I run into a real stupid problem with loads for my 45 Colt I have 4 molds for 45 all .452 diameter 225 to 230 grain cast molds I was trying to use some Trail Boss that I've had forever my problem is that every reloading manual has a COAL for flat nosed bullets and all 12 of my manuals only have a COAL for flat nosed how can I get a length for this they will not be hot loads just some paper punchers and some experimenting for possible future hunting loads Thanks in advance

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

45 Colt loads

- Thread starter rlphvac

- Start date

most cast bullets (especially those designed for revolvers) have a crimp groove in the design) some have two,

, you'll generally find that's what you use. and you select the longest OAL, or rear most crimp groove matching your revolver cylinder, that does not result in loaded cartridges that has bullets loaded too extend so much as the bullet extends out of the revolvers cylinder, the less distance the bullet moves before entering the barrel forcing cone the more consistent the accuracy tends to be!

crimp cast bullets firmly, as recoil may allow a improperly crimped bullet to move forward binding the cylinder.

ACURATELY measure ALL of your revolver cylinder's , the cylinder bore exit diam, really it should ideally be a thousandth or maybe 1.5 thousands larger than the barrel forcing cone and bore of the rifling diam.

cylinder bore exit diam. should never be equal too or smaller than forcing cone and bore diam or accuracy is going to be abysmal

forcing cone diam, should be about 1-1.5 thousands larger than bore diam.

yes this commonly means you lube size the cast bullets to a marginally larger diam. than the revolvers bore diam, to get best accuracy

450-.454 is the common bore diam. range on the 45 colt, most but not all,

newer ones are .452

newer ones are .452

bullets cast must be marginally larger than bore diameter for best accuracy,

bullets must be sized and lubed larger than forcing cone and rifle bore diam.

cylinder throat diam must be marginally larger than the forcing cone throat of the barrel and forcing cone to get any decent accuracy

cast bullets self center engaging the rifling and swage as they seal to bore

example most 44 mag revolvers have a .429 -430 bore, most cast 44 mag bullets are sized .430-.432 to get best accuracy

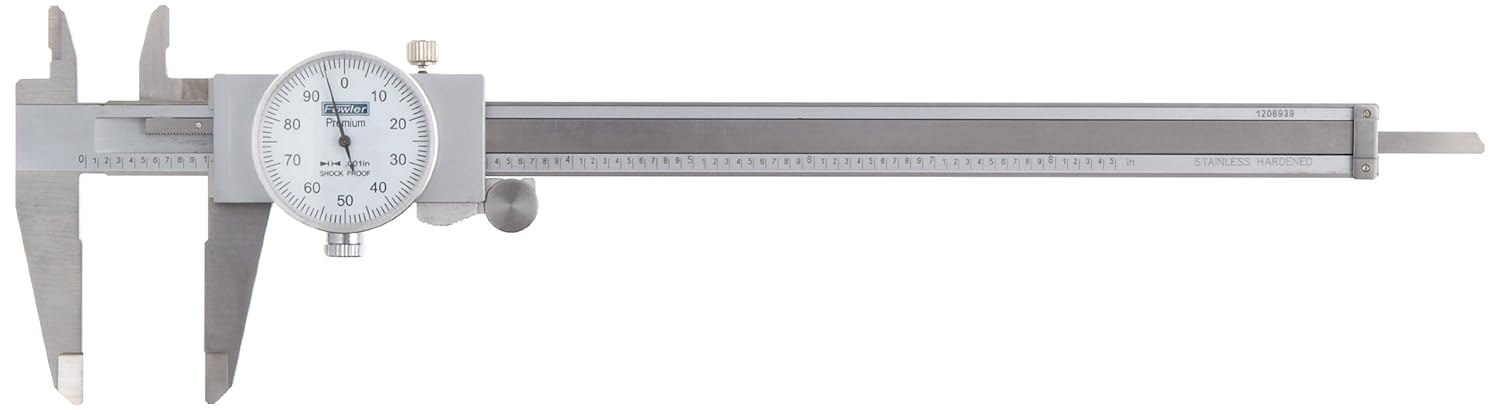

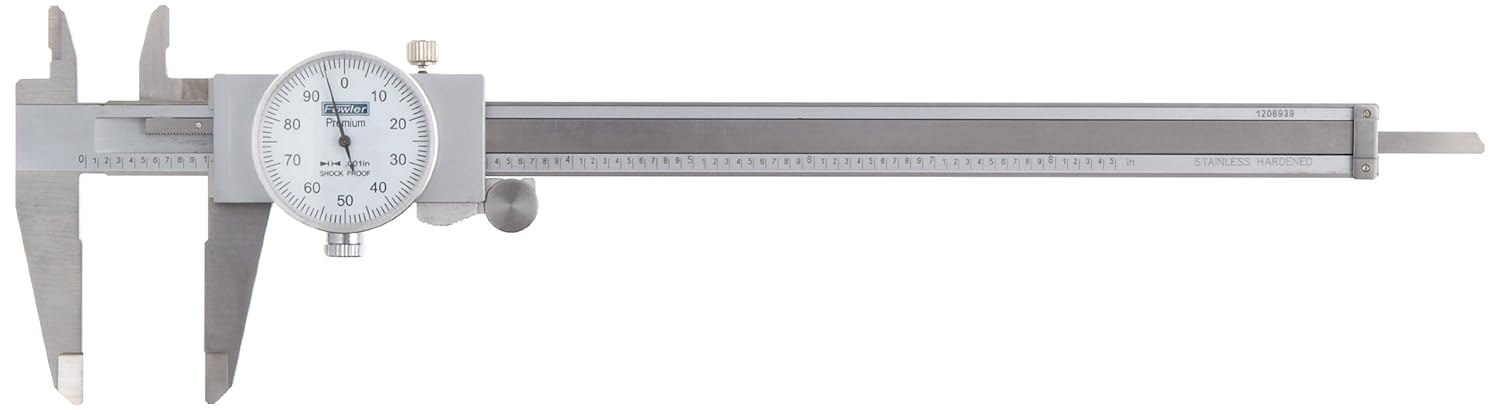

this info should help increase your hand load accuracy a great deal if followed carefully, DO YOU OWN A CALIPER

, you'll generally find that's what you use. and you select the longest OAL, or rear most crimp groove matching your revolver cylinder, that does not result in loaded cartridges that has bullets loaded too extend so much as the bullet extends out of the revolvers cylinder, the less distance the bullet moves before entering the barrel forcing cone the more consistent the accuracy tends to be!

crimp cast bullets firmly, as recoil may allow a improperly crimped bullet to move forward binding the cylinder.

ACURATELY measure ALL of your revolver cylinder's , the cylinder bore exit diam, really it should ideally be a thousandth or maybe 1.5 thousands larger than the barrel forcing cone and bore of the rifling diam.

cylinder bore exit diam. should never be equal too or smaller than forcing cone and bore diam or accuracy is going to be abysmal

forcing cone diam, should be about 1-1.5 thousands larger than bore diam.

yes this commonly means you lube size the cast bullets to a marginally larger diam. than the revolvers bore diam, to get best accuracy

450-.454 is the common bore diam. range on the 45 colt, most but not all,

newer ones are .452

newer ones are .452bullets cast must be marginally larger than bore diameter for best accuracy,

bullets must be sized and lubed larger than forcing cone and rifle bore diam.

cylinder throat diam must be marginally larger than the forcing cone throat of the barrel and forcing cone to get any decent accuracy

cast bullets self center engaging the rifling and swage as they seal to bore

example most 44 mag revolvers have a .429 -430 bore, most cast 44 mag bullets are sized .430-.432 to get best accuracy

this info should help increase your hand load accuracy a great deal if followed carefully, DO YOU OWN A CALIPER

Last edited:

btw

the brinell hardness of the cast bullet varies with alloy and heat treating

a typical cast bullet made from wheel weights and having 5% tin added too the alloy will have a brinell hardness if dropped into a bucket of water as you cast, btw a 7 gallon bucket with a towel in the bottom filled to within 5 -6 inches of the rim with room temp water works to catch

of 24-27 and easily handles 31k pressure and maintains consistent accuracy

btw a 7 gallon bucket is preferable over the more common 5 gallon bucket

the brinell hardness of the cast bullet varies with alloy and heat treating

a typical cast bullet made from wheel weights and having 5% tin added too the alloy will have a brinell hardness if dropped into a bucket of water as you cast, btw a 7 gallon bucket with a towel in the bottom filled to within 5 -6 inches of the rim with room temp water works to catch

of 24-27 and easily handles 31k pressure and maintains consistent accuracy

btw a 7 gallon bucket is preferable over the more common 5 gallon bucket

do you cast and hunt with bullets you made

have some 405 grain Magma bullets I bought from a caster in Montana. Loaded them above 36 grains of 5744. They go through the target sideways at 25 yards. Kind of worried one might circle back and get me. https://www.buffaloarms.com/bullet-moulds/buffalo-arms-bullet-moulds Rifle is a Miroku...

garage.grumpysperformance.com

Last edited:

btw , one of my friends started to use cast bullets in his SKS carbine, he used a150 grain 30 caliber mold that cast .,309 diam. bullets

that was designed to be used in a 30/30 he owned as they shot 2" 100 yard groups in his 30/30 marlin thus a known accurate bullet, but an SKS has a .311-.312 bore, the result was 6"-7" groups at 25 yards and 3 foot groups at 100 yards, I pointed out the potential flaw or reason the SKS and that bullet were not compatible, once he purchased the correct matching mold the SKS would shoot 6" 100 yard cast bullet groups at 100 yards, (until the gas system needed to be cleaned after about 70 shots,

(you should not use cast bullets in a semi auto with a gas powered system in my opinion)

cleaning the lube/lead sludge from the SKS gas systems a time consuming P.I.T.A.)

that was designed to be used in a 30/30 he owned as they shot 2" 100 yard groups in his 30/30 marlin thus a known accurate bullet, but an SKS has a .311-.312 bore, the result was 6"-7" groups at 25 yards and 3 foot groups at 100 yards, I pointed out the potential flaw or reason the SKS and that bullet were not compatible, once he purchased the correct matching mold the SKS would shoot 6" 100 yard cast bullet groups at 100 yards, (until the gas system needed to be cleaned after about 70 shots,

(you should not use cast bullets in a semi auto with a gas powered system in my opinion)

cleaning the lube/lead sludge from the SKS gas systems a time consuming P.I.T.A.)

tacticalwind

New Member

Ah, the joys of reloading and encountering specific challenges with load data! It's understandable that finding specific load data for your particular bullet shape can be frustrating, especially when most reloading manuals provide COAL (Cartridge Overall Length) recommendations for flat-nosed bullets. However, here are a few approaches you can take to determine a suitable COAL for your round-nosed or semi-wadcutter bullets.

Consult Bullet Manufacturers: If you know the brand or specific make of your bullet molds, it's worth checking the manufacturer's website or contacting their customer support. They might have load data or recommended COAL specifically for their bullets. They can provide valuable insights based on their testing and expertise.

Load Development and Testing: Since you mentioned these loads will be for paper punching and experimenting, you have some room for load development. Start by selecting a conservative starting load of Trail Boss powder based on the powder manufacturer's recommendations. Gradually work your way up, monitoring pressure signs, and assessing accuracy and performance. Remember to follow safe reloading practices and be cautious when increasing powder charges.

Adjusting COAL: In the absence of specific COAL data, you can start with a COAL recommended for a similar bullet shape, such as a flat-nosed bullet, and adjust it slightly. Increase or decrease the COAL in small increments (e.g., 0.010 inches) while checking for proper chambering, feeding, and accuracy. Be mindful of maintaining adequate bullet seating depth to ensure reliable functioning.

As always, when experimenting with loads, it's important to exercise caution, follow proper reloading procedures, and start with conservative loads. Keep detailed records of your loads, including bullet type, powder charge, COAL, and any notable observations or results. This will help you track your progress and ensure safety throughout the process.

Happy reloading and may your future loads be accurate and satisfying!

Consult Bullet Manufacturers: If you know the brand or specific make of your bullet molds, it's worth checking the manufacturer's website or contacting their customer support. They might have load data or recommended COAL specifically for their bullets. They can provide valuable insights based on their testing and expertise.

Load Development and Testing: Since you mentioned these loads will be for paper punching and experimenting, you have some room for load development. Start by selecting a conservative starting load of Trail Boss powder based on the powder manufacturer's recommendations. Gradually work your way up, monitoring pressure signs, and assessing accuracy and performance. Remember to follow safe reloading practices and be cautious when increasing powder charges.

Adjusting COAL: In the absence of specific COAL data, you can start with a COAL recommended for a similar bullet shape, such as a flat-nosed bullet, and adjust it slightly. Increase or decrease the COAL in small increments (e.g., 0.010 inches) while checking for proper chambering, feeding, and accuracy. Be mindful of maintaining adequate bullet seating depth to ensure reliable functioning.

As always, when experimenting with loads, it's important to exercise caution, follow proper reloading procedures, and start with conservative loads. Keep detailed records of your loads, including bullet type, powder charge, COAL, and any notable observations or results. This will help you track your progress and ensure safety throughout the process.

Happy reloading and may your future loads be accurate and satisfying!

BTW youll generally require a firm crimp to prevent bullets moving in a cylinder, potentially binding a revolver or being deeper seated raising pressure to alarming levels in a semi auto and generally seat to the longest length the bullet design allows that feeds 100% consistently and reliably yet allows that firm crimp