read thru this thread. and the linked info,provided, it will be well worth the effort.

like with the vast majority of products quality costs money,

and you tend to get what you pay for!

if two lifts look similar and the price is significantly cheaper on one,

THERES A DAMN GOOD REASON,

Id strongly suggest you do your research and not let price alone dictate your choices, as the old sayings go,

the sweetness of low price,

seldom lasts nearly as long ,

as the bitterness of low quality,

and yeah, theres plenty of cheap imported re-branded lifts available

"if you want good clean fresh oats you'll usually pay a fair market price....

if your happy with oats that have already made the trip through a horse...

well thats significantly cheaper"

before you purchase a lift call the state better business and local states attorney, in the state that is selling that lift and ask questions about complaints,involving that business theres a good deal of scam artists in this business, look thru the internet, look for rip-off reports

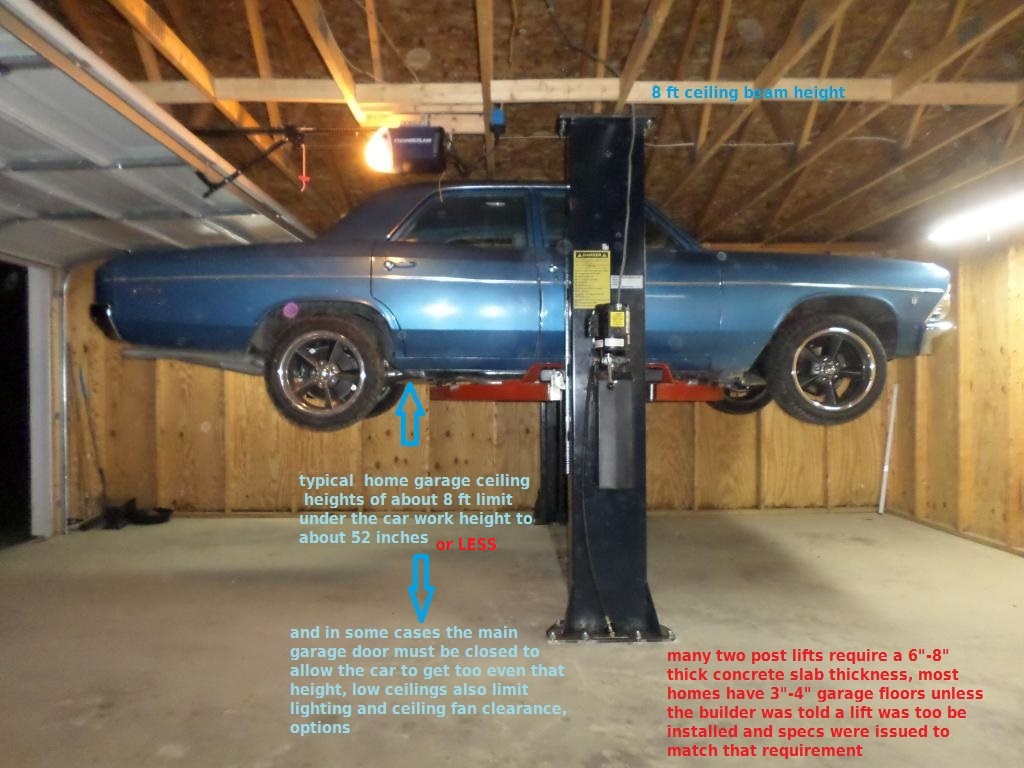

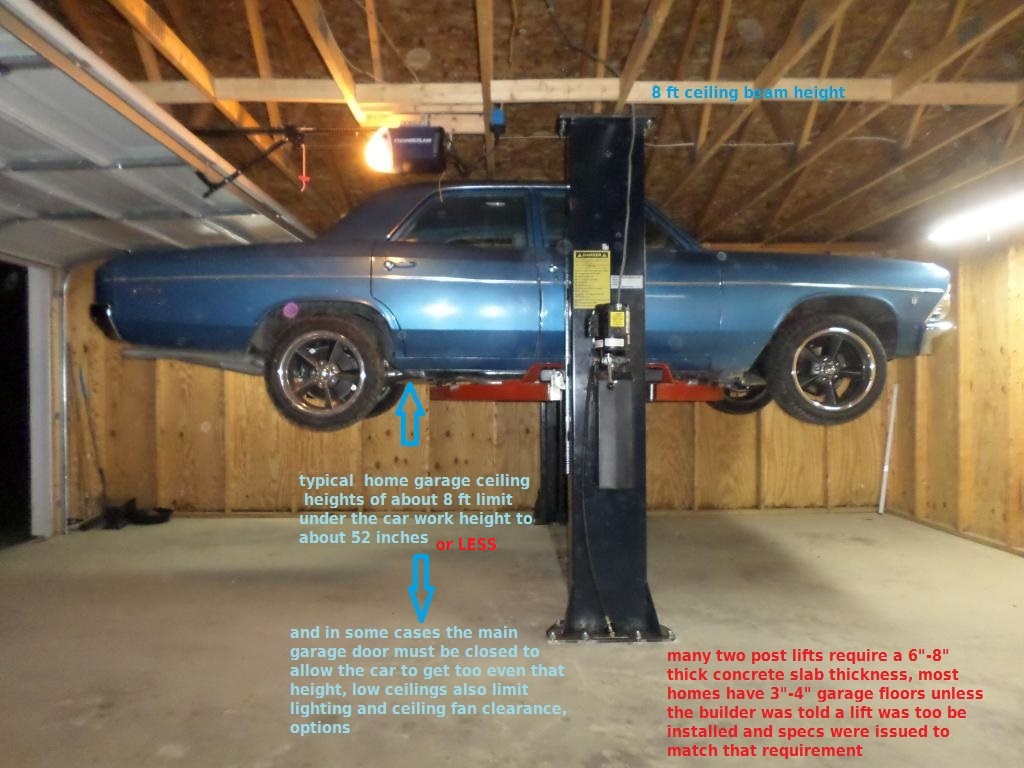

11 feet is about the average minimum ceiling height required for full height lifts, keep in mind most cars are about 5-6 feet tall and you need about 6 foot of clearance under the lift to work, be sure you measure WHERE YOUR GOING TO INSTALL THE LIFT then call your lift supplier BEFORE ORDERING A LIFT to BE SURE IT WILL FIT, if you are buying a two post lift check with the manufacturer about minimum floor strength /thickness required

BTW heres two calculators (Id add 10% )

you,ll generally want the posts for any 2 post lift placed so the front of the car on the lift , will not restrict movement around the car, so posts should be at least 13-14 feet from the nearest wall.

link to picture of the lift I had in my fla shop for 2 decades

http://grumpysperformance.com/garage11.jpg

yeah Im still refurbishing my texas shop

most home garages have an 8 FT ceiling height making installation of a decent lift and required clearances difficult, obviously if your car is 5.5 feet tall from pavement too the roof and you have a 8 ft ceiling you can,t lift the car to more than about 2 feet or so off the garage floor before the roof starts getting close to the ceiling clearance, especially if you've installed fans or shop florescent lighting fixtures.

while thats ok if you want too work on a mechanics creeper on your back, you certainly can,t sit or stand under the car too work.

http://www.concretenetwork.com/concrete/howmuch/calculator.htm

http://www.lowes.com/cd_Concrete+Pad+Calculator_100901113_

https://www.fastenal.com/products/details/0228905

Id point out that most two and most four post lifts require a 10-11 foot ceiling height simply cause most cars are 5-6 feet tall, and most people at 5.5-6.5 tall who work on cars thus to stand erect under the car youll need that height, obviously if you use a mechanics creeper you cut that requirement drastically lower as you only need 2-4 feet under the car to work, and get full access.

there are two post lifts that are only 8-9 foot tall but shop carefully for any lift and ask about certifications,many import lifts and some domestic lifts are cheap crap, that are not safe!

most four post lifts will bolt to almost any shop floor, some are even designed to roll around when there's nothing being lifted on them, a two post lift will generally need a 6"-8" thick solid concrete floor to anchor to securely and before you buy one you should consult both the manufacturer and drill your floor concrete to verify the slab thickness , and if its not adequate youll need to pout footers for the lift columns

in most cases its 6" minimum, if you have only the typical 3"-4" slab youll need a footer poured, when you plan a garage you might want to remember most lifts require a 11-13 ft ceiling clearance and if the car or truck is 5-6ft tall and your 6ft tall you need a 13 ft ceiling height to work on the car while standing up under it, it also helps to run the garage door roller track way up the inside wall for storage for as much distance as possible because a door stored vertically along the inside wall doesn,t block over head lighting or fans or potentially get into clearance issues with the car while up on a lift, one of my friends failed to think about that and has to close the garage door to put a car up on the lift, or it hits the horizontally stored door that has tracks that store the open door at about 8 ft off the shop floor

read thru these links and this thread carefully, 4" of concrete is marginal, or even dangerous with a two post lift, Id strongly suggest talking to the lift manufacturer about options, personally Id strongly suggest sinking/installing 4' x'4' x 2' feet concrete footers, tied into the slab, having a car over your head that might pull the anchor bolts is stupid at best, and a few yards of 5000 psi concrete will cost far less than your medical bills and car repair if a car falls when the anchor bolts pull free

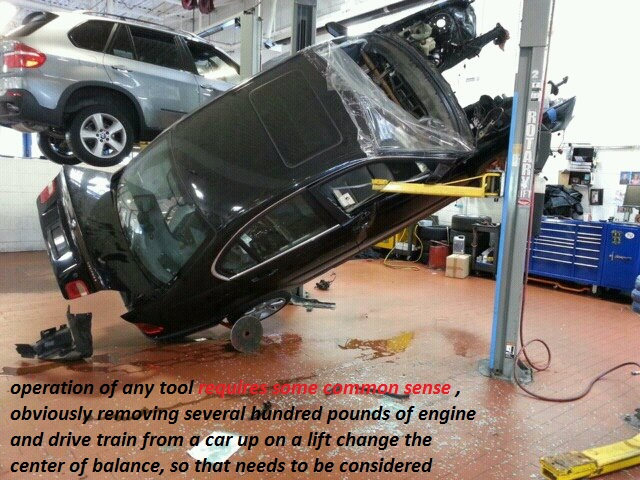

potential results of a small base, two post, lift installed on a 4" slab, in most cases manufacturers indicate a two post lift needs a MINIMUM of 6"-to 8" of concrete floor thickness and a minimum of 3600 psi concrete with 6"-8" anchor bolts to effectively and safely anchor a two post lift

on a 4 post lift its a fairly strait forward deal if youve got instructions, but on a TWO POST lift your concrete floor thickness and concrete strength are factors that need to be seriously considered.

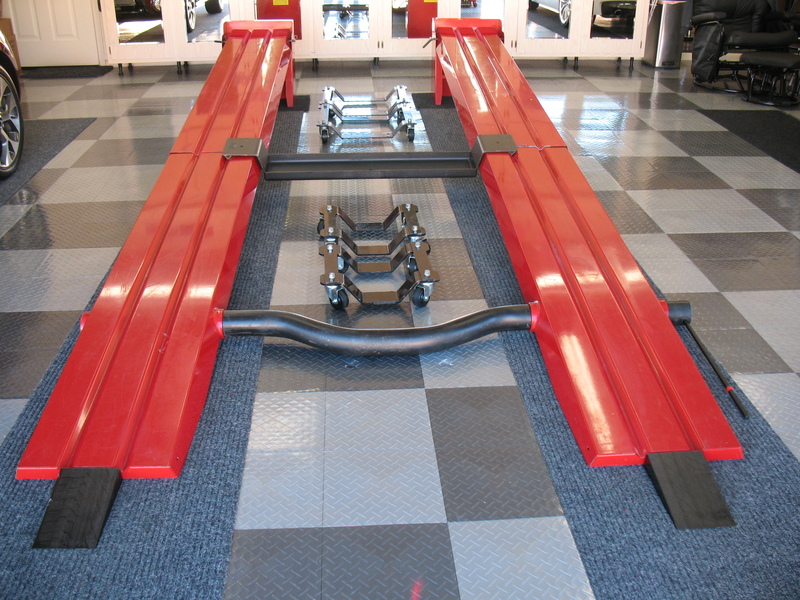

if your using the lift to store a car and allow a second car to occupy the same floor space a 4 post lift is ideal, if your using the lift mostly for working on a car ,, brakes,suspension engine,exhaust etc. a quality two post lift has several advantages.

but after using my buddys 4 post lift and having my QUALITY 2 post lift I can,t even imagine swapping to a 4 post unless all your doing is storing a car up out of the way and gaining useable floor space, theres just far to many things that are easy to access with a good two post that are a P.I.T.A. using a 4 post design

HERES ONE COMPANYS CONCRETE PAD SUGGESTIONS

http://www.rotarylift.com/uploadedFiles/FAQ1.pdf

you might want to keep in mind that if you screw it up or the lift fails and YOU installed it vs the factory reps that the manufacturer is 90% sure to blame faulty installation as the major cause, while thats seriously less likely with a factory rep installing it

when I first started looking at lifts I was convinced I wanted a drive-on style 4 post design, but after talking to several dozen corvette mechanics I was totally convinced of the advantages of a QUALITY two post lift, which is mainly far more access under the car and especially better wheel and suspension component access.[/color][/size]

if you've got ceiling clearance issues, or can,t install a permanent lift heres a couple options

http://www.kwik-lift.com/

http://www.ezcarlift.com/ezcarlift_video.html

[/color][/size]

SHOP CAREFULLY, HERES AN EXAMPLE COMPARING TWO SIMILAR LOOKING LIFTS,

THERES NO COMPARING STRENGTH

READ THRU THIS LIST OF QUESTIONS

http://www.mohawklifts.com/wp/consumer/ ... ost-lifts/

http://www.bestbuyautoequipment.com/v/B ... y-Lift.htm

racetoolsdirect.com

the BENDPACK HAS A GOOD DEAL MORE MASSIVE PARTS AND A BETTER DESIGN[/size][/b][/color]

racetoolsdirect.com

the BENDPACK HAS A GOOD DEAL MORE MASSIVE PARTS AND A BETTER DESIGN[/size][/b][/color]

http://www.autolift.org/members.htm

http://www.autolift.org/purchasing.htm

http://www.ali-directory.org/ali/ali2.n ... e?OpenForm

this should help

ID STRONGLY SUGGEST NOT BUYING A CHINESE BUILT LIFT AND BUYING FROM AN AMERICAN MANUFACTURER

/KEEP IN MIND THAT PARTS AVAILABILITY IN THE FUTURE AN SERVICE IS FAR MORE IMPORTANT THAN SAVING A FEW BUCKS ON THE UP FRONT COST

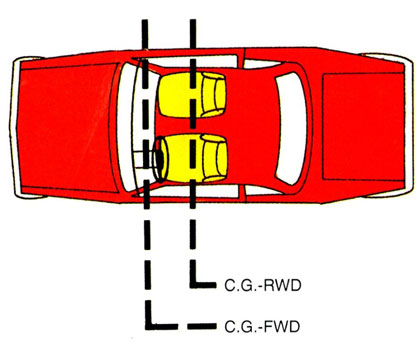

both the two post and four post designs have advantages and disadvantages, the question you should ask yourself first is WHATS the MAIN purpose of the lift......if its storage the 4 post is easier to deal with, but if you actually work on the car frequently I can,t see any real choice but a quality two post lift, especially if access for brake jobs and suspension work, and easy drive train access is important to you.

THE CERTIFICATION STICKER IS MANDATORY ON A DECENT LIFT

http://www.autolift.org/

any lift worth having will have this sticker, its NOT just a "STICKER" its a certification that the lift design HAS BEEN TESTED and will function under its rated load plus about 30%-50%, and that it meets some minimum safety feature requirements.

A certification for any product serves several purposes. The one that no one sees is consistency of manufacture. That's a big one and the one that should concern you with a product like a lift.

obviously theres always going to be a few IDIOTS that should never be allowed to operate machinery, who have accidents, but its at least reassuring to know that the basic lift is unlikely to structurally fail.

listed members,(below) but be aware in a few cases the same vendor may sell , BOTH certified and NON-CERTIFIED LIFTS, look for the sticker in the advertising and on the lift

http://www.autolift.org/members.htm

look at the listed members with certified lifts

any lift without that sticker is more than likely import junk that can,t pass safety testing

KEEP IN MIND THAT IF THE COMPANY YOUR DEALING WITH...

http://www.ali-directory.org/ALI/ALI2.n ... d%20Rating

DOES NOT HAVE,their physical ADDRESS displayed,

THAT'S A HUGE RED FLAG.........PROBABLY an EXCELLENT indicator to avoid them

IF they DON'T advertise their lifts as

ALI certified/validated by ETL

THAT'S A HUGE RED FLAG.........

IF THERE'S NO LOCAL DEALER

IF theres NO LOCAL INSTALLER AND REPAIR

THAT'S A HUGE RED FLAG.........

TAKE THE TIME TO DO RESEARCH and FIND OUT WHAT SEVERAL PREVIOUS CUSTOMERS THINK, HOW LONG THE COMPANY'S BEEN IN BUSINESS , ETC.

look on the internet for complaints and check with the state BBB about the company you are thinking of dealing with as several SCAM ARTISTS ARE IN THIS BUSINESS, ALL WAYS PAY WITH A CREDIT CARD< NOT CASH OR CHECK OR MONEY ORDER, so if you never get the lift the charges can be disputed,

ID also suggest going by several local dealerships and corvette clubs and asking what brands of lifts they prefer,and they use and how the parts availability and maintenance gets handled , if you don,t have access to repair parts from a dependable source in a few years you bought expensive junk, and these imported china knock-off brands go out of business after they sell off stock on hand so they don,t maintain a repair parts inventory

remember the price is only one factor, theres no gain in getting a good price on JUNK that can,t be repaired, something that parts are not going to be available for in a few years or something that will sooner or later get you killed, due to crappy workmanship or design or something being made out of marginally crappy steel, or thin steel to save weight but costing your lift strength......theres a GOOD REASON ITS CHEAPER, ITS WORTH A GOOD DEAL LESS AND IN MOST OF THE CASES, you TEND too GET what you pay for!

what have you gained if the damn lift stops working and you can,t get it repaired or fails and you or your car is seriously damaged or totaled, will that great low price off set ,being crippled for life or dead ,

check with each manufacturer before you buy a lift,

keep firmly in mind that most two post lifts requires a 6" or thicker concrete slab or a separate footer be installed in the shop floor to safely anchor the base of the support posts to prevent any potential tipping, most shop floors are 2"-3" thick if no lift was planned during their construction

BTW I bought the lift design and brand and model I did after closely inspecting several brands at several dealerships and repair shops and asking about repairs and support and if they had any problems after years of use, the lift I selected had rave reviews from mechanics

keep in mind that the better two post designs take up far less floor space than a 4 post lift and allow more access to the wheels and suspension and under the car drive train, on the down side they generally require a 4"-6"-8" MINIMUM concrete floor thickness, (something you might not have in a standard garage floor) (yes you can install a footer but that's an extra expense!) its always best that you can contact the lift company for their suggestions,and perhaps check the local building codes. your current floor may be fine with a standard or over size base plate which can be added to most lift designs, but several of my friends with older shops , simply figured out exactly where the two post lift base would be located and busted out some concrete,in a 4 foot box with the post location at its center and dug out two twin, 4 ft sq and 18-24" deep boxes, lined them with some rebar and plastic sheet and poured the recess with 3500psi concrete, and smoothed out the surface to match the original floor,

thats about one cubic yard, to maybe 1.2 cubic yard,s of high strength concrete for each post and its worked out just fine, around here thats about $130 a yard and damn cheap life insurance

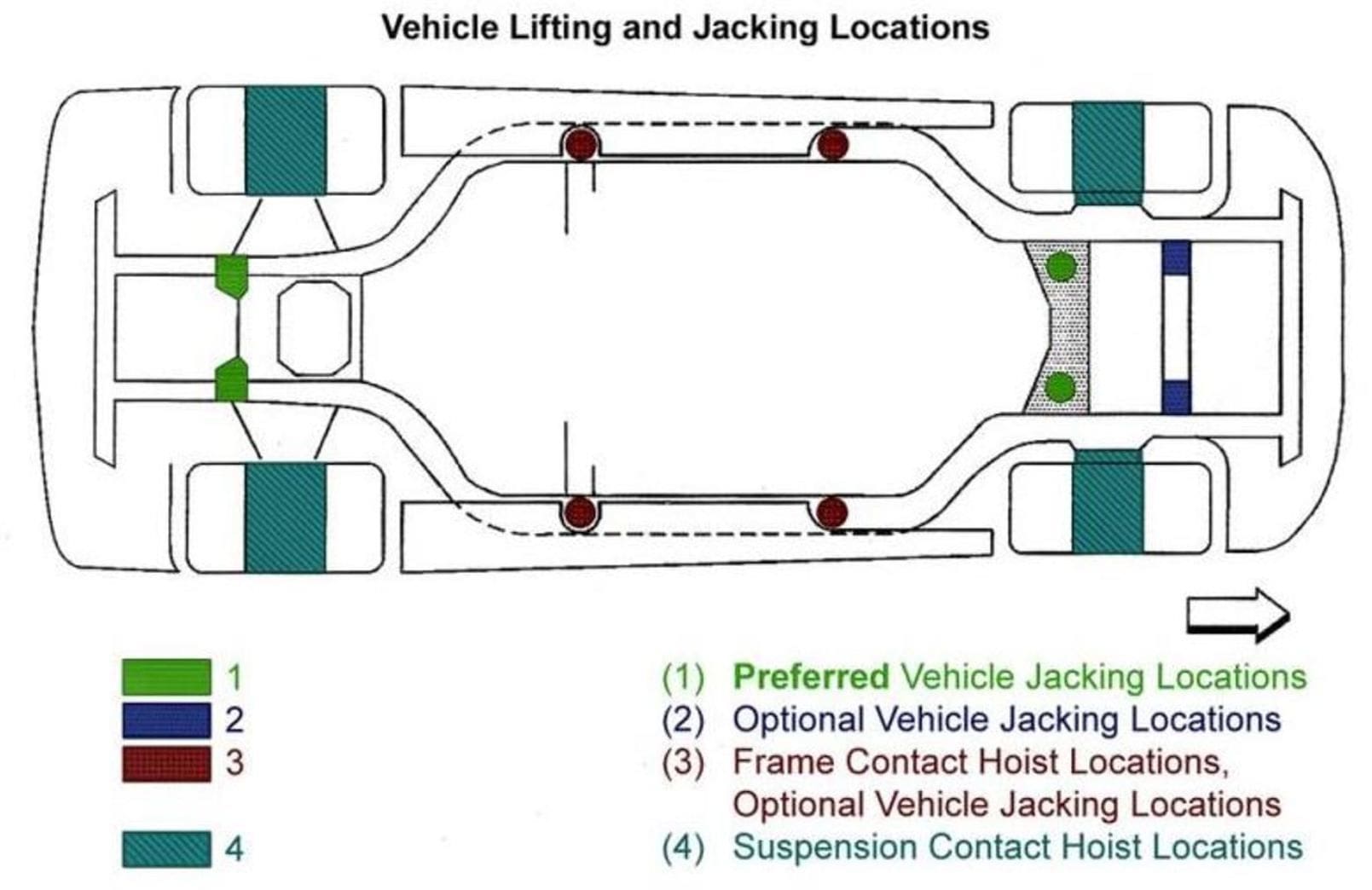

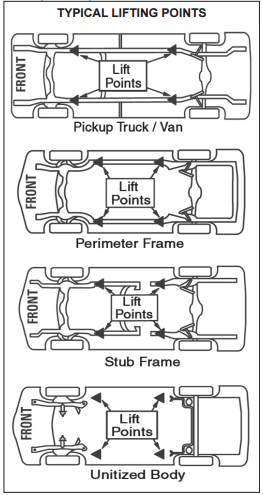

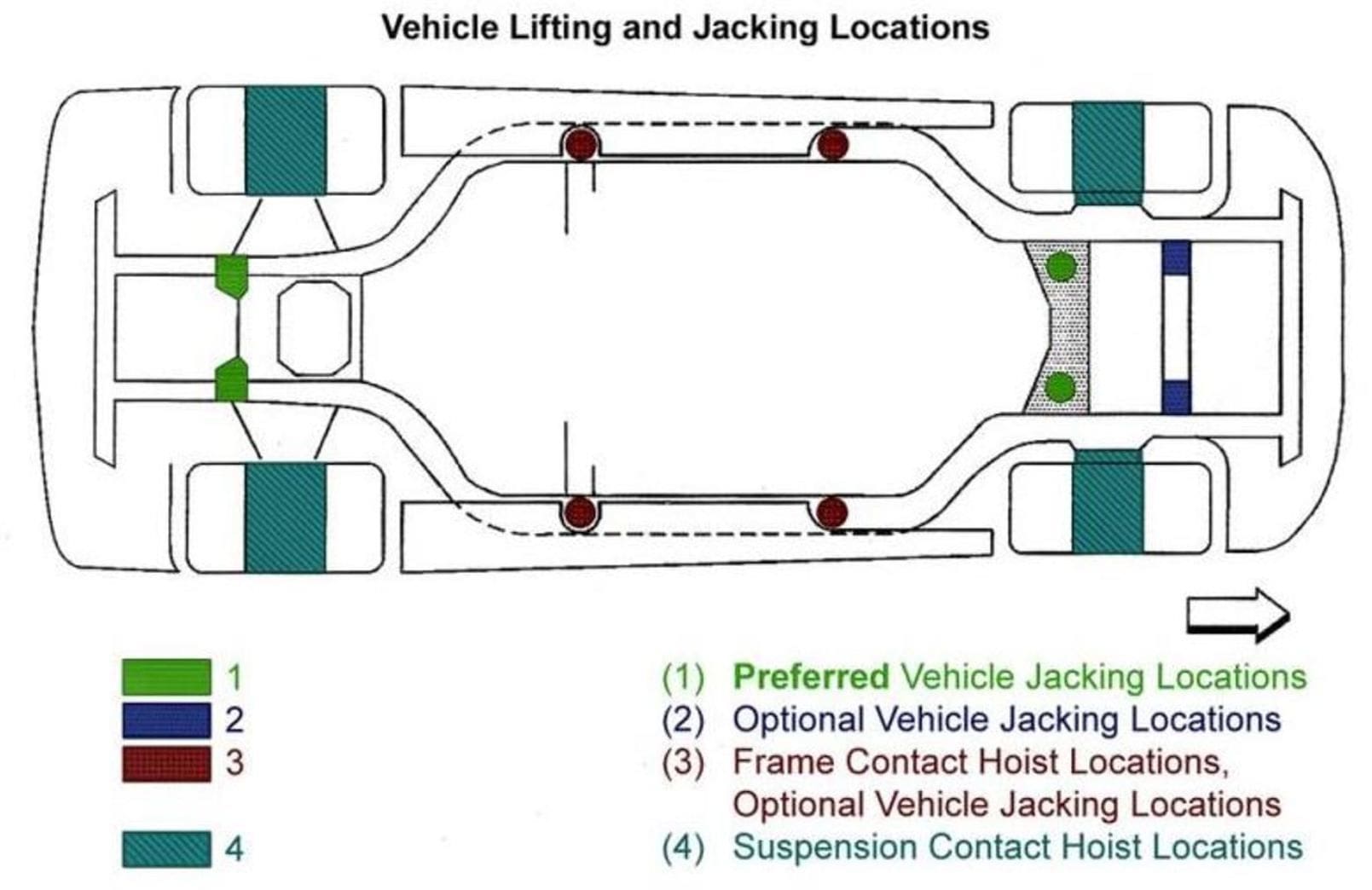

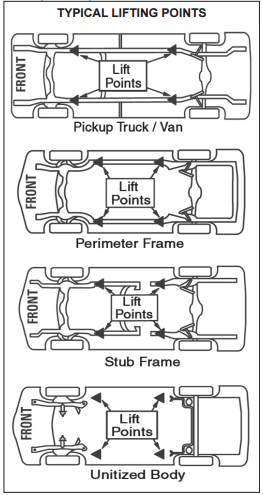

two post designs are a bit harder to get the car up on correctly and safely , because you don,t just drive onto them but need to swing the arms under the car and line up the support pads on the frame,but they are every bit as sturdy once properly installed and used correctly

heres the 9000 lb rated lift I purchased and had installed after going to dozens of local shops and dealerships and talking to the mechanics about what lifts they found to be the best and most durable, and lifts having had the least problems or service issues

HERES THE LIFT I CHOSE

Model 9000SI (Clear-Floor Symmetrical Style 9000 lb. capacity twin-post Lift)

Specifications

http://www.ben-pearson.com/twin-post_1092_c.aspx?pp=0

Ben Pearson's 9000SI Two-Post

Solid features separate this lift from the pack

Compare feature for feature, the 9000SI beats the competition hands down.

We could talk about quality. We could talk about the rugged durability. We could talk about the design. But we let the features do the talking for us;Single-Point Safety Release; Two Independent Heavy-Duty Hydraulic Cylinders; Convenient Stack-Pad System; Clear Floor Design: Automatic Arm Restraining System; ALI certified/validated by ETL - and that's just the beginning.

If Quality is what you're looking for, you'll find it in Ben Pearson's 9000SI Two-Post.

The reasons are simple, we build each lift to exacting specifications. Plus, we don't build any lift to meet our needs, we build them to meet your needs.

ALI certified/validated by ETL

Single point safety release

Padded overhead shut-off bar

2-5/8" & 5" truck adapters included

Extra long carriage for smooth lifting

Convenient stack-pad storage rack on post

Automatic engage and release arm restraint

Extra large ultra-high molecular bearing blocks

Low profile arms for low ground clearance

Optional height extension kits for taller vehicles

Clear floor design for convenient use of floor jacks

Precise and efficient automatic arm restraining system engages

in the lifting process and automatically releases once the lift is

lowered. Eliminates wasted time releasing up to 4 independent

pull-type releases. Utilizes a multi-toothed gear mechanism for

maximum arm locking positions.

The operator convenient stack-pad system consists of

(4) 2-5/8" adapters and (4) 5" truck adapters as standard

equipment with every 9000 series Ben Pearson 2-post lift.

A convenient stack-pad storage rack is located on each post.

Low profile arms for low ground clearance vehicles.

Optional power station utility box mounts on the left column

providing convenient access to two air outlets and four ground

fault electrical outlets. Built-in air regulator, water separator and

oiler, with tool holster and hooks, keep the bay area productive

and efficient.

The EH1 and EH2 optional extended height kits are available

for the 9AI and 9SI

LINKS to MANY of the Auto lift suppliers

http://www.autolift.org/

http://www.autolift.org/purchase_considerations.pdf

http://www.kwik-lift.com/

http://www.geminilift.com/

http://www.ben-pearson.com/model-10ad-_1005_p.aspx

http://revolutionlift.com/

http://www.ben-pearson.com/twin-post_1092_c.aspx?pp=0

http://www.hunter.com/pub/product/racks/index.htm

http://www.challengerlifts.com/products.shtml

http://www.directlift.com

http://www.gregsmithequipment.com/

http://www.gregsmithequipment.com/4-Post-Lift/Commercial-Grade/Lift-Type/4-Post-Lifts

http://www.ezcarlift.com/

http://www.levo-artis.com/

http://www.challengerlifts.com/pdf/EV1020.pdf

http://www.backyardbuddy.com

http://www.gregsmithequipment.com/Atlas ... ison-Guide

http://www.autolifts.com

http://www.maxjaxusa.com/specifications.html

http://www.westernhoist.com/

http://www.stingerlifts.com

http://www.doublepark.net

http://www.mohawklifts.com

http://www.autolifters.com

http://www.bendpak.com/

http://www.gregsmithequipment.com/Atlas-BP-9F

http://www.bendpak.com/product_info.isg?products_id=881

http://www.rotarylift.com/

http://eagleequip.com/Merchant2/merchant.mvc?Screen=CTGY&Category_Code=LI

viewtopic.php?f=27&t=26&p=34#p34

ok having just gone thru this , Id point out that theres a HUGE difference in the REPLACEMENT PARTS availability and TECH SUPPORT availability and getting the lift installed correctly between the American made and Chinese built lifts, you probably DON,T WANT a 12,000 lb lift unless you exclusively work on larger trucks as the lift arms may not have the necessary clearance to use on low slung cars

a 9000 lb lift will handle almost all personal cars/trucks.

IF YOU FIND WHAT YOU THINK IS A GREAT DEAL ON A NEW LIFT< STOP AND DO SOME RESEARCH BEFORE SPENDING YOUR CASH!!

I really don,t want too "RAIN ON YOUR PARADE"

but even MORE I don,t want you to fail to do the research BEFORE you buy a lift with the result that you get seriously injured when it fails and having seen several lifts that were "BARGAIN PRICED DEALS OF A LIFE-TIME" fail to do much more than cause cash to change hands and the purchaser feel they got totally screed in the process or have the lift fail shortly after it was installed I just say DO THE RESEARCH CAREFULLY BEFORE THE PURCHASE, and CONTACT THE LOCAL BBB office and check the internet before purchasing and for darn sure use a credit card that can dispute charges, if what you get (IF ANYTHING) does not match the description

heres what I finally bought and had installed, keep in mind that the higher the lifts weight rating the larger the arms need to be and the more difficult it will be to use on low ground clearance cars like corvettes/camaros ETC. and you'll rarely find personal cars/trucks over 6000lbs in weight with most being well under 4000-4500lbs

heres the lift I purchased, I felt it was the best value, HAD THE BEST SERVICE SUPPORT AND BEST ACCESS UNDER THE CAR, ACCESS TO THE WHEELS, TRANSMISSION,EXHAUST, etc.

http://www.ben-pearson.com/model-10ad-_1005_p.aspx

old pictures taken the first week I had the lift while I was sticking stuff from the old shop in my new garage

btw I purchased a two post lift on the advice of several repair shops after being convinced and thinking at first that I wanted a 4 post lift, they pointed out that access to the brakes and suspension and under the corvette working on the drive train the access was better.

now Id purchased the two post lift and have been using it for awhile and went over to help a buddy with his 4 post lift, putting the car up on the lift is far easier with the four post , and it looked and worked just fine, but after that I found the guys at the repair shops were totally correct, working access under the corvette sucked compared to my 2 post lift.

all Im suggesting is think thru your choice, if your doing mostly oil changes and storage, like using the lift to allow access for a second car, a 4 post is a far better choice but if your deep into various repairs, especially on the brakes and suspension, and engine swaps a two post might be a better choice, especially if you think about the area the lift takes up in floor space when its not in use

keep in mind you have a choice of 2 or 4 post is based on what you plan to do most. 4 posts are better for storage but you will be driven crazy working around the support ramps 10 minutes through the first job if you are working on wheels or brakes, exhaust systems etc.. I makes no difference how much you spend on the lift, if it is not anchored on a GOOD THICK concrete base, with the correct anchors and in concrete of the correct composition it will be dangerous, to work under ID strongly suggest a MINIMUM of an 8" thick 3500psi concrete slab under a two post lift and a 4"-6" slab under a 4 post. many standard garage floors are only 2"-3" thick and made from 2300psi concrete so a custom FOOTER might be, required under the lift base, being necessary, to provide the required stability,check with your lift manufacturer for specs.

http://www.ben-pearson.com/model-10ad-_1005_p.aspx

BTW BEFORE YOU DECIDE TO SAVE MONEY BY DRIVING TO THE MANUFACTURERS DOCK, LOADING IT ONTO A TRAILER AND DRIVING IT HOME, AND SAVE THE SHIPPING COSTS

If you have it delivered,from out of state, in most cases you will not pay sales tax. Consider the tax, AND COST OF THE GAS AND POSSIBLY THE TRAILER RENTAL FEES, versus the shipping cost before you decide to go pick it up.

BTW I was asked why I didn,t do the install myself and had the factory reps do the install?

I LOVE MY LIFT and IVE had no problems with it, I also thought the cost to have it installed was rather high, but it took two experienced guys about 4-to-5 hours to do it and I figured it was well worth the cost if I ever had problems, because , experience has taught me that the warranty , on ANY LIFT, would have been virtually worthless, from any company ,if it ever came to a law suit, as EVERY problem would instantly be (BECAUSE OF IMPROPER INSTALLATION) IF the factory did not install it?

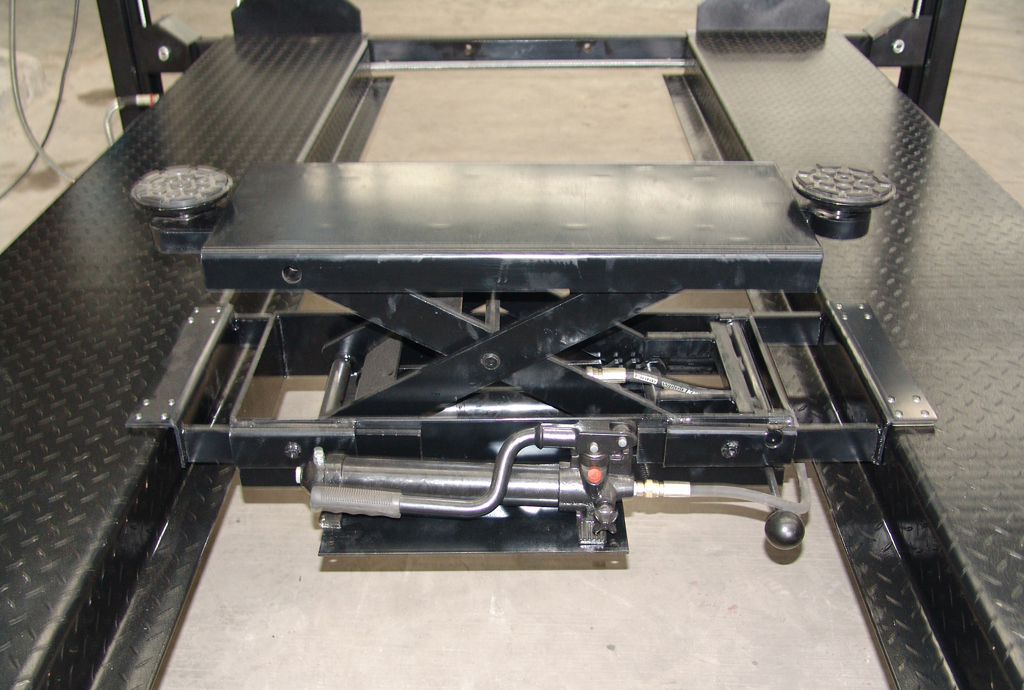

the CLEAR FLOOR FEATURE is a HUGE PLUS, as it makes use or a mechanics creeper or transmission jack far easier

like with the vast majority of products quality costs money,

and you tend to get what you pay for!

if two lifts look similar and the price is significantly cheaper on one,

THERES A DAMN GOOD REASON,

Id strongly suggest you do your research and not let price alone dictate your choices, as the old sayings go,

the sweetness of low price,

seldom lasts nearly as long ,

as the bitterness of low quality,

and yeah, theres plenty of cheap imported re-branded lifts available

"if you want good clean fresh oats you'll usually pay a fair market price....

if your happy with oats that have already made the trip through a horse...

well thats significantly cheaper"

11 feet is about the average minimum ceiling height required for full height lifts, keep in mind most cars are about 5-6 feet tall and you need about 6 foot of clearance under the lift to work, be sure you measure WHERE YOUR GOING TO INSTALL THE LIFT then call your lift supplier BEFORE ORDERING A LIFT to BE SURE IT WILL FIT, if you are buying a two post lift check with the manufacturer about minimum floor strength /thickness required

BTW heres two calculators (Id add 10% )

you,ll generally want the posts for any 2 post lift placed so the front of the car on the lift , will not restrict movement around the car, so posts should be at least 13-14 feet from the nearest wall.

link to picture of the lift I had in my fla shop for 2 decades

http://grumpysperformance.com/garage11.jpg

yeah Im still refurbishing my texas shop

most home garages have an 8 FT ceiling height making installation of a decent lift and required clearances difficult, obviously if your car is 5.5 feet tall from pavement too the roof and you have a 8 ft ceiling you can,t lift the car to more than about 2 feet or so off the garage floor before the roof starts getting close to the ceiling clearance, especially if you've installed fans or shop florescent lighting fixtures.

while thats ok if you want too work on a mechanics creeper on your back, you certainly can,t sit or stand under the car too work.

http://www.concretenetwork.com/concrete/howmuch/calculator.htm

http://www.lowes.com/cd_Concrete+Pad+Calculator_100901113_

https://www.fastenal.com/products/details/0228905

Id point out that most two and most four post lifts require a 10-11 foot ceiling height simply cause most cars are 5-6 feet tall, and most people at 5.5-6.5 tall who work on cars thus to stand erect under the car youll need that height, obviously if you use a mechanics creeper you cut that requirement drastically lower as you only need 2-4 feet under the car to work, and get full access.

there are two post lifts that are only 8-9 foot tall but shop carefully for any lift and ask about certifications,many import lifts and some domestic lifts are cheap crap, that are not safe!

most four post lifts will bolt to almost any shop floor, some are even designed to roll around when there's nothing being lifted on them, a two post lift will generally need a 6"-8" thick solid concrete floor to anchor to securely and before you buy one you should consult both the manufacturer and drill your floor concrete to verify the slab thickness , and if its not adequate youll need to pout footers for the lift columns

in most cases its 6" minimum, if you have only the typical 3"-4" slab youll need a footer poured, when you plan a garage you might want to remember most lifts require a 11-13 ft ceiling clearance and if the car or truck is 5-6ft tall and your 6ft tall you need a 13 ft ceiling height to work on the car while standing up under it, it also helps to run the garage door roller track way up the inside wall for storage for as much distance as possible because a door stored vertically along the inside wall doesn,t block over head lighting or fans or potentially get into clearance issues with the car while up on a lift, one of my friends failed to think about that and has to close the garage door to put a car up on the lift, or it hits the horizontally stored door that has tracks that store the open door at about 8 ft off the shop floor

read thru these links and this thread carefully, 4" of concrete is marginal, or even dangerous with a two post lift, Id strongly suggest talking to the lift manufacturer about options, personally Id strongly suggest sinking/installing 4' x'4' x 2' feet concrete footers, tied into the slab, having a car over your head that might pull the anchor bolts is stupid at best, and a few yards of 5000 psi concrete will cost far less than your medical bills and car repair if a car falls when the anchor bolts pull free

potential results of a small base, two post, lift installed on a 4" slab, in most cases manufacturers indicate a two post lift needs a MINIMUM of 6"-to 8" of concrete floor thickness and a minimum of 3600 psi concrete with 6"-8" anchor bolts to effectively and safely anchor a two post lift

on a 4 post lift its a fairly strait forward deal if youve got instructions, but on a TWO POST lift your concrete floor thickness and concrete strength are factors that need to be seriously considered.

if your using the lift to store a car and allow a second car to occupy the same floor space a 4 post lift is ideal, if your using the lift mostly for working on a car ,, brakes,suspension engine,exhaust etc. a quality two post lift has several advantages.

but after using my buddys 4 post lift and having my QUALITY 2 post lift I can,t even imagine swapping to a 4 post unless all your doing is storing a car up out of the way and gaining useable floor space, theres just far to many things that are easy to access with a good two post that are a P.I.T.A. using a 4 post design

HERES ONE COMPANYS CONCRETE PAD SUGGESTIONS

http://www.rotarylift.com/uploadedFiles/FAQ1.pdf

you might want to keep in mind that if you screw it up or the lift fails and YOU installed it vs the factory reps that the manufacturer is 90% sure to blame faulty installation as the major cause, while thats seriously less likely with a factory rep installing it

when I first started looking at lifts I was convinced I wanted a drive-on style 4 post design, but after talking to several dozen corvette mechanics I was totally convinced of the advantages of a QUALITY two post lift, which is mainly far more access under the car and especially better wheel and suspension component access.[/color][/size]

if you've got ceiling clearance issues, or can,t install a permanent lift heres a couple options

http://www.kwik-lift.com/

http://www.ezcarlift.com/ezcarlift_video.html

[/color][/size]

SHOP CAREFULLY, HERES AN EXAMPLE COMPARING TWO SIMILAR LOOKING LIFTS,

THERES NO COMPARING STRENGTH

READ THRU THIS LIST OF QUESTIONS

http://www.mohawklifts.com/wp/consumer/ ... ost-lifts/

http://www.bestbuyautoequipment.com/v/B ... y-Lift.htm

Race Tools Direct 11,000 lb. Direct Drive, Overhead 2 Post Lift- Bi-Symmetric Arms

The new Race Tools Direct 11,000 lb overhead 2 Post lift is the big brother to our RTD 9k Overhead lift to handle a wider range of vehicles.

racetoolsdirect.com

racetoolsdirect.com

http://www.autolift.org/members.htm

http://www.autolift.org/purchasing.htm

http://www.ali-directory.org/ali/ali2.n ... e?OpenForm

this should help

ID STRONGLY SUGGEST NOT BUYING A CHINESE BUILT LIFT AND BUYING FROM AN AMERICAN MANUFACTURER

/KEEP IN MIND THAT PARTS AVAILABILITY IN THE FUTURE AN SERVICE IS FAR MORE IMPORTANT THAN SAVING A FEW BUCKS ON THE UP FRONT COST

both the two post and four post designs have advantages and disadvantages, the question you should ask yourself first is WHATS the MAIN purpose of the lift......if its storage the 4 post is easier to deal with, but if you actually work on the car frequently I can,t see any real choice but a quality two post lift, especially if access for brake jobs and suspension work, and easy drive train access is important to you.

THE CERTIFICATION STICKER IS MANDATORY ON A DECENT LIFT

http://www.autolift.org/

any lift worth having will have this sticker, its NOT just a "STICKER" its a certification that the lift design HAS BEEN TESTED and will function under its rated load plus about 30%-50%, and that it meets some minimum safety feature requirements.

A certification for any product serves several purposes. The one that no one sees is consistency of manufacture. That's a big one and the one that should concern you with a product like a lift.

obviously theres always going to be a few IDIOTS that should never be allowed to operate machinery, who have accidents, but its at least reassuring to know that the basic lift is unlikely to structurally fail.

listed members,(below) but be aware in a few cases the same vendor may sell , BOTH certified and NON-CERTIFIED LIFTS, look for the sticker in the advertising and on the lift

http://www.autolift.org/members.htm

look at the listed members with certified lifts

any lift without that sticker is more than likely import junk that can,t pass safety testing

KEEP IN MIND THAT IF THE COMPANY YOUR DEALING WITH...

http://www.ali-directory.org/ALI/ALI2.n ... d%20Rating

DOES NOT HAVE,their physical ADDRESS displayed,

THAT'S A HUGE RED FLAG.........PROBABLY an EXCELLENT indicator to avoid them

IF they DON'T advertise their lifts as

ALI certified/validated by ETL

THAT'S A HUGE RED FLAG.........

IF THERE'S NO LOCAL DEALER

IF theres NO LOCAL INSTALLER AND REPAIR

THAT'S A HUGE RED FLAG.........

TAKE THE TIME TO DO RESEARCH and FIND OUT WHAT SEVERAL PREVIOUS CUSTOMERS THINK, HOW LONG THE COMPANY'S BEEN IN BUSINESS , ETC.

look on the internet for complaints and check with the state BBB about the company you are thinking of dealing with as several SCAM ARTISTS ARE IN THIS BUSINESS, ALL WAYS PAY WITH A CREDIT CARD< NOT CASH OR CHECK OR MONEY ORDER, so if you never get the lift the charges can be disputed,

ID also suggest going by several local dealerships and corvette clubs and asking what brands of lifts they prefer,and they use and how the parts availability and maintenance gets handled , if you don,t have access to repair parts from a dependable source in a few years you bought expensive junk, and these imported china knock-off brands go out of business after they sell off stock on hand so they don,t maintain a repair parts inventory

remember the price is only one factor, theres no gain in getting a good price on JUNK that can,t be repaired, something that parts are not going to be available for in a few years or something that will sooner or later get you killed, due to crappy workmanship or design or something being made out of marginally crappy steel, or thin steel to save weight but costing your lift strength......theres a GOOD REASON ITS CHEAPER, ITS WORTH A GOOD DEAL LESS AND IN MOST OF THE CASES, you TEND too GET what you pay for!

what have you gained if the damn lift stops working and you can,t get it repaired or fails and you or your car is seriously damaged or totaled, will that great low price off set ,being crippled for life or dead ,

check with each manufacturer before you buy a lift,

keep firmly in mind that most two post lifts requires a 6" or thicker concrete slab or a separate footer be installed in the shop floor to safely anchor the base of the support posts to prevent any potential tipping, most shop floors are 2"-3" thick if no lift was planned during their construction

BTW I bought the lift design and brand and model I did after closely inspecting several brands at several dealerships and repair shops and asking about repairs and support and if they had any problems after years of use, the lift I selected had rave reviews from mechanics

keep in mind that the better two post designs take up far less floor space than a 4 post lift and allow more access to the wheels and suspension and under the car drive train, on the down side they generally require a 4"-6"-8" MINIMUM concrete floor thickness, (something you might not have in a standard garage floor) (yes you can install a footer but that's an extra expense!) its always best that you can contact the lift company for their suggestions,and perhaps check the local building codes. your current floor may be fine with a standard or over size base plate which can be added to most lift designs, but several of my friends with older shops , simply figured out exactly where the two post lift base would be located and busted out some concrete,in a 4 foot box with the post location at its center and dug out two twin, 4 ft sq and 18-24" deep boxes, lined them with some rebar and plastic sheet and poured the recess with 3500psi concrete, and smoothed out the surface to match the original floor,

thats about one cubic yard, to maybe 1.2 cubic yard,s of high strength concrete for each post and its worked out just fine, around here thats about $130 a yard and damn cheap life insurance

two post designs are a bit harder to get the car up on correctly and safely , because you don,t just drive onto them but need to swing the arms under the car and line up the support pads on the frame,but they are every bit as sturdy once properly installed and used correctly

heres the 9000 lb rated lift I purchased and had installed after going to dozens of local shops and dealerships and talking to the mechanics about what lifts they found to be the best and most durable, and lifts having had the least problems or service issues

HERES THE LIFT I CHOSE

Model 9000SI (Clear-Floor Symmetrical Style 9000 lb. capacity twin-post Lift)

Specifications

http://www.ben-pearson.com/twin-post_1092_c.aspx?pp=0

Ben Pearson's 9000SI Two-Post

Solid features separate this lift from the pack

Compare feature for feature, the 9000SI beats the competition hands down.

We could talk about quality. We could talk about the rugged durability. We could talk about the design. But we let the features do the talking for us;Single-Point Safety Release; Two Independent Heavy-Duty Hydraulic Cylinders; Convenient Stack-Pad System; Clear Floor Design: Automatic Arm Restraining System; ALI certified/validated by ETL - and that's just the beginning.

If Quality is what you're looking for, you'll find it in Ben Pearson's 9000SI Two-Post.

The reasons are simple, we build each lift to exacting specifications. Plus, we don't build any lift to meet our needs, we build them to meet your needs.

ALI certified/validated by ETL

Single point safety release

Padded overhead shut-off bar

2-5/8" & 5" truck adapters included

Extra long carriage for smooth lifting

Convenient stack-pad storage rack on post

Automatic engage and release arm restraint

Extra large ultra-high molecular bearing blocks

Low profile arms for low ground clearance

Optional height extension kits for taller vehicles

Clear floor design for convenient use of floor jacks

Precise and efficient automatic arm restraining system engages

in the lifting process and automatically releases once the lift is

lowered. Eliminates wasted time releasing up to 4 independent

pull-type releases. Utilizes a multi-toothed gear mechanism for

maximum arm locking positions.

The operator convenient stack-pad system consists of

(4) 2-5/8" adapters and (4) 5" truck adapters as standard

equipment with every 9000 series Ben Pearson 2-post lift.

A convenient stack-pad storage rack is located on each post.

Low profile arms for low ground clearance vehicles.

Optional power station utility box mounts on the left column

providing convenient access to two air outlets and four ground

fault electrical outlets. Built-in air regulator, water separator and

oiler, with tool holster and hooks, keep the bay area productive

and efficient.

The EH1 and EH2 optional extended height kits are available

for the 9AI and 9SI

LINKS to MANY of the Auto lift suppliers

http://www.autolift.org/

http://www.autolift.org/purchase_considerations.pdf

http://www.kwik-lift.com/

http://www.geminilift.com/

http://www.ben-pearson.com/model-10ad-_1005_p.aspx

http://revolutionlift.com/

http://www.ben-pearson.com/twin-post_1092_c.aspx?pp=0

http://www.hunter.com/pub/product/racks/index.htm

http://www.challengerlifts.com/products.shtml

http://www.directlift.com

http://www.gregsmithequipment.com/

http://www.gregsmithequipment.com/4-Post-Lift/Commercial-Grade/Lift-Type/4-Post-Lifts

http://www.ezcarlift.com/

http://www.levo-artis.com/

http://www.challengerlifts.com/pdf/EV1020.pdf

http://www.backyardbuddy.com

http://www.gregsmithequipment.com/Atlas ... ison-Guide

http://www.autolifts.com

http://www.maxjaxusa.com/specifications.html

http://www.westernhoist.com/

http://www.stingerlifts.com

http://www.doublepark.net

http://www.mohawklifts.com

http://www.autolifters.com

http://www.bendpak.com/

http://www.gregsmithequipment.com/Atlas-BP-9F

http://www.bendpak.com/product_info.isg?products_id=881

http://www.rotarylift.com/

http://eagleequip.com/Merchant2/merchant.mvc?Screen=CTGY&Category_Code=LI

viewtopic.php?f=27&t=26&p=34#p34

ok having just gone thru this , Id point out that theres a HUGE difference in the REPLACEMENT PARTS availability and TECH SUPPORT availability and getting the lift installed correctly between the American made and Chinese built lifts, you probably DON,T WANT a 12,000 lb lift unless you exclusively work on larger trucks as the lift arms may not have the necessary clearance to use on low slung cars

a 9000 lb lift will handle almost all personal cars/trucks.

IF YOU FIND WHAT YOU THINK IS A GREAT DEAL ON A NEW LIFT< STOP AND DO SOME RESEARCH BEFORE SPENDING YOUR CASH!!

I really don,t want too "RAIN ON YOUR PARADE"

but even MORE I don,t want you to fail to do the research BEFORE you buy a lift with the result that you get seriously injured when it fails and having seen several lifts that were "BARGAIN PRICED DEALS OF A LIFE-TIME" fail to do much more than cause cash to change hands and the purchaser feel they got totally screed in the process or have the lift fail shortly after it was installed I just say DO THE RESEARCH CAREFULLY BEFORE THE PURCHASE, and CONTACT THE LOCAL BBB office and check the internet before purchasing and for darn sure use a credit card that can dispute charges, if what you get (IF ANYTHING) does not match the description

heres what I finally bought and had installed, keep in mind that the higher the lifts weight rating the larger the arms need to be and the more difficult it will be to use on low ground clearance cars like corvettes/camaros ETC. and you'll rarely find personal cars/trucks over 6000lbs in weight with most being well under 4000-4500lbs

heres the lift I purchased, I felt it was the best value, HAD THE BEST SERVICE SUPPORT AND BEST ACCESS UNDER THE CAR, ACCESS TO THE WHEELS, TRANSMISSION,EXHAUST, etc.

http://www.ben-pearson.com/model-10ad-_1005_p.aspx

old pictures taken the first week I had the lift while I was sticking stuff from the old shop in my new garage

btw I purchased a two post lift on the advice of several repair shops after being convinced and thinking at first that I wanted a 4 post lift, they pointed out that access to the brakes and suspension and under the corvette working on the drive train the access was better.

now Id purchased the two post lift and have been using it for awhile and went over to help a buddy with his 4 post lift, putting the car up on the lift is far easier with the four post , and it looked and worked just fine, but after that I found the guys at the repair shops were totally correct, working access under the corvette sucked compared to my 2 post lift.

all Im suggesting is think thru your choice, if your doing mostly oil changes and storage, like using the lift to allow access for a second car, a 4 post is a far better choice but if your deep into various repairs, especially on the brakes and suspension, and engine swaps a two post might be a better choice, especially if you think about the area the lift takes up in floor space when its not in use

keep in mind you have a choice of 2 or 4 post is based on what you plan to do most. 4 posts are better for storage but you will be driven crazy working around the support ramps 10 minutes through the first job if you are working on wheels or brakes, exhaust systems etc.. I makes no difference how much you spend on the lift, if it is not anchored on a GOOD THICK concrete base, with the correct anchors and in concrete of the correct composition it will be dangerous, to work under ID strongly suggest a MINIMUM of an 8" thick 3500psi concrete slab under a two post lift and a 4"-6" slab under a 4 post. many standard garage floors are only 2"-3" thick and made from 2300psi concrete so a custom FOOTER might be, required under the lift base, being necessary, to provide the required stability,check with your lift manufacturer for specs.

http://www.ben-pearson.com/model-10ad-_1005_p.aspx

BTW BEFORE YOU DECIDE TO SAVE MONEY BY DRIVING TO THE MANUFACTURERS DOCK, LOADING IT ONTO A TRAILER AND DRIVING IT HOME, AND SAVE THE SHIPPING COSTS

If you have it delivered,from out of state, in most cases you will not pay sales tax. Consider the tax, AND COST OF THE GAS AND POSSIBLY THE TRAILER RENTAL FEES, versus the shipping cost before you decide to go pick it up.

BTW I was asked why I didn,t do the install myself and had the factory reps do the install?

I LOVE MY LIFT and IVE had no problems with it, I also thought the cost to have it installed was rather high, but it took two experienced guys about 4-to-5 hours to do it and I figured it was well worth the cost if I ever had problems, because , experience has taught me that the warranty , on ANY LIFT, would have been virtually worthless, from any company ,if it ever came to a law suit, as EVERY problem would instantly be (BECAUSE OF IMPROPER INSTALLATION) IF the factory did not install it?

the CLEAR FLOOR FEATURE is a HUGE PLUS, as it makes use or a mechanics creeper or transmission jack far easier

Last edited by a moderator: