watch all three of the videos,

all the way through and

take a few notes,

ask questions, think things through,

if you have questions,

ask for clarification, and tips

related useful threads

block prep.

you really should read these links for a lot more USEFUL info, on block pre prep one of the least discussed & acknowledged, and yet more common reasons engines fail , is related to micro metallic crud left in the engine while its being assembled, especially engine's built on newly machined...

garage.grumpysperformance.com

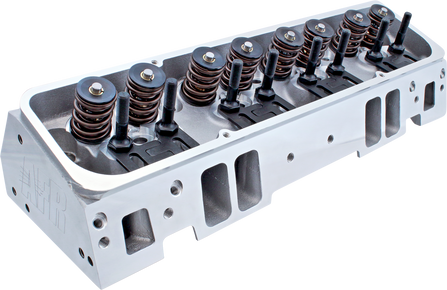

Cheap Good Cylinder Heads

Where do you find good and cheap cylinder heads? A set of these for $280 + valves + springs, reuse old rocker arms = $400 https://www.ebay.com/itm/393005918509 https://www.ebay.com/itm/322892146731 https://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/page-2 Buy...

garage.grumpysperformance.com

sellecting valve springs, and setting up the valve train

How do you determine the spring pressure needed to keep the valves under control for a given lift, duration, and max rpm. It might take you several hours to read thru all the links and sub links but its time very well spent as it could save your engine from destruction and save you thousands of...

garage.grumpysperformance.com

Precision measuring tools

I’m looking for the best quality precision tools on a limited budget (i.e. I don't want to pay $300 for one mic). I plan on building the occasional small- & big-block Chevy (more than one, less than 1000). Names that come up on the limited results I’ve found on the web include Starrett...

garage.grumpysperformance.com

checking piston to valve clearances

this is an old post I got asked to repost, naturally the first step is to install and correctly degree in your cam, http://garage.grumpysperformance.com/index.php?threads/measuring-piston-dome-volume.17255/...

garage.grumpysperformance.com

valve train clearances and problems

you might want to read thru these links and sub links it will help you avoid costly mistakes http://www.summitracing.com/parts/pro-66830/overview/ https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html...

garage.grumpysperformance.com

rocker/push rod wear issues

Put vortec heads on my L98 and ordered 1417 1.52 Roller Rockers and 7808 Pushrods from CompCams. Installed screw in rocker studs with guide tool before assembly of the engine. Checked valve geometry and the roller left a mark right on the center of the valve like its supposed to. Oil pressure...

garage.grumpysperformance.com

assembling and installing connecting rods/pistons

look closely at the connecting rods one edge of the main bearing are is beveled noticeably more than the other that beveled side faces away from the rod its paired with because it matches the slight radiased bevel of the crank journal many builder class pistons are designed to go in, in either...

garage.grumpysperformance.com

resistance to rotation, of crank durring short blk assembly

Ok youve just installed your crankshaft in the engine block, with new main bearings and everything's well coated with assembly lube,and oil, and youve torqued down the main caps to spec. in at least three stages, and then gone back and rechecked the studs or bolts per the manufacturers...

garage.grumpysperformance.com

ring gapping and basic piston ring info YOULL NEED

YES YOU NEED TO READ THRU THE LINKS THAT'S WHAT THEY ARE THERE FOR...AND THERE'S A GREAT DEAL OF USEFUL INFO IN THOSE LINKS, don,t get over whelmed, make a list and test adjust correct or replace each problem, and check it off the list then move to the next issue, its a finite list and theres...

garage.grumpysperformance.com

Piston And Rod Orientation & Clearance Issues Etc.

I got a new set of pistons (H423DCP/H640DCP) and a "new to me" set of OEM rods. The rods are numbered by cylinder, but the pistons aren't, and the dot is supposed to go toward the front of the block. I just put a rod on backward, so can it be interchanged with another cylinder on the opposite...

garage.grumpysperformance.com

thrust bearing face wear

Been a while since I don't post... meaning I did not break stuff... Disassembled my engine this winter to change some parts I bought and found half of the thrust bearing surface was almost gone (on the flywheel side of the motor). Luckily the bearing did not spin (I would've known from the...

garage.grumpysperformance.com

bearing clearances

Understanding Today’s Bearing Clearance Recipe ■Tech Center by Engine Builder Staff - Feb 6, 2015 0 3928 Print Email What’s needed to keep the rotating assembly rotating? It’s a recipe that includes three key ingredients: the bearing, the crankshaft and the oil. But understanding the...

garage.grumpysperformance.com

rotating assembly bearings

hi grumpy had a question , im rebuilding a 350 chevy. the crank readings are main bearing journal is 2.448 and rod journals read 2.098 so does this mean that I would need standard sized bearings? and also when installing new bearing from the box , do I need to clean them and if so with what ...

garage.grumpysperformance.com

oil system mods that help

heres a short list REMEMBER the object or goal in building and maintaining the lubrication system is too maintain a 100% dependable pressurized cooling flow of lubricant to the bearings, rockers ,valves etc. your most important tool, is your ability to think about how things are supposed to...

garage.grumpysperformance.com

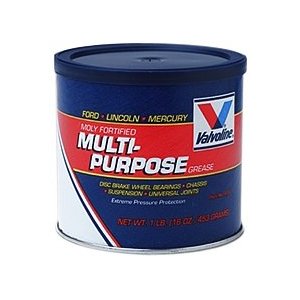

moly spray acts like a liquid solvent but in 15-20 minutes its just a slick fine grease, in two hours it looks like black soot., but you can,t see it soak into the micro surfaces, but you will feel THE DIFFERENCE AFTER REPEATED USE

http://www.engineersedge.com/lubrication/molybdenum_disulfide_characteristics.htm

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving surfaces in contact, rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on the rifle bore surface, This protective armor coating has a number of properties that are very beneficial for your rifles bore surface

The Moly platelets that make up the protective layers on your bore wall surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the bore to projectile surface contact

This coating effectively fills in the microscopic pores that cover the surface of all micro bore imperfections making them smoother. By filling in the craters and pores Moly improves this seal

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. The high pressures that occur between these moving surfaces that tend to squeeze normal lubricants out.

Last edited: Aug 31, 2021

Moly Lube

Grumpy I finally was able to find some moly lube and I can't find your process of how to use it and I am going to shoot my new 243 Mauser rifle and my 220 swift for the 1st time and I intend to start using the moly lube as part of my cleaning routine from now on but I searched a lot of posts and...

garage.grumpysperformance.com

Last edited: