FishFry

Active Member

Last night I had a long discussion with some friends on antifreeze.

I was amazed how many opposite opinions I heard on something that should have a pretty straight answer.

Ethylene, propylene, organic, inorganic, silicates, long life, distilled, non-distilled, bolt in zinc anodes andwhatnot.

Some say propylene based doesn't kill your bearings, when it gets into the oil, but it kills your seals on older engines (also silicone form-a-gasket stuff).

Some say distilled/demineralized water is corrosive and eats your engine, others say tap water makes deposits and scaling, and that some instructions say to use distilled water.

Everybody says they did this or that for 150 years (pretty much every possible combination) and never had a problem at all,

than the mechanics chime in and tell stories about leaking disasters with a certain orange type of antifreeze, they had to fix all the time etc.

The information you can find online is also all over the place and it's a mess.

I'm not a chemist, all I know for sure is that you should not mix different types, since they may gel.

On my daily drivers (most of the time 10-20 year old cars) I actually never gave it much thought. Always used the recomended type and tap water and called it a day. Also never had a problem with that. Maybe that means it's not THAT critical at the end of the day - who knows?

Can someone with more knowledge please shine some light on this?

I'm having a 41 Chevy with a hopped up 261 - iron block and head, but aluminum intake (water heated) and a radiator with brass parts.

It's a mixed bag of metals. Also sometimes our winters get pretty cold, so just Water Wetter doesn't do the trick.

Distilled/demineralized water or tap water? Organic/inorganic? Ethylene, propylene, silicates free?

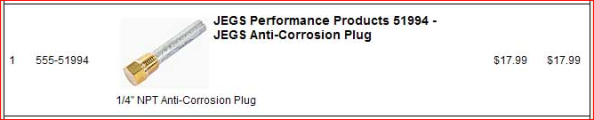

And what's the deal with those anodes? Do I just throw a magnesium stick on the radiator?

thanks, Frank

I was amazed how many opposite opinions I heard on something that should have a pretty straight answer.

Ethylene, propylene, organic, inorganic, silicates, long life, distilled, non-distilled, bolt in zinc anodes andwhatnot.

Some say propylene based doesn't kill your bearings, when it gets into the oil, but it kills your seals on older engines (also silicone form-a-gasket stuff).

Some say distilled/demineralized water is corrosive and eats your engine, others say tap water makes deposits and scaling, and that some instructions say to use distilled water.

Everybody says they did this or that for 150 years (pretty much every possible combination) and never had a problem at all,

than the mechanics chime in and tell stories about leaking disasters with a certain orange type of antifreeze, they had to fix all the time etc.

The information you can find online is also all over the place and it's a mess.

I'm not a chemist, all I know for sure is that you should not mix different types, since they may gel.

On my daily drivers (most of the time 10-20 year old cars) I actually never gave it much thought. Always used the recomended type and tap water and called it a day. Also never had a problem with that. Maybe that means it's not THAT critical at the end of the day - who knows?

Can someone with more knowledge please shine some light on this?

I'm having a 41 Chevy with a hopped up 261 - iron block and head, but aluminum intake (water heated) and a radiator with brass parts.

It's a mixed bag of metals. Also sometimes our winters get pretty cold, so just Water Wetter doesn't do the trick.

Distilled/demineralized water or tap water? Organic/inorganic? Ethylene, propylene, silicates free?

And what's the deal with those anodes? Do I just throw a magnesium stick on the radiator?

thanks, Frank

Last edited: