andrew said:I have 2 complete rear axle assemblies from 1958-1964 that I need to get off the floor of my shop.

Does anyone have any ideas, pictures, or links to something?

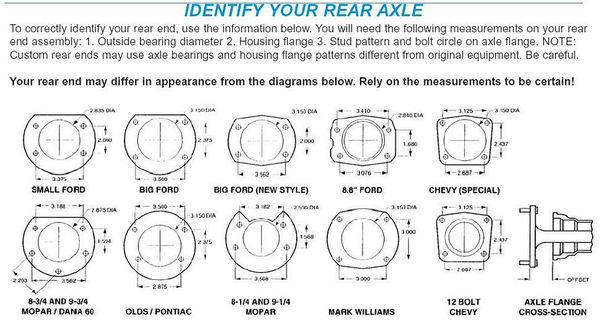

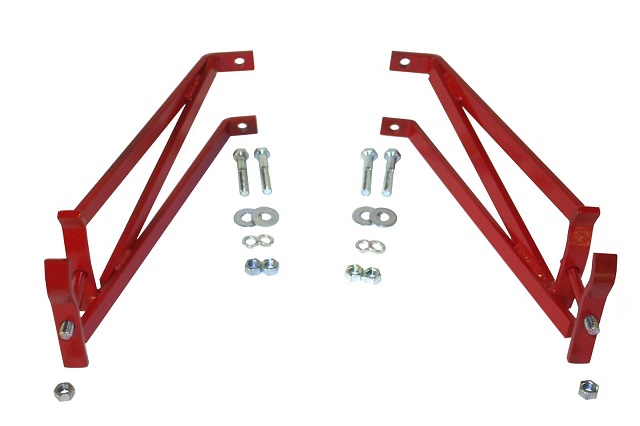

well it may not be what you had in mind , but many guys find the adapter kits that adapt the engine stands , they own, to holding a differential, rather handy when rebuilding the rear differential on their car, and since the cost for the adapter kits reasonably low and it generally works well, they go that route.

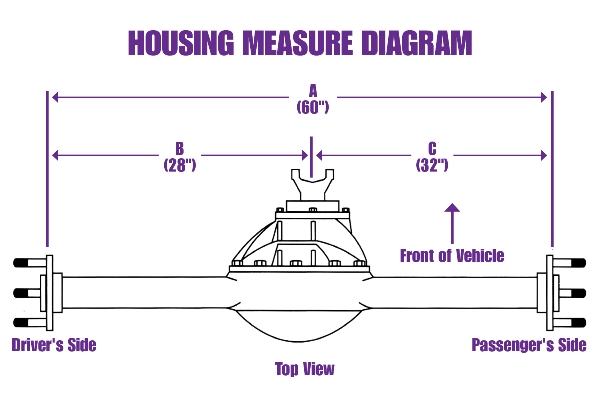

obviously this is one more in a nearly endless list of things you could easily fabricate, or build if you have a WELDER and a drill press , or mill and a saw of some type, and a great deal of originality or customization to match the application could be involved

http://www.harborfreight.com/2000-lb-capacity-foldable-engine-stand-69521.html

http://www.summitracing.com/parts/mrm-m998084

TOP QUALITY MIG THAT WILL HANDLE 95% OF AUTOMOTIVE WELDING

and a bit of careful measuring and a bit of ingenuity, and some thinking about what your trying to accomplish can do wonders

Last edited: