when clearances allow

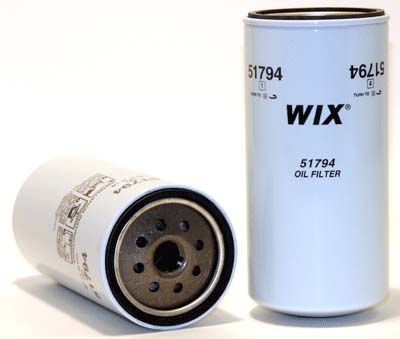

longer length, quality oil filters provide significantly larger surface area, this tends to both reduce pressure drop,

and increase the useful filtration time before the filter tends to partially clog due to trapped debris,

yes they still require frequent replacement but they tend to do a better job, over the same time frame

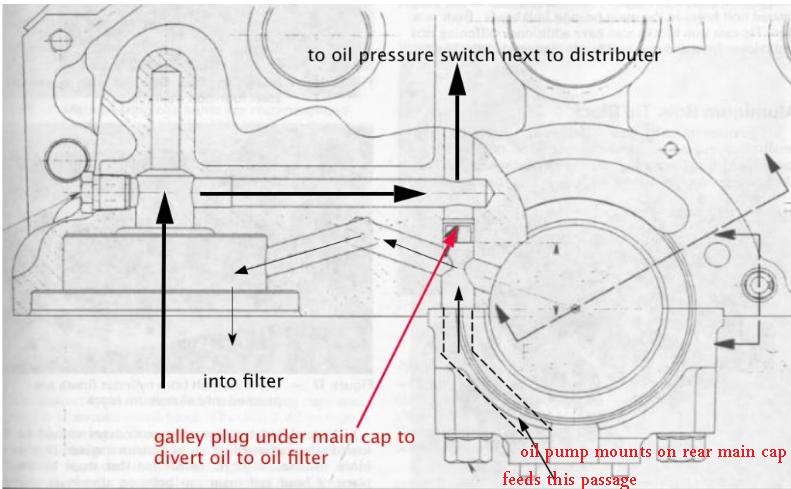

Big Block Chevrolet Gen V and Gen VI Oiling SystemSolving the mystery of the Gen V and Gen VI Priority Main Oiling system

Priority Main Oiling System

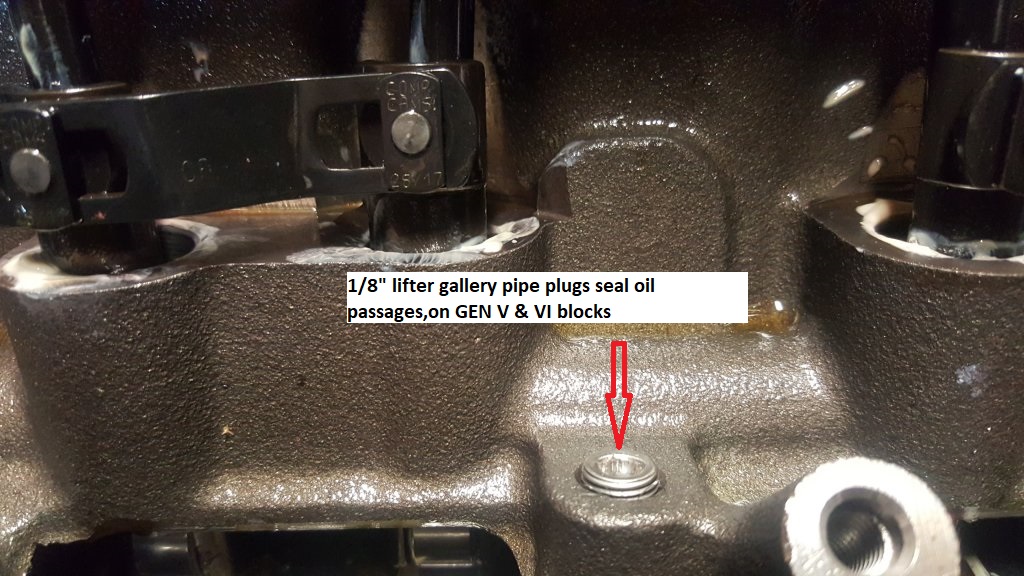

The Generation V and VI big block Chevrolet blocks feature a priority main oiling system where the main oil supply passage is located adjacent to the camshaft tunnel. Drilled passages which intersect this large oil tunnel carry oil directly to the main bearings. If you are facing the front of the block with the engine in the upright position, this main oil supply tunnel is located in the 2 o’clock position just below the right hand lifter oil supply line.

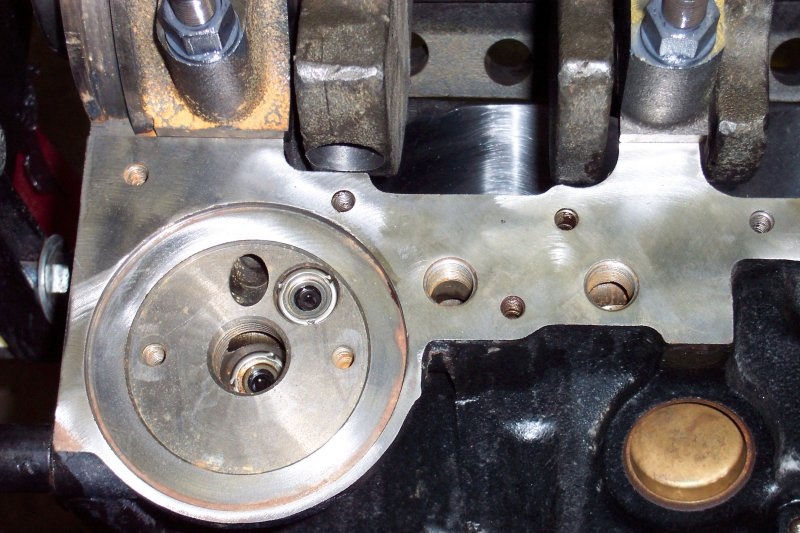

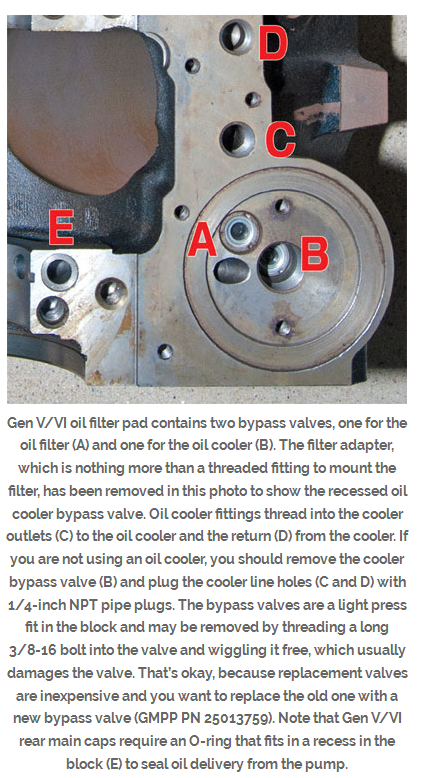

Oil Cooler Plumbing

Located along the oil pan rail just ahead of the oil filter pad are two drilled and tapped (3/8” NPT) oil passages for routing oil to an external oil cooler. The hole located closest to the oil filter pad (#2) is for the outgoing supply line to the oil cooler. The front passage (#1), which is farthest from the filter pad, is the return line from the oil cooler.

Careful examination reveals that these two passages intersect the same return line that feeds oil back to the main oil tunnel. This requires that a special fitting be used in the #2 supply line to prevent oil from short circuiting the oil cooler.

Part number SD1540 provides the necessary diverter basket to prevent the supply oil from entering the return line before going to the oil cooler. This fitting has a dash 10AN thread to allow the use of aftermarket components to plumb your external oil cooler. The front passage #1 will require a 3/8” NPT by dash 10AN adapter (#FCM2185), which is available from Scoggin-Dickey.

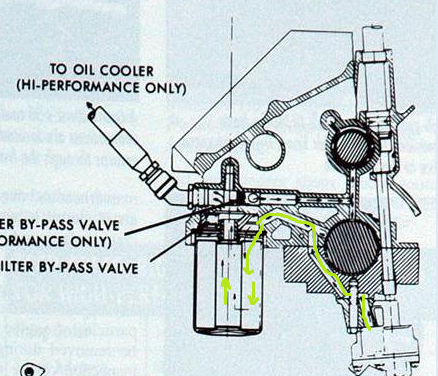

Understanding By-pass Valve Locations

Factory assembled 454, 502 engines and short blocks have two by-pass valves installed in the block. These factory installed by-pass valves (#25013759) will open at an 11

psi pressure differential. One by-pass valve is installed in the center hole on the oil filter pad (#4). This hole is the oil return passage from the oil filter. The second by-pass valve is installed in the adjacent hole (#3). The egg shaped hole (#5) is the high pressure oil supply passage from the oil pump.

For all racing application that will NOT use an oil cooler but will maintain the stock oil filter location, you must remove the center by-pass valve in location #4. Removing this valve eliminates three redundant right runs in the oil system. However, if you leave this by-pass in place the oil system will still function as it was intended, but a loss of oil pressure can result from the four right angle turns required for oil to return to the main oil tunnel.

If you intend to use a remote oil filter, a high pressure by-pass valve part number 25161284 must be installed in position #3. This valve will open at a 30 psi pressure differential. A plug will be installed in position #4 to prevent oil flow thru this passage. Oil should be returned to the block in the 3/8” hole located just able the oil filter pad. An oil filter block off plate kit (#SD3891) can be purchased from Scoggin-Dickey for Gen V and VI blocks to plumb your external oil filter.

If you intend to maintain the stock filter location and will use the factory provided oil cooler passages to install your oil cooler, then you must install two high pressure by-pass valves (#25161284). One will be installed in location #3 and the second in location #4.