Well they have used excessive force or something.

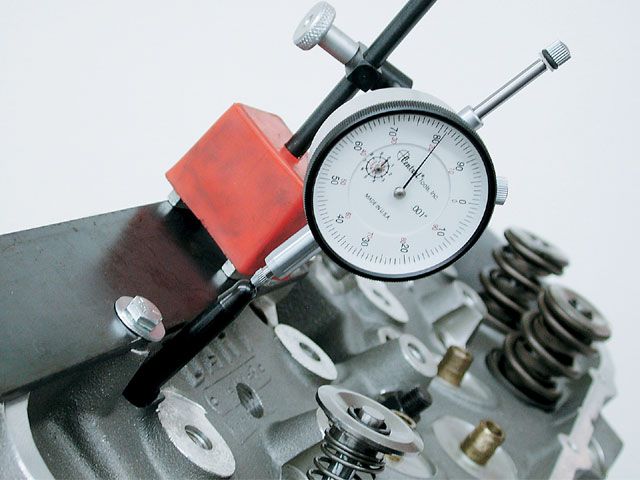

Anyway. We messed up the valve setting ( clearance) as well. Now doing it properly ( gone is the noise)

Now fiddling with the edelbrock carb ( which seems to be italian)

But the car goes as hell very controlled!

We have a car baptizing to attend Sunday!

Anyway. We messed up the valve setting ( clearance) as well. Now doing it properly ( gone is the noise)

Now fiddling with the edelbrock carb ( which seems to be italian)

But the car goes as hell very controlled!

We have a car baptizing to attend Sunday!