I recently had a guy ask me what valve spring he should use on his rebuilt corvette hydraulic roller cam, engine.

I strongly suggested he discuss the choice of valve springs with the cam manufacturer, and NOT JUST TAKE MY WORD or ANY ONES WORD, but too DO SOME RESEARCH ON THE ISSUE! and not to select the least expensive parts he could locate, and to always ask if there was any thing to be gained or potential problems that might occur if better springs were installed

now anyone with a functional brain cell should realize that if your given a choice between two different valve spring sets and one set cost $40 and a different set costs $240 that theres got to be a few differences in quality because no vendor is going to stay in business selling $40 springs for $240 available some place else for $40, theres always a reason, and its up to the purchaser to ask questions

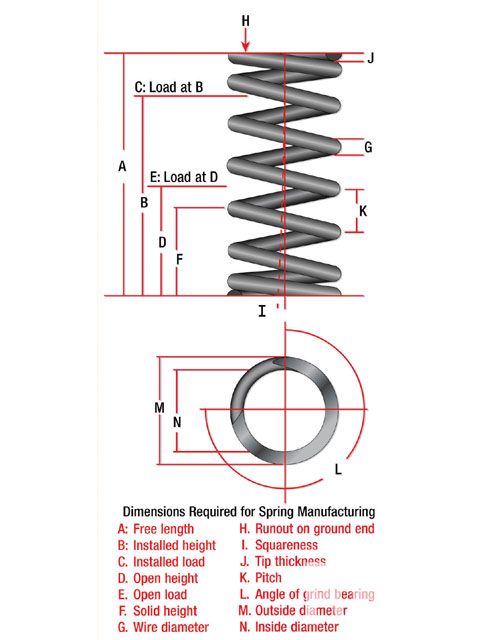

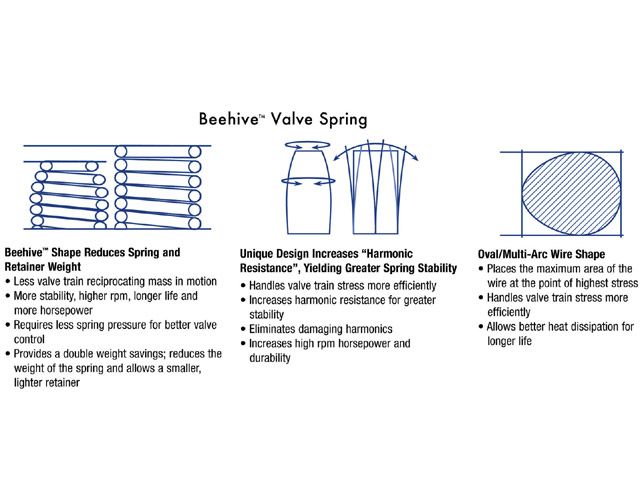

it should be rather obvious that you can,t compare directly cheaper OEM valve springs with better aftermarket springs and that the more expensive springs allow greater valve lifts and more clearance, and frequently are designed too use smaller lighter weight retainers

yeah! you may have guessed he at first selected the dirt cheap factory replacement springs and even though they worked he felt that the engine should pull a bit harder, so after several discussions the topic of the correct valve train geometry and valve springs was re-discussed and the decision was made to (TRY to do things correctly, and BEHOLD THERE WAS AN IMPROVEMENT! AMAZING

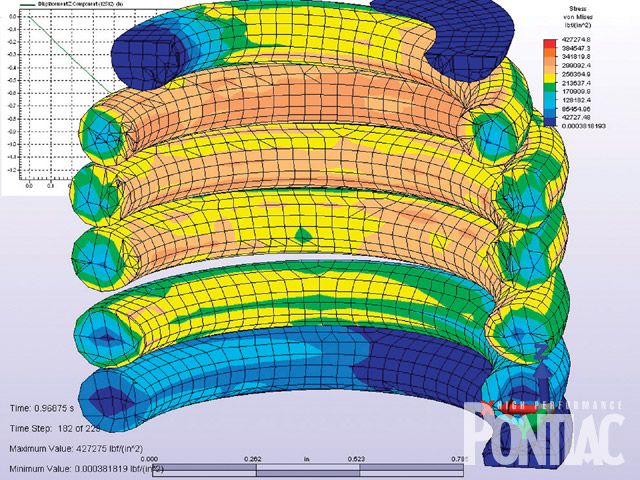

heres an example of two totally different valve springs that were used on the same heads and "amazingly" the more expensive springs and lighter retainers added about 800rpm to the engines power curve.....its amazing to some people that theres differences in quality but trust me THERE IS and you tend to get what you pay for!, if you ever wonder why some guys have an engine that can pull 6500rpm when a very similar engine seems to get into valve control issues at about 5700rpm, theres a reason

Part# PAC-1283

Weight 73.00 grams

Large End I.D. 0.845

Large End O.D. 1.25

InstallLoad 110.0

Install Height 1.750

Open Load 328.0

Open Height 1.150

Coil Bind Max 1.080

Lift Max 0.600

Frequency Base 33960

$240

http://www.racingsprings.com/Store/Prod ... ductID=213

http://www.racingsprings.com/ShoppingCa ... p?Buffer=1

Part Number:

12495494

Brand:

GM Performance Parts

SKU: 12495494

$40

This GM Performance Parts high performance Single Valve Spring has an outer diameter of 1.32". The kit includes 16 P/N 12551483 valve springs. This spring was originally used on 1996 LT4 Corvette Small Block Chevrolet engines.

Technical Note: Not recommended for cam lift over .525".

LT4 SB Chevrolet Valve Spring Kit (12495494) Specifications

Coil Bind (in.): 1.220

Installed Height (in.): 101 lbs. @ 1.780

Outside Diameter (in.): 1.32

http://sdparts.com/details/gm-performan ... s/12495494

related threads

viewtopic.php?f=52&t=181&p=215#p215

viewtopic.php?f=52&t=3124&p=9141&hilit=beehive#p9141

viewtopic.php?f=52&t=1716&p=4250&hilit=beehive#p4250

viewtopic.php?f=52&t=1005&p=1818#p1818

http://forum.grumpysperformance.com...=5522&p=16620&hilit=rocker+stud+girdle#p16620

WATCH THE VIDEO

http://howautowork.com/part_1/ch_1/valve_spring_22.html

I strongly suggested he discuss the choice of valve springs with the cam manufacturer, and NOT JUST TAKE MY WORD or ANY ONES WORD, but too DO SOME RESEARCH ON THE ISSUE! and not to select the least expensive parts he could locate, and to always ask if there was any thing to be gained or potential problems that might occur if better springs were installed

now anyone with a functional brain cell should realize that if your given a choice between two different valve spring sets and one set cost $40 and a different set costs $240 that theres got to be a few differences in quality because no vendor is going to stay in business selling $40 springs for $240 available some place else for $40, theres always a reason, and its up to the purchaser to ask questions

it should be rather obvious that you can,t compare directly cheaper OEM valve springs with better aftermarket springs and that the more expensive springs allow greater valve lifts and more clearance, and frequently are designed too use smaller lighter weight retainers

yeah! you may have guessed he at first selected the dirt cheap factory replacement springs and even though they worked he felt that the engine should pull a bit harder, so after several discussions the topic of the correct valve train geometry and valve springs was re-discussed and the decision was made to (TRY to do things correctly, and BEHOLD THERE WAS AN IMPROVEMENT! AMAZING

heres an example of two totally different valve springs that were used on the same heads and "amazingly" the more expensive springs and lighter retainers added about 800rpm to the engines power curve.....its amazing to some people that theres differences in quality but trust me THERE IS and you tend to get what you pay for!, if you ever wonder why some guys have an engine that can pull 6500rpm when a very similar engine seems to get into valve control issues at about 5700rpm, theres a reason

Part# PAC-1283

Weight 73.00 grams

Large End I.D. 0.845

Large End O.D. 1.25

InstallLoad 110.0

Install Height 1.750

Open Load 328.0

Open Height 1.150

Coil Bind Max 1.080

Lift Max 0.600

Frequency Base 33960

$240

http://www.racingsprings.com/Store/Prod ... ductID=213

http://www.racingsprings.com/ShoppingCa ... p?Buffer=1

Part Number:

12495494

Brand:

GM Performance Parts

SKU: 12495494

$40

This GM Performance Parts high performance Single Valve Spring has an outer diameter of 1.32". The kit includes 16 P/N 12551483 valve springs. This spring was originally used on 1996 LT4 Corvette Small Block Chevrolet engines.

Technical Note: Not recommended for cam lift over .525".

LT4 SB Chevrolet Valve Spring Kit (12495494) Specifications

Coil Bind (in.): 1.220

Installed Height (in.): 101 lbs. @ 1.780

Outside Diameter (in.): 1.32

http://sdparts.com/details/gm-performan ... s/12495494

related threads

viewtopic.php?f=52&t=181&p=215#p215

viewtopic.php?f=52&t=3124&p=9141&hilit=beehive#p9141

viewtopic.php?f=52&t=1716&p=4250&hilit=beehive#p4250

viewtopic.php?f=52&t=1005&p=1818#p1818

http://forum.grumpysperformance.com...=5522&p=16620&hilit=rocker+stud+girdle#p16620

WATCH THE VIDEO

http://howautowork.com/part_1/ch_1/valve_spring_22.html