I try to look for and buy American made products any time I can and don,t mind one bit paying an additional 10%-20%-even 30% more because I know from experience that theres frequently a good deal more quality components than in import clone parts, making the parts well worth the cost difference, there not much point in saving 30% on a part or tool that won,t do the job its designed to do, or one that can,t do its job safely!

but in a side by side comparison the import looked to be better made,

So I think your fighting a lost battle here,the last time I researched this, a decent 10-12 ton rated American made jack stand that has a wide base and can get a car frame 20'-24" off the floor safely, is well over 200$ EACH

http://www.acjacks.com/acjacks_003.htm

good floor jack

Ive used 6 12 ton rated jack stands like these for almost 20 years now in my shop they are well made

http://garage.grumpysperformance.com/index.php?threads/floor-jacks.969/#post-24460

Safely Jacking a C4

by Wes Burch

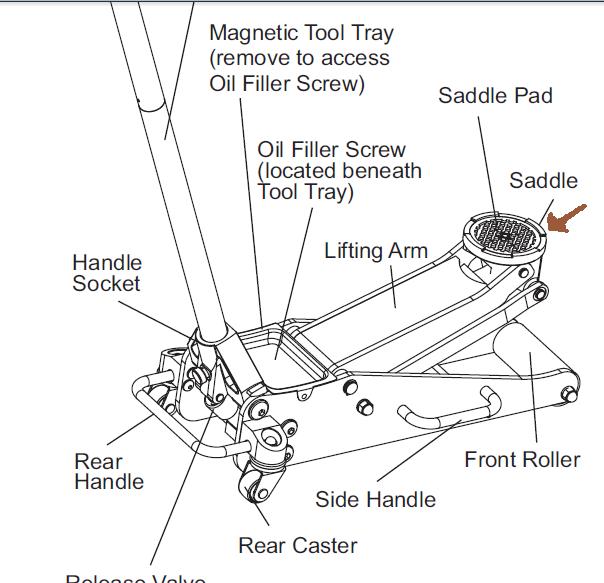

Tools Required: 1 Floor Jack (3,000 lb min) and at least 2 Jack Stands. (You really do not want to bet your life on that used ten cent O-Ring in that Floor Jack do you?) Four jack stands is better.

Level of Difficulty: This is far easier than digging a hole under the Corvette so you work on it.

Until you have done this a few times, think about each step before doing it!

(1) Caution: GM did not design the C4 for home maintenance. There are no GM recommended jacking points for a C4 other than those that require a single or dual post lift. So use this procedure at your own risk.

(2) To start you need to be on a solid level surface. Jacking the car on grass will most likely result in sinking either the jack or jack stand into the sand. Better to dig the hole. If the car is an automatic verify the transmission is in park. With a manual make sure the transmission is in gear. Engaging the parking brake is also a good idea.

(3) Because the C4 chassis is remarkably flexible you should pop the hood release while the car is still on the ground. I've seen a few C4s that once they are on jack stands the hood will not release. Do not fully open the hood until you are finished jacking and supporting the car on jack stands.

(4) A strong point for the C4 chassis is the pinch weld joint that runs just behind the lip at the bottom of the sill. But because of the fiberglass floor kick-down; that area is not wide enough to center your jack pad under the pinch weld. I catch two of the "teeth" from my floor jack behind the pinch joint. (Photo 1) That will help prevent the pad from slipping out from under the car while jacking. (As you can see in the photo from my car it is HIGHLY LIKELY that you will chip a bit of paint from the lower edge of the sill.) ALSO BE CAREFUL TO NOT GET THE FLOOR JACK UNDER THE FLOOR! YOU CAN MAKE A NEAT INTERIOR DRAIN HOLE IF YOU DO. THE FLOOR WILL NOT SUPPORT THE WEIGHT OF THE CAR.

Photo 1

(5) Place the floor jack just behind the outside rear view mirror. (Photo 2) That is very near the center of weight for the car. The front and rear of the car should raise more or less evenly as you pump the jack.

Photo 2

(6) I believe the best place to support the rear of the car is where several pinch joints come together just ahead of the rear tire. (Photo 3) Note the shims on the top of the jack stand (more on that later).

Photo 3

(7) There are two places to support the front of the car. Just behind the front tire is a nice flat part of the chassis. Just be sure the jack is on the metal frame and not the plastic that constitutes part of the inner fender. (Photo 4) I have also placed a jack stand under the full-of-holes bar that connects the end links of the lower control arm. (Photo 5)

Photo 4

Photo 5

(8) If you are jacking all four corners of the car, before you place your valuable body parts under the car, verify all the jack stands are supporting the car. I use a small hammer and tap each jack stand. If the jack stand has weight on it the result is a dull thunk. If not, it will sound more like a bell and the jack stand may even move. If a jack has no weight on it I use some shims (photo 3) so that jack is supporting weight. Afterwards, I also walk around the car and gently push each corner to make sure the load is stable.

(9) Now you can safely perform maintenance on the car….enjoy. If your maintenance includes changing fluids, be sure you close the drain before adding fresh fluid. If the wheels were removed be sure to torque the wheels after the car is back on the ground (100 lb-ft for aluminum wheels).

(10) Getting the car back on the ground is just a reverse of the above steps. Just be sure to lower the car slowly so it does not slip on the floor jack on the opposite side.

http://www.corvettemagazine.com/tech-articles/1956-1982-corvette-driveshaft-u-joint-replacement/

http://www.homedepot.com/buy/tools-hard ... 70912.html

http://www.northerntool.com/shop/tools/ ... _200330725

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

http://www.zr1netregistry.com/jackupzr1.htm

12 ton jack stands #34924 while a good deal of the stuff didn,t impress me, or is in my opinion not a decent value theres a few exceptions

I bought 6 of these on sale about 20 years ago, the new ones look almost identical, Ive used them constantly, they have proven to be a good value

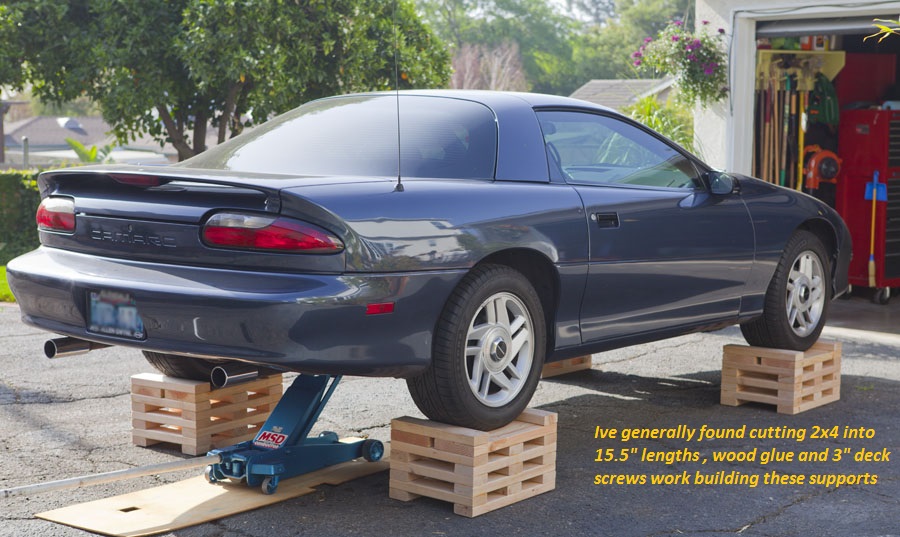

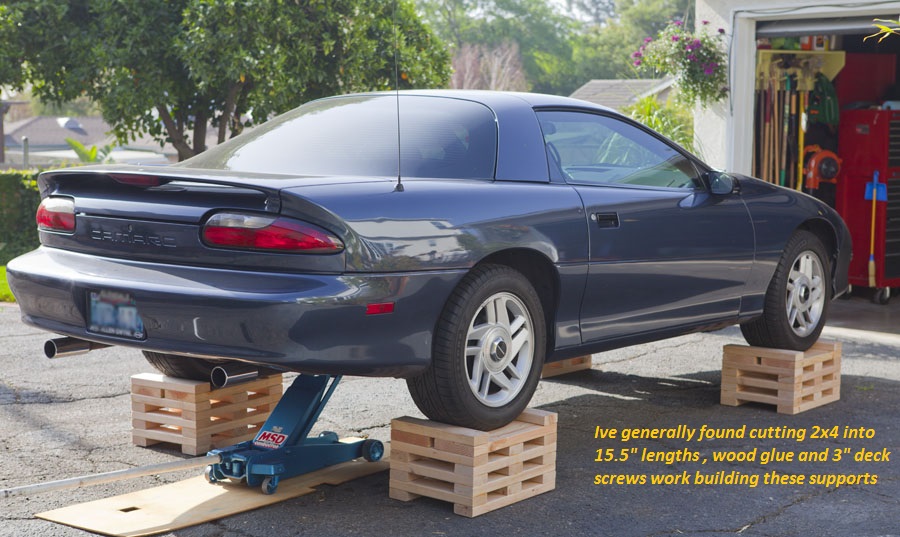

another option, is using jack stands under the frame AND ADDITIONAL home made wood stands under the tires as a extra support or even in place of jack stands if they are properly designed, ...wood GLUED AND BOLTED TOGETHER

normally $80 for two, now on sale for $55 for two

http://www.harborfreight.com/cpi/ctaf/d ... mber=34924

IN MANY CASES USING A SMALL RAMP AIDS CLEARANCE FOR A FLOOR JACK

RELATED INFO

viewtopic.php?f=27&t=9873&p=37685&hilit=jack+stands#p37685

JACK ONLY THE FRONT OF THE CAT AND SUPPORTING ONLY THE FRONT< LEAVES THE CAR IN A POTENTIALLY DANGEROUS POSITION WHERE IT MIGHT ROLL

+++++++++

+++++++++

THE CARS MORE STABLE ON FOUR 12 TON JACK STANDS IF YOU WANT TO USE A MECHANICS CREEPER

viewtopic.php?f=27&t=26

http://www.levo-artis.com/

I bought three sets of these and Ive found them to be perfectly fine (ONE OF THE VERY FEW THINGS IVE GOTTEN FROM HF THAT WAS)at some point it just doesn,t make sence to make things cheaper or from inferior materials because the product is so low tech and the cost of materials is so close it makes no sence to try to get it built for less, as theres almost no potenial to save on manufacturing costs (feel the 12 ton jack stands are probably in that catagory)

now theres not much at harbor freight thats well worth the price but these are low tech and well worth the cost, Ive had 6 in the shop for years, they are just the correct height at the lowest setting to work under your car and FAR AWAY MUCH LARGER AND STEADIER, more heavily built, and not nearly as easy to tip the car over with when you use them as the cheap and more comon 3 and 6 ton jack stands most guys use

are you not going to feel like a morron if the car falls from some cheap bargin jack stand when for a few dollars more you could have had substantiaslly larger and strong and much more stabile stands under the frame?

ANOTHER OPTION IS USE OF RAMPS BUT.. your average auto store ramps ,(especially the cheap stamped steel versions)are dangerous and won,t allow the corvettes low approch angle to drive up on them, get the tires centered off/center and they frequently bend or tip, the RINO RAMPS work ok, but are FAR from high enought or stabile enought for serious work, and they tend to skid as you try to roll up on them occasionally

heres some better options

http://www.chapmanenterprise.com/jack_rabbit.html

look closely at the details on these ramps, you could buy those or weld up something similar at reasonable cost and with custom dimensions

http://www.raceramps.com/store/shopexd.asp?id=62

much better but not nearly high enought for serious work

http://www.discountramps.com/sports_car_ramps.htm

http://www.discountramps.com/mini-sports-car-lift-ramps.jpg

much better

but still too low

http://www.kwiklift.com/

http://www.kwiklift.com/Options.htm

I know several guys that have one,.....they ALL have garages with 8 foot ceiling heights.(and that was a huge factor in thier selection.)

Ive worked on several cars while useing them, and they are much easier to get the car up on and ready to work on than the (4) 12 ton jack stands I usually use when a lift is not easily available, but Ive found the 12 ton jack stands make the car easier to work on once its up on the stands and certainly the brake jobs are easier and access under the car is easier with the jack stands IN MY OPINION

theres not a darn thing wrong with them for a great deal of the stuff youll do on a car but they a certainly NOT on the same level with a good quality two post lift or a decent four post lift for many reasons, heres a thread on lift info that might help

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=98

excellent value but expensive at $1600 for the heavy duty set Id suggest as its a small increase in price over the standard set

http://www.chapmanenterprise.com/products.html

these are made to YOUR specs if you want them custom

btw about 75%-90% of the stuff you see on sale at HF is not good quality, but there are a few exceptions, the 12 ton jack stands I think are in that few, that are decent quality, simply because the technology is old, the steel is cheap and theres a significant safety margin in useing a 12 ton rated jack stand on a car that will place less than 1800 lbs or ONE TON load per jack. I would not use the 3 ton rated jacks on a lawn mower, the 6 ton are ok, but a good deal smaller/lighter, and since its MY BUTT under the car I use the 12 ton HF jack stands, and in many cases I leave the two hydrolic jacks supporting the car also, and Ive left the rhino ramps under the front wheels when they won,t cause an access problem, like when changing u-joints, or half shafts, brake jobs, changing a fuel filter ,etc.

iF youve ever checked OUT those 12 ton jack stands closely youll soon see that those are a HUGE EXCEPTION to the normal CRAPPY HF stuff, probably because STEEL, and HEAVY CASTINGS are fairly cheap to produce and the TECHNOLOGY is VERY OLD and EASY TO PRODUCE in CHINA at a VERY reasonable cost

which do you think is a better deal, (4) 8 ton jack stands for $800 with only 3 heights

http://www.asedeals.com/jack_stands.html

or (4) 12 ton jack stands for under $140 68LBS FOR TWO (thats a good bit of steel) with about 8 height choices and a far stronger locking mechanisum

http://www.harborfreight.com/cpi/cta...emnumber=34924

BTW,the 12 ton jacks give the clearance for an extra mechanics pad and a mechanics creeper

http://www.northerntool.com/webapp/w...8274_200198274

they do make a 6 ton version, and its far better than your average auto parts store crappy 3 ton stands

"how do you get the HF 12 ton jack stands under the vette?, my floor jack won,t lift that high (20")"

GOOD VALID QUESTION!, PROBABLY WE SHOULD discuss it

If your going to work under your car I hope you support the car safely, some of you might think Im old fashion but some repairs (even thou I own a LIFT) are easier to do with (4) 12 ton jack stands and a mechanics creeper, but for your own safety ID STRONGLY SUGGEST you buy and USE 4 of these 12 ton jack stands and work on a LEVEL CONCRETE FLOOR when ever you can, yes IM well aware that you can buy smaller ,less expensive jack stands, how much is YOUR LIFE WORTH!, if its worth a couple hundred dollars, and a few minutes of your time, to keep from being killed or crippled for life I figure its worth the time and money

most common floor jacks have a max lift height between 18"-22" I have a pair of 3 ton floor jacks,that originally only lift to 20" and thats really too tight to clear,

your surely not alone in having too lift the car in steps to place the taller 12 ton jack stands or similarly tall jack stands that allow full access under the car.

now in my case I found the darn floor jack won,t fit under the corvette as it sits on the shop floor unless you use some careful planing first, I drive the vette up on plastic rhino ramps to get the necessary clearance, I place the first floor jack and lift the front K-member and place the two front 12 ton jack stands on the frame near the a arms on the frame, I then remove the front floor jack and place it and my second floor jack under the rear side frame behind the doors on each side, I jack each side up a bit, then swap to the other side in several stages IF im alone, (naturally if I have help both sides get jacked up at the same time)untill its high enough to place each of the two or four remaining 12 ton jacks into place under the frame.

now a bit of info Ive installed 1 3/4" thick rubber pads that are approximately 4" in diam. on both my floor jacks to both get the necessary lift and protect the frame from scratches these are made from thick sections of earth mover or dump truck tire tread rubber I found at a dump

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

If your going to work under your car I hope you support the car safely, some of you might think Im old fashion but some repairs (even thou I own a LIFT) are easier to do with (4) 12 ton jack stands and a mechanics creeper

prices are up recently,

http://www.harborfreight.com/12-ton-jac ... 34924.html

http://promocodesforyou.com/index.php?i ... 7AodJGG8BQ

check on sales, look for discount coupons and ask for the manager of the store as he has a great deal of leeway in pricing, when I bought mine the standard price was $60 a pair, but I went during a sale and they were marked 10% off plus I told the store manager I had a desire to buy 2 pairs if he made it worth my while, he dropped the price to $150 for 6 stands and no sales taxes

look closely at the FLIMSY JACK STANDS IN THIS PICTURE, Ive seen several of that jack stand design , suddenly fail and collapse

theres always a small percentage of idiots with a death wish

IVE seen several of these style jack stands shear pins and drop cars, with zero warning, if you have some ID pitch them in the nearest dumpster after a couple good hits with a sledge hammer to prevent some trusting fool from taking and using them

heres some cheap ass failure prone 3 ton jack stands, trust me knocking the whole car over on those jack stands does not take a great deal off effort, and I would sure not want to be under the car on those stand if some moron slammed the door on the car hard, or your forced to use a breaker bar to loosen a frame mount bolt.

both the design and quality of manufacture matter its your choice but remember your going to be under the car ,no mater what you select, so be damn sure its sturdy with a healthy safety margin and a wide base,making them hard to tip,and be sure theres a good bit of metal in the design,several good designs , are available

theres NOTHING preventing you buying the HF design and drilling a few 5/8" holes to allow inserting a grade 8 bolt in those as a second safety either

http://www.harborfreight.com/12-ton-jac ... 34924.html

"1: why 12 ton? Ain't 6 ton more than enough?

2: how do you jack up the car? do you enroll your wife?

3: what floor jack do you use? Prices vary quite a bit?"

(1)

the 12 ton are BOTH FAR MORE STABLE from tipping or the car shifting, AND on the first notch they are exactly the correct height to allow comfortably accessing the under side of the car, place the 6 ton next to a 12 ton and raise both to the height of the 12 ton stands on the first notch, theres absolutely no comparison in your safety under the car, THERES ABSOLUTELY NO WAY YOU CAN COMPARE THE DEGREE OF STABILITY THE LARGER BASE AND STRONGER MATERIALS THE 12 TON STANDS PROVIDE

(2) your hardly the first guy to run into this, problem, you may need to fabricate or purchase floor jack spacer pads if your floor jack won,t raise the car high enough, I know I did, it was an easy process and I welded up my own, and both bolted and glued a 6: square section of old tire tread to the pads upper surface to prevent scaring the vettes car frame, so I could use the 12 ton jack stands, because my sears floor jacks could just barely reach the required height I fabricated spacers, with out the spacer pads, getting the 12 ton jack stands in place was more of a hassle,obviously this requires a bit of thinking in the procedure in getting the car up safely,to allow the taller jack height under the car frame,

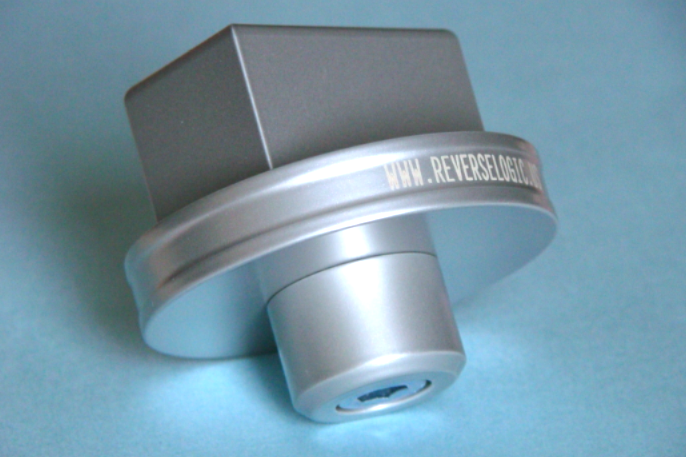

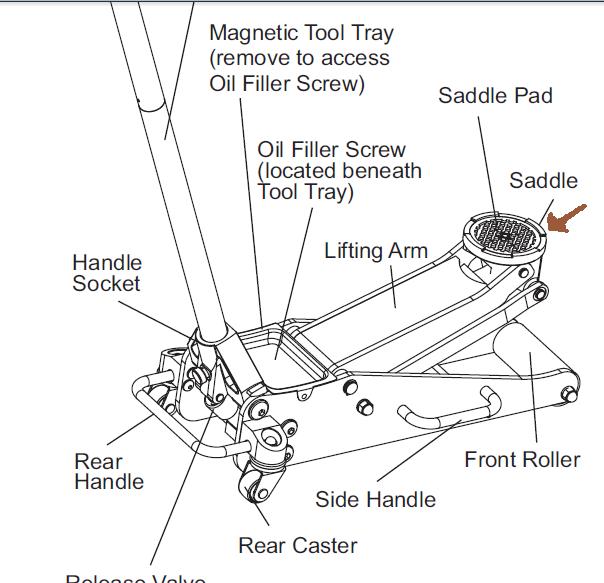

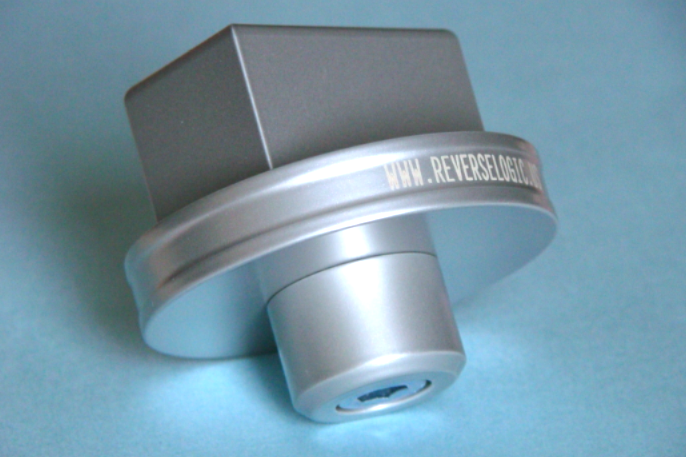

on most floor jacks the lift pad is easily interchangeable , you can buy a replacement jack saddle

and weld a 2"-3" thick pad to the spares and drill and bolt and glue a section of old tire tread you find on any high way or from an old tire you can cut with a sawsall to make a second custom set of jack spacers if your floor jack won,t allow the car to be lifted high enough

one of my old geezer friends found 4 of these plates for $1 each at a yard sale and used a large center bolt, two washers and his shop welder to make a custom floor jack spacer pad for both his floor jacks, I thought that was rather ingenious s

btw keep your eyes out for used floor jacks at yard sales, and if a friends floor jack fails it might only require minimal maintenance to repair,this is were having a bit of curiosity and mechanical skill helps , one of my friends has a sears jack that he used for 20 years, it eventually started having a problem where it would slowly loose height if not regularly pumped up so he donated it to me and bought a new floor jack, it took me about 45 minutes to figure out how to disassemble and clean it , and replace a couple worn o-rings but for 45-60 minutes work and less than 80 cents in o-ring's, and $7 in hydraulic jack oil, I had a spare functional floor jack.

OK first you DON,T raise a car one corner at a time! you drive it up on the inclined ramps to get clearance for the floor jack then slide the floor jack with the spacer if your floor jack requires one under the center of the front (CROSS MEMBER) and lift the front and place BOTH front 12 ton jack stands, under the frame , wide spaced, then the angle of the frame allows you to either use a second floor jack or move the front floor jack to the rear frame of the car, and lift the whole back or move both floor jacks to the rear frame on opposite sides and place both REAR 12 ton jack stands, on the rear frame. now personally I usually leave the rear jack stands and the jack holding the rear up ,and the 12 ton jack stands on the front with the tires hanging just above the inclined ramps, that way theres almost less chance the car can fall, even if some component were to fail.

Ill ALSO point out I have and have always used two floor jacks, twin rhino ramps and 4 12 ton jack stand WHEN I was under the corvette I use those 12 ton stand on when I use a mechanics creeper as I don,t want to be doing bench presses with a vette!:

but in a side by side comparison the import looked to be better made,

So I think your fighting a lost battle here,the last time I researched this, a decent 10-12 ton rated American made jack stand that has a wide base and can get a car frame 20'-24" off the floor safely, is well over 200$ EACH

http://www.acjacks.com/acjacks_003.htm

good floor jack

Ive used 6 12 ton rated jack stands like these for almost 20 years now in my shop they are well made

http://garage.grumpysperformance.com/index.php?threads/floor-jacks.969/#post-24460

by Wes Burch

Tools Required: 1 Floor Jack (3,000 lb min) and at least 2 Jack Stands. (You really do not want to bet your life on that used ten cent O-Ring in that Floor Jack do you?) Four jack stands is better.

Level of Difficulty: This is far easier than digging a hole under the Corvette so you work on it.

Until you have done this a few times, think about each step before doing it!

(1) Caution: GM did not design the C4 for home maintenance. There are no GM recommended jacking points for a C4 other than those that require a single or dual post lift. So use this procedure at your own risk.

(2) To start you need to be on a solid level surface. Jacking the car on grass will most likely result in sinking either the jack or jack stand into the sand. Better to dig the hole. If the car is an automatic verify the transmission is in park. With a manual make sure the transmission is in gear. Engaging the parking brake is also a good idea.

(3) Because the C4 chassis is remarkably flexible you should pop the hood release while the car is still on the ground. I've seen a few C4s that once they are on jack stands the hood will not release. Do not fully open the hood until you are finished jacking and supporting the car on jack stands.

(4) A strong point for the C4 chassis is the pinch weld joint that runs just behind the lip at the bottom of the sill. But because of the fiberglass floor kick-down; that area is not wide enough to center your jack pad under the pinch weld. I catch two of the "teeth" from my floor jack behind the pinch joint. (Photo 1) That will help prevent the pad from slipping out from under the car while jacking. (As you can see in the photo from my car it is HIGHLY LIKELY that you will chip a bit of paint from the lower edge of the sill.) ALSO BE CAREFUL TO NOT GET THE FLOOR JACK UNDER THE FLOOR! YOU CAN MAKE A NEAT INTERIOR DRAIN HOLE IF YOU DO. THE FLOOR WILL NOT SUPPORT THE WEIGHT OF THE CAR.

Photo 1

(5) Place the floor jack just behind the outside rear view mirror. (Photo 2) That is very near the center of weight for the car. The front and rear of the car should raise more or less evenly as you pump the jack.

Photo 2

(6) I believe the best place to support the rear of the car is where several pinch joints come together just ahead of the rear tire. (Photo 3) Note the shims on the top of the jack stand (more on that later).

Photo 3

(7) There are two places to support the front of the car. Just behind the front tire is a nice flat part of the chassis. Just be sure the jack is on the metal frame and not the plastic that constitutes part of the inner fender. (Photo 4) I have also placed a jack stand under the full-of-holes bar that connects the end links of the lower control arm. (Photo 5)

Photo 4

Photo 5

(8) If you are jacking all four corners of the car, before you place your valuable body parts under the car, verify all the jack stands are supporting the car. I use a small hammer and tap each jack stand. If the jack stand has weight on it the result is a dull thunk. If not, it will sound more like a bell and the jack stand may even move. If a jack has no weight on it I use some shims (photo 3) so that jack is supporting weight. Afterwards, I also walk around the car and gently push each corner to make sure the load is stable.

(9) Now you can safely perform maintenance on the car….enjoy. If your maintenance includes changing fluids, be sure you close the drain before adding fresh fluid. If the wheels were removed be sure to torque the wheels after the car is back on the ground (100 lb-ft for aluminum wheels).

(10) Getting the car back on the ground is just a reverse of the above steps. Just be sure to lower the car slowly so it does not slip on the floor jack on the opposite side.

http://www.corvettemagazine.com/tech-articles/1956-1982-corvette-driveshaft-u-joint-replacement/

http://www.homedepot.com/buy/tools-hard ... 70912.html

http://www.northerntool.com/shop/tools/ ... _200330725

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

http://www.zr1netregistry.com/jackupzr1.htm

12 ton jack stands #34924 while a good deal of the stuff didn,t impress me, or is in my opinion not a decent value theres a few exceptions

I bought 6 of these on sale about 20 years ago, the new ones look almost identical, Ive used them constantly, they have proven to be a good value

another option, is using jack stands under the frame AND ADDITIONAL home made wood stands under the tires as a extra support or even in place of jack stands if they are properly designed, ...wood GLUED AND BOLTED TOGETHER

normally $80 for two, now on sale for $55 for two

http://www.harborfreight.com/cpi/ctaf/d ... mber=34924

IN MANY CASES USING A SMALL RAMP AIDS CLEARANCE FOR A FLOOR JACK

RELATED INFO

viewtopic.php?f=27&t=9873&p=37685&hilit=jack+stands#p37685

JACK ONLY THE FRONT OF THE CAT AND SUPPORTING ONLY THE FRONT< LEAVES THE CAR IN A POTENTIALLY DANGEROUS POSITION WHERE IT MIGHT ROLL

THE CARS MORE STABLE ON FOUR 12 TON JACK STANDS IF YOU WANT TO USE A MECHANICS CREEPER

viewtopic.php?f=27&t=26

http://www.levo-artis.com/

I bought three sets of these and Ive found them to be perfectly fine (ONE OF THE VERY FEW THINGS IVE GOTTEN FROM HF THAT WAS)at some point it just doesn,t make sence to make things cheaper or from inferior materials because the product is so low tech and the cost of materials is so close it makes no sence to try to get it built for less, as theres almost no potenial to save on manufacturing costs (feel the 12 ton jack stands are probably in that catagory)

now theres not much at harbor freight thats well worth the price but these are low tech and well worth the cost, Ive had 6 in the shop for years, they are just the correct height at the lowest setting to work under your car and FAR AWAY MUCH LARGER AND STEADIER, more heavily built, and not nearly as easy to tip the car over with when you use them as the cheap and more comon 3 and 6 ton jack stands most guys use

are you not going to feel like a morron if the car falls from some cheap bargin jack stand when for a few dollars more you could have had substantiaslly larger and strong and much more stabile stands under the frame?

ANOTHER OPTION IS USE OF RAMPS BUT.. your average auto store ramps ,(especially the cheap stamped steel versions)are dangerous and won,t allow the corvettes low approch angle to drive up on them, get the tires centered off/center and they frequently bend or tip, the RINO RAMPS work ok, but are FAR from high enought or stabile enought for serious work, and they tend to skid as you try to roll up on them occasionally

heres some better options

http://www.chapmanenterprise.com/jack_rabbit.html

look closely at the details on these ramps, you could buy those or weld up something similar at reasonable cost and with custom dimensions

http://www.raceramps.com/store/shopexd.asp?id=62

much better but not nearly high enought for serious work

http://www.discountramps.com/sports_car_ramps.htm

http://www.discountramps.com/mini-sports-car-lift-ramps.jpg

much better

but still too low

http://www.kwiklift.com/

http://www.kwiklift.com/Options.htm

I know several guys that have one,.....they ALL have garages with 8 foot ceiling heights.(and that was a huge factor in thier selection.)

Ive worked on several cars while useing them, and they are much easier to get the car up on and ready to work on than the (4) 12 ton jack stands I usually use when a lift is not easily available, but Ive found the 12 ton jack stands make the car easier to work on once its up on the stands and certainly the brake jobs are easier and access under the car is easier with the jack stands IN MY OPINION

theres not a darn thing wrong with them for a great deal of the stuff youll do on a car but they a certainly NOT on the same level with a good quality two post lift or a decent four post lift for many reasons, heres a thread on lift info that might help

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=98

excellent value but expensive at $1600 for the heavy duty set Id suggest as its a small increase in price over the standard set

http://www.chapmanenterprise.com/products.html

these are made to YOUR specs if you want them custom

btw about 75%-90% of the stuff you see on sale at HF is not good quality, but there are a few exceptions, the 12 ton jack stands I think are in that few, that are decent quality, simply because the technology is old, the steel is cheap and theres a significant safety margin in useing a 12 ton rated jack stand on a car that will place less than 1800 lbs or ONE TON load per jack. I would not use the 3 ton rated jacks on a lawn mower, the 6 ton are ok, but a good deal smaller/lighter, and since its MY BUTT under the car I use the 12 ton HF jack stands, and in many cases I leave the two hydrolic jacks supporting the car also, and Ive left the rhino ramps under the front wheels when they won,t cause an access problem, like when changing u-joints, or half shafts, brake jobs, changing a fuel filter ,etc.

iF youve ever checked OUT those 12 ton jack stands closely youll soon see that those are a HUGE EXCEPTION to the normal CRAPPY HF stuff, probably because STEEL, and HEAVY CASTINGS are fairly cheap to produce and the TECHNOLOGY is VERY OLD and EASY TO PRODUCE in CHINA at a VERY reasonable cost

which do you think is a better deal, (4) 8 ton jack stands for $800 with only 3 heights

http://www.asedeals.com/jack_stands.html

or (4) 12 ton jack stands for under $140 68LBS FOR TWO (thats a good bit of steel) with about 8 height choices and a far stronger locking mechanisum

http://www.harborfreight.com/cpi/cta...emnumber=34924

BTW,the 12 ton jacks give the clearance for an extra mechanics pad and a mechanics creeper

http://www.northerntool.com/webapp/w...8274_200198274

they do make a 6 ton version, and its far better than your average auto parts store crappy 3 ton stands

"how do you get the HF 12 ton jack stands under the vette?, my floor jack won,t lift that high (20")"

GOOD VALID QUESTION!, PROBABLY WE SHOULD discuss it

If your going to work under your car I hope you support the car safely, some of you might think Im old fashion but some repairs (even thou I own a LIFT) are easier to do with (4) 12 ton jack stands and a mechanics creeper, but for your own safety ID STRONGLY SUGGEST you buy and USE 4 of these 12 ton jack stands and work on a LEVEL CONCRETE FLOOR when ever you can, yes IM well aware that you can buy smaller ,less expensive jack stands, how much is YOUR LIFE WORTH!, if its worth a couple hundred dollars, and a few minutes of your time, to keep from being killed or crippled for life I figure its worth the time and money

most common floor jacks have a max lift height between 18"-22" I have a pair of 3 ton floor jacks,that originally only lift to 20" and thats really too tight to clear,

your surely not alone in having too lift the car in steps to place the taller 12 ton jack stands or similarly tall jack stands that allow full access under the car.

now in my case I found the darn floor jack won,t fit under the corvette as it sits on the shop floor unless you use some careful planing first, I drive the vette up on plastic rhino ramps to get the necessary clearance, I place the first floor jack and lift the front K-member and place the two front 12 ton jack stands on the frame near the a arms on the frame, I then remove the front floor jack and place it and my second floor jack under the rear side frame behind the doors on each side, I jack each side up a bit, then swap to the other side in several stages IF im alone, (naturally if I have help both sides get jacked up at the same time)untill its high enough to place each of the two or four remaining 12 ton jacks into place under the frame.

now a bit of info Ive installed 1 3/4" thick rubber pads that are approximately 4" in diam. on both my floor jacks to both get the necessary lift and protect the frame from scratches these are made from thick sections of earth mover or dump truck tire tread rubber I found at a dump

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

If your going to work under your car I hope you support the car safely, some of you might think Im old fashion but some repairs (even thou I own a LIFT) are easier to do with (4) 12 ton jack stands and a mechanics creeper

prices are up recently,

http://www.harborfreight.com/12-ton-jac ... 34924.html

http://promocodesforyou.com/index.php?i ... 7AodJGG8BQ

check on sales, look for discount coupons and ask for the manager of the store as he has a great deal of leeway in pricing, when I bought mine the standard price was $60 a pair, but I went during a sale and they were marked 10% off plus I told the store manager I had a desire to buy 2 pairs if he made it worth my while, he dropped the price to $150 for 6 stands and no sales taxes

look closely at the FLIMSY JACK STANDS IN THIS PICTURE, Ive seen several of that jack stand design , suddenly fail and collapse

theres always a small percentage of idiots with a death wish

IVE seen several of these style jack stands shear pins and drop cars, with zero warning, if you have some ID pitch them in the nearest dumpster after a couple good hits with a sledge hammer to prevent some trusting fool from taking and using them

heres some cheap ass failure prone 3 ton jack stands, trust me knocking the whole car over on those jack stands does not take a great deal off effort, and I would sure not want to be under the car on those stand if some moron slammed the door on the car hard, or your forced to use a breaker bar to loosen a frame mount bolt.

both the design and quality of manufacture matter its your choice but remember your going to be under the car ,no mater what you select, so be damn sure its sturdy with a healthy safety margin and a wide base,making them hard to tip,and be sure theres a good bit of metal in the design,several good designs , are available

theres NOTHING preventing you buying the HF design and drilling a few 5/8" holes to allow inserting a grade 8 bolt in those as a second safety either

http://www.harborfreight.com/12-ton-jac ... 34924.html

"1: why 12 ton? Ain't 6 ton more than enough?

2: how do you jack up the car? do you enroll your wife?

3: what floor jack do you use? Prices vary quite a bit?"

(1)

the 12 ton are BOTH FAR MORE STABLE from tipping or the car shifting, AND on the first notch they are exactly the correct height to allow comfortably accessing the under side of the car, place the 6 ton next to a 12 ton and raise both to the height of the 12 ton stands on the first notch, theres absolutely no comparison in your safety under the car, THERES ABSOLUTELY NO WAY YOU CAN COMPARE THE DEGREE OF STABILITY THE LARGER BASE AND STRONGER MATERIALS THE 12 TON STANDS PROVIDE

(2) your hardly the first guy to run into this, problem, you may need to fabricate or purchase floor jack spacer pads if your floor jack won,t raise the car high enough, I know I did, it was an easy process and I welded up my own, and both bolted and glued a 6: square section of old tire tread to the pads upper surface to prevent scaring the vettes car frame, so I could use the 12 ton jack stands, because my sears floor jacks could just barely reach the required height I fabricated spacers, with out the spacer pads, getting the 12 ton jack stands in place was more of a hassle,obviously this requires a bit of thinking in the procedure in getting the car up safely,to allow the taller jack height under the car frame,

on most floor jacks the lift pad is easily interchangeable , you can buy a replacement jack saddle

and weld a 2"-3" thick pad to the spares and drill and bolt and glue a section of old tire tread you find on any high way or from an old tire you can cut with a sawsall to make a second custom set of jack spacers if your floor jack won,t allow the car to be lifted high enough

one of my old geezer friends found 4 of these plates for $1 each at a yard sale and used a large center bolt, two washers and his shop welder to make a custom floor jack spacer pad for both his floor jacks, I thought that was rather ingenious s

btw keep your eyes out for used floor jacks at yard sales, and if a friends floor jack fails it might only require minimal maintenance to repair,this is were having a bit of curiosity and mechanical skill helps , one of my friends has a sears jack that he used for 20 years, it eventually started having a problem where it would slowly loose height if not regularly pumped up so he donated it to me and bought a new floor jack, it took me about 45 minutes to figure out how to disassemble and clean it , and replace a couple worn o-rings but for 45-60 minutes work and less than 80 cents in o-ring's, and $7 in hydraulic jack oil, I had a spare functional floor jack.

OK first you DON,T raise a car one corner at a time! you drive it up on the inclined ramps to get clearance for the floor jack then slide the floor jack with the spacer if your floor jack requires one under the center of the front (CROSS MEMBER) and lift the front and place BOTH front 12 ton jack stands, under the frame , wide spaced, then the angle of the frame allows you to either use a second floor jack or move the front floor jack to the rear frame of the car, and lift the whole back or move both floor jacks to the rear frame on opposite sides and place both REAR 12 ton jack stands, on the rear frame. now personally I usually leave the rear jack stands and the jack holding the rear up ,and the 12 ton jack stands on the front with the tires hanging just above the inclined ramps, that way theres almost less chance the car can fall, even if some component were to fail.

Ill ALSO point out I have and have always used two floor jacks, twin rhino ramps and 4 12 ton jack stand WHEN I was under the corvette I use those 12 ton stand on when I use a mechanics creeper as I don,t want to be doing bench presses with a vette!:

Last edited by a moderator: