a far better general shop welder, in that it could do heavier welding on frames and suspension components along with exhaust systems

http://www.welders-direct.com/merchant2 ... ode=907422

http://www.clearcoproducts.com/cold_...e_primers.html

http://www.porcupinepress.com/_bending/segmentbends.htm

http://www.zoro.com/i/G0999047/?utm_sou ... gQodHoIAWA

READ THESE RELATED THREADS ALSO

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=961

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=1166

http://forum.grumpysperformance.com/viewtopic.php?f=60&t=72&hilit=stainless+welding

http://forum.grumpysperformance.com/viewtopic.php?f=60&t=1108&p=2185&hilit=stainless+welding#p2185

viewtopic.php?f=56&t=495

BTW standard aluminized steel exhaust systems are one area of welding where ,in the hands of a guy with some decent experience, a good oxy- acetylene torch or a 110 volt mig welder can do every bit as well as the higher amp 220 volt migs, but while a good tig welder may take longer it generally produces a superior weld in skilled hands

just keep in mind if you weld outside in a fully exposed area with a steady breeze the exposure is FAR lower than you get inside a closed garage

The fumes contain carcinogenic hexavalent chromium, sometimes written as CR(VI).

Respirator Procedures for Welding Stainless Steel exhausts

When you are welding stainless steel, wear a 1/2 facepiece respirator with a filter that has a “100″ rating.

If you are working within 10 feet of welding, or if you are grinding or sweeping, wear a “95″ rated disposable respirator or 1/2 facepiece respirator.

The dust is much less toxic than fumes but should be treated with care. Burning and smoking it should be done with caution.

Recognize that the bother respirators cause is worth it. They keep scratchy throats and lung cancer away. They can be slightly uncomfortable. It is difficult to be heard when speaking through a disposable respirator and you have to really speak up to be heard through a 1/2 facepiece respirator.

Always work in an area with excellent ventilation. Outside is best. If not possible, open windows & doors, push (or pull) fumes outdoors with a fan or fume extractor.

Alert people nearby what you are welding and of the danger. If indoors, alert everyone in the building and suggest they wear “95″ rated respirators.

After being near welding for a long time, be sure to shower when you get home to get the particles off you. Keep your work clothes separate from your other clothes. Do not eat your work clothes.

Get your own disposable and 1/2 facepiece respirators. They will fit better, you’ll know that they’ve been cared for, and they won’t smell of someone else’s copious sweat and snot.

When you’re not using them, keep your respirators in a plastic bag. “OV†filters will slowly degrade if left in the open air, decreasing their effectiveness. Also, the plastic bag will keep potentially toxic shop dusts out of the insides.

Replace the filter in your respirator if you detect a funny taste or smell through it or if it becomes difficult to breathe through. Those are signs that it’s useful life is over. There aren’t any hard and fast rules about this but you should get 4-40 hours of actively breathing through the respirator.

About Respirators

You must use at least an “N95″ or better respirator to protect yourself from stainless steel dust and fumes. It’s a very good idea to use a better respirator because the better fit and filtering will ensure safer working, especially for people that are less experienced (like myself!) with such work environments. The literature from 3M and OSHA says that a 95 rated respirator should be enough to protect you from dangerous levels of CR(VI). Scientists simply haven’t figured out exactly why people in the welding professions have higher lung cancer rates."

IF YOU WELD STAINLESS EXHAUST PIPE without a back flush you can get weld crystallizing or SUGARING , an ARGON back flush and taping both ends to exclude oxygen helps reduce this significantly as will tig paste

http://www.solarflux.com/Pages/Productinfo.html

SOLAR FLUX is a complex chemical compound in the form of a very fine powder – finer even than a lady's face powder. SOLAR FLUX, is mixed with alcohol (methanol/methyl acohol preferred) and brushed on the back of the weld joint. It is formulated to shield the BACK of the weld joint from oxygen, dissipate heat and unwanted oxides, and to clean the surface of the metal. It will aid in the flow of filler metal over base metal and form a protective barrier to prevent re-oxidation and heat scale

now having a decent MIG or TIG welder is a HUGE advantage in building exhaust systems,

BACK FILLING THE EXHAUST WITH SHIELD GAS, AND USE OF PROTECTIVE SHIELD WELDING PASTE,

HELPS KEEP THE WELD QUALITY HIGH

you can do excellent work on EXHAUST SYSTEMS with a little 110 volt mig like this

http://www.welders-direct.com/merchant2 ... ode=907335

but this mig below would be a far better general shop welder, in that it could do heavier welding on frames and suspension components along with exhaust systems

http://www.welders-direct.com/merchant2 ... ode=907422

Last edited by a moderator: