We did an article on the Dart SHP block, thought you guys might want to check it out - the entire article is below.

TO WATCH THE VIDEO, click here -->

http://www.streetlegaltv.com/forum/dart ... -1853.html

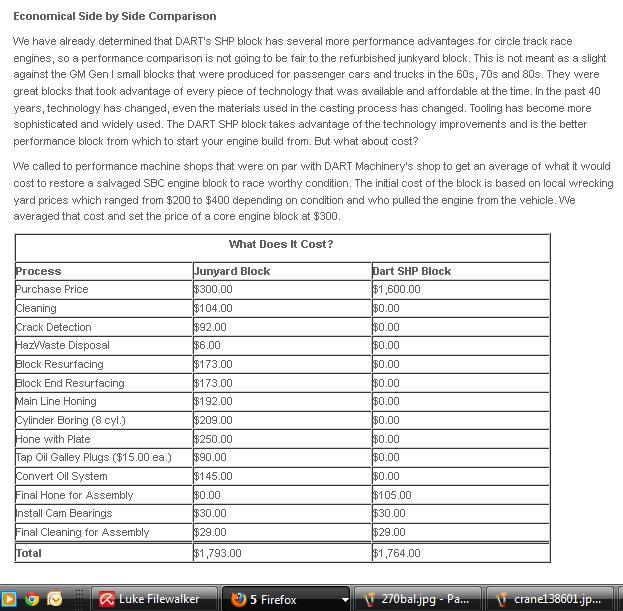

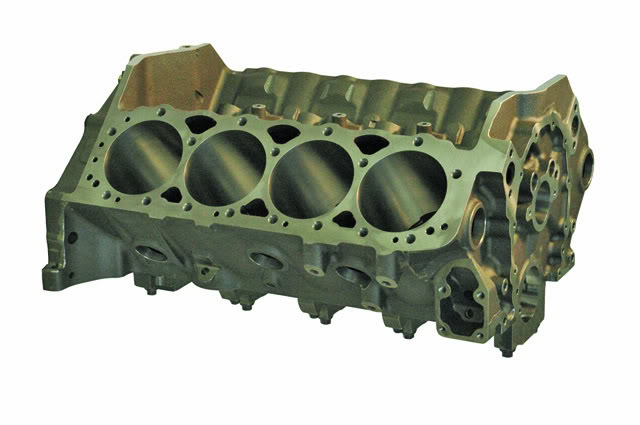

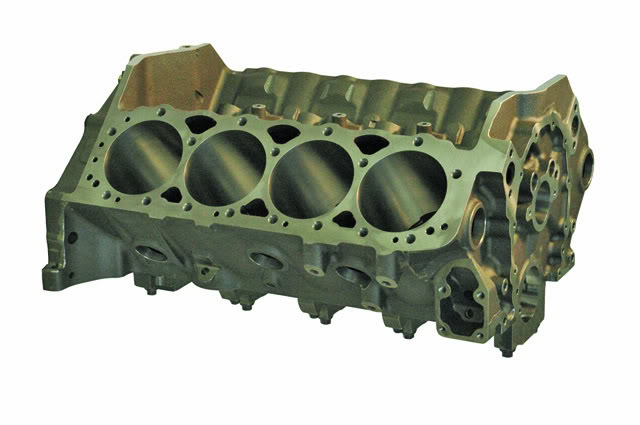

Good-condition 350 cube Chevy 4-bolt small-blocks are becoming increasingly hard to find. If by some slim chance that junk ’71 Nova at the local boneyard still has a good 4-bolt block, it won't be cheap. Between buying the donor block and machine work, you'll be into it for at least $800. And, at the end of the day, you have a stock block. Of course, you can pick up a brand-new race block, but you'll spend the better part of $2,000 or more.

Until now, there have been few options in the middle. Dart realizes this problem. Their answer: The new SHP block. SHP stands for “Special High Performance." SHP is a division of Dart that was created specifically the production of this block, which incorporates a lot of the features you’ll find in their high-end blocks, but with a MSRP barely over $1,500.

The History Behind Dart’s Heads and Blocks

In the mid ’70’s, Dart's founder Richard Maskin came up with many of the innovations racers take for granted today. Raised intake runners, offset pushrods, and sheet metal intakes set the Pro Stock world on fire. Maskin started making cylinder heads out of his two-car garage in 1981. Right off the bat, he jumped into Top Fuel Hemi heads that crushed the 300-mile-per-hour and 4 second ET barriers. By 1988 Dart had made their first block, The Rocket, that came with splayed caps, wide pan rails (effectively widening the stock crankcase), a raised cam location for extra crankshaft clearance, a 4.120 bore, and a 9.3-inch deck. The additional deck height compared to GM 350 block of that era required a significant amount of fabricated parts that are commonplace today. The current versions of Dart’s iron Chevy blocks came in 1998 with the Big M and 2000 with the Little M. Lightweight alloy blocks were introduced in 1997 with the aluminum version of the Rocket block. To cover the Blue Oval end of the spectrum, Ford blocks were added to the Dart lineup in 2004.

Benefits of the SHP Block

With a long history of race block design and production, Dart had to decide which features from their high end blocks would apply to the SHP block so that it would outshine stock pieces in every important area, without sacrificing economy. Fortunately, Dart’s experience made it possible to combine affordability and durability with very few compromises.

To do this on a budget, Dart completely redesigned their tooling so the foundry creates a block that requires less machine work, allowing them to cut their block qualification time in half. Even after the SHP block has been shipped to the technology center for inspection, it does not require all the fit and finish other blocks do. Processing work such as finishing the mains, cam tunnel, and lifter bores are all now done at the machining center. Less machine time equates to less processing expense per block, without sacrificing important advantages over stock-based blocks. Let’s look at the top five key features that cross over to the SHP block from Dart’s high-end blocks:

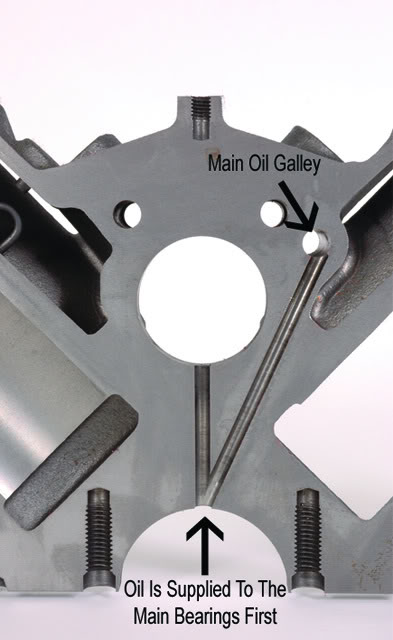

PRIORITY MAIN OILING

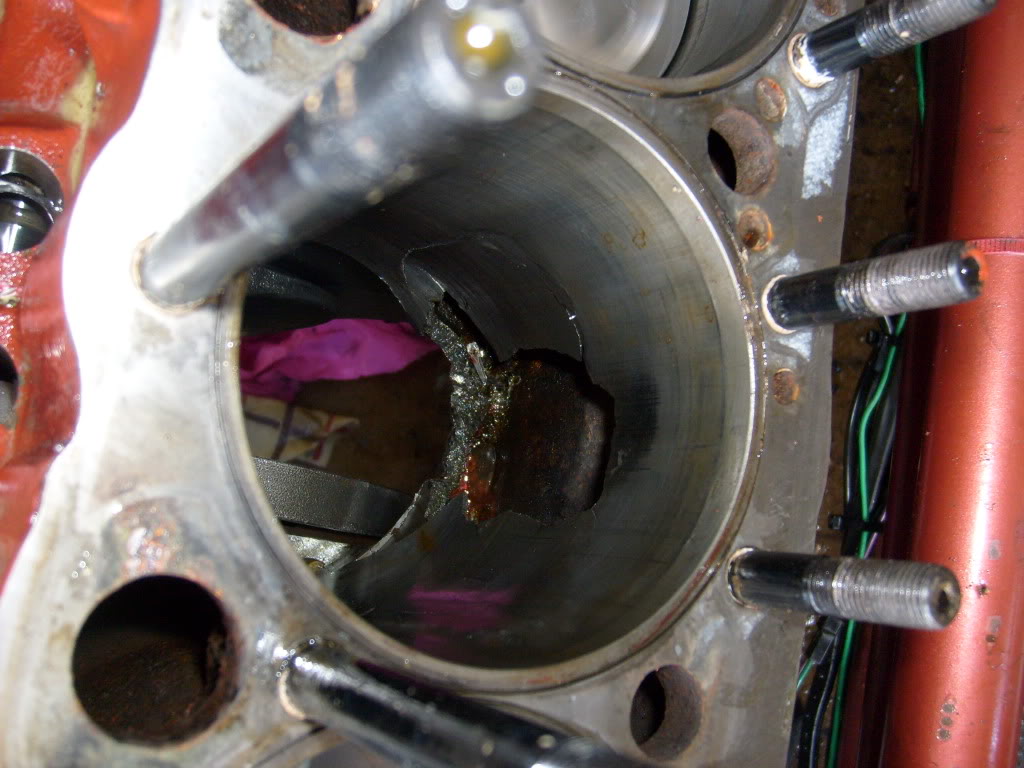

In the eyes of many racers and professional engine builders, this is the most crucial feature. A stock 350 block sends oil to the cam before making its way to the main bearings. As a result, there is a pressure loss due to the complex route the oil has to take before it gets to the mains, and a broken cam or other oiling problem inevitably leads to crankshaft damage. Dart reconfigured the oil passages so the mains are fed with the higher-pressure oil and secondary passages are created for the cam. The added lubrication to the mains will help against spinning or scoring a bearing. I karate chopped the block in half so you can see what it looks like.

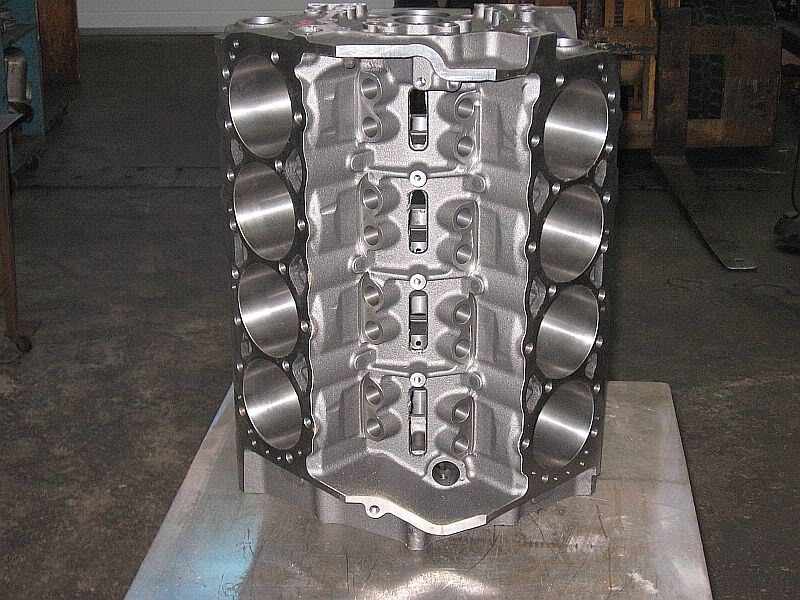

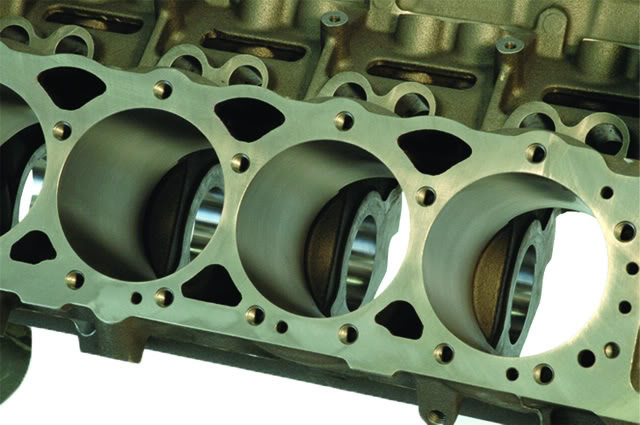

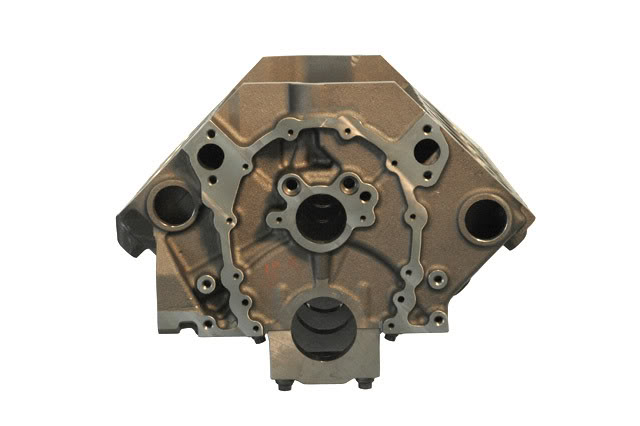

SIAMESED CYLINDER BORES

Instead of cylinders being separated by water jackets, the cylinders tie together (think of two 8’s on their side) and this in turn ties the whole block together. The extra support keeps the cylinder bores round and less likely to go oval under extreme temperature and pressure conditions. The SHP block is offered in a 4” and 4.125” bore diameter.

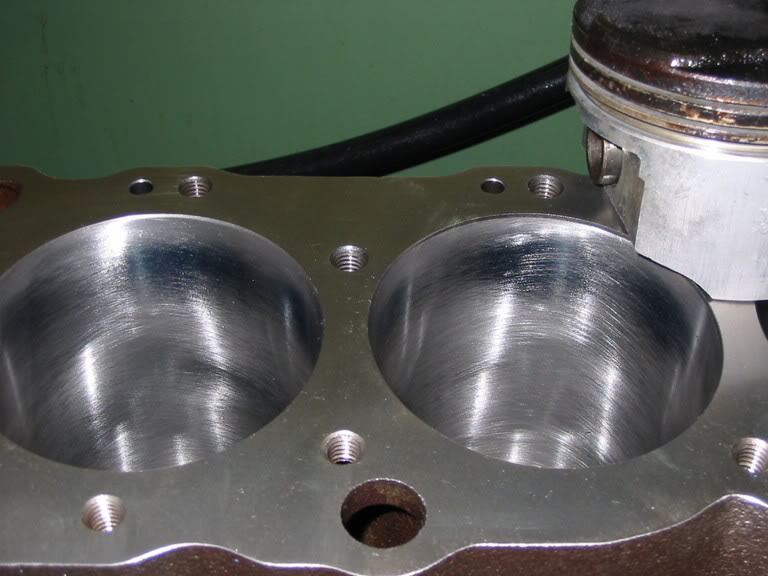

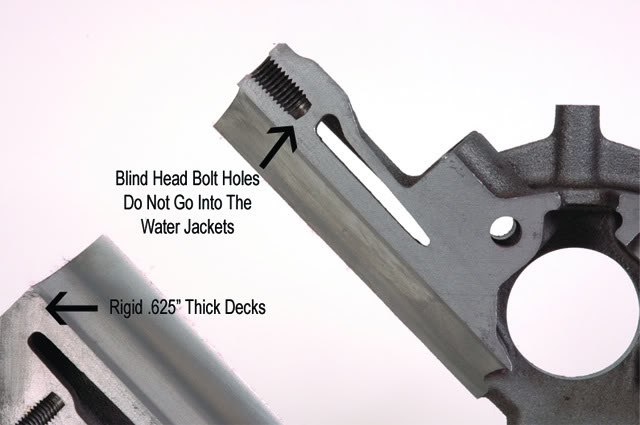

RIGID DECK AND BLIND HOLES

As we mentioned above, the cylinders are tied together from side to side, which adds stability to the bores. Up top, a thick deck ties the block together as well. The SHP .625” minimum deck thickness also plays a huge role in keeping the cylinders round. Having a thicker deck also means it’s more likely to stay flat, which will keep the head gasket happier (and in place). Right below the head bolt holes in the block are the water jackets. Typical stock block design leaves the bottom of these holes open to the water jacket, but the SHP’s blind bolt holes keep the studs out of the water jacket. This also keeps out the need for sealant. One important item to remember when it comes to dealing with blind bolt holes is properly installing the head studs, as they can bottom out – the studs only need to be finger-tight in the block, with the nuts taking the final torque load.

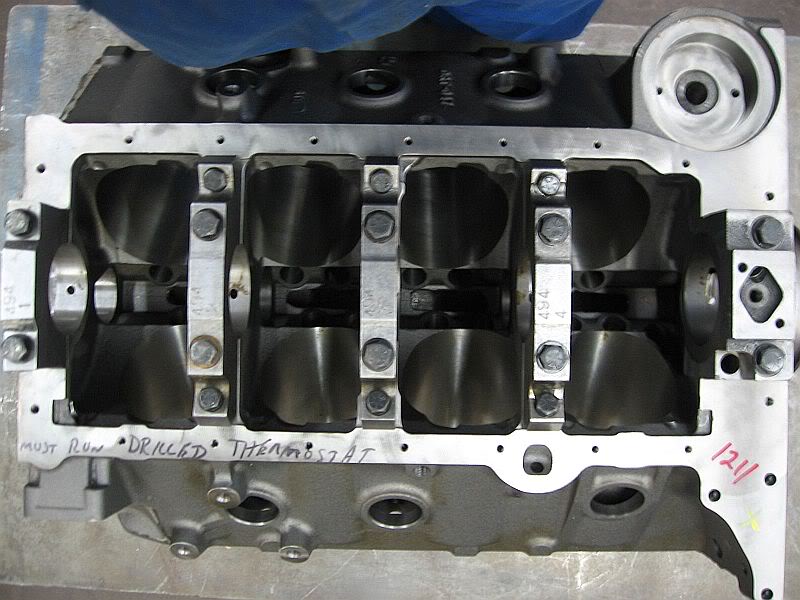

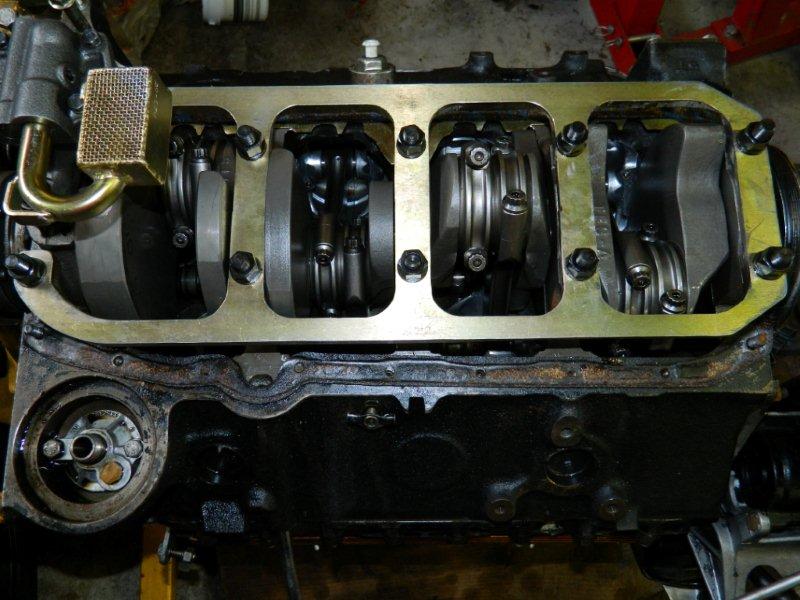

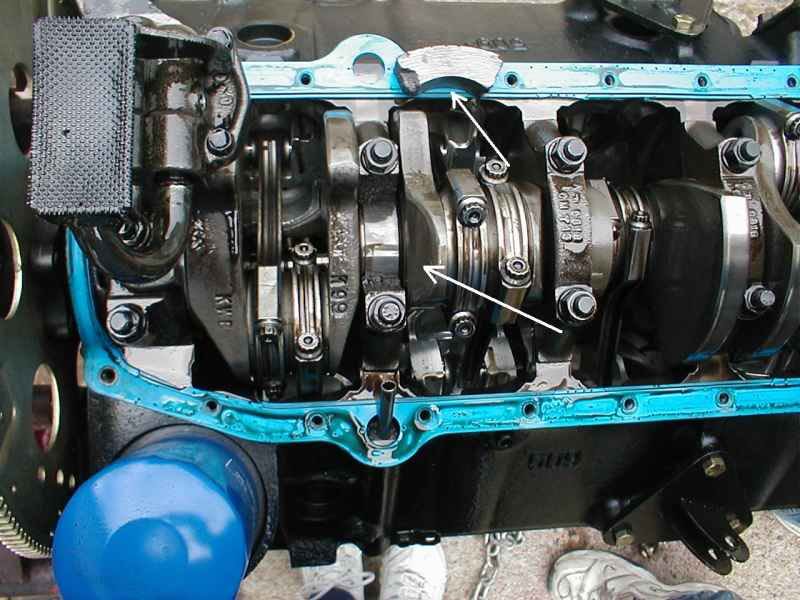

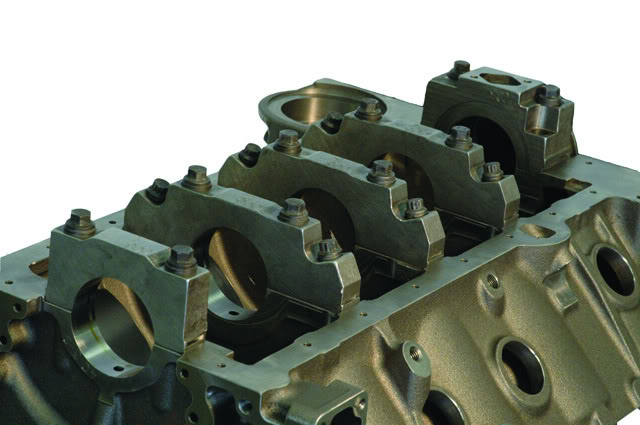

DUCTILE IRON FOUR-BOLT MAIN BEARING CAPS

With the top end properly tied together, Dart turned their attention to keeping the crank in place. The ductile iron main caps are made from the same grade iron found on race blocks. Before you even get the caps on, the block has deep steps to accurately register the dowel pins on the caps, and take side loads off the main bolts. To help tie those caps down are thick 7/16” center bolts. The middle three caps add two additional splayed outer bolts. The outer bolt holes angle towards the meaty center of the block to firmly hold the crank in place. The outer bolts are 3/8” diameter and clear stock-style pans. Those that own a 400 cubic inch small block Chevy know that crank choices are fewer (and often more expensive) than the 350 cubic inch motors. The fact that the SHP block has the same main bearing bore as a 350 opens up a wider variety of off-the-shelf crank choices.

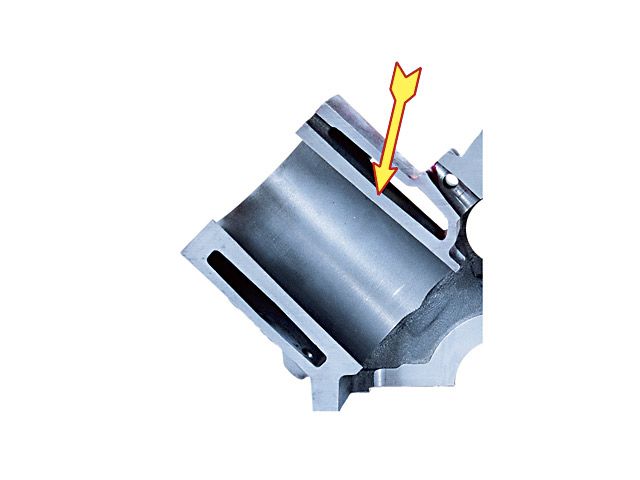

STROKER CRANK CLEARANCE

Our final top five feature is additional stroker crank clearance. Since it costs as much to build a stock-displacement engine as it does to pick up a few more cubes with a long-throw crank, most customers will go for the gusto and build something big. With a stock block, clearance for the big end of the rods has to be gained with a die grinder, but Dart notches the cylinder barrels at the bottom of the SHP block to clear up to a 3.75” stroke. Main bearing bulkheads are also machined for counterweight clearance.

Q&A with Jack McInnis of Dart

What does “Special High Performance” mean?

We decided on the "Special High Performance" name because we felt it was representative of the intent. The new block, [assembled] short blocks, and other products that will be marketed under the SHP name are designed as high performance components, whereas traditionally most of Dart's products have been associated with maximum-effort racing. The SHP block is priced hundreds of dollars lower than a race block, and brings a lot of value to hot rodders, bracket racers, restricted circle track classes, and others.

Look closely and you won’t find a Dart stamp on the block; is SHP its own division?

SHP is a component of Dart intended to serve a specific market segment. It is not a separate company or location.

The reason there is not a Dart logo on the block is because we wanted to allow engine builders to be able to market their own “branded” engines based on this block. Dart has always supported the local engine builders and speed shops; the SHP program is an important part of that support.

How did the whole SHP program come about?

Richard Maskin came up with the idea for the SHP block as a way to support the aftermarket manufacturers, and give local engine builders a way to be competitive with factory crate motors. The local engine builders and mom & pop speed shops built the performance aftermarket through hard work and innovation. Without them you would have no other choices than a factory crate motor, and that would not be a good thing for performance enthusiasts.

How long as this block been in R&D?

About a year and a half. After seeing the increasing presence of factory crate motors at the PRI show in 2006, Richard Maskin realized there was a need to enable the independent engine builders to compete, and a viable block would be essential to do this.

What problems did you face when designing and producing the SHP block?

One of the biggest challenges was that we were determined that the SHP block would be an American-made product. That meant we had to really put some ingenuity into the design of the foundry tooling and the machining process in order to produce a block which lives up to Dart’s standards, and make it at an affordable price.

How did Dart figure out what features to cross over from the higher-end blocks?

That was really the easy part. The priority main oiling system, siamesed cylinder bores, and 4-bolt mains were essential to making a true high-performance block. Things like provisions for dry-sump oiling and billet steel caps are not needed in the applications the SHP block was designed for.

How did Dart find a way to make the SHP block affordable without compromising the features and durability you needed?

This was a challenge, to be able to produce a very high-quality block at the price we were targeting. When we designed the foundry tooling to make the castings, a lot of thought went into simplifying the entire process. The castings incorporate many features which are machined in our race blocks. The way the blocks are machined was completely re-thought as well. We made new fixtures, which allowed us to reduce the total machining time without sacrificing the quality of the finished product. The entire manufacturing process was thoroughly re-examined.

The block looks like a different color compared to your normal iron blocks. Is the metallurgy different, or is it just a cosmetic difference?

The iron alloy differs somewhat from our race blocks. We evaluated the requirements of the SHP design and looked at all the factors which could help reduce the cost without compromising the quality. The alloy used was one of the changes which allow us to bring this block to the market at an affordable price.

Is there a new Ford SHP block on the horizon?

We are looking at the Ford blocks, but due to the fact that there are several versions it is more of a challenge than with the Chevys. We may go down that road in the future; in the mean time we will offer SHP short blocks for Fords based on our Sportsman blocks.

What are the differences in maximum horsepower between the SHP block and your race pieces, and do the SHP blocks require any different treatment by the engine builder?

The SHP block is not intended to accommodate the kind of horsepower levels which are possible with our race blocks. 600 horsepower is the recommended maximum. The SHP block is finish-machined and only requires the engine builder to final-hone the cylinders to suit the pistons before assembly, while race blocks are frequently subject to a variety of customized machining options.

Dart's Short Block Program

Another new venture for Dart is their short-block assembly area. The SHP block has sparked enough interest to have full-time engine builders assembling two variants of the SHP block, a 372 and 400 cubic inch short block. Dart is not trying to compete with their engine builders on these short blocks which is why they are offering them only in limited configurations.

Both engine configurations feature:

• Internal Balance

• Plate Honed

• Hypereutectic Flat Top Pistons with Floating Pin

• Forged 4340 I Beam Rods with 3/8" Cap Screws

• Hastings Moly Rings

• Clevite Bearings

• Coated Cam Bearings

372 will feature

• 4.125" Bore x 3.480" Stroke

• Cast Steel Crank

400 will feature:

• 4.125" Bore x 3.750" Stroke

• Forged 4340 Steel Crank

It’s clear from the parts used that Dart is building these short-blocks with one mission in mind – creating budget engines that make great power, in a professionally-built and thoroughly-tested package.

On a 372 with 180cc Dart heads, the power levels came out to 470 HP at 5600 RPM and 470 foot-pounds at 4000 RPM. On the 400 inch short block, equipped with Dart 200cc heads, power jumped to 525 HP at 6000 RPM and 525 foot pounds at 4000 RPM. Both motors were dynoed with mild hydraulic roller cams. Dart recommends keeping the horsepower to around 600 at the flywheel for any SHP-based build. But here at powerTV we like to push the limits, so we will be doing engine dyno testing that will push the SHP short-block into the low 700 horsepower range with some nitrous. Our short-block is an upgraded package that Dart offers, given our desired power numbers. The difference includes forged pistons and forged H-beam rods. Make sure you check back for updates to see the maximum horsepower per dollar we can get out of this new SHP block.

TECH SPECS

Part# 31161111 (4.000” Bore) / 31161211 (4.125” Bore)

Material: Superior iron alloy

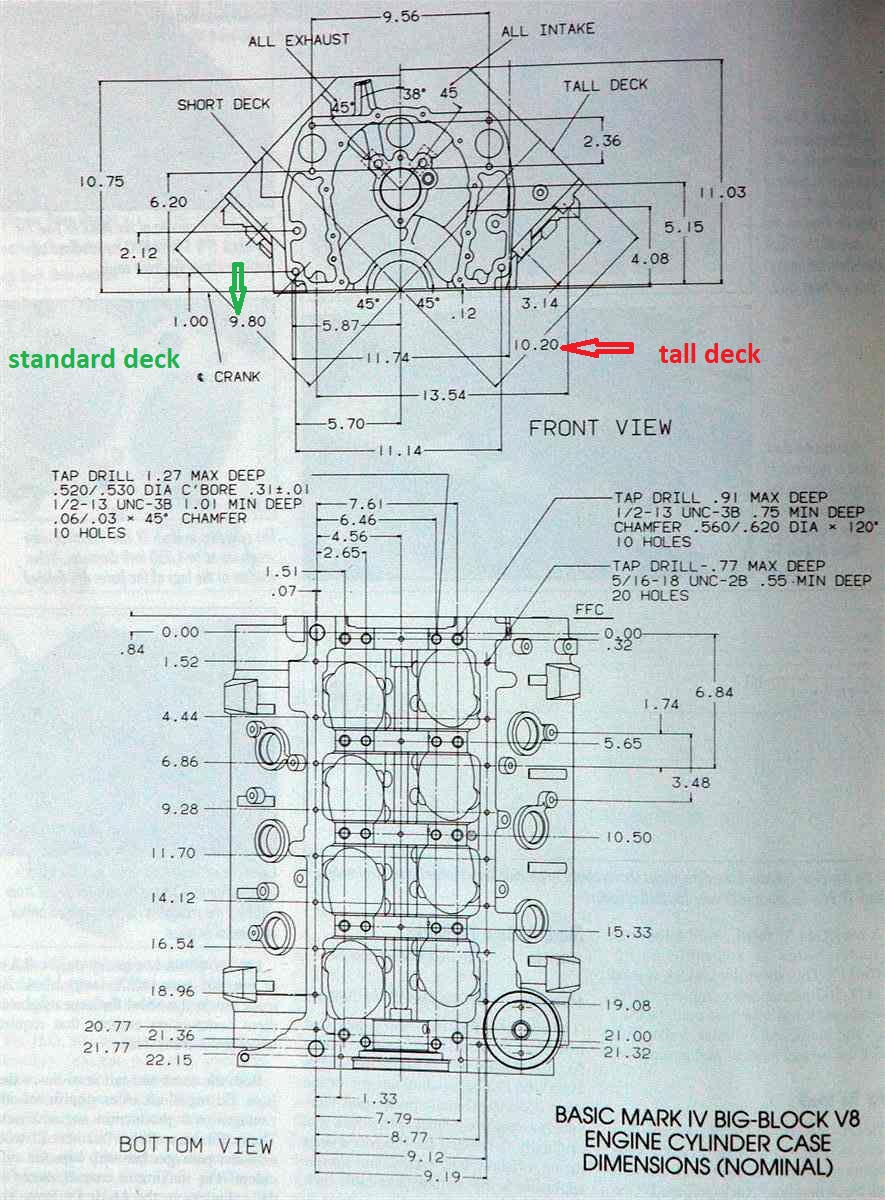

Bore: 4.00” or 4.125” unfinished

Bore & stroke: 4.165” x 3.750” max recommended

Cam bearing bore ID: SBC - 2.00”

Cam bearings: Special coated, grooved, w/3 oil holes (not included)

Cam Bearing O.S. + .010”, +.020”, +.030”

Cam bearing press: .002”

Cam journal OD: Standard SBC - 1.869”

Cam Plug: 2-7/64” Shallow Cup

Cylinder Wall Thickness: .230” min @ 4.165” bore

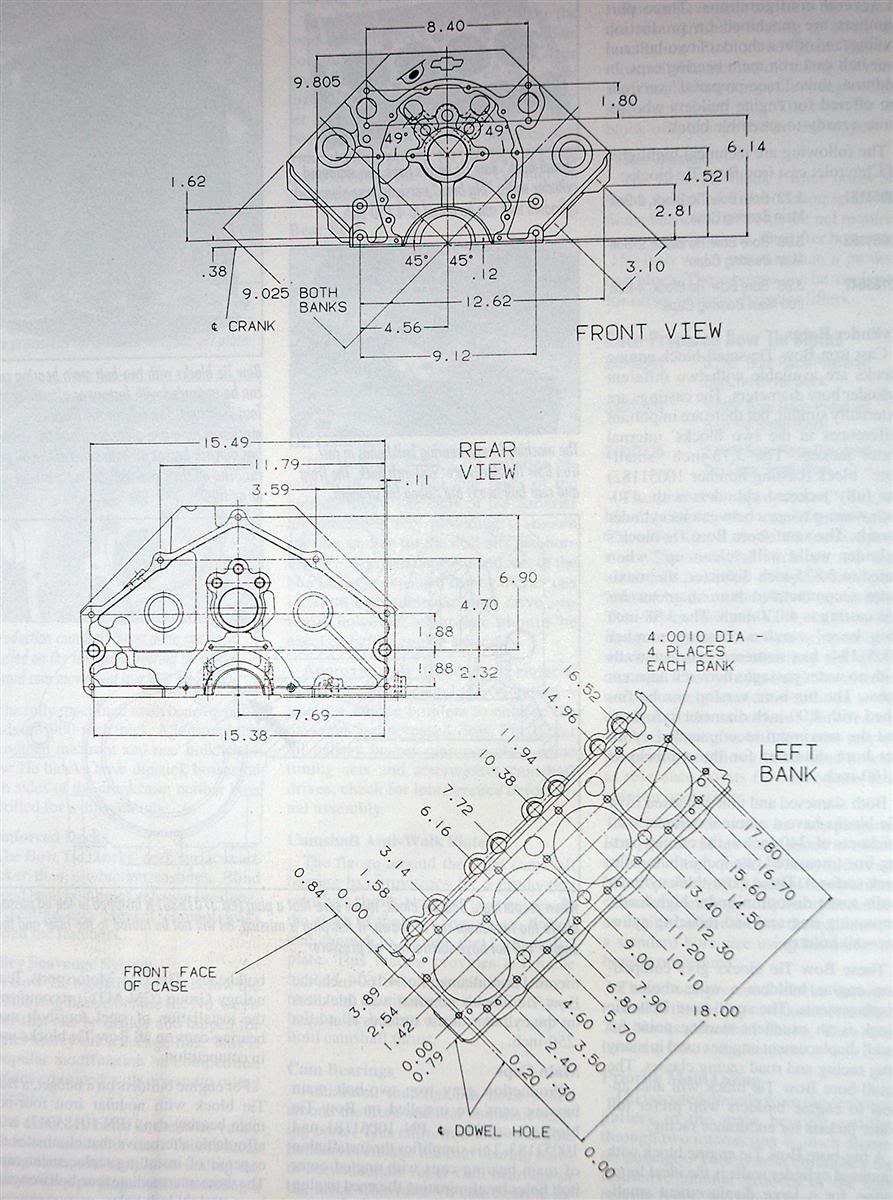

Deck Height: 9.025”

Deck Thickness: .625” min.

Fuel Pump: Mechanical pump provision

Fuel Pump Pushrod: Standard Length

Freeze Plugs: Press in cup plugs – 1-5/8”

Lifter Bores: SBC .8430” - .8440”

Main bearing size: 2.450” (350)

Main bearing bore: (350) 2.6405 – 2.6415

Main Cap Bolts: #1 7/16” (2)

#2, #3, #4 7/16” (2) 3/8” splayed (2)

#5 7/16” (2)

Main caps: Class 35 Iron - 4 bolt, center 3

Main cap register: Deep stepped register on each side (no need for dowels)

Oil system: Wet Sump - Main Priority Oiling

Oil Pump shaft: 350 main = Stock shaft (.481” OD)

Oil Filter: Standard SBC filter, uses 2 bolt filter adapter

Oil Pan: Standard SBC oil pan

Rear Main Seal 350 main - std seal 2-piece

Serial No. Left front & main caps

Starter: Standard SBC

Stud Holes, Head: Blind holes

Timing chain/gears Standard SBC components

Timing Cover: Can use stock cover / Stamped Steel or Plastic

Torque Specs: 7/16” bolts - 65 ft lbs

3/8” bolts - 35 ft lbs

Weight: 175 lbs @ 4.00” bore

Source:

Dart Machinery

Web:

http://www.dartheads.com,

http://www.dartSHP.com

Phone: 248-362-1188