these look great, and theres little doubt they are a quality tool.

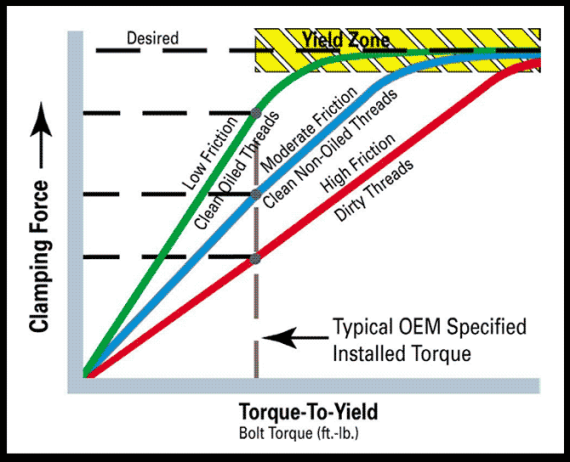

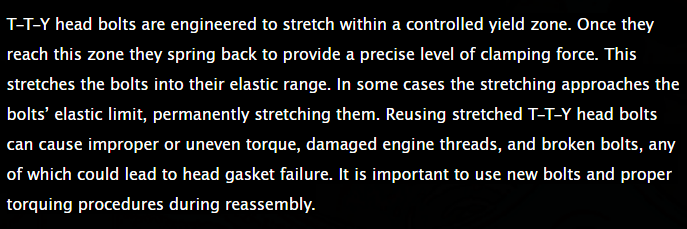

keep in mind the purpose of a torque wrench, its designed to allow you to tighten bolts to a known and consistent and repeatable or duplicate-able level, that insures the bolt or fastened applies a consistent predictable clamping force ...when you fail to clean the threads surfaces on the fastener or the block, your using those fasteners on, or you fail to use the suggested lubricants or sealants on the threads your effectively changing that resulting intended clamping force.

failure to read the directions or randomly changing the sealants or improper use of the torque wrench WILL result in a different clamping force being applied

you'll occasionally see places like NORTHERN TOOL,AND HARBOR FREIGHT, sell click style torque wrenches for $15-$20,

I would not suggest spending money on a HF, or similar dirt cheap torque wrench, simply because, as with most precision tools you tend to get what you pay for to a great degree!

Ive personally tested several against the much more expensive torque wrenches I own,Ive got a large drawer in my tool chest with at least 9 torque wrenches (sears,husky, CDI,SNAP-ON ) plus the fact that the HF sells for less than 7% of the cost, do you really think they can sell a tool for 7%-10% of the cost of what other places charge and have comparable quality and durability/accuracy/

of even the mid priced torque wrenches, cost $80-$180 each that fact alone should, obviously be telling you that theres some reason they are dirt cheap, quality,durability and precision in a tool, or component is rarely dirt cheap yes I own a HF 3/8" drive inch lb torque wrench I bought just to test it against several others , and its not as bad as I expected, but certainly not as consistent as several others I own

1: http://www.emaxaction.com/cdi1503mfrmh.aspx

2: http://www.toolsource.com/torque-wrench-microadj-metal-handle-20150-ftlbs-plain-head-p-95221.html

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://www.eaglerod.com/mosmodule/bolt_torque.html

CONSISTENCY and REPEATABILITY ,rather than exact torque, is the key, if your off a ft lb its not catastrophic.

Ive used both a SEARS and a HOME DEPOT TQ Wrenches FOR MANY YEARS. built over 150 engines and had zero problems

consistent technique and consistency in the way you lube and work the torque loads up in stages and having the bolts and studs lubed and cycling, the bolt/stud up to the recommended torque and loosening it and repeating that process several times tends too give much more consistent clamping load results, AND ITS A GOOD IDEA TOO USE ARP FASTENERS

HARDENED washers DESIGNED FOR USE WITH MATCHING ARP HEAD BOLTS under the head bolt heads are ALWAYS A GOOD IDEA, they reduce friction and gauling and spread the clamp loads and tend to make the torque readings far more consistent, especially on aluminum heads and when the correct lubricants are used , use of standard soft iron washers or lock washers are a bad idea

cleaning threads before assembly is always a good idea

check manufactures tech guide info

having consistent clamp loads are mandatory for proper assembly

THIS BEAM STYLE TORQUE WRENCH<IS THE TYPE TORQUE WRENCH YOU WANT TO CHECK ROTATIONAL RESISTANCE

BUT NOT WHAT YOULL USE TO TIGHTEN HEAD BOLTS

that's why you'll need a torque beam deflection torque wrench to check the resistance to rotation during short block assembly

https://www.amazon.com/Presa-Drive-...ocphy=9012039&hvtargid=pla-669567243785&psc=1

read the labels and load rates carefully before ordering they make inch lb, ft lb versions

1/4",

3/8"

and 1/2"

drive versions

and having an inch lb rated one helps at times $25 on amazon

https://www.amazon.com/Neiko-03727A...ocphy=9012039&hvtargid=pla-572951906812&psc=1

https://www.ebay.com/itm/224242691491?epid=23014633155&_trkparms=ispr=1&hash=item3435e7eda3:g:sBkAAOSw5MFfuDZS&amdata=enc:AQAGAAACoPYe5NmHp%2B2JMhMi7yxGiTJkPrKr5t53CooMSQt2orsSvtkx670Z0mbyfWqmxLFLYbSgftsPKn4P4%2BuyGMgnhW%2FjIce0dpW9M3RoBZspmh1OP12%2B1VAxoUJJj3RoXfTi%2BdPDYwWVpZhnEHOtxRJrO9BgZbW7EgR6P7ToLFxxssR3y9JK0MrcC1gFkn3SW32QlRm1jVDvf75zsqK4K6a3ZYjn8qwXzUYq6h4garZZxJfbfur3C7bxYsXM6Kd0RP%2Bc1qcqgfVJHBlQgVk4udvEWA36jrjTVJl5%2BCY4o1Ivq4bl7iQqsi7Hf9CMDhs1uIRQNOVZaGYqWg9k4J0UBWdzz8l8X%2FOqd9t3DRpXca5J9mjp65pFUANhTN3TfDEtTpSfCkWmlHnqMmYCOvLSwvD1QZMXkSF0aOKRqnGjBtvV0xFal9s9EMVlX8gRTesUivsA%2FodQ%2FlEYPwFdqVXGP1WdDLW4J90gTGRKzasKw%2FOHt7XrubOgzy515noBgagP9s2M1iGfVGLK2dXotGyaTVcSbvCHNSmbSUvaKVX7Jm7hgX3UZIvrnEYFwbpAec4a0%2BqRPqov5SRFpkQ0DGE9tAvXszC8xwzF9%2F%2FxSK%2FPmvpoJ%2FxGmwoio1ZR88UMdq6GHkjzFQIpQE946bHSep0BzmPBPXyILyvAcxWgs1vPcytjTHBLwAMI0lLADbjgWGGJUMAl8nR2wLczSCeJC7Sd5lIfZ%2FPNxz8aB0qf73TtmocTHjhkcVWW3C0bmckieELPrUXPfLp6ltQmqHsGXDFoITaQRs0mPFQ4TRBoUyYcGtfrS8V8XHcQ0TZtCtqoni0tUGwbdHFKQGYpD%2FFFTpEYitoFjODdATrumb5yl7bb5fAiIRVou6oUBD75feDSqdDpB7G23g%3D%3D|ampid L_CLK|clp:2334524

L_CLK|clp:2334524

I generally use CLEVITE (H) bearings as they have a bit more edge to crank journal edge radias clearance for the bearing shell to crank counter weight clearances

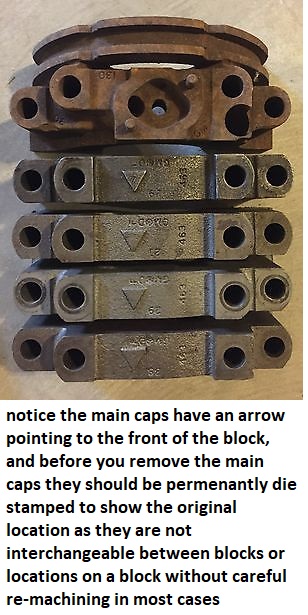

With the crank shaft alone in the main bearings, any inconsistency in the assembly lube thickness, or journal surface finish could and probably will cause a difference in rotational resistance or drag, if it spins fairly easily with a couple fingers on the crank snout with all the mains torqued down and your plastic-gauge checks and micrometers say the bearing clearances are correct your going to be fine, I generally look to have less than 5 ft lbs resistance , on keeping it rotating, once it starts to move, a properly installed strait crank in a properly honed set of main caps with properly clearances main cap bearings well coated with a 50%/50% mix of assembly lube and marvel mystery oil on the bearing crank surfaces and less than 10 lbs to get it to start rotating as the surface tension of most assembly lubes will resist rotation until it starts to rotate, then the resistance to rotation drops off rapidly,

on a newly rebuilt engine the SHORT BLOCK (no heads installed) and with the bearings and cylinder bores oil coated, it should require LESS than 40ft lbs to get rotating and less to keep it rotating, a crank ALONE installed in the correctly tightened main caps should require LESS than 10 lbs to start rotating and far less to keep spinning.

a used engine will develop a bit looser clearances and require LESS force to rotate after the heads are removed.

on a racing engine the crank alone can easily be spun in the main bearings with your fingers and over about 25-28 lbs resistance when using low drag rings usually indicates a problem

a used engine will develop a bit looser clearances and require LESS force to rotate after the heads are removed.

yes having an accurate torque wrench is mandatory when you build an engine, yes having the piston to bore clearance, ring end gap and bearing clearances correct helps a great deal, and yes low tension rings DO tend to reduce the resistance to rotation, and yes, some assembly lubes DO make the engine a bit harder to start the rotation.

obviously a slightly bent crank, inconsistent bearing clearances, non-round crank journals , rough polish surfaces on journals or a block that needs to be line honed or a bent cam or tight cam bearing journals or improper bearing clearance or dry bearing surfaces tend to increase resistance.

IF your engine resists rotation to a higher torque load rate

FIND OUT WHATS BINDING BEFORE PROCEEDING FURTHER, you sure won,t be the first guy to have installed something incorrectly or had the wrong clearance's but catch it BEFORE proceeding further

youll need a good quality torque wrench

and a torque angle gauge

https://www.summitracing.com/parts/otc-4554

https://www.summitracing.com/parts/oes-25424?rrec=true

https://www.harborfreight.com/12-in...MI7pzMt5-Z6QIVSrzACh3a5ABmEAQYASABEgIDiPD_BwE

the new ICON line looks decent

https://www.harborfreight.com/12-in-50-250-ft-lb-professional-torque-wrench-64064.html

https://www.napaonline.com/en/p/BK_7768041

HUSKY $88 (worked rather well, over all I was pleased)

http://www.homedepot.com/p/Husky-1-2-in-Click-Torque-Wrench-H2DTW/202916180?N=5yc1vZc6ev

http://www.homedepot.com/webapp/wcs...langId=-1&catalogId=10053&productId=100058237

http://www.sears.com/shc/s/p_10153_...s&cName=Mechanics+Tools&sName=Torque+Wrenches

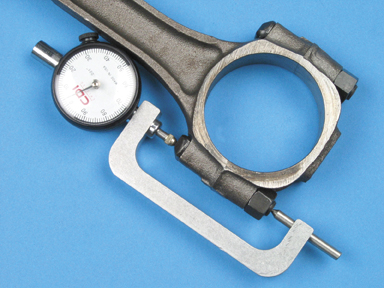

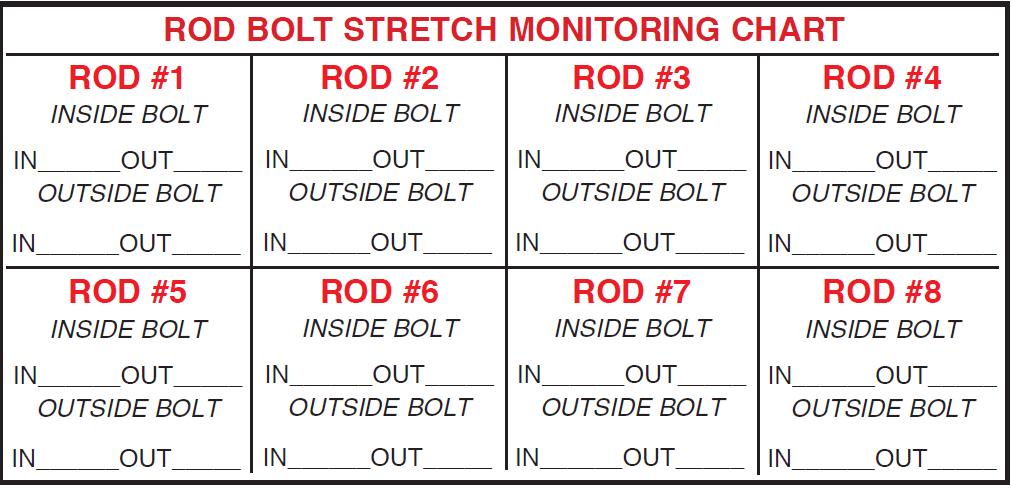

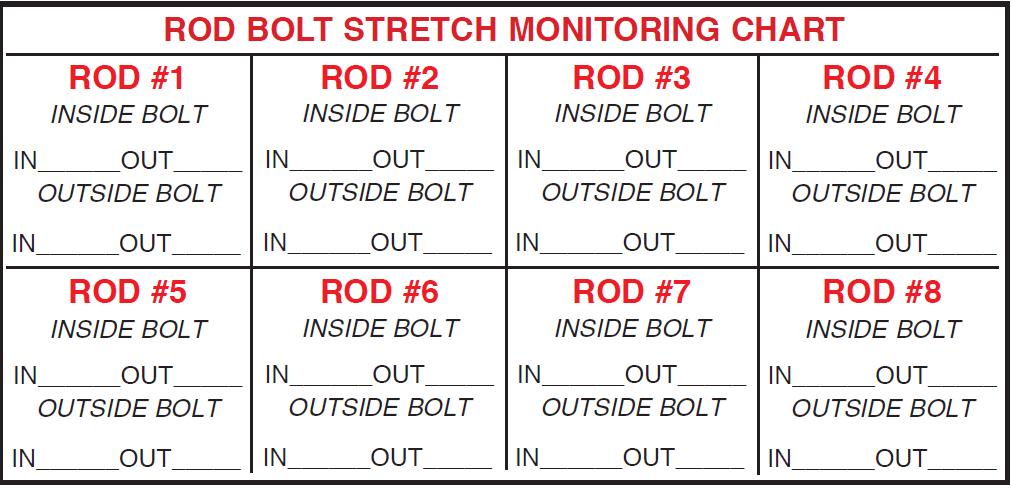

btw rod bolts SHOULD have a stretch gauge used but its not 100% mandatory, cycling them up to spec and releasing the tq then repeating several times with a tq wrench, following the APR instructions gets you very consistent results IVE checked the tq wrench results with the stretch gauge

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ARP-100-9942&N=700+115&autoview=sku

lets assume your looking for a 3/8" drive inch lb torque wrench to tighten little things like intake bolts, logic should tell you that a decent quality tool will not be dirt cheap, and that you don,t need the best available tool for that use so you start pricing your options

the whole OBJECT of you using a torque wrench is to allow you to maintain consistent TORQUE values, do you really think the HF torque wrench will be consistent, when most other sources what 4-5 times as much, think it thru, obviously you don,t need a lab quality tool, but the cheapest option is not likely to be a rational choice either.

harbor freight ($15)

http://www.harborfreight.com/cpi/ctaf/d ... number=807

home depot ($74)

http://www.homedepot.com/h_d1/N-5yc1vZ1 ... ogId=10053

sears($69)

http://www.sears.com/shc/s/p_10153_1260 ... que+wrench

tool source ($57)

http://www.toolsource.com/torque-wrench ... 5_778.html

GOOD QUALITY ($225)

http://www.toolsource.com/dial-dual-sca ... 94631.html

http://shop.advanceautoparts.com/webapp ... P2078_____ ($360)

http://www.webbikeworld.com/r3/torque-wrench/

WATCH THIS VIDEO

http://www.youtube.com/watch?v=zgwwOJ0B ... r_embedded

NEVER USE A TORQUE WRENCH LIKE A BREAKER BAR TO LOOSEN BOLTS as it TENDS TO QUICKLY DESTROY ITS ACCURACY & consistency

http://www.youtube.com/watch?v=zgwwOJ0B ... r_embedded

http://www.eaglerod.com/mosmodule/bolt_torque.html

http://www.harborfreight.com/1-2-half-i ... h-239.html

common, and reasonably accurate

http://www.sears.com/shc/s/p_10153_1260 ... 944593000P

http://www.homedepot.com/h_d1/N-5yc1vZ1 ... ogId=10053

better

http://www.google.com/products/catalog? ... E4Q8wIwAw#

much better

https://www.amazon.com/CDI-Torque-2...ra_a_rv_mr_ho_xx_P1400_1000&tag=dradisplay-20

http://www.sears.com/shc/s/p_10153_1260 ... 0001&aff=Y

http://buy1.snapon.com/catalog/item.asp ... ir=catalog

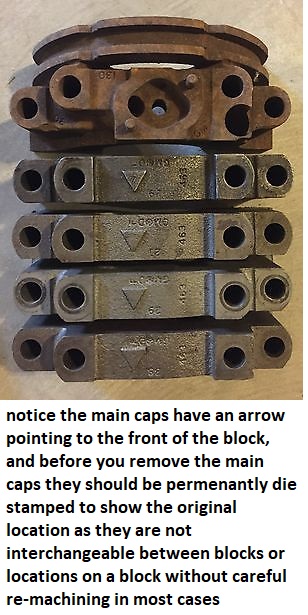

Id point out that a bit of thought as to the direction of forces when your torquing your main caps or trying to rotate your engine location will help a great deal, ESPECIALLY WITH THE SMALLER BASE ENGINE STAND DESIGNS

more than one guy has failed to pay attention to that and placed a good deal of force on the end of a torque wrench or breaker bar and flipped the engine, off balance.....trust me when I say your first instinct is to try and catch or push the engine back as it falls and you are not going to win that contest....if 600-800lb of engines headed to the floor you better NOT get in the way, so its best to use a very stable wide base engine stand and pay attention to keeping forces along the engine block center-line.

this picture (above) tends to make me think this guys NOT thinking that factor thru, moving the handle, on the torque wrench 90 degrees , so hes pulling it inline parallel to the crank center line, rather than at right angles too it, and if possible toward the engine stand base, support, .could lower the engines tendency to tip.

viewtopic.php?f=99&t=3511

SBC HEADS

Big Chevy

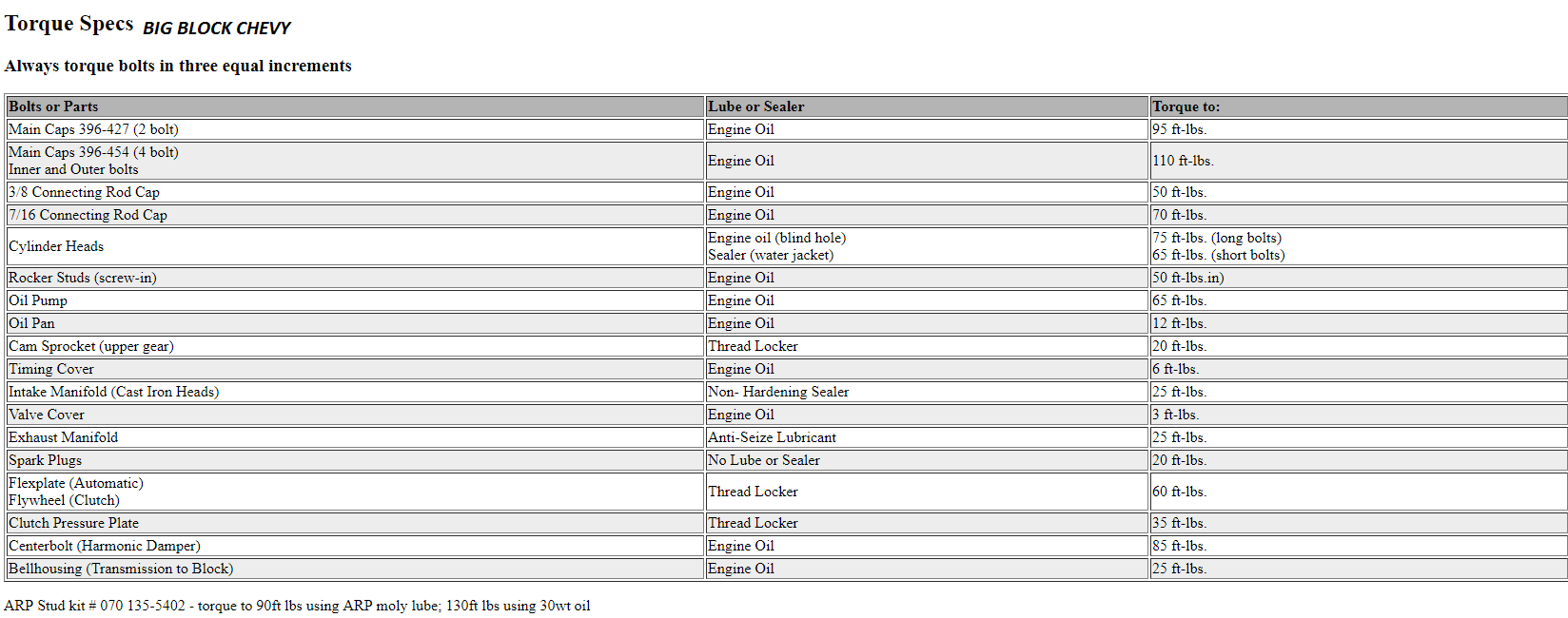

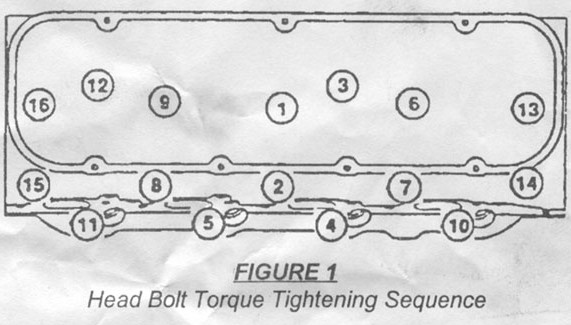

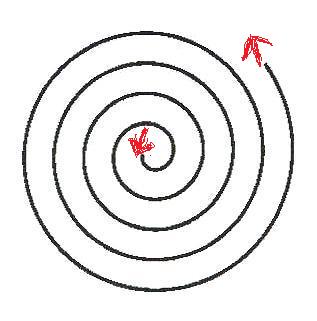

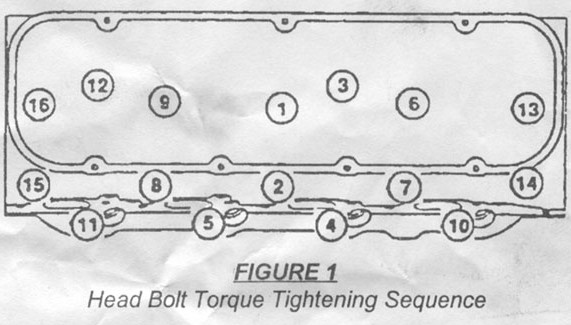

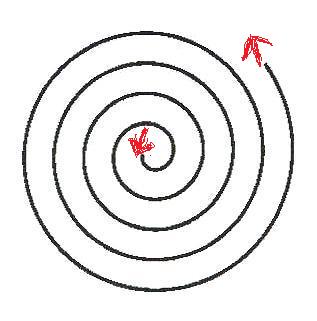

if you don,t have a particular engines torque sequence its a safe bet that you start with the center head bolts and tighten each , in stages in a spiral outward pattern, then repeat the sequence with each increased torque setting moving in that same outward expanding spiral increasing diam spiral moving from the center to outer bolt locations.

dip the head bolt threads in sealant before installation to prevent coolant leaks

http://arp-bolts.com/pages/technical_installation.shtml

keep in mind the purpose of a torque wrench, its designed to allow you to tighten bolts to a known and consistent and repeatable or duplicate-able level, that insures the bolt or fastened applies a consistent predictable clamping force ...when you fail to clean the threads surfaces on the fastener or the block, your using those fasteners on, or you fail to use the suggested lubricants or sealants on the threads your effectively changing that resulting intended clamping force.

failure to read the directions or randomly changing the sealants or improper use of the torque wrench WILL result in a different clamping force being applied

you'll occasionally see places like NORTHERN TOOL,AND HARBOR FREIGHT, sell click style torque wrenches for $15-$20,

I would not suggest spending money on a HF, or similar dirt cheap torque wrench, simply because, as with most precision tools you tend to get what you pay for to a great degree!

Ive personally tested several against the much more expensive torque wrenches I own,Ive got a large drawer in my tool chest with at least 9 torque wrenches (sears,husky, CDI,SNAP-ON ) plus the fact that the HF sells for less than 7% of the cost, do you really think they can sell a tool for 7%-10% of the cost of what other places charge and have comparable quality and durability/accuracy/

of even the mid priced torque wrenches, cost $80-$180 each that fact alone should, obviously be telling you that theres some reason they are dirt cheap, quality,durability and precision in a tool, or component is rarely dirt cheap yes I own a HF 3/8" drive inch lb torque wrench I bought just to test it against several others , and its not as bad as I expected, but certainly not as consistent as several others I own

1: http://www.emaxaction.com/cdi1503mfrmh.aspx

2: http://www.toolsource.com/torque-wrench-microadj-metal-handle-20150-ftlbs-plain-head-p-95221.html

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://www.eaglerod.com/mosmodule/bolt_torque.html

CONSISTENCY and REPEATABILITY ,rather than exact torque, is the key, if your off a ft lb its not catastrophic.

Ive used both a SEARS and a HOME DEPOT TQ Wrenches FOR MANY YEARS. built over 150 engines and had zero problems

consistent technique and consistency in the way you lube and work the torque loads up in stages and having the bolts and studs lubed and cycling, the bolt/stud up to the recommended torque and loosening it and repeating that process several times tends too give much more consistent clamping load results, AND ITS A GOOD IDEA TOO USE ARP FASTENERS

HARDENED washers DESIGNED FOR USE WITH MATCHING ARP HEAD BOLTS under the head bolt heads are ALWAYS A GOOD IDEA, they reduce friction and gauling and spread the clamp loads and tend to make the torque readings far more consistent, especially on aluminum heads and when the correct lubricants are used , use of standard soft iron washers or lock washers are a bad idea

cleaning threads before assembly is always a good idea

check manufactures tech guide info

having consistent clamp loads are mandatory for proper assembly

THIS BEAM STYLE TORQUE WRENCH<IS THE TYPE TORQUE WRENCH YOU WANT TO CHECK ROTATIONAL RESISTANCE

BUT NOT WHAT YOULL USE TO TIGHTEN HEAD BOLTS

that's why you'll need a torque beam deflection torque wrench to check the resistance to rotation during short block assembly

https://www.amazon.com/Presa-Drive-...ocphy=9012039&hvtargid=pla-669567243785&psc=1

read the labels and load rates carefully before ordering they make inch lb, ft lb versions

1/4",

3/8"

and 1/2"

drive versions

and having an inch lb rated one helps at times $25 on amazon

https://www.amazon.com/Neiko-03727A...ocphy=9012039&hvtargid=pla-572951906812&psc=1

https://www.ebay.com/itm/224242691491?epid=23014633155&_trkparms=ispr=1&hash=item3435e7eda3:g:sBkAAOSw5MFfuDZS&amdata=enc:AQAGAAACoPYe5NmHp%2B2JMhMi7yxGiTJkPrKr5t53CooMSQt2orsSvtkx670Z0mbyfWqmxLFLYbSgftsPKn4P4%2BuyGMgnhW%2FjIce0dpW9M3RoBZspmh1OP12%2B1VAxoUJJj3RoXfTi%2BdPDYwWVpZhnEHOtxRJrO9BgZbW7EgR6P7ToLFxxssR3y9JK0MrcC1gFkn3SW32QlRm1jVDvf75zsqK4K6a3ZYjn8qwXzUYq6h4garZZxJfbfur3C7bxYsXM6Kd0RP%2Bc1qcqgfVJHBlQgVk4udvEWA36jrjTVJl5%2BCY4o1Ivq4bl7iQqsi7Hf9CMDhs1uIRQNOVZaGYqWg9k4J0UBWdzz8l8X%2FOqd9t3DRpXca5J9mjp65pFUANhTN3TfDEtTpSfCkWmlHnqMmYCOvLSwvD1QZMXkSF0aOKRqnGjBtvV0xFal9s9EMVlX8gRTesUivsA%2FodQ%2FlEYPwFdqVXGP1WdDLW4J90gTGRKzasKw%2FOHt7XrubOgzy515noBgagP9s2M1iGfVGLK2dXotGyaTVcSbvCHNSmbSUvaKVX7Jm7hgX3UZIvrnEYFwbpAec4a0%2BqRPqov5SRFpkQ0DGE9tAvXszC8xwzF9%2F%2FxSK%2FPmvpoJ%2FxGmwoio1ZR88UMdq6GHkjzFQIpQE946bHSep0BzmPBPXyILyvAcxWgs1vPcytjTHBLwAMI0lLADbjgWGGJUMAl8nR2wLczSCeJC7Sd5lIfZ%2FPNxz8aB0qf73TtmocTHjhkcVWW3C0bmckieELPrUXPfLp6ltQmqHsGXDFoITaQRs0mPFQ4TRBoUyYcGtfrS8V8XHcQ0TZtCtqoni0tUGwbdHFKQGYpD%2FFFTpEYitoFjODdATrumb5yl7bb5fAiIRVou6oUBD75feDSqdDpB7G23g%3D%3D|ampid

I generally use CLEVITE (H) bearings as they have a bit more edge to crank journal edge radias clearance for the bearing shell to crank counter weight clearances

With the crank shaft alone in the main bearings, any inconsistency in the assembly lube thickness, or journal surface finish could and probably will cause a difference in rotational resistance or drag, if it spins fairly easily with a couple fingers on the crank snout with all the mains torqued down and your plastic-gauge checks and micrometers say the bearing clearances are correct your going to be fine, I generally look to have less than 5 ft lbs resistance , on keeping it rotating, once it starts to move, a properly installed strait crank in a properly honed set of main caps with properly clearances main cap bearings well coated with a 50%/50% mix of assembly lube and marvel mystery oil on the bearing crank surfaces and less than 10 lbs to get it to start rotating as the surface tension of most assembly lubes will resist rotation until it starts to rotate, then the resistance to rotation drops off rapidly,

on a newly rebuilt engine the SHORT BLOCK (no heads installed) and with the bearings and cylinder bores oil coated, it should require LESS than 40ft lbs to get rotating and less to keep it rotating, a crank ALONE installed in the correctly tightened main caps should require LESS than 10 lbs to start rotating and far less to keep spinning.

a used engine will develop a bit looser clearances and require LESS force to rotate after the heads are removed.

on a racing engine the crank alone can easily be spun in the main bearings with your fingers and over about 25-28 lbs resistance when using low drag rings usually indicates a problem

a used engine will develop a bit looser clearances and require LESS force to rotate after the heads are removed.

yes having an accurate torque wrench is mandatory when you build an engine, yes having the piston to bore clearance, ring end gap and bearing clearances correct helps a great deal, and yes low tension rings DO tend to reduce the resistance to rotation, and yes, some assembly lubes DO make the engine a bit harder to start the rotation.

obviously a slightly bent crank, inconsistent bearing clearances, non-round crank journals , rough polish surfaces on journals or a block that needs to be line honed or a bent cam or tight cam bearing journals or improper bearing clearance or dry bearing surfaces tend to increase resistance.

IF your engine resists rotation to a higher torque load rate

FIND OUT WHATS BINDING BEFORE PROCEEDING FURTHER, you sure won,t be the first guy to have installed something incorrectly or had the wrong clearance's but catch it BEFORE proceeding further

youll need a good quality torque wrench

and a torque angle gauge

https://www.summitracing.com/parts/otc-4554

https://www.summitracing.com/parts/oes-25424?rrec=true

https://www.harborfreight.com/12-in...MI7pzMt5-Z6QIVSrzACh3a5ABmEAQYASABEgIDiPD_BwE

the new ICON line looks decent

https://www.harborfreight.com/12-in-50-250-ft-lb-professional-torque-wrench-64064.html

https://www.napaonline.com/en/p/BK_7768041

HUSKY $88 (worked rather well, over all I was pleased)

http://www.homedepot.com/p/Husky-1-2-in-Click-Torque-Wrench-H2DTW/202916180?N=5yc1vZc6ev

http://www.homedepot.com/webapp/wcs...langId=-1&catalogId=10053&productId=100058237

http://www.sears.com/shc/s/p_10153_...s&cName=Mechanics+Tools&sName=Torque+Wrenches

btw rod bolts SHOULD have a stretch gauge used but its not 100% mandatory, cycling them up to spec and releasing the tq then repeating several times with a tq wrench, following the APR instructions gets you very consistent results IVE checked the tq wrench results with the stretch gauge

http://store.summitracing.com/partdetail.asp?autofilter=1&part=ARP-100-9942&N=700+115&autoview=sku

lets assume your looking for a 3/8" drive inch lb torque wrench to tighten little things like intake bolts, logic should tell you that a decent quality tool will not be dirt cheap, and that you don,t need the best available tool for that use so you start pricing your options

the whole OBJECT of you using a torque wrench is to allow you to maintain consistent TORQUE values, do you really think the HF torque wrench will be consistent, when most other sources what 4-5 times as much, think it thru, obviously you don,t need a lab quality tool, but the cheapest option is not likely to be a rational choice either.

harbor freight ($15)

http://www.harborfreight.com/cpi/ctaf/d ... number=807

home depot ($74)

http://www.homedepot.com/h_d1/N-5yc1vZ1 ... ogId=10053

sears($69)

http://www.sears.com/shc/s/p_10153_1260 ... que+wrench

tool source ($57)

http://www.toolsource.com/torque-wrench ... 5_778.html

GOOD QUALITY ($225)

http://www.toolsource.com/dial-dual-sca ... 94631.html

http://shop.advanceautoparts.com/webapp ... P2078_____ ($360)

http://www.webbikeworld.com/r3/torque-wrench/

WATCH THIS VIDEO

http://www.youtube.com/watch?v=zgwwOJ0B ... r_embedded

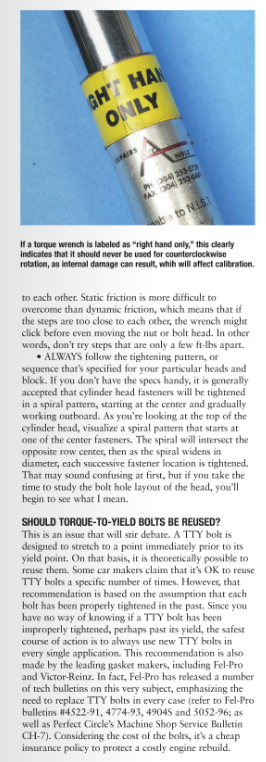

NEVER USE A TORQUE WRENCH LIKE A BREAKER BAR TO LOOSEN BOLTS as it TENDS TO QUICKLY DESTROY ITS ACCURACY & consistency

http://www.youtube.com/watch?v=zgwwOJ0B ... r_embedded

http://www.eaglerod.com/mosmodule/bolt_torque.html

http://www.harborfreight.com/1-2-half-i ... h-239.html

common, and reasonably accurate

http://www.sears.com/shc/s/p_10153_1260 ... 944593000P

http://www.homedepot.com/h_d1/N-5yc1vZ1 ... ogId=10053

better

http://www.google.com/products/catalog? ... E4Q8wIwAw#

much better

https://www.amazon.com/CDI-Torque-2...ra_a_rv_mr_ho_xx_P1400_1000&tag=dradisplay-20

http://www.sears.com/shc/s/p_10153_1260 ... 0001&aff=Y

http://buy1.snapon.com/catalog/item.asp ... ir=catalog

Id point out that a bit of thought as to the direction of forces when your torquing your main caps or trying to rotate your engine location will help a great deal, ESPECIALLY WITH THE SMALLER BASE ENGINE STAND DESIGNS

more than one guy has failed to pay attention to that and placed a good deal of force on the end of a torque wrench or breaker bar and flipped the engine, off balance.....trust me when I say your first instinct is to try and catch or push the engine back as it falls and you are not going to win that contest....if 600-800lb of engines headed to the floor you better NOT get in the way, so its best to use a very stable wide base engine stand and pay attention to keeping forces along the engine block center-line.

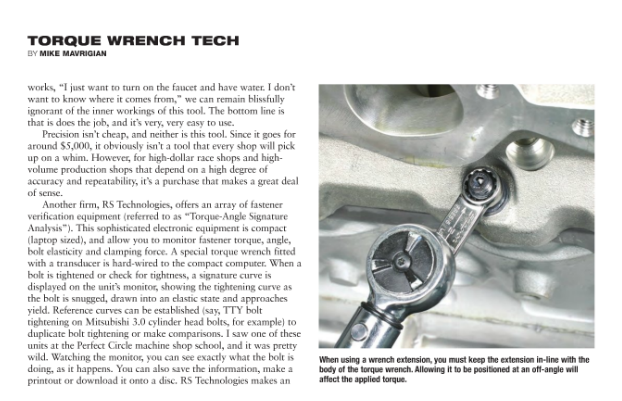

this picture (above) tends to make me think this guys NOT thinking that factor thru, moving the handle, on the torque wrench 90 degrees , so hes pulling it inline parallel to the crank center line, rather than at right angles too it, and if possible toward the engine stand base, support, .could lower the engines tendency to tip.

viewtopic.php?f=99&t=3511

SBC HEADS

Big Chevy

if you don,t have a particular engines torque sequence its a safe bet that you start with the center head bolts and tighten each , in stages in a spiral outward pattern, then repeat the sequence with each increased torque setting moving in that same outward expanding spiral increasing diam spiral moving from the center to outer bolt locations.

dip the head bolt threads in sealant before installation to prevent coolant leaks

http://arp-bolts.com/pages/technical_installation.shtml

Last edited by a moderator: