Don Norton

Member

I have run into a little issue here. I have a SB Chevy 407, Aluminium heads, Z28 intake. I set the compression at 10.5:1, Timing is set at 6 degrees BTDC, MSD Atomic EFI and the A/F ratio is set at 14.7, Flex Lite 429 dual fans that are controlled by the MSD Atomic EFI controller ( Fan 1 ON @ 182, Fan 2 ON @ 187). 180 thermostat. 50/50 mix anti freeze (orange) Prestone. Running down the road I have no problem maintaining the desired 180 degree engine temp. But, when I stop and turn the motor off the next thing you know the coolant temp spikes to 230 -250 degrees and boils the anti freeze. I now have gotten into the habit of allowing for a cool down period before shutting the motor off and that seams to prevent the problem. I'm looking the the Flex lite dual fan controller that allows the fans to continue to run after the motor is shut off.

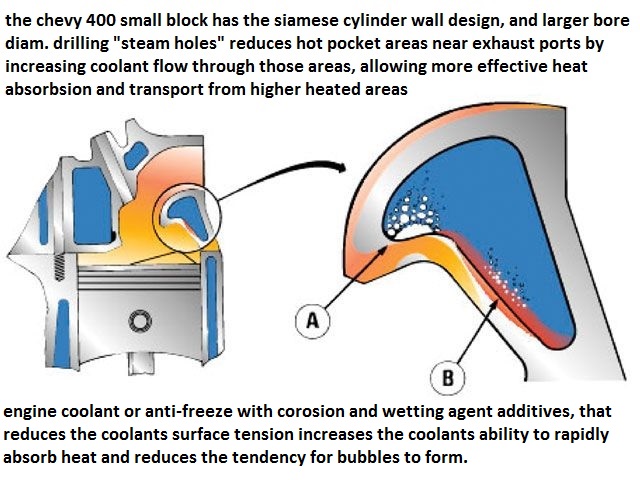

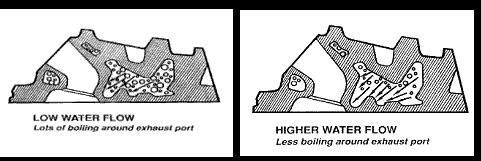

The other thing that has been bugging is the head gaskets. I'm using the Fel-Pro MLS 144053. I noticed that they only had steamer holes on the upper section of the gasket and none on the lower section. I call Fel-pro and questioned them about it. They said the steamer holes we're not needed on the lower section because of the design of the gasket. I still question this. I think I should of gone ahead of drilled steamer holes in the head gaskets. What's your thought on this?

The other thing that has been bugging is the head gaskets. I'm using the Fel-Pro MLS 144053. I noticed that they only had steamer holes on the upper section of the gasket and none on the lower section. I call Fel-pro and questioned them about it. They said the steamer holes we're not needed on the lower section because of the design of the gasket. I still question this. I think I should of gone ahead of drilled steamer holes in the head gaskets. What's your thought on this?