You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wisps Of Smoke Coming From Breather

- Thread starter DorianL

- Start date

" the answer is it may be"

and depends on several factors , like how well the ring to bore seal is,

effective compression ratio, valve seal, and engine oil control,

and yes in most cases you can increase the effective crank case vacuum,

to eliminate the issue but it might require mods to the engine,

related threads

http://garage.grumpysperformance.co...breather-hole-in-valve-covers.2005/#post-5328

http://garage.grumpysperformance.com/index.php?threads/need-help-with-evac-system.15939/#post-95997

http://garage.grumpysperformance.com/index.php?threads/catch-can-related-info.4636/#post-12451

http://garage.grumpysperformance.co...w-engine-smokes-at-start-up.15778/#post-94476

http://garage.grumpysperformance.com/index.php?threads/leakdown-compression-test.881/#post-56489

http://garage.grumpysperformance.com/index.php?threads/pcv-system-routing.10999/#post-48572

https://auto.howstuffworks.com/positive-crankcase-ventilation-system.htm

and depends on several factors , like how well the ring to bore seal is,

effective compression ratio, valve seal, and engine oil control,

and yes in most cases you can increase the effective crank case vacuum,

to eliminate the issue but it might require mods to the engine,

related threads

http://garage.grumpysperformance.co...breather-hole-in-valve-covers.2005/#post-5328

http://garage.grumpysperformance.com/index.php?threads/need-help-with-evac-system.15939/#post-95997

http://garage.grumpysperformance.com/index.php?threads/catch-can-related-info.4636/#post-12451

http://garage.grumpysperformance.co...w-engine-smokes-at-start-up.15778/#post-94476

http://garage.grumpysperformance.com/index.php?threads/leakdown-compression-test.881/#post-56489

http://garage.grumpysperformance.com/index.php?threads/pcv-system-routing.10999/#post-48572

https://auto.howstuffworks.com/positive-crankcase-ventilation-system.htm

Last edited:

Loves302Chevy

"One test is worth a thousand expert opinions."

Also do your leak down test at BDC (bottom dead center).

Really? I didn’t know that. Thanks !Also do your leak down test at BDC (bottom dead center).

Loves302Chevy

"One test is worth a thousand expert opinions."

Yes, meaning in addition to doing it at TDC. It is possible to pass a leakdown test at TDC because any scratches in the cylinder walls are below the rings at TDC.Really? I didn’t know that. Thanks !

I had an engine that passed at TDC, but it was shooting oil droplets out of the tailpipe and using a quart of oil on the way to work. Some camshaft lobes were gone and all that shrapnel circulated through the engine, scoring the cylinder walls and embedding in the piston skirts. This engine never would have passed a leakdown test at BDC.

Last edited by a moderator:

Loves302Chevy

"One test is worth a thousand expert opinions."

You are correct.

Well, I think we can say the engine is in good shape. All cylinders are at 190-200 PSI.

The leak down is 2-2.5% all around.

So I decided to pursue teardown for the cam shaft swap. Everything was straightforward. The lifters look good. Everything looks good.

The teardown was super easy until I got stuck in the oil pan. This oil pan has kick outs and in that area I cannot seem to get a socket on there because I can press squarely down the 7/16.

For the moment I’m kinda stuck. It’s too cold and too dark to work outside so I’ll pause and regroup.

Maybe some thin wall sockets will work ? To me it seems like the lip of the oil pan is preventing my socket from fully seating. And because of the kick outs, I can’t tap them on.

Any suggestions?

The leak down is 2-2.5% all around.

So I decided to pursue teardown for the cam shaft swap. Everything was straightforward. The lifters look good. Everything looks good.

The teardown was super easy until I got stuck in the oil pan. This oil pan has kick outs and in that area I cannot seem to get a socket on there because I can press squarely down the 7/16.

For the moment I’m kinda stuck. It’s too cold and too dark to work outside so I’ll pause and regroup.

Maybe some thin wall sockets will work ? To me it seems like the lip of the oil pan is preventing my socket from fully seating. And because of the kick outs, I can’t tap them on.

Any suggestions?

congrats on the good leak-down test results

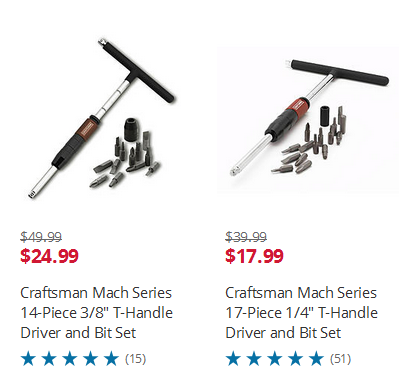

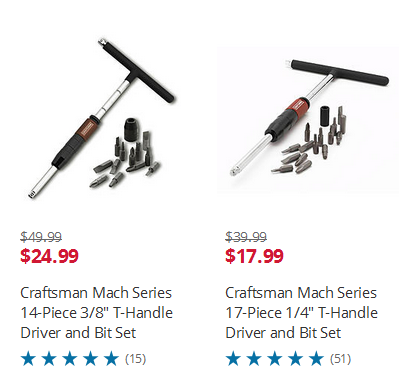

while the tool below is not a ratchet it does come in very handy at times

at times some rather odd tools can be useful like flexible extensions

https://maxedbuy.com/en/detail/1414...html?msclkid=0e474fe695cd193999612ff192b41739

at times a ratchet like this is a good tool to have and a short 7/16" 1/4" drive socket

https://www.harborfreight.com/14-in-38-in-drive-long-reach-dual-flex-head-ratchet-67994.html

https://www.harborfreight.com/t-bar-with-3-8-eighth-inch-flexible-ratchet-98484.html

while the tool below is not a ratchet it does come in very handy at times

at times some rather odd tools can be useful like flexible extensions

https://maxedbuy.com/en/detail/1414...html?msclkid=0e474fe695cd193999612ff192b41739

at times a ratchet like this is a good tool to have and a short 7/16" 1/4" drive socket

https://www.harborfreight.com/14-in-38-in-drive-long-reach-dual-flex-head-ratchet-67994.html

https://www.harborfreight.com/t-bar-with-3-8-eighth-inch-flexible-ratchet-98484.html

of course if you have a decent welder and a drill press, and accurate measuring, you could rather easily drill three 3/4" diameter holes directly under the three bolts that are difficult to reach easily,

through the sump, and weld in three short sections of 3/4" tube in the sump that would allow a matching socket on a 1/4" drive extension,

socket and extension to reach the bolts directly through the oil pan sump.

BTW heres an old trick that may help

you buy a dozen 2" long 1/4" 20 bolts

you thread the nylock nuts on the bolts with a washer

place a washer between the nut and oil pan rail re-enforcing plate to further distribute clamping pressure,

and you use the chevy oil pan rail re-enforcing plates

and you use the chevy oil pan rail re-enforcing plates

this allows easy access to the hex heads as they now stick out about 1.5" below the oil pan rails for much easier access to those bolts over the sump extension,

you buy a dozen 2" long 1/4" 20 bolts

you thread the nylock nuts on the bolts with a washer

place a washer between the nut and oil pan rail re-enforcing plate to further distribute clamping pressure,

this allows easy access to the hex heads as they now stick out about 1.5" below the oil pan rails for much easier access to those bolts over the sump extension,

Loves302Chevy

"One test is worth a thousand expert opinions."

Someone got those bolts on there, most likely with a thin-wall socket. Loosen then the same way.

You can't use an open-end wrench to get them started?

You can't use an open-end wrench to get them started?

Thanks for kicking me off the fence. Let’s try some thin wall sockets before getting overly dramatic.

I just need to order them from the U.S. again.

I’m going to try to get them one more time this noon with my 1/4 inch drive sockets. Maybe they are thin wall.

I just need to order them from the U.S. again.

I’m going to try to get them one more time this noon with my 1/4 inch drive sockets. Maybe they are thin wall.