theres a great deal of useful info in these links , and sub linked info so don,t skip over them without looking thru carefully, as theres years of experience to be gained

yeah its amazing how everything costs ten times what you think it will and takes five times longer to do even at that inflated price

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://garage.grumpysperformance.co...eld-gas-selection-for-welding.1108/#post-2185

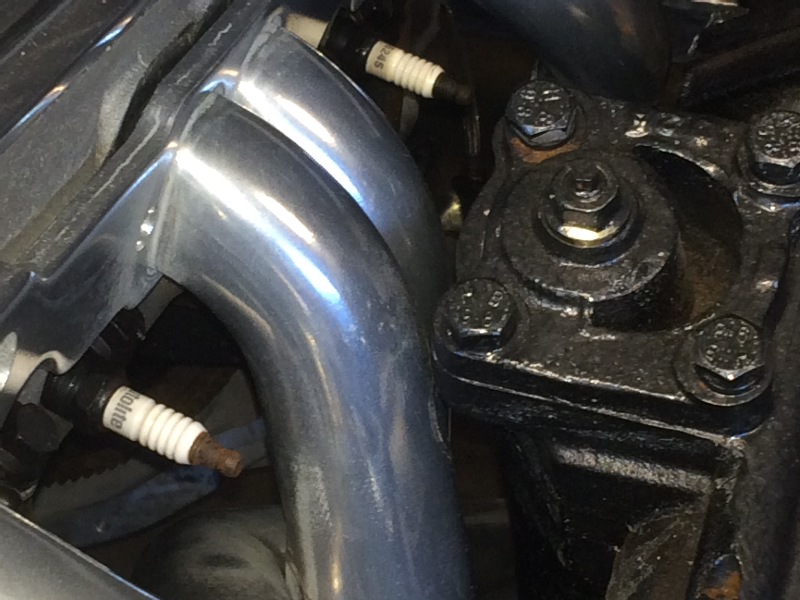

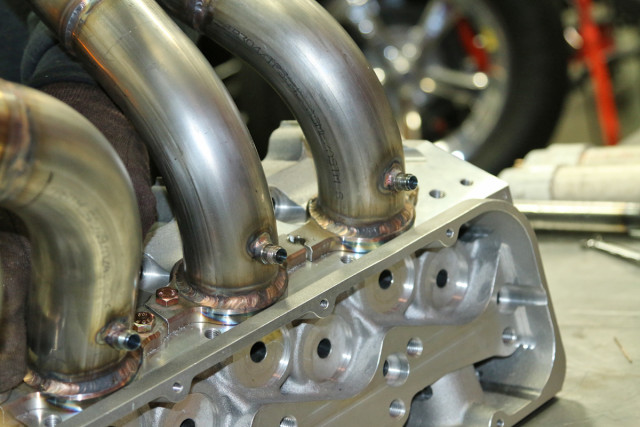

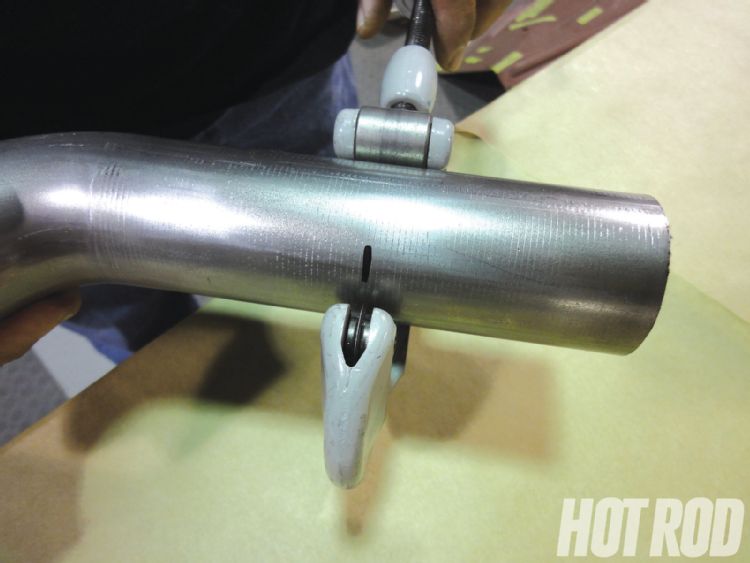

BTW, its not really all that rare to find that the headers you have present a spark plug wire clearance issue,

SPACING THE HEADER FLANGE A BIT FURTHER AWAY FROM THE CYLINDER HEAD WITH A SPACER PLATE CAN AT TIMES BE HELPFUL

SPACING THE HEADER FLANGE A BIT FURTHER AWAY FROM THE CYLINDER HEAD WITH A SPACER PLATE CAN AT TIMES BE HELPFUL

that makes installing the spark plug boots in such a way that they don,t contact the hot metal surfaces almost impossible , this can sometimes be helped a great deal by the addition of a header flange, or SPACER PLATE, that MATCHES YOUR PARTICULAR ENGINES CYLINDER HEAD EXHAUST PORT AND HEADERS,

thats significantly thicker being welded to the existing header flange , to space it out further away from the cylinder heads, obviously you don,t want to do this without testing all the clearances so installing the extra header flange with an exhaust gasket on both the cylinder head surface and between the header flange spacer and the existing headers as a test is strongly suggested as a test.

THIS IS ALSO USEFUL AT TIMES TO ADAPT THE ENGINE TO A DIFFERENT BOLT PATTERN OR SPACING

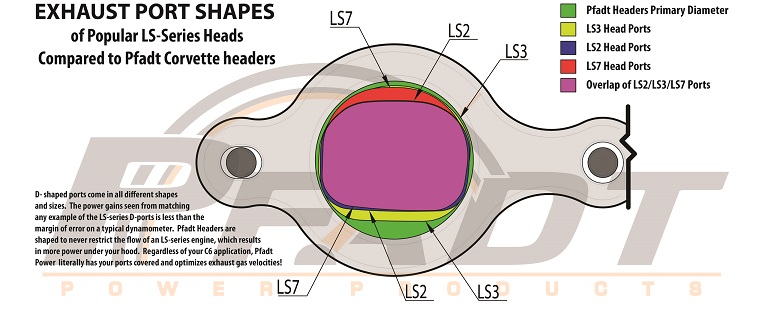

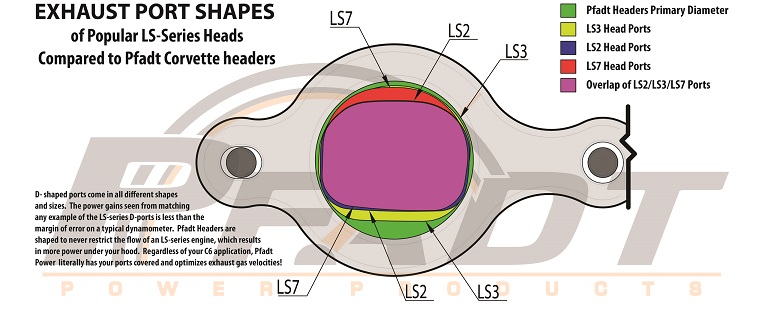

as long as the exhaust port entrance in the header flange and stubs in that flange,

is marginally larger internally in cross sectional area,

and there's no rapid and restrictive change in exhaust flow direction, or very rapid deduction in area,

and the header flange does not block the exhaust port exit around its circumference,

the shape of the exhaust pipe is all but meaningless beyond the port

btw

you can generally port and smooth the header flange entrance to some small extent to perfectly match the exhaust ports exit in the head casting

(be sure you match the exhaust gaskets and verify they won't overhang into the ports

http://www.jegs.com/i/JEGS-Performance-Products/555/30790/10002/-1?parentProductId=977236

heres where you get spacer header flange plates

http://garage.grumpysperformance.com/index.php?threads/header-paints-and-coatings.6086/#post-57067

http://garage.grumpysperformance.com/index.php?threads/thermal-coatings.2610/#post-12861

http://www.jegs.com/p/JEGS-Performance-Products/JEGS-Header-Exhaust-Flanges/1127498/10002/-1

http://www.summitracing.com/search/Part-Type/Header-Flanges/

http://www.hedmanhusler.com/Hedder-Flanges-without-Stubs

http://rehermorrison.com/product/adapter-plates/

http://www.stainlessheaders.com/turboheader

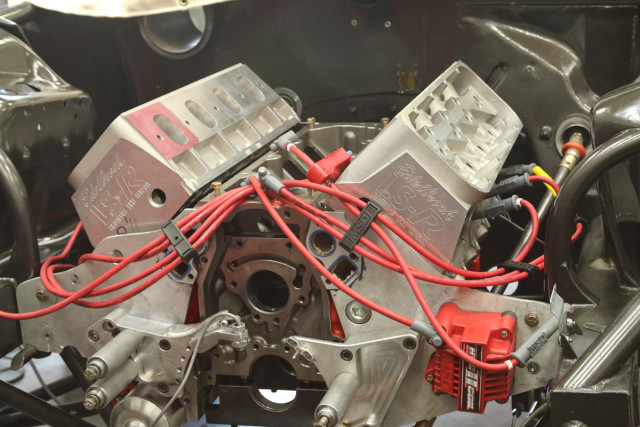

Accel Extreme 9000 Ceramic Wire Sets

ACCEL now offers the cure for burnt spark plug wire boots with Extreme 9000 Ceramic Wire kits. The 8mm Ferro-Spiral core wire now has ceramic boots on the spark plug end of the wires that will withstand up to 2,000° F. If you are running headers with close tolerances, an engine bay with little room, or an RV with boots that melt because of heat, these wire kits are the answer. and yeah! youll still need the heat resistant plug boots to prevent the wires from melting past the ceramic plug boot

http://www.stainlessheaders.com/

http://wallaceracing.com/Calculators.htm

http://hotrodenginetech.com/icengineworks-header-modeling-kits/

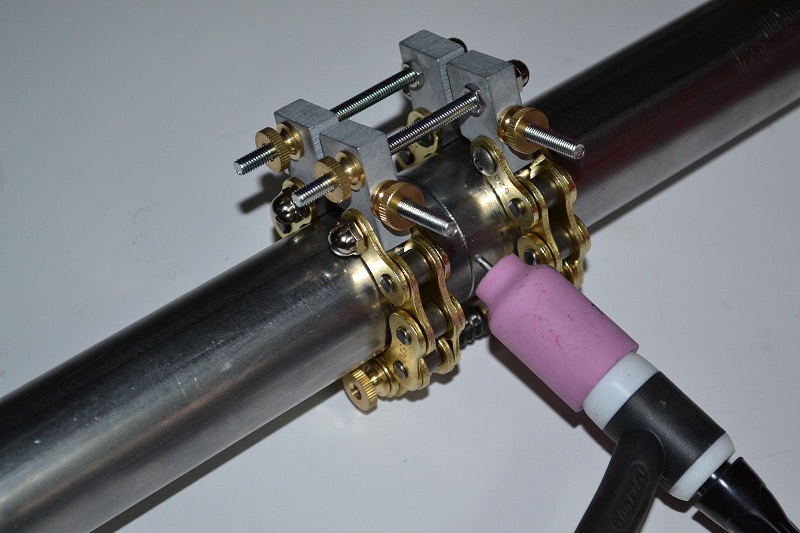

at times you need to do some minor fabrication to get things to fit & function, so having a welder and knowing where to get header flanges helps, but some careful measuring will yield surprising results at times, like BIG BLOCK CHEVY HEADERS CAN BE MODIFIED TO FIT A 500 CADDY ENGINE

you might want to install a 496 big block chevy in a 1969 AMX, and a DANA 60 rear differential, that will require a bunch of carefully measured custom fabricated custom components, something any true hot rodder can do with the correct tools like a decent welder and access to a mill,but you won,t find the parts required in any catalog.

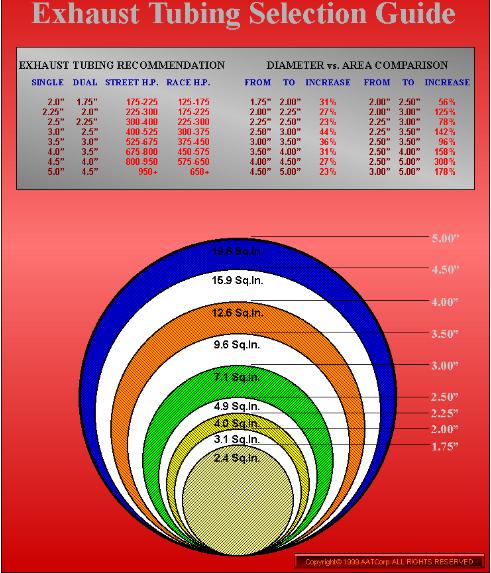

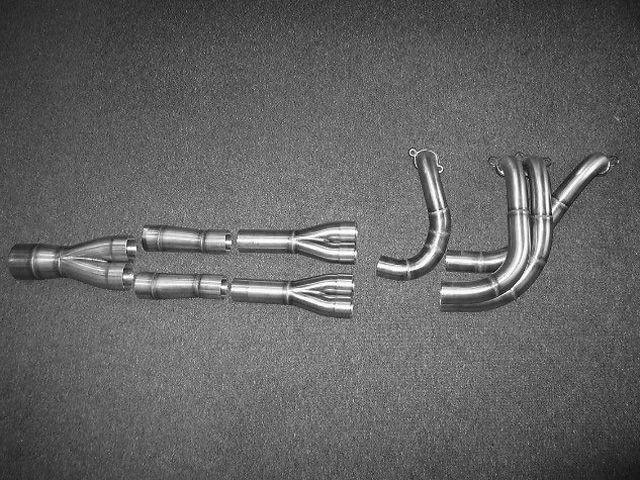

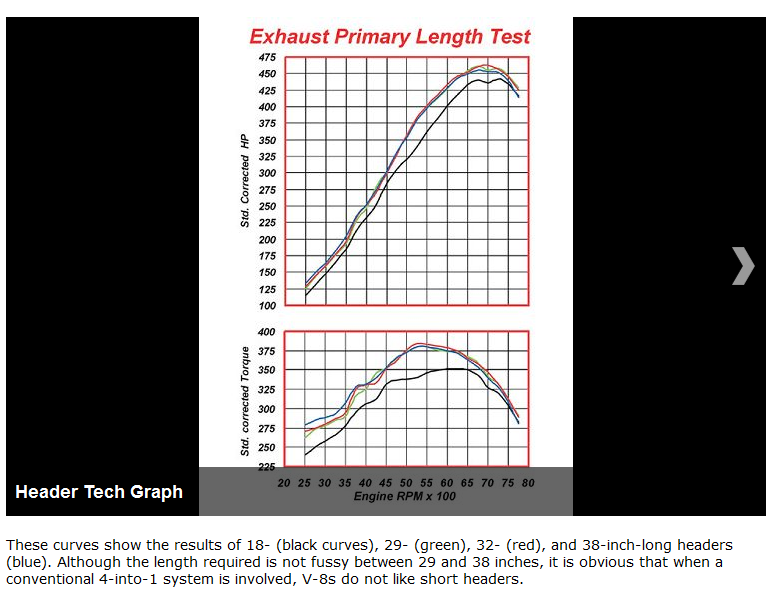

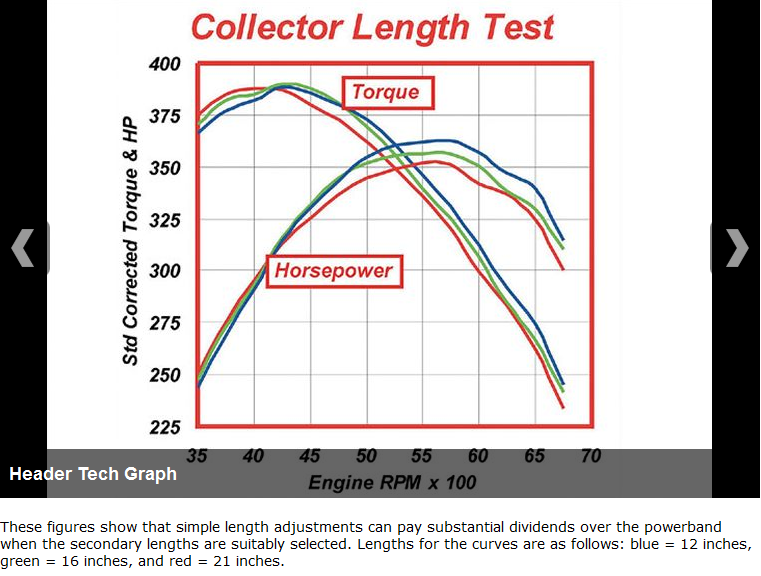

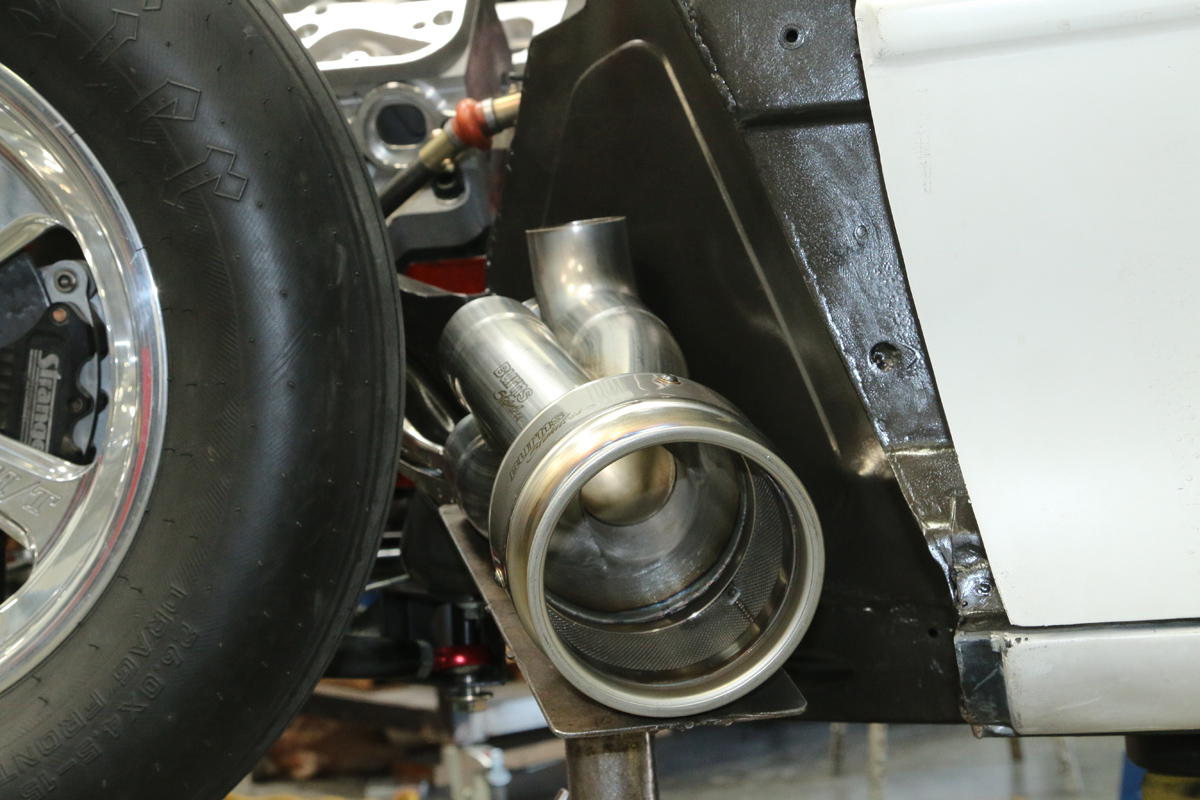

if you have ever done the math required to calculate the ideal header dimensions for a serious big block engine youll find most headers would require longer header primary tube lengths, closer to the 36"-39" length and using the 3.5"-4" collectors at least 18"-22" long that are rather easily built with the side exhaust design but almost always too restrictive to fit for clearance issues with an under the car exhaust.

or put a different way, the basic lay-out of a properly designed side exhaust lends itself more easily to a max effort exhaust,provided you junk or replace the highly restrictive inserts and replace them with some other option

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=2350

http://garage.grumpysperformance.com/index.php?threads/shield-gas-selection-for-welding.1108/

http://forum.grumpysperformance.com/viewtopic.php?f=80&t=793&p=30576&hilit=+side+pipes#p30576

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=9296&p=33590#p33590

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=7831&p=26979&hilit=+side+pipes#p26979

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=495

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=185

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=1166

http://www.coneeng.com/collector_components.html

http://icengineworks.com/Catalog2012Ed2 ... sionLR.pdf

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/header_length.php

http://www.jefflilly.com/fabrication/he ... brication/

http://maxracesoftware.com/pipemax36xp2.htm

http://www.icengineworks.com/icewmain.htm

http://www.hotrod.com/techarticles/hrdp ... ipe_dream/

http://www.hotrod.com/techarticles/hrdp ... ipe_dream/

http://www.stainlessheaders.com/headerfabrication

http://www.metalgeek.com/static/cope.pcgi

http://www.superchevy.com/technical/eng ... index.html

http://www.bgsoflex.com/bestheader.html

http://www.carcraft.com/techarticles/he ... usion.html

http://www.centuryperformance.com/exhau ... g-137.html

http://www.mandrel-bends.com/catalog/ma ... -gauge-74/

http://www.carcraft.com/howto/ccrp_0803 ... _list.html

http://www.spectrum5racing.com/Technica ... erRevA.pdf

http://victorylibrary.com/mopar/header-tech-c.htm

http://www.pontiacracing.net/js_header_length1.htm

http://www.mk5cortinaestate.co.uk/calculator5.php

http://www.carcraft.com/howto/ccrp_0803 ... index.html

http://www.carcraft.com/howto/0304_head/index.html

http://www.centuryperformance.com/exhau ... g-137.html

http://stockcarracing.automotive.com/49 ... sions.html

http://www.carcraft.com/techarticles/11 ... ndex2.html

http://www.stainlessworks.net/cart/pressrelease.php

http://www.jefflilly.com/Fabrication/Fa ... t/page.htm

viewtopic.php?f=56&t=352

http://victorylibrary.com/mopar/header-tech-c.htm

http://store.racing-solutions.org/

http://store.summitracing.com/largeimag ... OK-2956HKR

http://www.burnsstainless.com/MergeColl ... ctors.html

http://www.stahlheaders.com/Frame Flanges.htm

http://www.stansheaders.com/gm_flanges.htm

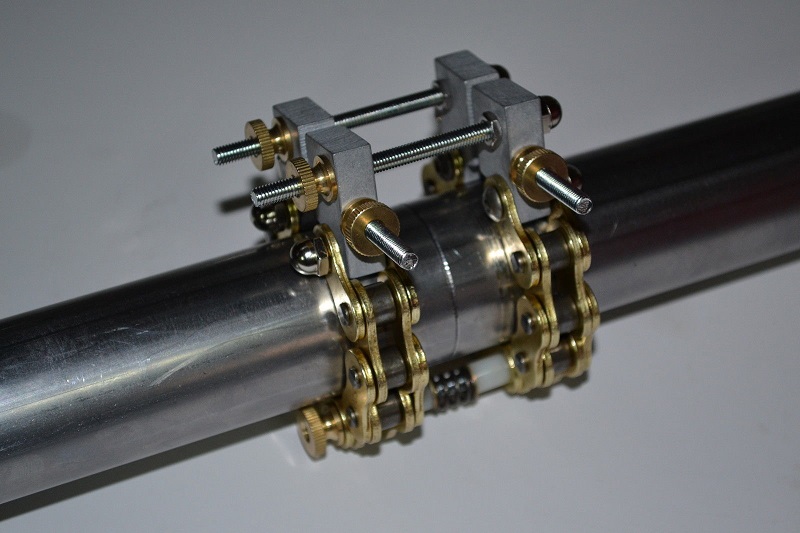

IF your are unfamiliar with SMURF TUBE ITS USED FOR ELECTRICAL CONDUIT

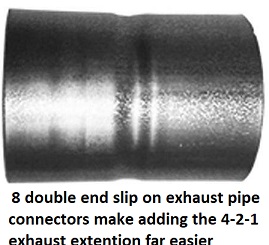

now obviously the exhaust lego kit the links point too, is a better route but I never knew they existed until recently and their kit of fabrication parts, is very expensive..

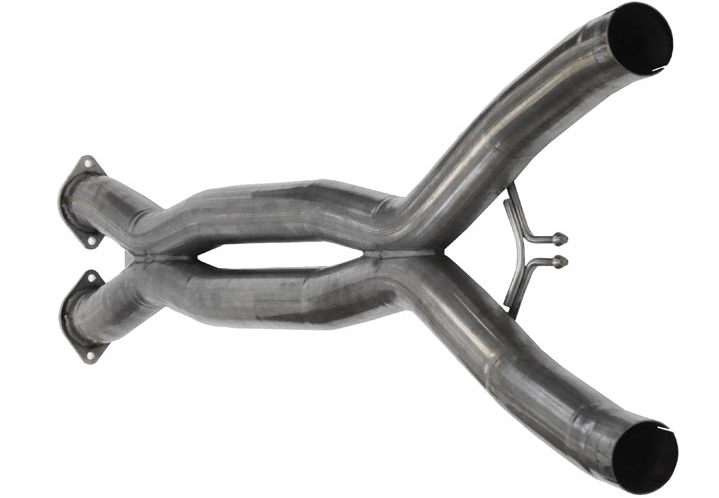

Ive done this many times its not that hard. here is what I do, get some of that plastic smurf tubing in the 2" diam. size and some ceiling hanger wire and some of that hard set construction insulation foam. now weld 1" stubs of the exhaust tube to the header flange exhaust ports and bolt it to the cylinder heads. clamp the collectors to a 6 foot section of 2x6" wood and jack it up solid under the car (collectors not touching the car anywhere)to position them where you want them under the car, now cut (8) sections of smurf tubing too about 36"-42" long(theres a formula to figure the exact length)slide 4-6 pieces of ceiling suspension wire in each tube with the ends looped over inside the tube. now starting with the upper inside collector position and the rear exhaust port, bend and fit the smurf tubing to fit, the next forward exhaust port goes to the lower inside collector port the next exhaust to the upper outside collector port and the furthest forward to the lower outside collector port , once they are all bent to fit shoot the tubes full of hardening construction foam, let it harden and then pull each individual tube off one at a time and duplicate it in steel tubing, by cutting and welding sections and dozens of trial fits before you permanently weld ANYTHING!(or have your local muffler shop duplicate it,.. MOST WON,T AS ITS VERY LABOR INTENSIVE) this method REALLY makes the fit and try time minimal.(YES ITS STILL A ROYAL P.I.T.A.) and assures equal length tube headers.SMURF TUBE is flexible plastic electrical conduit that's normally BLUE or ORANGE and COMMONLY called smurf tubing by contractors its a plastic version of that metal GREENFIELD tubing that electrical contractors use but its cheaper and easier to work with, it resembles a canister type vacuum cleaner pickup hose but stiffer, its available at big hardware stores,and electrical supply houses dirt cheap in 10' lengths about $6 each or less you will need (3)BTW the 4-6 wires act like re-bar in concrete, the loops keep the wires from moving in the foam while their encased in the construction foam, the hard plastic foam is what keeps it stiff and no it will not be exact you will still need to tweak it to get it to fit but it will speed up the process of making the tube pattern shapes. just keep in mind that you can buy headers fairly cheaply (under $300 in many cases) for most cars its when you go and get an odd ball combo this comes in handy, like putting a 502bbc in a 57 vette or a 392 hemi in a 63 falcon.

IN MANY CASES A SIMILAR CARS HEADER CAN BE USED AND ONLY ONE OR TWO PRIMAIRY TUBES NEED RE-ROUTING

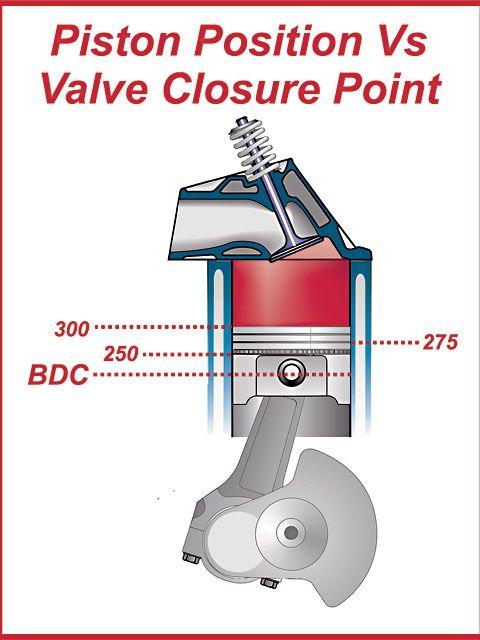

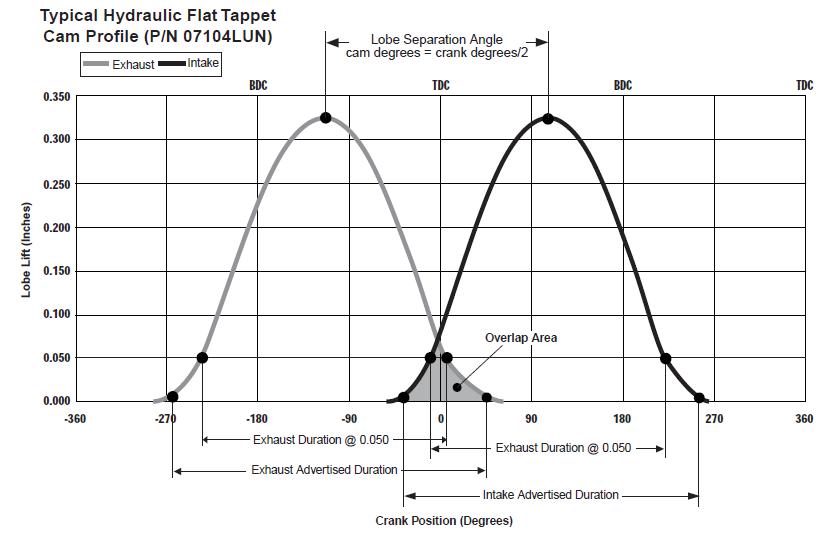

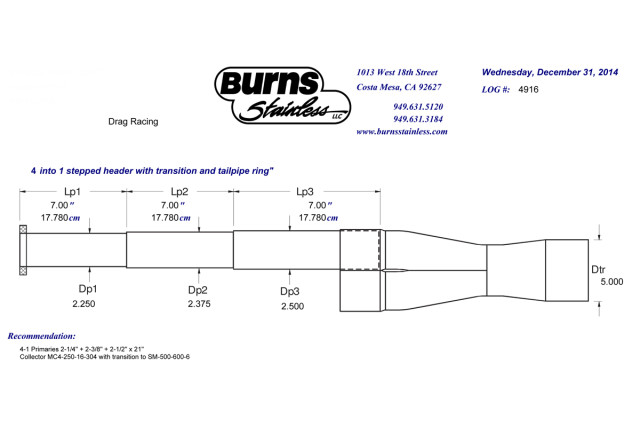

example , my 383 vette has a cam with exhaust cam timing that opens at 83degs bbdc, thats 97 degs atdc, http://dab7.cranecams.com/SpecCard/D...1=Display+Card

Bore: (Inches) 4.03"<BR>Exhaust Valve Opening Point: (Degrees ATDC) 97 degs

Peak Power RPM: 5500rpm Calculated information appears below

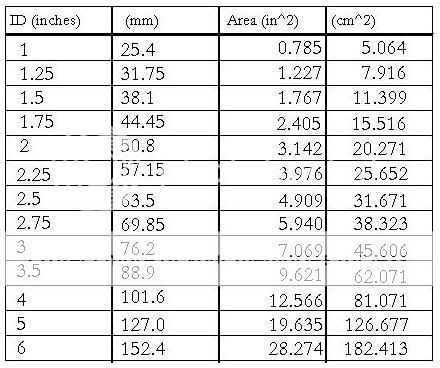

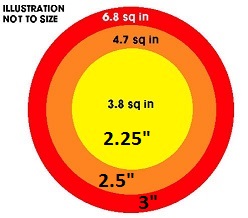

Header Pipe Diameter: (Inches) 1.84"<

Header Pipe Length: (Inches) 37.65

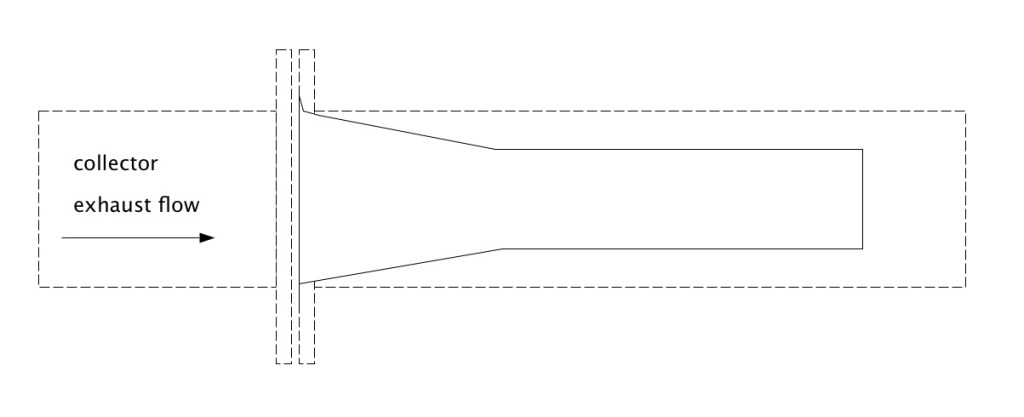

Collector Diameter: (Inches) 3.5

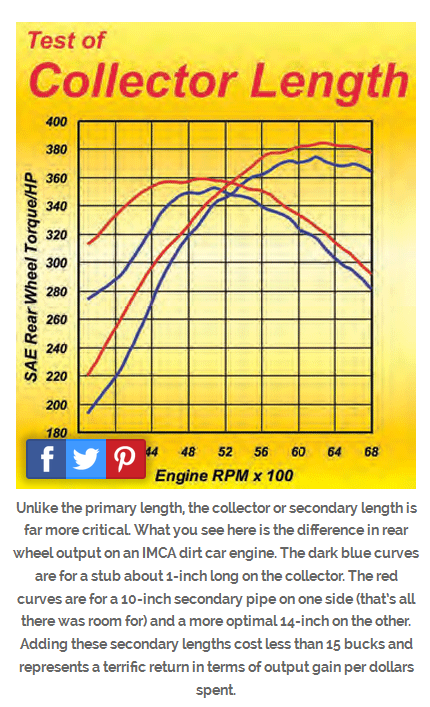

Collector Length: (Inches) 18.82

yeah its amazing how everything costs ten times what you think it will and takes five times longer to do even at that inflated price

building custom headers

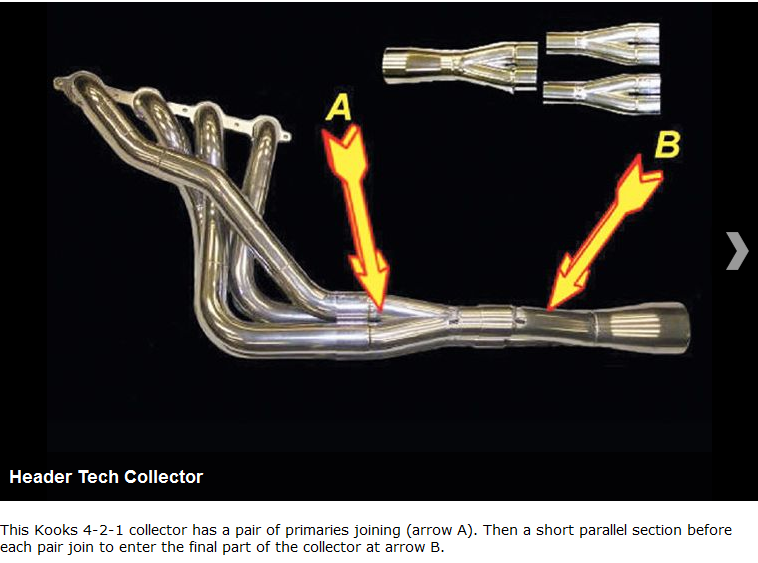

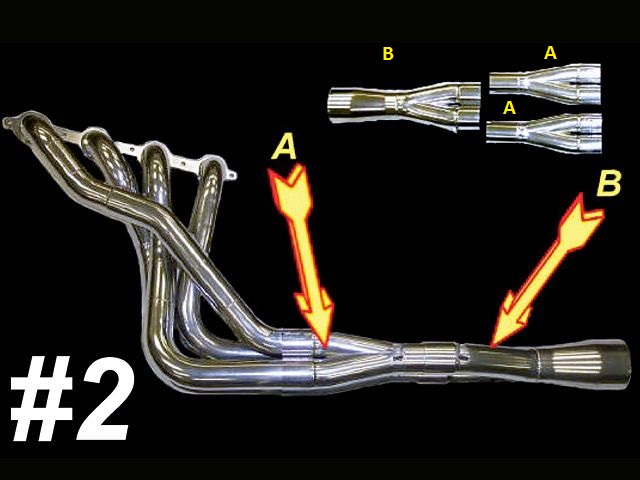

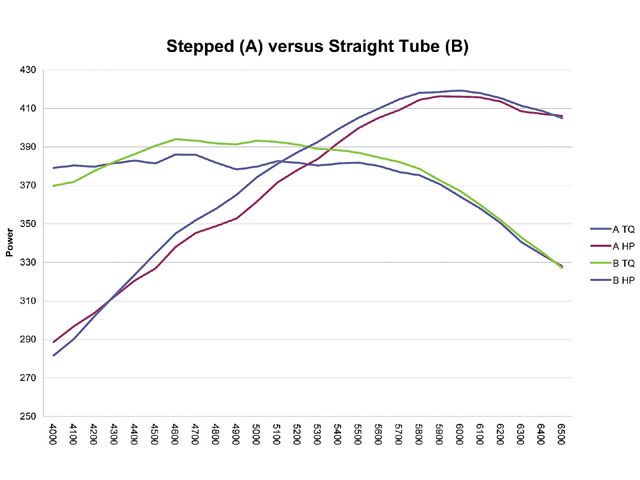

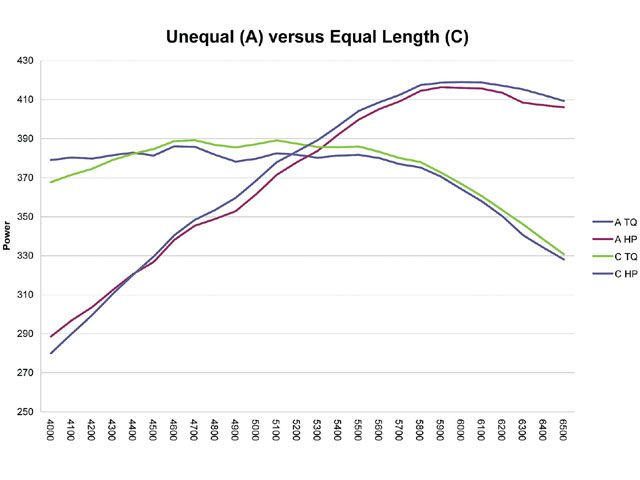

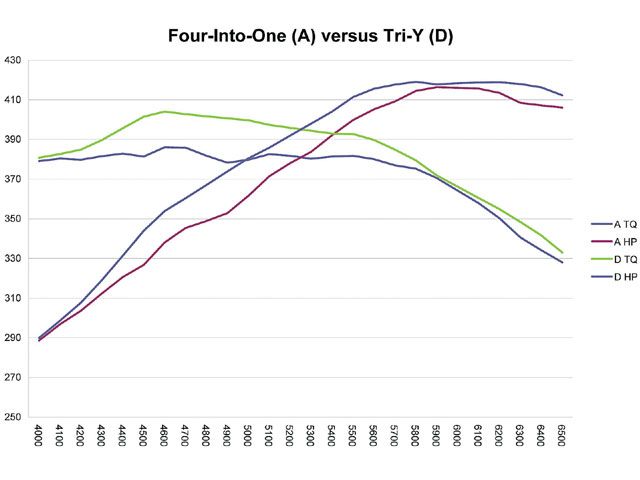

Its a Good topic to review today once again Grumpy. Thinking of Tri-Y headers. Be nice to have another set For My T/A Tri Y design. Broden the Torque band on the street or at least try it. Experiment & Tune. HO Racing made them in the past for my TA with Round Port heads. Long gone headers...

garage.grumpysperformance.com

that makes installing the spark plug boots in such a way that they don,t contact the hot metal surfaces almost impossible , this can sometimes be helped a great deal by the addition of a header flange, or SPACER PLATE, that MATCHES YOUR PARTICULAR ENGINES CYLINDER HEAD EXHAUST PORT AND HEADERS,

thats significantly thicker being welded to the existing header flange , to space it out further away from the cylinder heads, obviously you don,t want to do this without testing all the clearances so installing the extra header flange with an exhaust gasket on both the cylinder head surface and between the header flange spacer and the existing headers as a test is strongly suggested as a test.

THIS IS ALSO USEFUL AT TIMES TO ADAPT THE ENGINE TO A DIFFERENT BOLT PATTERN OR SPACING

as long as the exhaust port entrance in the header flange and stubs in that flange,

is marginally larger internally in cross sectional area,

and there's no rapid and restrictive change in exhaust flow direction, or very rapid deduction in area,

and the header flange does not block the exhaust port exit around its circumference,

the shape of the exhaust pipe is all but meaningless beyond the port

btw

you can generally port and smooth the header flange entrance to some small extent to perfectly match the exhaust ports exit in the head casting

(be sure you match the exhaust gaskets and verify they won't overhang into the ports

http://www.jegs.com/i/JEGS-Performance-Products/555/30790/10002/-1?parentProductId=977236

heres where you get spacer header flange plates

http://garage.grumpysperformance.com/index.php?threads/header-paints-and-coatings.6086/#post-57067

http://garage.grumpysperformance.com/index.php?threads/thermal-coatings.2610/#post-12861

building custom headers

theres a great deal of useful info in these links , and sub linked info so don,t skip over them without looking thru carefully, as theres years of experience to be gained yeah its amazing how everything costs ten times what you think it will and takes five times longer to do even at that...

garage.grumpysperformance.com

http://www.jegs.com/p/JEGS-Performance-Products/JEGS-Header-Exhaust-Flanges/1127498/10002/-1

http://www.summitracing.com/search/Part-Type/Header-Flanges/

http://www.hedmanhusler.com/Hedder-Flanges-without-Stubs

http://rehermorrison.com/product/adapter-plates/

http://www.stainlessheaders.com/turboheader

Accel Extreme 9000 Ceramic Wire Sets

ACCEL now offers the cure for burnt spark plug wire boots with Extreme 9000 Ceramic Wire kits. The 8mm Ferro-Spiral core wire now has ceramic boots on the spark plug end of the wires that will withstand up to 2,000° F. If you are running headers with close tolerances, an engine bay with little room, or an RV with boots that melt because of heat, these wire kits are the answer. and yeah! youll still need the heat resistant plug boots to prevent the wires from melting past the ceramic plug boot

http://www.stainlessheaders.com/

http://wallaceracing.com/Calculators.htm

http://hotrodenginetech.com/icengineworks-header-modeling-kits/

at times you need to do some minor fabrication to get things to fit & function, so having a welder and knowing where to get header flanges helps, but some careful measuring will yield surprising results at times, like BIG BLOCK CHEVY HEADERS CAN BE MODIFIED TO FIT A 500 CADDY ENGINE

you might want to install a 496 big block chevy in a 1969 AMX, and a DANA 60 rear differential, that will require a bunch of carefully measured custom fabricated custom components, something any true hot rodder can do with the correct tools like a decent welder and access to a mill,but you won,t find the parts required in any catalog.

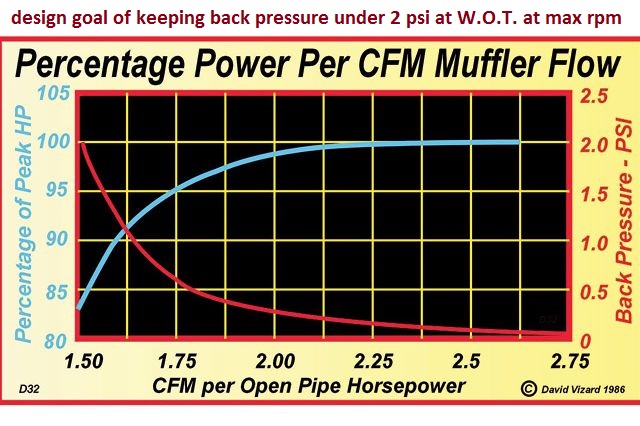

if you have ever done the math required to calculate the ideal header dimensions for a serious big block engine youll find most headers would require longer header primary tube lengths, closer to the 36"-39" length and using the 3.5"-4" collectors at least 18"-22" long that are rather easily built with the side exhaust design but almost always too restrictive to fit for clearance issues with an under the car exhaust.

or put a different way, the basic lay-out of a properly designed side exhaust lends itself more easily to a max effort exhaust,provided you junk or replace the highly restrictive inserts and replace them with some other option

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=2350

http://garage.grumpysperformance.com/index.php?threads/shield-gas-selection-for-welding.1108/

http://forum.grumpysperformance.com/viewtopic.php?f=80&t=793&p=30576&hilit=+side+pipes#p30576

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=9296&p=33590#p33590

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=7831&p=26979&hilit=+side+pipes#p26979

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=495

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=185

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=1166

http://www.coneeng.com/collector_components.html

http://icengineworks.com/Catalog2012Ed2 ... sionLR.pdf

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/header_length.php

http://www.jefflilly.com/fabrication/he ... brication/

http://maxracesoftware.com/pipemax36xp2.htm

http://www.icengineworks.com/icewmain.htm

http://www.hotrod.com/techarticles/hrdp ... ipe_dream/

http://www.hotrod.com/techarticles/hrdp ... ipe_dream/

http://www.stainlessheaders.com/headerfabrication

http://www.metalgeek.com/static/cope.pcgi

http://www.superchevy.com/technical/eng ... index.html

http://www.bgsoflex.com/bestheader.html

http://www.carcraft.com/techarticles/he ... usion.html

http://www.centuryperformance.com/exhau ... g-137.html

http://www.mandrel-bends.com/catalog/ma ... -gauge-74/

http://www.carcraft.com/howto/ccrp_0803 ... _list.html

http://www.spectrum5racing.com/Technica ... erRevA.pdf

http://victorylibrary.com/mopar/header-tech-c.htm

http://www.pontiacracing.net/js_header_length1.htm

http://www.mk5cortinaestate.co.uk/calculator5.php

http://www.carcraft.com/howto/ccrp_0803 ... index.html

http://www.carcraft.com/howto/0304_head/index.html

http://www.centuryperformance.com/exhau ... g-137.html

http://stockcarracing.automotive.com/49 ... sions.html

http://www.carcraft.com/techarticles/11 ... ndex2.html

http://www.stainlessworks.net/cart/pressrelease.php

http://www.jefflilly.com/Fabrication/Fa ... t/page.htm

viewtopic.php?f=56&t=352

http://victorylibrary.com/mopar/header-tech-c.htm

http://store.racing-solutions.org/

http://store.summitracing.com/largeimag ... OK-2956HKR

http://www.burnsstainless.com/MergeColl ... ctors.html

http://www.stahlheaders.com/Frame Flanges.htm

http://www.stansheaders.com/gm_flanges.htm

IF your are unfamiliar with SMURF TUBE ITS USED FOR ELECTRICAL CONDUIT

now obviously the exhaust lego kit the links point too, is a better route but I never knew they existed until recently and their kit of fabrication parts, is very expensive..

Ive done this many times its not that hard. here is what I do, get some of that plastic smurf tubing in the 2" diam. size and some ceiling hanger wire and some of that hard set construction insulation foam. now weld 1" stubs of the exhaust tube to the header flange exhaust ports and bolt it to the cylinder heads. clamp the collectors to a 6 foot section of 2x6" wood and jack it up solid under the car (collectors not touching the car anywhere)to position them where you want them under the car, now cut (8) sections of smurf tubing too about 36"-42" long(theres a formula to figure the exact length)slide 4-6 pieces of ceiling suspension wire in each tube with the ends looped over inside the tube. now starting with the upper inside collector position and the rear exhaust port, bend and fit the smurf tubing to fit, the next forward exhaust port goes to the lower inside collector port the next exhaust to the upper outside collector port and the furthest forward to the lower outside collector port , once they are all bent to fit shoot the tubes full of hardening construction foam, let it harden and then pull each individual tube off one at a time and duplicate it in steel tubing, by cutting and welding sections and dozens of trial fits before you permanently weld ANYTHING!(or have your local muffler shop duplicate it,.. MOST WON,T AS ITS VERY LABOR INTENSIVE) this method REALLY makes the fit and try time minimal.(YES ITS STILL A ROYAL P.I.T.A.) and assures equal length tube headers.SMURF TUBE is flexible plastic electrical conduit that's normally BLUE or ORANGE and COMMONLY called smurf tubing by contractors its a plastic version of that metal GREENFIELD tubing that electrical contractors use but its cheaper and easier to work with, it resembles a canister type vacuum cleaner pickup hose but stiffer, its available at big hardware stores,and electrical supply houses dirt cheap in 10' lengths about $6 each or less you will need (3)BTW the 4-6 wires act like re-bar in concrete, the loops keep the wires from moving in the foam while their encased in the construction foam, the hard plastic foam is what keeps it stiff and no it will not be exact you will still need to tweak it to get it to fit but it will speed up the process of making the tube pattern shapes. just keep in mind that you can buy headers fairly cheaply (under $300 in many cases) for most cars its when you go and get an odd ball combo this comes in handy, like putting a 502bbc in a 57 vette or a 392 hemi in a 63 falcon.

IN MANY CASES A SIMILAR CARS HEADER CAN BE USED AND ONLY ONE OR TWO PRIMAIRY TUBES NEED RE-ROUTING

example , my 383 vette has a cam with exhaust cam timing that opens at 83degs bbdc, thats 97 degs atdc, http://dab7.cranecams.com/SpecCard/D...1=Display+Card

Bore: (Inches) 4.03"<BR>Exhaust Valve Opening Point: (Degrees ATDC) 97 degs

Peak Power RPM: 5500rpm Calculated information appears below

Header Pipe Diameter: (Inches) 1.84"<

Header Pipe Length: (Inches) 37.65

Collector Diameter: (Inches) 3.5

Collector Length: (Inches) 18.82

Last edited by a moderator: