as too costs involved here's one SBC 383 builds partial cost list, which may help you remember some of the costs your more than likely over looking

the fact is this engine building remains mostly well understood and known science, a teachable skill,

(for anyone willing to learn what works with a bit of RESEARCH)

I'm fairly sure many of the guys reading through this don,t or have not dealt with, or built enough engines, and been involved with enough of the engine builds to realize the various manufacturers approach building components with a great many different objectives in mind,

component parts vary and careful research and selection is required!

I've always found SCAT and CROWER parts seem to be a good value!

keep in mind the "weakest link in the chain" concept,

Any logical engine builder needs to sellect components with a firm goal in mind and recognize the intended power band and rpm limitations.

need there's not much sense in selecting a rotating assembly that is built to easily handle lets say 1200 hp and 7800 rpm, at 4500 fpm in piston speeds,

if the block main caps walk at much lower stress levels, or if the block your thinking of using it in,will most likely have the caps walk well below that stress level.

nore would it make sense, using such a high dollar rotating assembly if your going to match it with a valve train and hydraulic roller cam that floats valves at 6400 rpm, or heads that reach port stall at 6700 rpm

and a bit of skilled ART , but the biggest and most common, and unfortunately repeated, mistake I've seen made, is guys who fail to ask questions,when they run into areas where they are not dead certain of what needs to be done, and fail to stop and ask questions, understand both the answers and WHY things, MUST be done a certain way for best results!

IF you find you don,t remember how to do something,

or can,t remember the clearance required,

torque specs ,the best parts to be used,

the correct wire color,

or correct sealant or

any thing else,

STOP do a bit of research, and DON,T SCREW IT UP,

a bit of research beats making mistakes .

BECAUSE AVOIDING MISTAKES generally costs a great deal less time and money!

A COUPLE HOURS READING CAN RESULT IN PREVENTING WEEKS OF WASTED WORK AND THOUSANDS OF DOLLARS SAVED!

DON,T GUESS!

get the required info from at least two and preferably three independent sources

keep in mind the concept of the weakest link in a chain, you'll always need to keep that in mind, the best parts are all dependent on other component function, to reach their full potential.

if your cars not geared to operate in the engines most effective power band your working at a big dis-advantage,

if the cam won,t allow the valves to open long and wide enough to maximize the port and runner flow your working at a dis-advantage.

the same concept of inter-dependency will be found in compression, exhaust flow and a dozen other areas!

now the thing that simply amazes me is that the vast majority of those people are absolutely , almost religiously opposed to doing, anything like spending a few hours reading or spending a couple hundred dollars on books on the subject. the fact is that spending the time and money before you get into purchasing components on detailed research into almost any area that might require a person to do in depth research , pays off in big savings , in less mistakes, fewer purchases of miss matched parts and far less assembly mistakes made.

yet many of those same people will take the advise of some 18 -20 year old kid standing on the opposite side of the local auto parts store , or some rather unskilled friend might have suggested as if it was written in granite slabs by the LORD!

this hobby is basically based on your ability to use tools, your ability too think about what each automotive sub system does and how you can make it function to its full efficiency or maybe even improve on what that system does.

keep in mind the change in port volume between something like a 195cc vs the minimally larger 210cc AFR ports is going to have a rather minimal effect on the cars engine performance in the lower and mid rpm ranges but it will be noticeable on the peak power ,

IF THE CAM AND EXHAUST SCAVENGING IS SET UP TO MAXIMIZE UPPER RPM AIR FLOW!

DorianL should be able to comment here, as he previously swapped from TRICK FLOW 195cc to AFR 210 cc heads on his former performance engine build in that recently sold car, and would have noticed the difference in peak power that the minimal port cross sectional area increase provided, and I think he might agree that it had less than a huge effect on his previous engines off idle and lower rpm torque which is commonly the major concern people who have very little hands on experience always seem to be concerned with.

remember its the, cam timing, duration, lift and LSA,and its effect on how effective the exhaust scavenging, is that has a much more noticeable effect on the engines ability to effectively fill the cylinder rather than the port cross sectional area

if your looking for a local machine shop,

in the west palm beach fla area

be damn sure you get all the details in writing

dates prices, details on what needs to be done

delivery dates and take pictures

these guys generally do decent work

first choice (use them fairly often to rebuild heads)

Engine Rebuilders-Palm Beach,

1722 Donna Rd, West Palm Beach, FL 33409

second choice (mostly for block line hone & decking)

Keener's Engine Machine Inc

2517 N Military Trl, West Palm Beach, FL 33409

third choice

these guys get decent reviews but Ive only been there once)

170 Commerce Rd, Suite 1A

Boynton Beach Florida 33426

https://www.mprracingengines.com/

watch the video, and like I stated many times,

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.

especially when Id suggest using a set of smaller 300cc-320cc, aluminum,rectangle port heads on a 496 BBC, or 200 cc-210cc heads on a 406 sbc, I was asked to build

yet on every engine I've ever had built or had some guy ask me to look at, to see why it ran a great deal less impressively than he expected it too,

they brought into my shop its was very obvious (at least to me) that it was the combo of low compression, too little displacement, with too much cam duration ,

a restrictive exhaust or some guy who was trying to save money and continuing to use a stock stall speed torque converter, or retain a badly mis-matched 2.87:1-3.08:1 rear gear ratio,

with an engine that he miss matched components by slapping a large carburetor , and a single plane intake on,an engine that will rarely exceed 6000 rpm, that was the major reason.

if you want an engine combo to run your first step is to logically match the list of components you,ll use to the application,

and that requires you stop, engage the brain and think things through carefully,

and the most common way to screw up the process is to over cam a low compression engine,

have a restrictive exhaust or mis-match the drive train gearing to the engines power band.

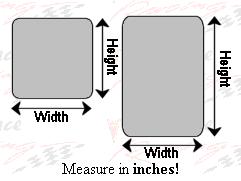

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

you may be amazed to find a great deal of research and testing has been done and theres actually proven facts rather than random guess work to use in planing a well built engine combo

READ THROUGH THIS LINK

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

http://forum.grumpysperformance.com...=8460&p=32923&hilit=curtain+flow+angle#p32923

http://www.wallaceracing.com/max-rpm2.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/header_length.php

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://www.bgsoflex.com/bestheader.html

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0209-chevy-gm-cylinder-heads/

A VERY USEFUL set of CALCULATORs

http://www.rbracing-rsr.com/runnertorquecalc.html

http://users.erols.com/srweiss/calccsa.htm

http://users.erols.com/srweiss/calcplv.htm

http://users.erols.com/srweiss/calcfps.htm

http://users.erols.com/srweiss/calcacsa.htm

just a bit of info on intake gaskets sizes to match port cross sectional areas

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

SO lets do a bit of math

a cylinder head with a 2.02' intake valve and a cam with a .450 lift at the valve with a 1.5:1 rocker will in theory produce a valve curtain area of 2.79 sq inches, swapping to a 1.6:1 ratio increases the lift to .480 lift 2.98 sq inches, increasing the available port flow potential at least in theory by about 6%, but keep in mind the port can only flow at full valve lift for the limited time the valve remains at full lift and if the narrowest section of the port cross sectional areas less that the valve curtain area that not the valve restricts flow

reading a few links might help here, but ID also point out that DISPLACEMENT, EXHAUST SCAVENGING EFFICIENCY, AND COMPRESSION RATIO ARE MAJOR FACTORS

example

if a 383 SBC makes 1.3 hp & ft lbs of tq per cubic inch of displacement

thats 498 hp & ft lbs of tq

if a 496 BBC makes 1.3 hp & ft lbs of tq per cubic inch of displacement

thats 645 hp & ft lbs of tq

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-51341

take the effort to read the threads ,

buy the suggested books,as they are a good reference,

and pat attention too sub links ,they contain decades of knowledge

http://garage.grumpysperformance.com/index.php?threads/454-bbc-on-the-cheap-well-to-start.11739/

https://www.summitracing.com/search...Default&SortOrder=Ascending&autoview=SKU&ar=1

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/page-2#post-46729

http://garage.grumpysperformance.co...k-for-in-a-good-engine-combo.9930/#post-46399

http://garage.grumpysperformance.com/index.php?threads/port-and-runner-math.148/#post-182

http://garage.grumpysperformance.co...reasonable-mild-but-dependable-upgrade.12130/

we ALL learn from mistakes,

and WE ALL make them,

its part of the learning process,

the trick is in simply remembering,

NOT TO REPEAT OR DUPLICATE,

the MISTAKES YOU MAKE,

AND LEARN FROM THE MISTAKES,

YOUR FRIENDS MAKE ALSO!

I got asked why I seem to have a marked preference for building big block engines VS the far more common small block,

you really should get these books and read them before going any further, it will help a good deal

http://www.amazon.com/exec/obidos/A...5079777/sr=2-1/ref=sr_2_1/102-1234339-0571324

http://www.amazon.com/exec/obidos/t...gy_img_2/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t...gy_img_2/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t..._books_1/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t..._books_3/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t...f=sr_1_2/102-1234339-0571324?v=glance&s=books

INVESTING THE TIME AND EFFORT IN PURCHASING AND READING A FEW BOOKS WILL BE VERY COST EFFECTIVE

http://www.dragzine.com/tech-stories/en ... ine-block/

"

SMALL BLOCK REFERENCE BOOKS YOULL WANT

start by buying these books and watching the video

http://www.themotorbookstore.com/resmchstvi.html

http://www.amazon.com/David-Vizards...8&qid=1456194032&sr=8-5&keywords=DAVID+VIZARD

HOW TO BUILD MAX PERFORMANCE CHEVY SMALL BLOCKS ON A BUDGET by DAVID VIZARD

.

JOHN LINGENFELTER on modifying small-block chevy engines

http://www.amazon.com/Lingenfelter-...=1456193940&sr=8-1&keywords=JOHN+LINGENFELTER

http://www.amazon.com/Smokey-Yunick...2&sr=8-1&keywords=smokey+yunick+power+secrets

http://www.amazon.com/Chevrolet-Rac...ords=The-Chevrolet-Racing-Engine-Bill-Jenkins

http://garage.grumpysperformance.com/index.php?threads/idea-for-new-calculator.4851/#post-39018

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-50173

http://garage.grumpysperformance.com/index.php?threads/newbie-here.11767/#post-55608

http://garage.grumpysperformance.com/index.php?threads/a-few-calculator-links.7108/#post-27382

and it is SFI certified, IDEALLY billet, your feet will thank you,

and ideally, you use a blow proof bell housing, thats a good idea

and I would select a 28 lb-36 lb flywheel,for street use.

if its the newer sbc single rear seal block.

be sure its for a single rear seal crank,

and they make 153 and 168 tooth gear designs,

you need to match your application, and your bell housing and starter

also be aware there are internal and externally balanced 383 SBC kits and 5.7" and 6" rod kits,

and some that require a neutrally balanced damper and an externally balanced flywheel

https://www.summitracing.com/parts/...MIyrK1kZaY6QIVFP_jBx05Vw71EAQYAyABEgL4HfD_BwE

as usual, there's a ton of related info in the links and sub links

http://garage.grumpysperformance.co...ectly-installing-bellhousings.584/#post-21691

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/#post-10338

http://garage.grumpysperformance.com/index.php?threads/selecting-a-flywheel.1042/#post-1945

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-9433

http://garage.grumpysperformance.com/index.php?threads/sfi-tested-parts-sources.3011/#post-7917

related

read the links its worth your time and effort

https://www.engineprofessional.com/EPQ3-2020/mobile/index.html#p=16

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-59253

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-68651

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51823

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-51146

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/#post-49857

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/#post-49737

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52466

http://garage.grumpysperformance.co...ting-started-in-the-car-hobby.339/#post-60187

not all the links relate to your build but may be helpful

https://www.speedwaymotors.com/Moroso-37800-Chevy-Block-Deck-Plug-Kit,590.html

http://www.superchevy.com/how-to/engines-drivetrain/83818-block-plug-basics/

https://www.chevyhardcore.com/tech-...g-101-getting-started-with-your-engine-build/

https://www.chevrolet.com/performance/engine-components/small-block/race-blocks

https://www.hotrod.com/articles/hrdp-1210-chevrolet-350-small-block-comparison/

https://www.dragzine.com/news/engine-machining-101-getting-started-with-your-engine-build/

https://www.chevydiy.com/big-block-chevrolet-engine-step-step-rebuid-machine-shop-guide/

https://www.chevydiy.com/machine-shop-guide-build-chevy-small-block-engines/

http://www.budgetenginerebuilders.com/machining-services/

https://www.steveschmidtracing.com/machine-shop

the fact is this engine building remains mostly well understood and known science, a teachable skill,

(for anyone willing to learn what works with a bit of RESEARCH)

I'm fairly sure many of the guys reading through this don,t or have not dealt with, or built enough engines, and been involved with enough of the engine builds to realize the various manufacturers approach building components with a great many different objectives in mind,

component parts vary and careful research and selection is required!

I've always found SCAT and CROWER parts seem to be a good value!

keep in mind the "weakest link in the chain" concept,

Any logical engine builder needs to sellect components with a firm goal in mind and recognize the intended power band and rpm limitations.

need there's not much sense in selecting a rotating assembly that is built to easily handle lets say 1200 hp and 7800 rpm, at 4500 fpm in piston speeds,

if the block main caps walk at much lower stress levels, or if the block your thinking of using it in,will most likely have the caps walk well below that stress level.

nore would it make sense, using such a high dollar rotating assembly if your going to match it with a valve train and hydraulic roller cam that floats valves at 6400 rpm, or heads that reach port stall at 6700 rpm

and a bit of skilled ART , but the biggest and most common, and unfortunately repeated, mistake I've seen made, is guys who fail to ask questions,when they run into areas where they are not dead certain of what needs to be done, and fail to stop and ask questions, understand both the answers and WHY things, MUST be done a certain way for best results!

IF you find you don,t remember how to do something,

or can,t remember the clearance required,

torque specs ,the best parts to be used,

the correct wire color,

or correct sealant or

any thing else,

STOP do a bit of research, and DON,T SCREW IT UP,

a bit of research beats making mistakes .

BECAUSE AVOIDING MISTAKES generally costs a great deal less time and money!

A COUPLE HOURS READING CAN RESULT IN PREVENTING WEEKS OF WASTED WORK AND THOUSANDS OF DOLLARS SAVED!

DON,T GUESS!

get the required info from at least two and preferably three independent sources

keep in mind the concept of the weakest link in a chain, you'll always need to keep that in mind, the best parts are all dependent on other component function, to reach their full potential.

if your cars not geared to operate in the engines most effective power band your working at a big dis-advantage,

if the cam won,t allow the valves to open long and wide enough to maximize the port and runner flow your working at a dis-advantage.

the same concept of inter-dependency will be found in compression, exhaust flow and a dozen other areas!

now the thing that simply amazes me is that the vast majority of those people are absolutely , almost religiously opposed to doing, anything like spending a few hours reading or spending a couple hundred dollars on books on the subject. the fact is that spending the time and money before you get into purchasing components on detailed research into almost any area that might require a person to do in depth research , pays off in big savings , in less mistakes, fewer purchases of miss matched parts and far less assembly mistakes made.

yet many of those same people will take the advise of some 18 -20 year old kid standing on the opposite side of the local auto parts store , or some rather unskilled friend might have suggested as if it was written in granite slabs by the LORD!

this hobby is basically based on your ability to use tools, your ability too think about what each automotive sub system does and how you can make it function to its full efficiency or maybe even improve on what that system does.

keep in mind the change in port volume between something like a 195cc vs the minimally larger 210cc AFR ports is going to have a rather minimal effect on the cars engine performance in the lower and mid rpm ranges but it will be noticeable on the peak power ,

IF THE CAM AND EXHAUST SCAVENGING IS SET UP TO MAXIMIZE UPPER RPM AIR FLOW!

DorianL should be able to comment here, as he previously swapped from TRICK FLOW 195cc to AFR 210 cc heads on his former performance engine build in that recently sold car, and would have noticed the difference in peak power that the minimal port cross sectional area increase provided, and I think he might agree that it had less than a huge effect on his previous engines off idle and lower rpm torque which is commonly the major concern people who have very little hands on experience always seem to be concerned with.

remember its the, cam timing, duration, lift and LSA,and its effect on how effective the exhaust scavenging, is that has a much more noticeable effect on the engines ability to effectively fill the cylinder rather than the port cross sectional area

if your looking for a local machine shop,

in the west palm beach fla area

be damn sure you get all the details in writing

dates prices, details on what needs to be done

delivery dates and take pictures

these guys generally do decent work

first choice (use them fairly often to rebuild heads)

Engine Rebuilders-Palm Beach,

1722 Donna Rd, West Palm Beach, FL 33409

second choice (mostly for block line hone & decking)

Keener's Engine Machine Inc

2517 N Military Trl, West Palm Beach, FL 33409

third choice

these guys get decent reviews but Ive only been there once)

170 Commerce Rd, Suite 1A

Boynton Beach Florida 33426

https://www.mprracingengines.com/

watch the video, and like I stated many times,

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly,

For 5 decades I've heard endlessly about how installing larger free flowing cylinder heads would devastate the engines ability to make any low or mid rpm torque.

especially when Id suggest using a set of smaller 300cc-320cc, aluminum,rectangle port heads on a 496 BBC, or 200 cc-210cc heads on a 406 sbc, I was asked to build

yet on every engine I've ever had built or had some guy ask me to look at, to see why it ran a great deal less impressively than he expected it too,

they brought into my shop its was very obvious (at least to me) that it was the combo of low compression, too little displacement, with too much cam duration ,

a restrictive exhaust or some guy who was trying to save money and continuing to use a stock stall speed torque converter, or retain a badly mis-matched 2.87:1-3.08:1 rear gear ratio,

with an engine that he miss matched components by slapping a large carburetor , and a single plane intake on,an engine that will rarely exceed 6000 rpm, that was the major reason.

if you want an engine combo to run your first step is to logically match the list of components you,ll use to the application,

and that requires you stop, engage the brain and think things through carefully,

and the most common way to screw up the process is to over cam a low compression engine,

have a restrictive exhaust or mis-match the drive train gearing to the engines power band.

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

you may be amazed to find a great deal of research and testing has been done and theres actually proven facts rather than random guess work to use in planing a well built engine combo

READ THROUGH THIS LINK

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

http://forum.grumpysperformance.com...=8460&p=32923&hilit=curtain+flow+angle#p32923

http://www.wallaceracing.com/max-rpm2.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/header_length.php

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://www.bgsoflex.com/bestheader.html

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0209-chevy-gm-cylinder-heads/

A VERY USEFUL set of CALCULATORs

http://www.rbracing-rsr.com/runnertorquecalc.html

http://users.erols.com/srweiss/calccsa.htm

http://users.erols.com/srweiss/calcplv.htm

http://users.erols.com/srweiss/calcfps.htm

http://users.erols.com/srweiss/calcacsa.htm

just a bit of info on intake gaskets sizes to match port cross sectional areas

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

SO lets do a bit of math

a cylinder head with a 2.02' intake valve and a cam with a .450 lift at the valve with a 1.5:1 rocker will in theory produce a valve curtain area of 2.79 sq inches, swapping to a 1.6:1 ratio increases the lift to .480 lift 2.98 sq inches, increasing the available port flow potential at least in theory by about 6%, but keep in mind the port can only flow at full valve lift for the limited time the valve remains at full lift and if the narrowest section of the port cross sectional areas less that the valve curtain area that not the valve restricts flow

reading a few links might help here, but ID also point out that DISPLACEMENT, EXHAUST SCAVENGING EFFICIENCY, AND COMPRESSION RATIO ARE MAJOR FACTORS

example

if a 383 SBC makes 1.3 hp & ft lbs of tq per cubic inch of displacement

thats 498 hp & ft lbs of tq

if a 496 BBC makes 1.3 hp & ft lbs of tq per cubic inch of displacement

thats 645 hp & ft lbs of tq

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-51341

take the effort to read the threads ,

buy the suggested books,as they are a good reference,

and pat attention too sub links ,they contain decades of knowledge

http://garage.grumpysperformance.com/index.php?threads/454-bbc-on-the-cheap-well-to-start.11739/

https://www.summitracing.com/search...Default&SortOrder=Ascending&autoview=SKU&ar=1

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/page-2#post-46729

http://garage.grumpysperformance.co...k-for-in-a-good-engine-combo.9930/#post-46399

http://garage.grumpysperformance.com/index.php?threads/port-and-runner-math.148/#post-182

http://garage.grumpysperformance.co...reasonable-mild-but-dependable-upgrade.12130/

we ALL learn from mistakes,

and WE ALL make them,

its part of the learning process,

the trick is in simply remembering,

NOT TO REPEAT OR DUPLICATE,

the MISTAKES YOU MAKE,

AND LEARN FROM THE MISTAKES,

YOUR FRIENDS MAKE ALSO!

I got asked why I seem to have a marked preference for building big block engines VS the far more common small block,

you really should get these books and read them before going any further, it will help a good deal

http://www.amazon.com/exec/obidos/A...5079777/sr=2-1/ref=sr_2_1/102-1234339-0571324

http://www.amazon.com/exec/obidos/t...gy_img_2/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t...gy_img_2/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t..._books_1/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t..._books_3/102-1234339-0571324?v=glance&s=books

http://www.amazon.com/exec/obidos/t...f=sr_1_2/102-1234339-0571324?v=glance&s=books

INVESTING THE TIME AND EFFORT IN PURCHASING AND READING A FEW BOOKS WILL BE VERY COST EFFECTIVE

http://www.dragzine.com/tech-stories/en ... ine-block/

"

SMALL BLOCK REFERENCE BOOKS YOULL WANT

start by buying these books and watching the video

http://www.themotorbookstore.com/resmchstvi.html

http://www.amazon.com/David-Vizards...8&qid=1456194032&sr=8-5&keywords=DAVID+VIZARD

HOW TO BUILD MAX PERFORMANCE CHEVY SMALL BLOCKS ON A BUDGET by DAVID VIZARD

.

JOHN LINGENFELTER on modifying small-block chevy engines

http://www.amazon.com/Lingenfelter-...=1456193940&sr=8-1&keywords=JOHN+LINGENFELTER

http://www.amazon.com/Smokey-Yunick...2&sr=8-1&keywords=smokey+yunick+power+secrets

http://www.amazon.com/Chevrolet-Rac...ords=The-Chevrolet-Racing-Engine-Bill-Jenkins

http://garage.grumpysperformance.com/index.php?threads/idea-for-new-calculator.4851/#post-39018

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-50173

http://garage.grumpysperformance.com/index.php?threads/newbie-here.11767/#post-55608

http://garage.grumpysperformance.com/index.php?threads/a-few-calculator-links.7108/#post-27382

be sure that FLYWHEEL,you select matches the intended application"cnc blocks" said:Did a budget build for a customer last year used a 880 GM block it was all machined cleaned magged, sonic tested, line honed, stroker clearanced, zero decked to 9.00 (Tom Mobley the intake fit just fine ) bored and plate honed.

Machine work on block 695.00

ARP Main bolt kit 48.00

Scat 9000 series crank 280.00

Scat I beam 6.0 rods with 7/16 bolts 350.00

Wiseco pistons with rings 450.00

Dart SHP 180 64CC heads 1176.00

Internally balance crank 225.00

polish crank 45.00

rod and main bearings 45.00

Performance cam bearings 32.00

Brass freeze plug kit 28.00

Install cam bearings and freeze plugs 60.00

Head gaskets 75.00

ARP head bolts 90.00

GM Hot cam Think it was 238/242 185.00

GM roller lifter kit with dog bones and spider 190.00

8 quart Y pan with pick up 230.00

Melling 10552 oil pump 115.00

Cloyes hex-A-just 136.00

GM balancer 89.00

Size both ends of rods 120.00

Air Gap intake 275.00

With misalliances fasteners and gaskets ETC.

Customer fit his own rings and assembled his own engine.

(roughly 430 hp)

For under 5500.00 the engine seems to be a Kick A$$ piece runs better then I expected.

and it is SFI certified, IDEALLY billet, your feet will thank you,

and ideally, you use a blow proof bell housing, thats a good idea

and I would select a 28 lb-36 lb flywheel,for street use.

if its the newer sbc single rear seal block.

be sure its for a single rear seal crank,

and they make 153 and 168 tooth gear designs,

you need to match your application, and your bell housing and starter

also be aware there are internal and externally balanced 383 SBC kits and 5.7" and 6" rod kits,

and some that require a neutrally balanced damper and an externally balanced flywheel

https://www.summitracing.com/parts/...MIyrK1kZaY6QIVFP_jBx05Vw71EAQYAyABEgL4HfD_BwE

as usual, there's a ton of related info in the links and sub links

http://garage.grumpysperformance.co...ectly-installing-bellhousings.584/#post-21691

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/#post-10338

http://garage.grumpysperformance.com/index.php?threads/selecting-a-flywheel.1042/#post-1945

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-9433

http://garage.grumpysperformance.com/index.php?threads/sfi-tested-parts-sources.3011/#post-7917

related

read the links its worth your time and effort

https://www.engineprofessional.com/EPQ3-2020/mobile/index.html#p=16

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-59253

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-68651

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51823

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-51146

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/#post-49857

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/#post-49737

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52466

http://garage.grumpysperformance.co...ting-started-in-the-car-hobby.339/#post-60187

not all the links relate to your build but may be helpful

https://www.speedwaymotors.com/Moroso-37800-Chevy-Block-Deck-Plug-Kit,590.html

http://www.superchevy.com/how-to/engines-drivetrain/83818-block-plug-basics/

https://www.chevyhardcore.com/tech-...g-101-getting-started-with-your-engine-build/

https://www.chevrolet.com/performance/engine-components/small-block/race-blocks

https://www.hotrod.com/articles/hrdp-1210-chevrolet-350-small-block-comparison/

https://www.dragzine.com/news/engine-machining-101-getting-started-with-your-engine-build/

https://www.chevydiy.com/big-block-chevrolet-engine-step-step-rebuid-machine-shop-guide/

https://www.chevydiy.com/machine-shop-guide-build-chevy-small-block-engines/

http://www.budgetenginerebuilders.com/machining-services/

https://www.steveschmidtracing.com/machine-shop

Last edited: