I have a strong engineering (paperwork too prove it)back ground,

and occasionally I see things that make me convinced that G.M. in the later 1970s-too-current

hire guys off the street, or local drug rehab hospitals,

to be engine accessory designers ,

who are instructed to find ways to make mechanics lives more difficult.

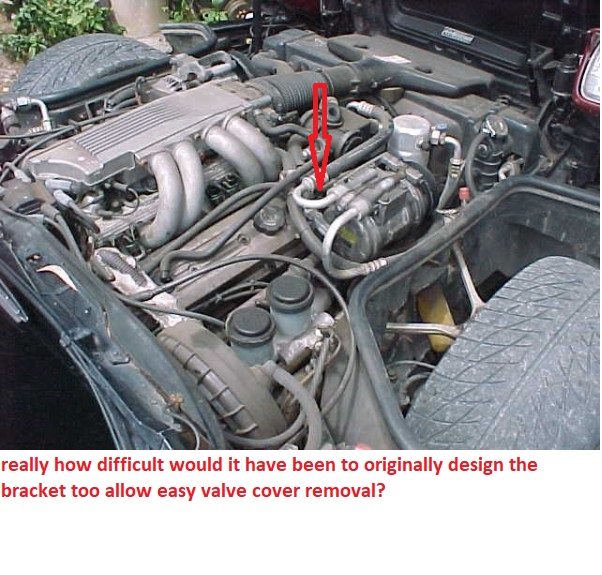

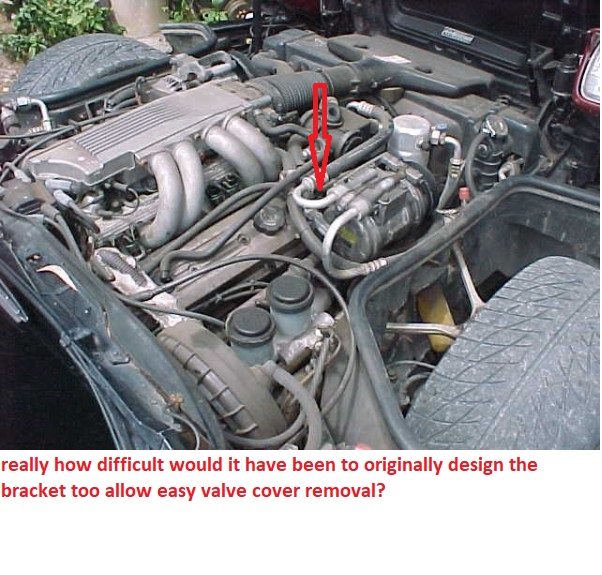

the pass side valve cover will not be easily removed for valve adjustments,

without removing the fan belt and loosening the air conditioner bracket,

it only needs to go about 1/2"-3/4" forward ,

or out away from the cylinder head side ways, toward the wheel well,

about the same distance,to clear,

but surely a bit more thought going into the process would have made this far less time intensive and difficult,

if the bracket and hose lay-out was only marginally,moved or changed,

moving the whole bracket/compressor deal slightly,

would have made the whole process far easier,

and while I'm bitching, who ever designed the dip stick,

and cylinder head heat sensor location,

should be right there also.

heres a standard drive vette

yes Im aware this is a right hand drive car (below)

but the location and bracket did not change

this 1989 is A P.I.T.A.

the earlier 1984-87 c4 corvettes were easy to access

obviously the engineer designing the alternator bracket had worked on cars and had some sympathy for mechanics

and occasionally I see things that make me convinced that G.M. in the later 1970s-too-current

hire guys off the street, or local drug rehab hospitals,

to be engine accessory designers ,

who are instructed to find ways to make mechanics lives more difficult.

the pass side valve cover will not be easily removed for valve adjustments,

without removing the fan belt and loosening the air conditioner bracket,

it only needs to go about 1/2"-3/4" forward ,

or out away from the cylinder head side ways, toward the wheel well,

about the same distance,to clear,

but surely a bit more thought going into the process would have made this far less time intensive and difficult,

if the bracket and hose lay-out was only marginally,moved or changed,

moving the whole bracket/compressor deal slightly,

would have made the whole process far easier,

and while I'm bitching, who ever designed the dip stick,

and cylinder head heat sensor location,

should be right there also.

heres a standard drive vette

yes Im aware this is a right hand drive car (below)

but the location and bracket did not change

this 1989 is A P.I.T.A.

the earlier 1984-87 c4 corvettes were easy to access

obviously the engineer designing the alternator bracket had worked on cars and had some sympathy for mechanics

Last edited: