The main thing you need to understand when bedding a rifle action is WHAT youre trying to accomplish and why and how some things are done to reach the goal.

The main goal is insuring CONSISTENCY; the idea is to lock the action firmly into the stock without inducing stress to the action that will change, the way the barrel vibrates as it changes temperature.

Generally youll want to provide a totally solid foundation, in the stock for the action to bed against that exactly matches the lower receivers contours, a section of threaded brass tubing cut slightly shorter than the locking bolts, recessed length and placed in the bolt holes and epoxy, mixed with aluminum dust, as a sub structure works really effectively provided the area its attached to is rough and porous enough for it to get an excellent grip, in place, holding the action in place , and insuring consistent, and easily repeatable action location in the stock.

Ive generally found the action and the first 3 inches of barrel being epoxied supported in the stock is a good idea

http://www.brownells.com/

http://www.brownells.com/aspx/NS/store/catsearch.aspx?k=bedding kit&ps=10&si=True

Sells good bedding kits and release agents

Waxing the metal parts then coating them with both a single thickness of masking tape and a release agent will tend to prevent epoxies from bonding where its not wanted

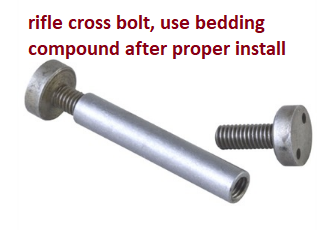

A cross bolt behind the recoil lug(s) can be epoxy glued into the stock on the higher recoil level calibers as an extra precaution, a common mistake is not removing a bit of stock internal surface and finish under the action and barrel to allow sufficient thickness of the epoxy to have the required strength, and theres no reason not to use threaded bolt or rods acting like REBAR in concrete in that epoxy bedding foundation in a few cases where extra strength may be required, for example on my 458 LOTT theres a forward recoil lug, about 5" forward of the action on the barrel, a channel in the stock about 4 inches long and 5/8" wide and 1/3rd of an inch deep was machined and two 1/4" thread rod sections covered with epoxy were installed to back up that recoil lug, and two action length sections were welded to a cross bar and epoxied into the area under and to the sides of the action, behind the main action recoil lug, plus a cross bar bolt just below to prevent the stock from splitting.

all obviously not necessary on low recoil level rifles, but on a 458 win or 458 Lott the additional work prevents problems

I own several wby markV rifles and every one of them shot a bit better groups once I rebedded then with the receivers & barrels supported for about 3" forward of the receivers and the barrels free floated a bit off the stock forearm at least enough off the forearm to slide a dollar bill up to with-in 3" of the receiver

http://www.varminthunters.com/tech/bedding.html

http://www.shootingtimes.com/gunsmithing/ST_bedarifle_200904/index3.html

http://riflestocks.tripod.com/bedding.html

--------------------------------------------------------------------------------

someones bound to ask about muzzle brakes,muzzle brakes work best on very high velocity cartridges where the powder charge is a significant percentage of the ejected mass, leaving the bore, they are also loud, now Ive got a couple heavy caliber rifles with brakes, and they do make a difference, in felt recoil, but on a hunting rifle Ive never seen a huge advantage simply because you seldom take more than one or two shots at game in the field, under conditions where your very likely to be wearing a heavy coat, or padded shooting vest and youll have NO ear protection, youll seldom feel the single shots recoil but your ears may ring for hours

The main goal is insuring CONSISTENCY; the idea is to lock the action firmly into the stock without inducing stress to the action that will change, the way the barrel vibrates as it changes temperature.

Generally youll want to provide a totally solid foundation, in the stock for the action to bed against that exactly matches the lower receivers contours, a section of threaded brass tubing cut slightly shorter than the locking bolts, recessed length and placed in the bolt holes and epoxy, mixed with aluminum dust, as a sub structure works really effectively provided the area its attached to is rough and porous enough for it to get an excellent grip, in place, holding the action in place , and insuring consistent, and easily repeatable action location in the stock.

Ive generally found the action and the first 3 inches of barrel being epoxied supported in the stock is a good idea

http://www.brownells.com/

http://www.brownells.com/aspx/NS/store/catsearch.aspx?k=bedding kit&ps=10&si=True

Sells good bedding kits and release agents

Waxing the metal parts then coating them with both a single thickness of masking tape and a release agent will tend to prevent epoxies from bonding where its not wanted

A cross bolt behind the recoil lug(s) can be epoxy glued into the stock on the higher recoil level calibers as an extra precaution, a common mistake is not removing a bit of stock internal surface and finish under the action and barrel to allow sufficient thickness of the epoxy to have the required strength, and theres no reason not to use threaded bolt or rods acting like REBAR in concrete in that epoxy bedding foundation in a few cases where extra strength may be required, for example on my 458 LOTT theres a forward recoil lug, about 5" forward of the action on the barrel, a channel in the stock about 4 inches long and 5/8" wide and 1/3rd of an inch deep was machined and two 1/4" thread rod sections covered with epoxy were installed to back up that recoil lug, and two action length sections were welded to a cross bar and epoxied into the area under and to the sides of the action, behind the main action recoil lug, plus a cross bar bolt just below to prevent the stock from splitting.

all obviously not necessary on low recoil level rifles, but on a 458 win or 458 Lott the additional work prevents problems

I own several wby markV rifles and every one of them shot a bit better groups once I rebedded then with the receivers & barrels supported for about 3" forward of the receivers and the barrels free floated a bit off the stock forearm at least enough off the forearm to slide a dollar bill up to with-in 3" of the receiver

http://www.varminthunters.com/tech/bedding.html

http://www.shootingtimes.com/gunsmithing/ST_bedarifle_200904/index3.html

http://riflestocks.tripod.com/bedding.html

--------------------------------------------------------------------------------

someones bound to ask about muzzle brakes,muzzle brakes work best on very high velocity cartridges where the powder charge is a significant percentage of the ejected mass, leaving the bore, they are also loud, now Ive got a couple heavy caliber rifles with brakes, and they do make a difference, in felt recoil, but on a hunting rifle Ive never seen a huge advantage simply because you seldom take more than one or two shots at game in the field, under conditions where your very likely to be wearing a heavy coat, or padded shooting vest and youll have NO ear protection, youll seldom feel the single shots recoil but your ears may ring for hours

Last edited by a moderator: