YES THE SUB LINK INFO IS WELL WORTH READING ALSO

if your serious about maintaining good peak hp numbers use the calculators in the linked threads to actually calculate the ideal matched header dimensions, this is not a guessing game its strait physics and easily calculated to maximize exhaust scavenging and max volumetric efficiency, resulting in max power , at any given rpm and displacement, compression , cam timing etc this stuff can be calculated, but when dealing with an average and without knowing all the specifics you go by averages,and assume that peak hp takes a higher value than off idle torque

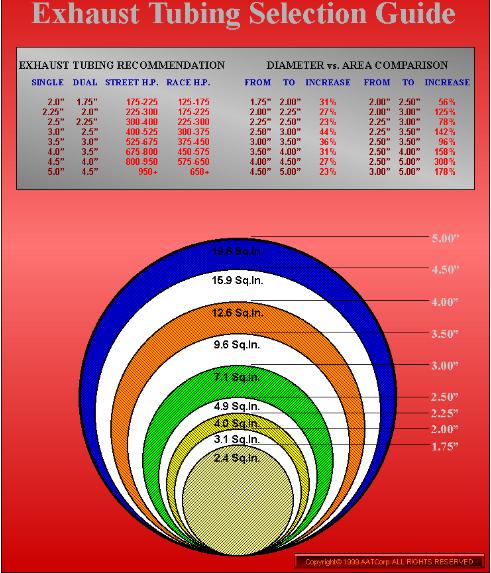

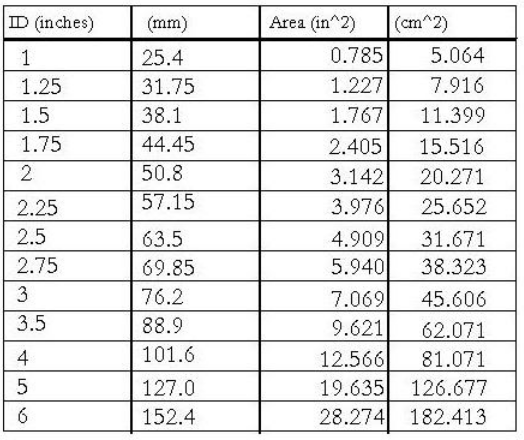

ok as a rule of thumb,when calculating and engines expected exhaust flow rates you can roughly assume 2.257 cfm per horsepower produced

http://www.wallaceracing.com/header_length.php

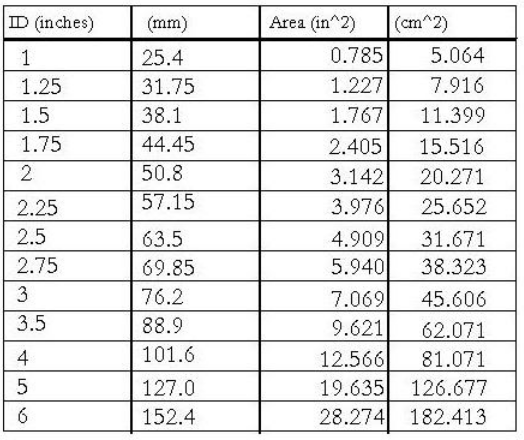

if you have a 500hp engine it will in theory produce 500 x 2.257=1128.5 cfm of exhaust flow

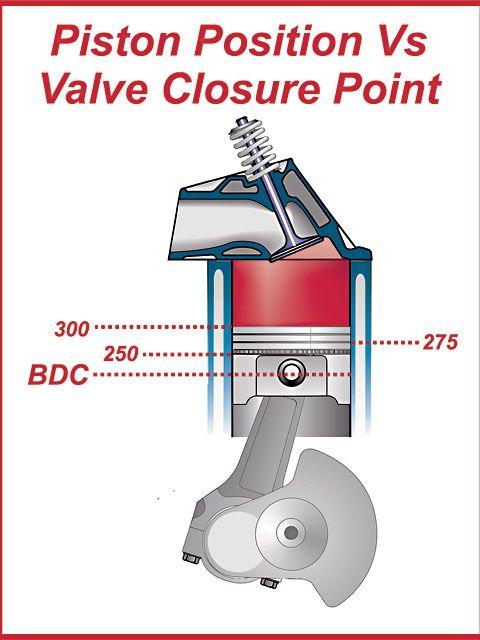

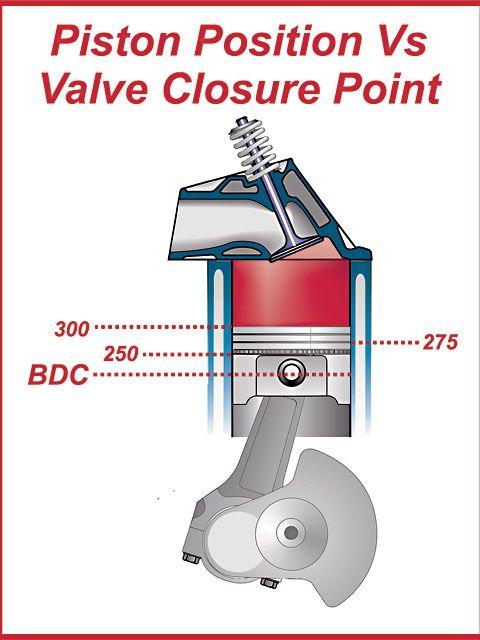

or 141 cfm exhaust flow per cylinder, but your exhaust valve is only open about 220-290 degrees and the time between power strokes gets shorter as the rpms increase.

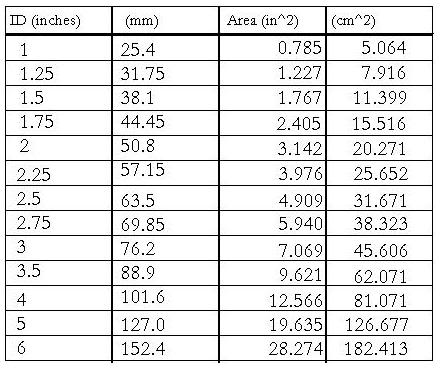

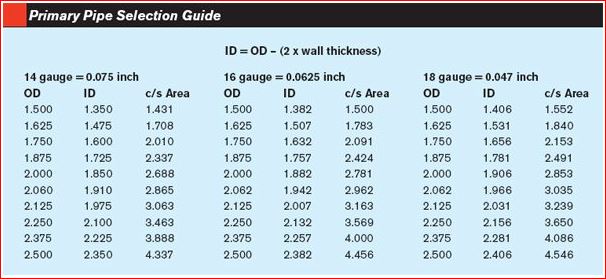

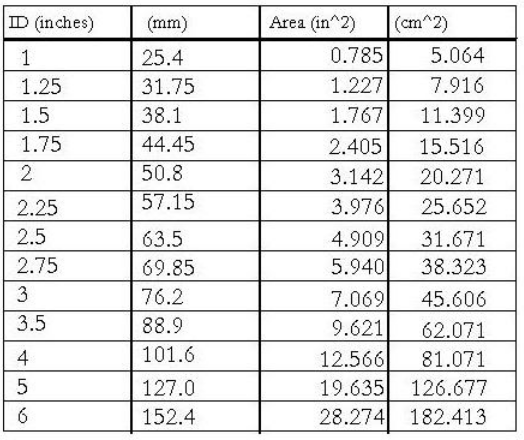

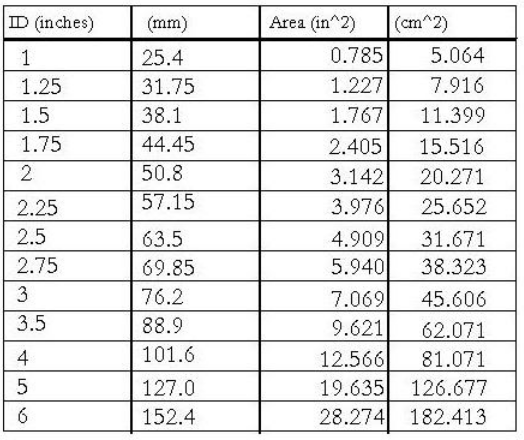

Of the 720 degrees in a complete engine cycle, there is lets say 250 degrees , or 250/720=1/3rd of the time, but it doesn't all exit instantly so you can figure on about 1/2 the time the header primary's under significant pressure and pressure and pulse frequency varies with the rpms so the exhaust dump rates not at a constant flow or pressure, the header must handle 141 x 2=282cfm /115 =2.45 sq inches for exhaust flow per cubic inch , you look at the chart and find thats about a 1.7/8 diam. subtracting the pipe wall thickness

http://garage.grumpysperformance.co...-pipe-leading-into-a-x-pipe.15118/#post-86157

www.summitracing.com

www.summitracing.com

www.summitracing.com

www.summitracing.com

www.motortrend.com

www.motortrend.com

be aware that headers only become noticeably more efficient at scavenging the cylinders and boosting power,

be aware that headers only become noticeably more efficient at scavenging the cylinders and boosting power,

if they have an open collector OR a low flow restriction exhaust behind them.

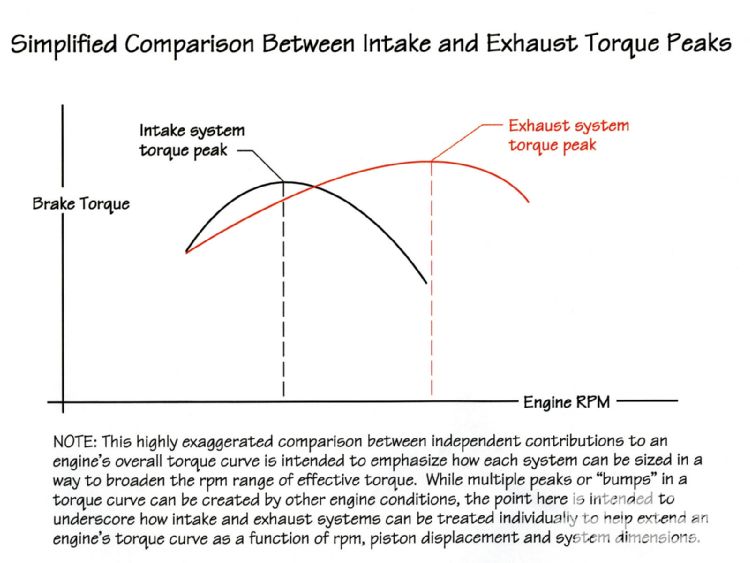

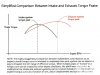

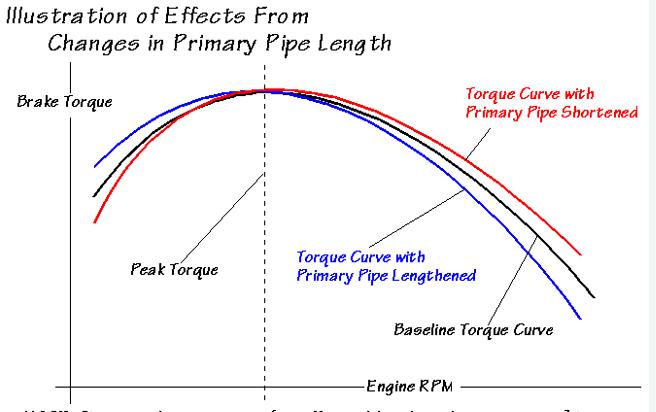

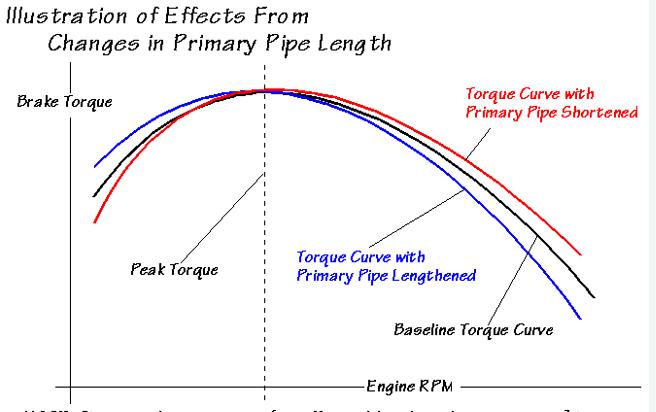

varying the primary tube length and diameter, and matching collector length and diameter can change, boost, torque, widen, that power band or restrict it,

and theres generally a specific power/rpm band where they provide a very noticeable boost in power or a "SWEET SPOT" ideally you design the headers to boost the torque and cylinder scavenging in an rpm range that does benefit you most of the time.

if in doubt, about the header component size and length etc.

always assume a marginally ,or a bit longer primary tube and marginally smaller diameter collector, to be a valid choice.

as this tends to slightly favor the mid rpm ranges,

of a bit shorter length exiting to a LARGER diameter exhaust.

(preferably with an X-pipe within as close a distance as possible and low flow restriction muffler's)

will work rather well.

keep in mind the scavenging efficiency changes with rpms, displacement and compression ratio as well as with the ignition timing

fuel air ratio , valve sizes, port flow rates and exhaust gas temps, so minor changes in length/diameter etc.

only marginally change where in the rpm range peak cylinder scavenging efficiency occurs,

minor changes won't be very noticeable, could you even begin to feel a peak scavenging efficiency or peak power,

if the difference was 30-60 rpm difference? as you run up through the gears, remember you might only be in a gear, for a couple seconds,

and during that couple seconds the engine might go from 5500rpm-6800rpm on an engine you built for performance use,

and while a street engine may be in a gear between shifts marginally longer ,

and may operate at only lets say 4500rpm-5900rpm that 30-60 rpm difference will be only seen on a precise dyno,

and that peak power last less than a fraction of a single second at best during a gear change.

so don,t sweat minor changes in collector or primary tube length.

watch video

keep firmly in mind that the header exhaust scavenging ,efficiency and intake runners ability to effectively fill the engines cylinders is very much dependent on carefully matched, cam timing, headers designed to match the engines displacement, intended rpm band, ,maximum compression ratio, for the fuel octane used,and a low restriction exhaust behind the header collectors, when all the factors are well matched correctly theres an easy 20% or higher power gain over most stock engines in this area alone.

correctly matched headers, compression, cam timing, displacement etc, can easily increase the cylinder fill efficiency, and intake runner air flow velocity by over 30%

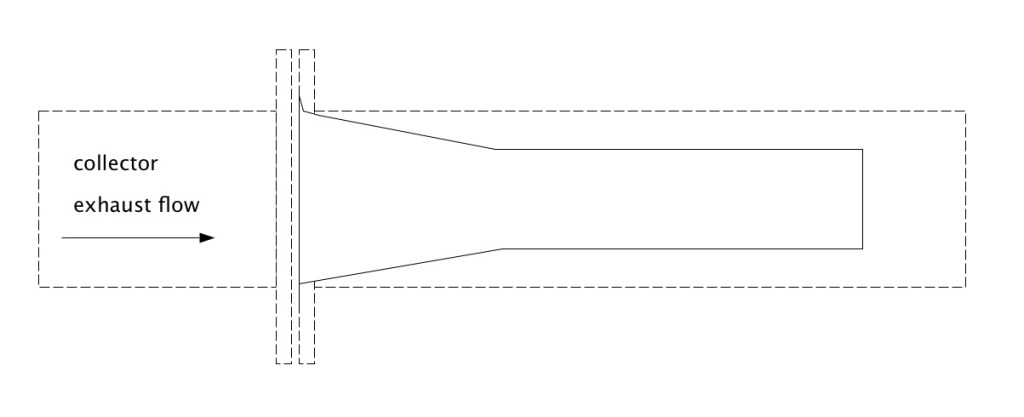

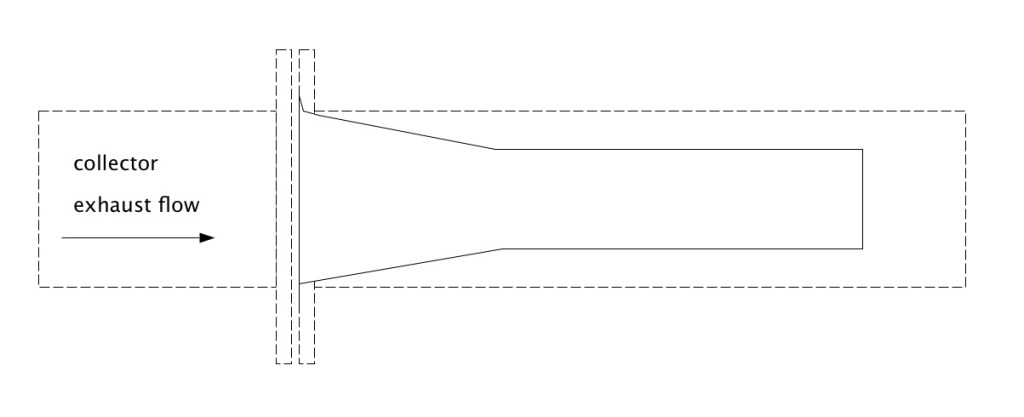

adding an anti-reversion baffle to a 18"-24" longer collector on open headers with the internal pipe about 1/2 the collector length tends to help scavenging on some engines, no header will function to full efficiency with any significant back pressure so take the effort to accurately measure any restriction to exhaust flow AT your upper rpm range of your engines power band and be darn sure its not choking your power curve.

if you want max engine performance under predictable conditions,

it will take some testing, measuring and though,

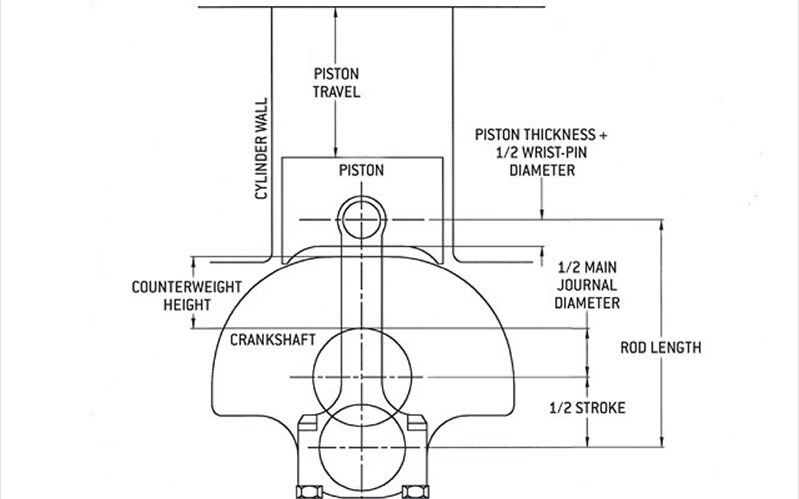

could you give us some idea as too,

engine displacement"

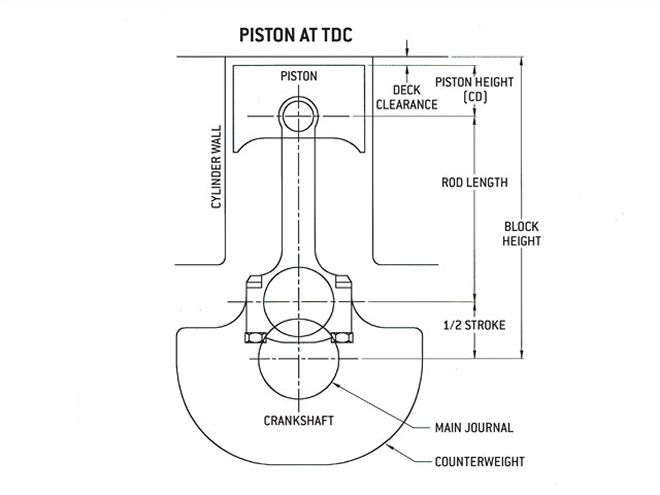

bore and stroke ?

connecting rod length,

engines intended power band?

transmission shift points?

the cam timing, (lift ,duration)?

cylinder head flow rates,?

static compression ratio,?

ignition advance curve,?

intake valve diameter?

intake port cross sectional area?

intake runner length?

exhaust valve diameter?

, and header primary tube diameter?

and length?

fuel/air ratio every 1000 rpm?

exhaust back pressure in the collector every 1000 rpm?

intake plenum vacuum every 1000 rpm?

with that data we can stop random guess work,

and have at least some facts to work with,

to make a semi logical guess as to what changes might help.

guessing is fast and easy, getting a few facts and working out the details is a bit harder but more productive

http://www.wallaceracing.com/Calculators.htm

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...ful-exhaust-valve-size-and-header-info.11265/

http://garage.grumpysperformance.com/index.php?threads/dyno-testing-headers.3529/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...-guys-that-just-slap-on-factory-headers.3155/

reading these threads and sub links may help

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...-between-shorty-and-full-length-headers.1303/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

the basic well proven fact is that almost all the commercial headers were and are designed with fit and ease of fabrication as the primary design parameters and max performance far down the list.

low cost and ease of manufacture , and designing a single header too fit as many applications as possible to simplify inventory issues, has almost always been the manufacturers goal.

longer primary tub length has frequently proven to provide both more mid rpm torque and more average torque, and its the torque within 2000-rpm-3000 -rpm of the peak torque that moves the car during almost all the time in performance use.

longer tubes cost more money and make the header harder to design too fit well, so most manufactures rather design a shorter headers that may fit several similar cars rather than the ideal longer header for a single application.

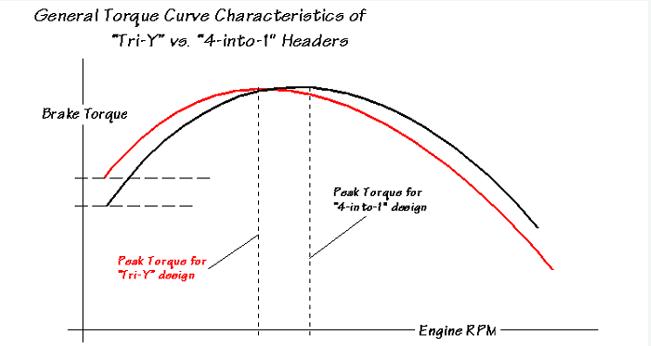

4 into two, into one collector designs (LIKE BELOW)have also proven to be excellent performers,

but the generally work best if the cam timing and high compression are well matched

one of the rather well established racer tricks has always been to run open collectors too reduce back pressure, as

( headers scavenge best, with zero back pressure)

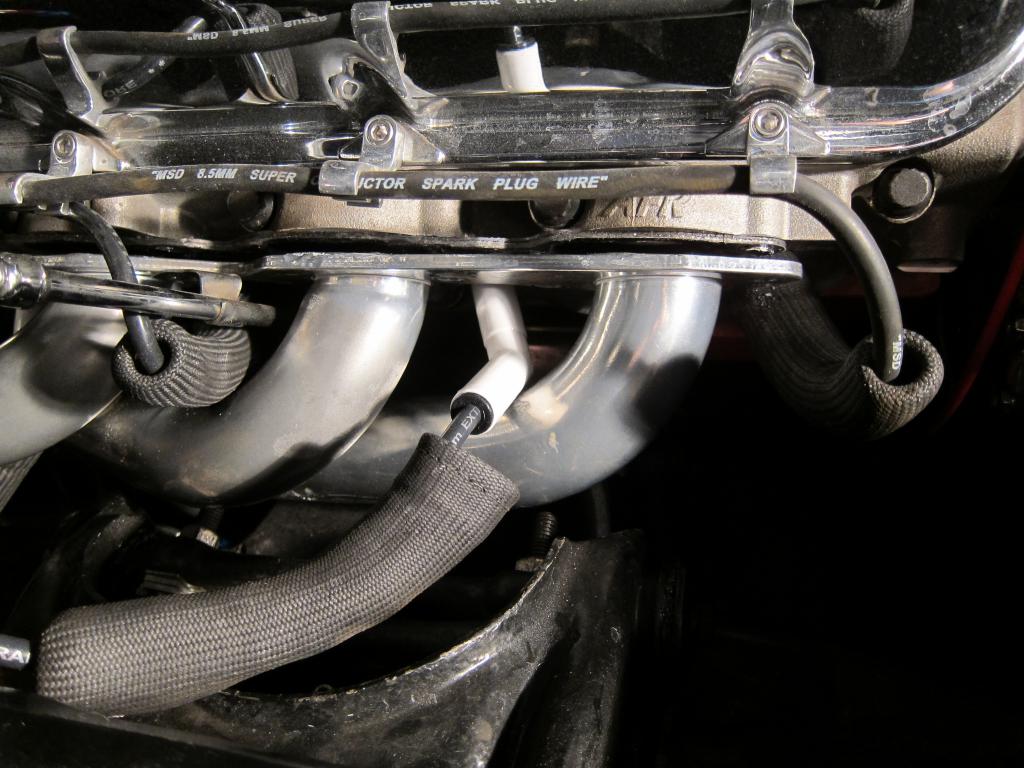

and in many cases, where clearances allowed, we cut the collectors of commercial headers , and welded on pre made extensions

(LIKE THESE BELOW)and almost always saw a boost in performance

https://www.summitracing.com/parts/FLO-C134218234/

one reason side exhaust on corvettes were and are used is the design allowed decent ground clearance AND long efficient header primary tube header designs.

http://www.wallaceracing.com/intake-runner-length.php

http://www.bgsoflex.com/intakeln.html

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

CALCULATORS TO PLAY WITH

http://www.wallaceracing.com/Calculators.htm

http://www.velocity-of-sound.com/velocity_of_sound/calculator3.htm

http://www.velocity-of-sound.com/velocity_of_sound/velocity_stacks.htm

http://www.swartzracingmanifolds.com/tech/index.htm

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

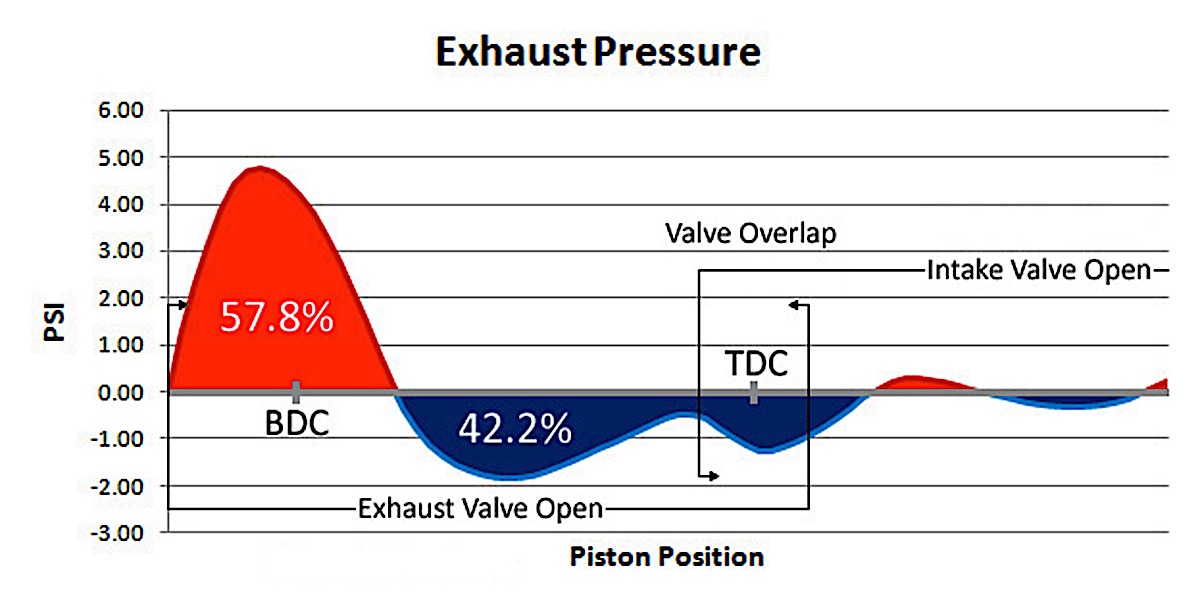

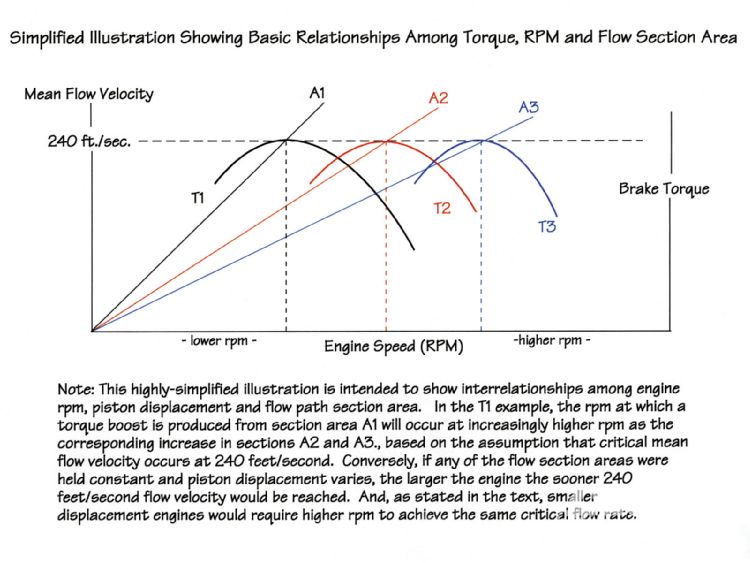

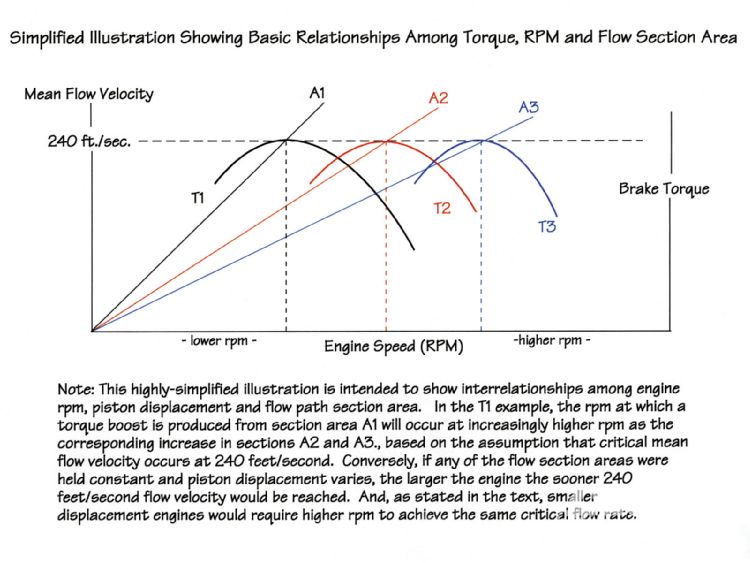

cylinder fill efficiency is a compromise, your engine design is forced to make selecting the way components are matched, the factors of cam timing compression and exhaust header tuning all must fall in the same 3000 rpm power band and ideally in the same 1500 rpm range to maximize power.

the choices between cam timing and compression ratio, and head and intake flow rates, valve size and valve lift and duration,

has a huge effect on,exhaust scavenging and while most people think the port flow rate is mostly the result of the piston dropping away from TDC,

lowering the cylinder pressure , thus drawing in the intake runner charge, this is not the major factor once the engine rpms increase significantly.

its exhaust scavenging during the valve over lap , being well matched to the engine displacement and cam timing, header diameter, and length, and collector design,

and intake ram tuning that can significantly boost cylinder fill and cylinder scavenging efficiency rates.

OK, first fact! the piston can,t compress anything being trapped in the cylinder by the piston compressing it as it raises,until both valves seat & seal

http://garage.grumpysperformance.com/index.php?threads/calculate-compression.9162/#post-32706

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

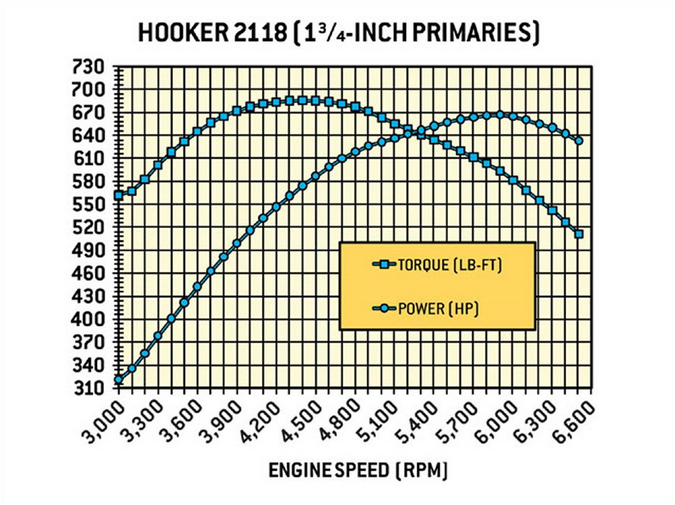

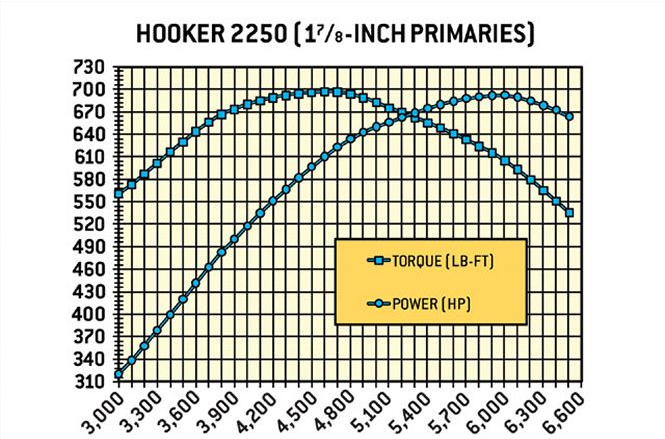

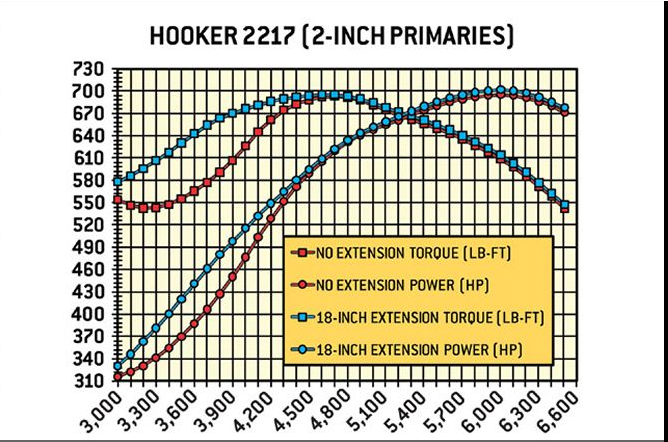

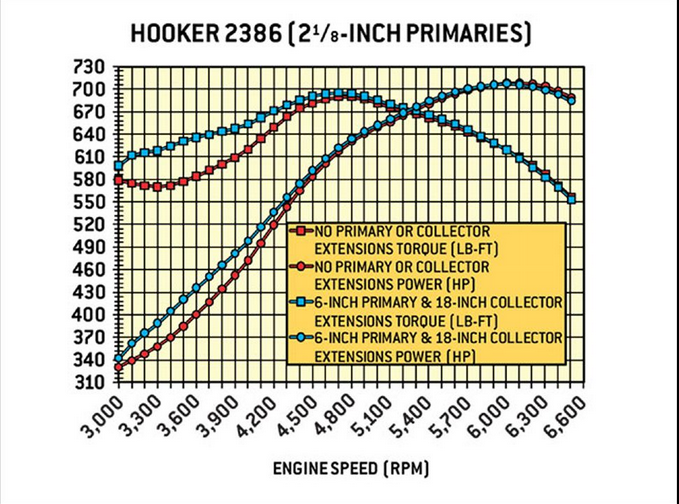

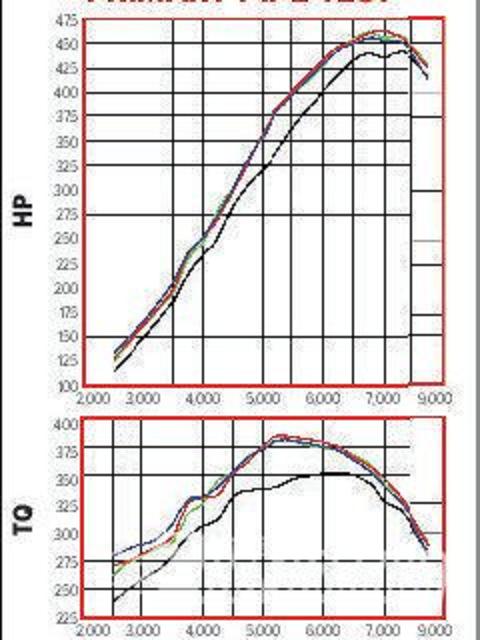

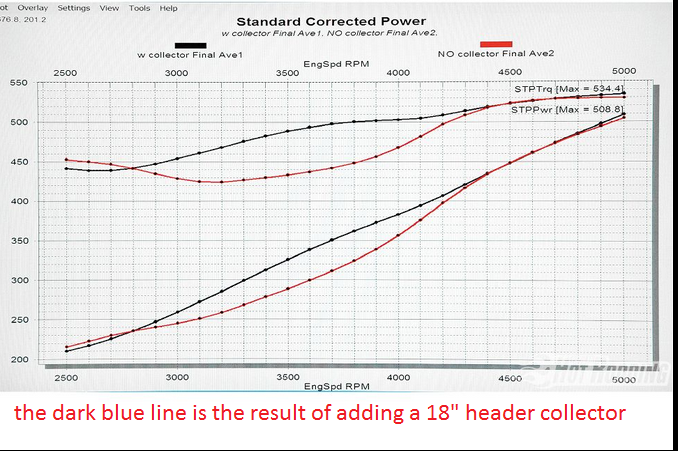

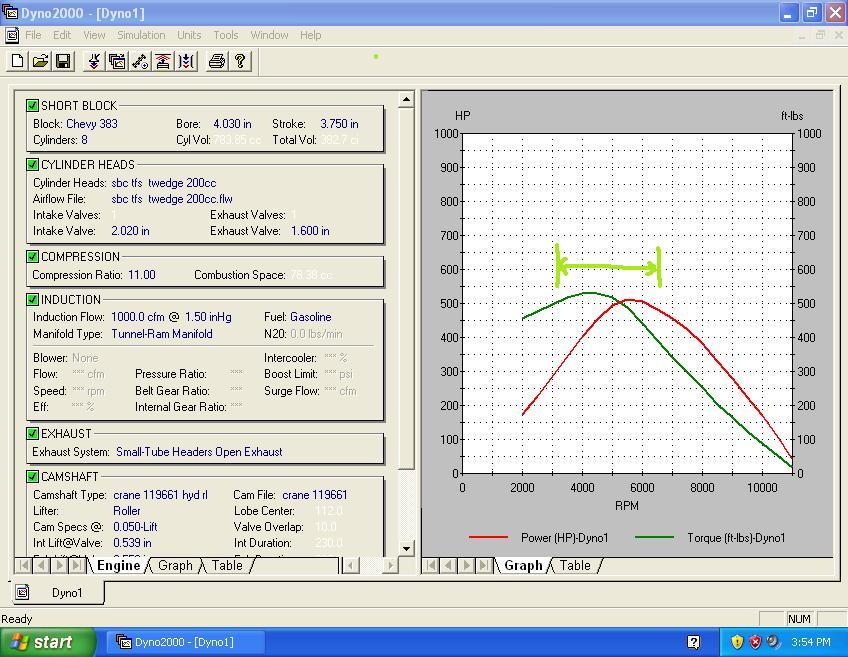

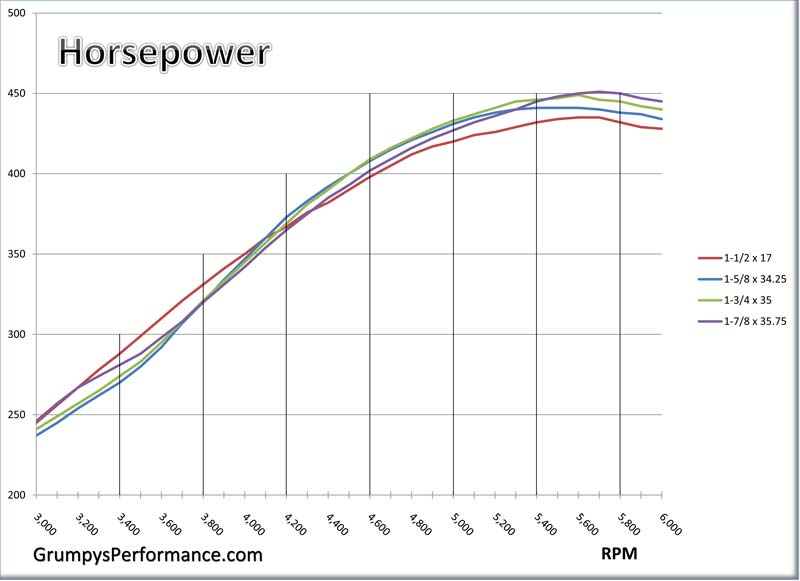

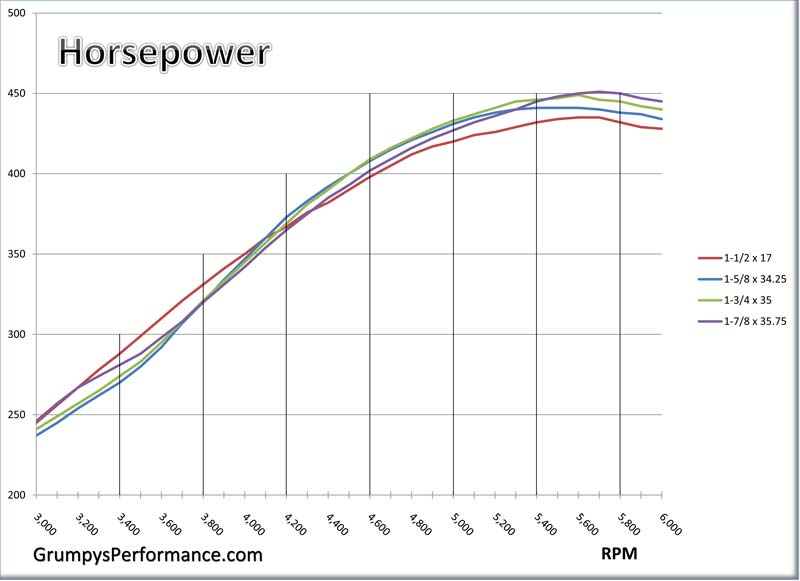

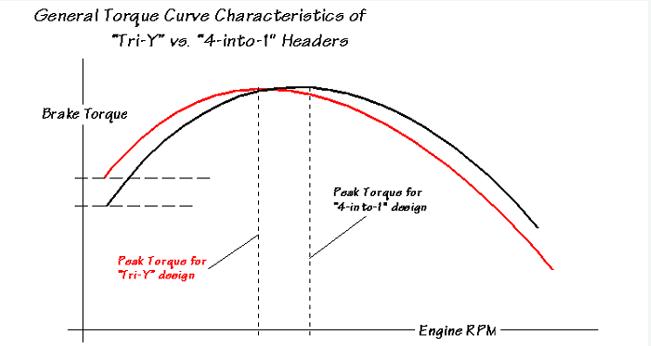

you will occasionally see dyno test results similar to this, that show about a 20 hp spread in the power curve, that seem to indicate that the difference in header configuration is not overly critical,but keep in mind these results are almost always done on 350-383 displacement engines with fairly mild compression , below 9.5:1 and fairly low duration cams ( example ,below 230 deg @.050 lift )and stock or mildly restricted exhaust systems, an engine with a fairly tight LSA and high compression and a low restriction or open exhaust can take full advantage of the headers scavenging the cylinders in a tuned rpm range significantly boosting the power produced, the tuned exhaust header has a greater effect on a higher compression ratio engine of larger displacement with a tighter LSA cam

you might want to read these also

http://victorylibrary.com/mopar/header-tech-c.htm

PRIMARY PIPE DIAMETER FACTORS

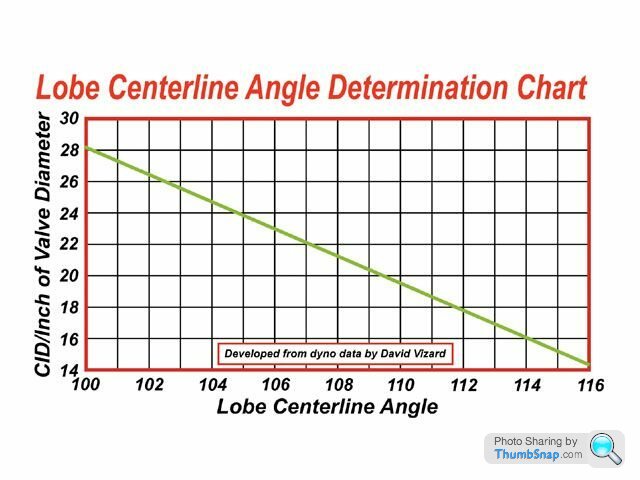

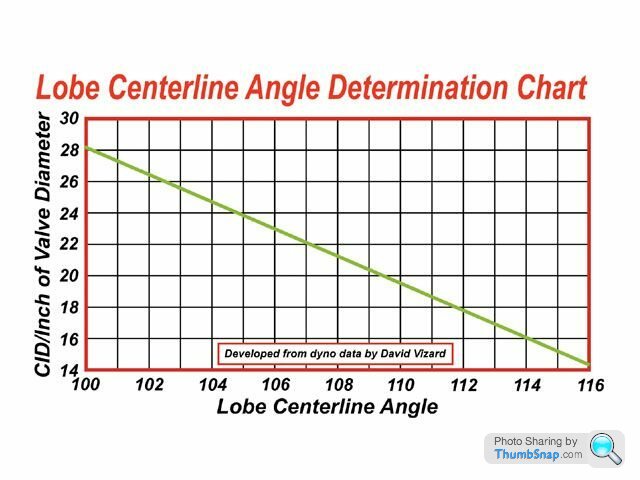

The primary header pipe diameter is determined using basic engine mechanical specifications, such as: Bore Stroke Compression Ratio Valve diameter Cam specifications (lift and duration) Target rpm range

http://www.pontiacracing.net/js_header_length1.htm

http://victorylibrary.com/mopar/header-tech-c.htm

http://maxracesoftware.com/pipemax36xp2.htm

http://www.wallaceracing.com/header_length.php

http://www.boyleworks.com/ta400/psp/exhaust3.html

http://www.autolounge.net/calculators/e ... izing.html

http://www.bgsoflex.com/auto.html

http://www.custom-car.us/exhaust/header.aspx

http://www.mk5cortinaestate.co.uk/calculator5.php

http://www.custom-car.us/exhaust/default.aspx

http://www.superchevy.com/technical/eng ... index.html

http://www.superchevy.com/technical/eng ... index.html

https://www.hotrod.com/articles/proper-exhaust-header-collector-volume-vs-engine-size/

http://www.carcraft.com/techarticles/03 ... index.html

http://autolounge.net/calculators/exhau ... izing.html

most exhaust pipe is 16 gauge, or .065 wall thickness

http://www.engineersedge.com/gauge.htm

How do you judge the i.d of a pipe?

3" o.d = 2.87" diam. inside

2.75 o.d = 2.62"diam. inside

2.5 o.d = 2.37" diam. inside

2.25 o.d = 2.12" diam. inside

theres THREE distinct areas of pressure/velocity

(1)

gases in the cylinders and header primary tubes as the exhaust exits the cylinders

(2)

gases in the header primary tubes and header primary tubes as the exhaust exits the header COLLECTORS

(3) the exhaust system past the collectors

(1) and (2) must be calculated to match the intended displacement ,cam timing and intended rpm range

(3) (traditional back pressure ) should be MINIMIZED

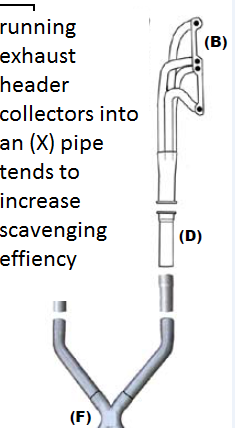

keep in mind installing an (X) almost increases the effective cross sectional area, of the dual exhaust ,or collector cross sectional area to double what it had been behind a single header collector, by doubling the area that the exhaust flow sees, dropping the restriction to flow almost in half

looking thru an (X) pipe

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/auto.html

PRIMARY PIPE LENGTH

"The overall length of the primary header pipe is governed almost exclusively by the target engine's rpm range, and displacement which is dependent upon wave tuning. Typically, a lower engine rpm range likes a longer primary pipe, while a high rpm engine prefers a shorter primary."

SECONDARY PIPE DIAMETER (collector length in a 4 into one design)

While typical off-the-shelf street 4-into-1 headers do not have true secondary pipes, Burns' research has proven repeatedly that his Tri-Y designs make more overall power over a broader rpm range. While traditional lines of thought have street enthusiasts knowing Tri-Y pipes make more bottom-end torque, further research by Burns into the design have resulted in headers making more power all across the rpm range. With more components as part of the Tri-Y design, more tuning possibilities exist, and therefore more potential lives within.

"The secondary pipe diameter is determined by considering both pressure waves and reflective waves throughout the system. Since the pipes are paired according to the firing order, these waves can work together or against each other. Naturally, our designs work with the waves to increase the efficiency of the header, using the wave pulses to help pull gases from the engine.

"There are two basic kinds of waves we're dealing with. First, there are pressure waves. The pressure wave travels the length of the primary pipe in a 4-into-1 header, then is reflected from the collector where the area changes from the small-diameter primary into the larger-area collector. A reflection of negative pressure goes back up the primary pipe.

"In a Tri-Y design, the pressure of additional area changes (where the primary pipes become secondary pipes) produces additional reflections, so the Tri-Y must be designed in a different manner with respect to wave control. Given this, the area of the Tri-Y header between the first and second collectors becomes critical, and tuneable. The entire header is affected by this crucial length of pipe, and can be fine-tuned accordingly through proper sizing for optimal broad-range performance.

"The 4-into-1 pipe is also affected by altering pipe lengths, of course. But, without these secondary pipes it is impossible to tune with the same level of precision as with the Tri-Y headers. It's for this reason we prefer the Tri-Y design in most applications. The tuneability is so much more accurate, we're able to find more power over a broader rpm range. This is especially critical in engines expected to work well over a wide rpm range, like street machines."

Another huge reason for the move to Tri-Y headers is weight savings. Burn's claims most of their Tri-Y headers weigh in at about _ the weight of comparable 4-into-1 pipes for the same application, due to the smaller pipe diameters used throughout similar applications. Also, with less internal volume than comparable 4-into-1 headers, the Tri-Y equipped engine is typically more responsive. Tri-Y designs require physically smaller collectors as well, contributing further to space and fit concerns, and adding further to crisp engine responsiveness.

COLLECTORS

"There is much power to be found in researching collector design and size. The optimal collector is determined by several variables, and it's engineering interacts with the entire exhaust system. The internal volume, the outlet size diameter, and the angles at which the pipes come together within the collector are all factors that must be maximized for the header to perform to its full potential."

1 - Primary Pipe Entry Size

"Our computer model design program determines many of these hard dimensions based on data gathered over many years, including the length and diameter of the primary or secondary pipe entering the collector."

2- PRIMARY PIPE ENTRY ANGLE

"The pipe entry angle is typically between 10-20 degrees, with most pipes being right at 15 degrees. The cone (or goilet) formed between the pipes as they transition from primary to collector is formed as a consequence of these angles, nothing more. The mass of gases moving through the pipe does not want to change direction, so keeping these "pyramid" cones true to the pipe entry angle helps smooth the transition from the relatively small volume of the feed pipe to the larger volume of the collector."

3 - COLLECTOR OUTLET DIAMETER

"The collector outlet diameter is the most critical dimension in the header. It's what makes the merged collector work the way it does. Each collector we sell is custom-sized to each customer's engine, and there's no real 'formula' to get a broad-based general determination for street machines. As a rule, the overwhelming majority of aftermarket headers designed for the street market have way too big of a collector outlet diameter. Most street guys are losing power because of badly designed, manufactured, or engineered street headers. There is much room for improvement here."

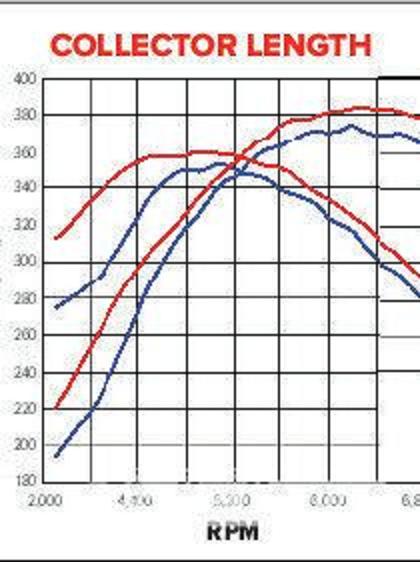

4 - OVERALL COLLECTOR LENGTH

"Overall collector length is not critical. Once the other variables in the header design have been determined, the collector ends up being as long as it needs to be. We've found no benefit in lengthening or minimizing this dimension. It's more important to properly engineer what's going on inside the merged collector, and let the length determine itself once all the other important factors are optimized."

AFT OF THE COLLECTOR

One of the growing areas of research at Burns is the critical area just aft of the all-important collector outlet. Burns' dyno research led him to begin experimenting with interchangeable venturis, which slip into receivers just aft of the collector. While these prototype dyno parts were initially crafted to assist Jack in determining the critical overall collector diameter size, he soon realized they could be a marketable product. His initial "DynoSYS" product for dyno research evolved into a line of interchangeable sleeves called the Burns Tuneable Exhaust Collector, or BTEC for short.

The BTEC system has shown capability to alter the entire power curve of the engine. By changing only the insert, racers can change the entire tune on their engines to fine-tune for track conditions, weather, or driver preferences. Mostly used by drag racers, many in Pro Stock, the BTEC system offers enthusiasts a glimpse into the future of header design. While the drag racers have already embraced the benefits of BTEC, a number of road racers are beginning to experiment with the system as well.

X-PIPES

One area street machine enthusiasts are aware of is the evolution of the X-pipe. Early on, connecting the left and right halves of a true-dual exhaust system with an H-pipe resulted in measurable benefits. This theory evolved into the X-pipe, which allowed both left and right portions of the exhaust system to share some common flow area and resulted in even greater gains in power with a notable reduction in exhaust noise.

placing two x pipes in sequence seems to work well at both mellowing the exhaust note, and increasing the exhaust scavenging of the cylinders as it blends and smooths out the exhaust flow by allowing the individual cylinder pulse strength to dissipate rapidly, the first (x) reduces flow restriction, the second allows the exhaust pulse to run into itself further disrupting the individual pulse strength

http://www.bgsoflex.com/auto.html

http://www.engr.colostate.edu/~allan/fl ... /pipe.html

http://www.bgsoflex.com/bestheader.html

http://www.engr.colostate.edu/~allan/fl ... age7f.html

very short version on header design

exhaust gases have a known mass, temp range,expanded volume and velocity,

the engines cylinder volume, ignition timing, combustion burn times,

and fuel/air mixture are variables, everything is always a compromise in some area.

but the calcs are generally assumed all those to be close to optimal

at the generally accepted power band for a 383 sbc thats from about 4300 rpm to about 6300 rpm

remember piston speeds must remain under critical stress levels (think red-line)

the max negative pressure at the exhaust valve in that rpm range and its timing can be calculated.

read the links it should help

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/x-or-h-pipe.1503/

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/bestheader.html

https://www.musclecardiy.com/perfor...t-system-math-build-high-performance-engines/

https://www.centuryperformance.com/exhaust-header-tube-sizing-and-length.html

https://www.sandersonheaders.com/lets-get-technical.html

https://www.hotrod.com/articles/proper-exhaust-header-collector-volume-vs-engine-size/

https://www.centuryperformance.com/exhaust-header-tube-sizing-and-length.html

http://www.headerdesign.com/extras/engine.asp

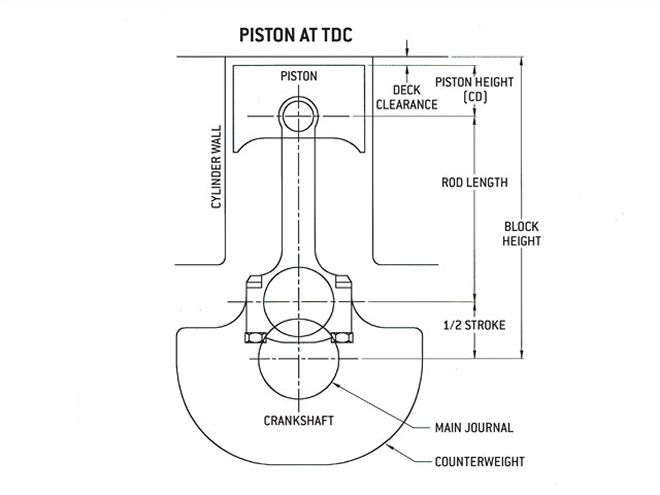

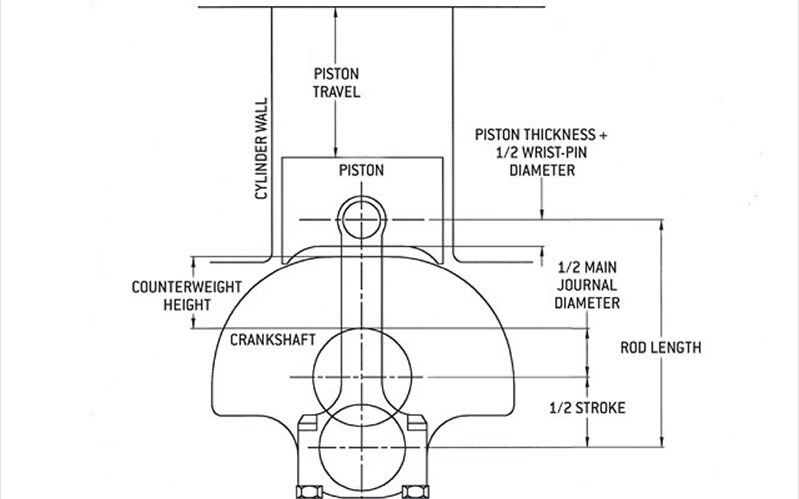

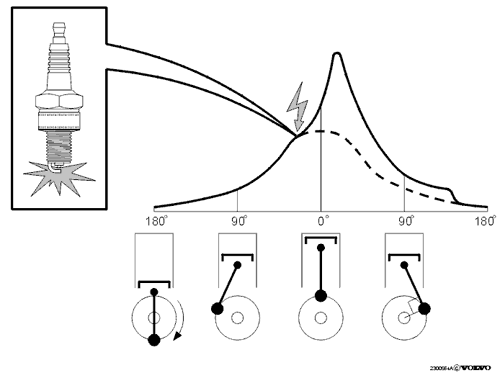

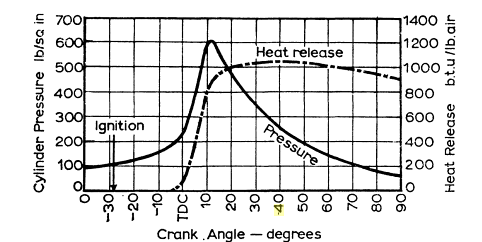

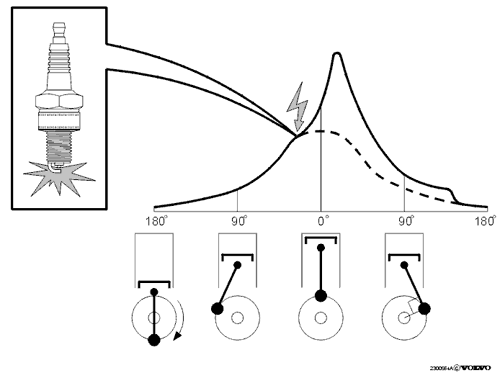

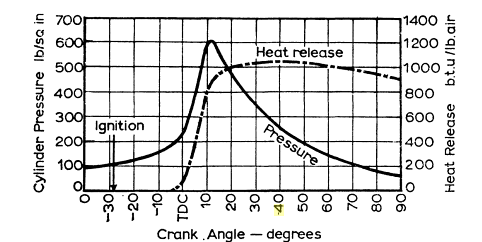

at lower engine rpms less ignition advance is needed because theres more time available, between ignition and cylinder pressure building , over the piston ,as the flame crosses the cylinder, so most of the pressure occurs after the cranks rod journal passes TDC, at lower rpms this burn & pressure build can take 50 thousands of a second, as rpms increase the time available is much shorter requiring a longer lead time or a greater "ADVANCE" but as rpms further increase ,turbulence caused by rapid compression increasingly speeds burn times

http://www.carcraft.com/techarticles/he ... index.html

http://victorylibrary.com/mopar/header-tech-c.htm

http://www.headerdesign.com/

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/bestheader.html

http://www.porcupinepress.com/_bending/segmentbends.htm

http://www.pontiacracing.net/js_header_length1.ht

http://www.hotrod.com/news/1402-new-products/

http://racingarticles.com/blog/2008/02/ ... aders.html

http://garage.grumpysperformance.co...oughts-on-a-welder-purchase.15648/#post-93766

http://garage.grumpysperformance.com/index.php?threads/tips-on-mig-welding.14225/

http://garage.grumpysperformance.com/index.php?threads/bits-of-tig-welding-info.295/

http://garage.grumpysperformance.com/index.php?threads/most-versital-shop-welder.1594/

http://garage.grumpysperformance.com/index.php?threads/shield-gas-selection-for-welding.1108/

http://garage.grumpysperformance.co...-t-do-stupid-stuff-get-decent-equipment.1669/

http://garage.grumpysperformance.co...azed-at-the-price-increases-on-welders.15497/

if your serious about maintaining good peak hp numbers use the calculators in the linked threads to actually calculate the ideal matched header dimensions, this is not a guessing game its strait physics and easily calculated to maximize exhaust scavenging and max volumetric efficiency, resulting in max power , at any given rpm and displacement, compression , cam timing etc this stuff can be calculated, but when dealing with an average and without knowing all the specifics you go by averages,and assume that peak hp takes a higher value than off idle torque

ok as a rule of thumb,when calculating and engines expected exhaust flow rates you can roughly assume 2.257 cfm per horsepower produced

http://www.wallaceracing.com/header_length.php

if you have a 500hp engine it will in theory produce 500 x 2.257=1128.5 cfm of exhaust flow

or 141 cfm exhaust flow per cylinder, but your exhaust valve is only open about 220-290 degrees and the time between power strokes gets shorter as the rpms increase.

Of the 720 degrees in a complete engine cycle, there is lets say 250 degrees , or 250/720=1/3rd of the time, but it doesn't all exit instantly so you can figure on about 1/2 the time the header primary's under significant pressure and pressure and pulse frequency varies with the rpms so the exhaust dump rates not at a constant flow or pressure, the header must handle 141 x 2=282cfm /115 =2.45 sq inches for exhaust flow per cubic inch , you look at the chart and find thats about a 1.7/8 diam. subtracting the pipe wall thickness

http://garage.grumpysperformance.co...-pipe-leading-into-a-x-pipe.15118/#post-86157

ICEngineworks Fabricating Products | Summit Racing

Find ICEngineworks header modeling kits at Summit Racing and then build your custom exhaust headers. We carry ICEngineworks kits in a variety of diameters.<br />

ICEngineworks 2000EHPRO ICEngineworks 2000 Series Pro Kits | Summit Racing

Free Shipping - ICEngineworks 2000 Series Pro Kits with qualifying orders of $109. Shop Header Weld-Up Pattern Tools at Summit Racing.

Determining the Correct Intake Port Volume for Your Engine - Super Chevy Magazine

Measuring for and finding the optimal intake port valume for your engine build will help you find max horsepower - Super Chevy Magazine

Calculate CA From RPM and Bore/Stroke Calculator

Calculate CA From RPM and Bore/Stroke - by Wallace Racing Home of Pontiac Powered Firebirds,Trans Ams,Pontiac Powered Dragsters,Pontiac Power Rules!

www.wallaceracing.com

Head Flow From CID and RPM Calculator

Calculate Head Flow From CID and RPM - by Wallace Racing Home of Pontiac Powered Firebirds,Trans Ams,Pontiac Powered Dragsters,Pontiac Power Rules!

www.wallaceracing.com

Estimate Intake Airflow needed from Horse Power wanted

Estimate Intake Airflow needed from Horse Power wanted

www.wallaceracing.com

Primary Header Tube Length and Diameter Calculator

Calculate Header Tube Length and Diameter - by Wallace Racing Home of Pontiac Powered Firebirds,Trans Ams,Pontiac Powered Dragsters,Pontiac Power Rules!

www.wallaceracing.com

calculating header design

YES THE SUB LINK INFO IS WELL WORTH READING ALSO if your serious about maintaining good peak hp numbers use the calculators in the linked threads to actually calculate the ideal matched header dimensions, this is not a guessing game its strait physics and easily calculated to maximize exhaust...

garage.grumpysperformance.com

if they have an open collector OR a low flow restriction exhaust behind them.

varying the primary tube length and diameter, and matching collector length and diameter can change, boost, torque, widen, that power band or restrict it,

and theres generally a specific power/rpm band where they provide a very noticeable boost in power or a "SWEET SPOT" ideally you design the headers to boost the torque and cylinder scavenging in an rpm range that does benefit you most of the time.

if in doubt, about the header component size and length etc.

always assume a marginally ,or a bit longer primary tube and marginally smaller diameter collector, to be a valid choice.

as this tends to slightly favor the mid rpm ranges,

of a bit shorter length exiting to a LARGER diameter exhaust.

(preferably with an X-pipe within as close a distance as possible and low flow restriction muffler's)

will work rather well.

keep in mind the scavenging efficiency changes with rpms, displacement and compression ratio as well as with the ignition timing

fuel air ratio , valve sizes, port flow rates and exhaust gas temps, so minor changes in length/diameter etc.

only marginally change where in the rpm range peak cylinder scavenging efficiency occurs,

minor changes won't be very noticeable, could you even begin to feel a peak scavenging efficiency or peak power,

if the difference was 30-60 rpm difference? as you run up through the gears, remember you might only be in a gear, for a couple seconds,

and during that couple seconds the engine might go from 5500rpm-6800rpm on an engine you built for performance use,

and while a street engine may be in a gear between shifts marginally longer ,

and may operate at only lets say 4500rpm-5900rpm that 30-60 rpm difference will be only seen on a precise dyno,

and that peak power last less than a fraction of a single second at best during a gear change.

so don,t sweat minor changes in collector or primary tube length.

watch video

keep firmly in mind that the header exhaust scavenging ,efficiency and intake runners ability to effectively fill the engines cylinders is very much dependent on carefully matched, cam timing, headers designed to match the engines displacement, intended rpm band, ,maximum compression ratio, for the fuel octane used,and a low restriction exhaust behind the header collectors, when all the factors are well matched correctly theres an easy 20% or higher power gain over most stock engines in this area alone.

correctly matched headers, compression, cam timing, displacement etc, can easily increase the cylinder fill efficiency, and intake runner air flow velocity by over 30%

adding an anti-reversion baffle to a 18"-24" longer collector on open headers with the internal pipe about 1/2 the collector length tends to help scavenging on some engines, no header will function to full efficiency with any significant back pressure so take the effort to accurately measure any restriction to exhaust flow AT your upper rpm range of your engines power band and be darn sure its not choking your power curve.

if you want max engine performance under predictable conditions,

it will take some testing, measuring and though,

could you give us some idea as too,

engine displacement"

bore and stroke ?

connecting rod length,

engines intended power band?

transmission shift points?

the cam timing, (lift ,duration)?

cylinder head flow rates,?

static compression ratio,?

ignition advance curve,?

intake valve diameter?

intake port cross sectional area?

intake runner length?

exhaust valve diameter?

, and header primary tube diameter?

and length?

fuel/air ratio every 1000 rpm?

exhaust back pressure in the collector every 1000 rpm?

intake plenum vacuum every 1000 rpm?

with that data we can stop random guess work,

and have at least some facts to work with,

to make a semi logical guess as to what changes might help.

guessing is fast and easy, getting a few facts and working out the details is a bit harder but more productive

http://www.wallaceracing.com/Calculators.htm

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...ful-exhaust-valve-size-and-header-info.11265/

http://garage.grumpysperformance.com/index.php?threads/dyno-testing-headers.3529/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.co...-guys-that-just-slap-on-factory-headers.3155/

reading these threads and sub links may help

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://garage.grumpysperformance.co...-between-shorty-and-full-length-headers.1303/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

low cost and ease of manufacture , and designing a single header too fit as many applications as possible to simplify inventory issues, has almost always been the manufacturers goal.

longer primary tub length has frequently proven to provide both more mid rpm torque and more average torque, and its the torque within 2000-rpm-3000 -rpm of the peak torque that moves the car during almost all the time in performance use.

longer tubes cost more money and make the header harder to design too fit well, so most manufactures rather design a shorter headers that may fit several similar cars rather than the ideal longer header for a single application.

4 into two, into one collector designs (LIKE BELOW)have also proven to be excellent performers,

but the generally work best if the cam timing and high compression are well matched

one of the rather well established racer tricks has always been to run open collectors too reduce back pressure, as

( headers scavenge best, with zero back pressure)

and in many cases, where clearances allowed, we cut the collectors of commercial headers , and welded on pre made extensions

(LIKE THESE BELOW)and almost always saw a boost in performance

https://www.summitracing.com/parts/FLO-C134218234/

one reason side exhaust on corvettes were and are used is the design allowed decent ground clearance AND long efficient header primary tube header designs.

http://www.wallaceracing.com/intake-runner-length.php

http://www.bgsoflex.com/intakeln.html

http://garage.grumpysperformance.com/index.php?threads/header-dimension-calculator.15013/

CALCULATORS TO PLAY WITH

http://www.wallaceracing.com/Calculators.htm

http://www.velocity-of-sound.com/velocity_of_sound/calculator3.htm

http://www.velocity-of-sound.com/velocity_of_sound/velocity_stacks.htm

http://www.swartzracingmanifolds.com/tech/index.htm

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

cylinder fill efficiency is a compromise, your engine design is forced to make selecting the way components are matched, the factors of cam timing compression and exhaust header tuning all must fall in the same 3000 rpm power band and ideally in the same 1500 rpm range to maximize power.

the choices between cam timing and compression ratio, and head and intake flow rates, valve size and valve lift and duration,

has a huge effect on,exhaust scavenging and while most people think the port flow rate is mostly the result of the piston dropping away from TDC,

lowering the cylinder pressure , thus drawing in the intake runner charge, this is not the major factor once the engine rpms increase significantly.

its exhaust scavenging during the valve over lap , being well matched to the engine displacement and cam timing, header diameter, and length, and collector design,

and intake ram tuning that can significantly boost cylinder fill and cylinder scavenging efficiency rates.

OK, first fact! the piston can,t compress anything being trapped in the cylinder by the piston compressing it as it raises,until both valves seat & seal

http://garage.grumpysperformance.com/index.php?threads/calculate-compression.9162/#post-32706

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

you will occasionally see dyno test results similar to this, that show about a 20 hp spread in the power curve, that seem to indicate that the difference in header configuration is not overly critical,but keep in mind these results are almost always done on 350-383 displacement engines with fairly mild compression , below 9.5:1 and fairly low duration cams ( example ,below 230 deg @.050 lift )and stock or mildly restricted exhaust systems, an engine with a fairly tight LSA and high compression and a low restriction or open exhaust can take full advantage of the headers scavenging the cylinders in a tuned rpm range significantly boosting the power produced, the tuned exhaust header has a greater effect on a higher compression ratio engine of larger displacement with a tighter LSA cam

you might want to read these also

http://victorylibrary.com/mopar/header-tech-c.htm

PRIMARY PIPE DIAMETER FACTORS

The primary header pipe diameter is determined using basic engine mechanical specifications, such as: Bore Stroke Compression Ratio Valve diameter Cam specifications (lift and duration) Target rpm range

http://www.pontiacracing.net/js_header_length1.htm

http://victorylibrary.com/mopar/header-tech-c.htm

http://maxracesoftware.com/pipemax36xp2.htm

http://www.wallaceracing.com/header_length.php

http://www.boyleworks.com/ta400/psp/exhaust3.html

http://www.autolounge.net/calculators/e ... izing.html

http://www.bgsoflex.com/auto.html

http://www.custom-car.us/exhaust/header.aspx

http://www.mk5cortinaestate.co.uk/calculator5.php

http://www.custom-car.us/exhaust/default.aspx

http://www.superchevy.com/technical/eng ... index.html

http://www.superchevy.com/technical/eng ... index.html

https://www.hotrod.com/articles/proper-exhaust-header-collector-volume-vs-engine-size/

http://www.carcraft.com/techarticles/03 ... index.html

http://autolounge.net/calculators/exhau ... izing.html

most exhaust pipe is 16 gauge, or .065 wall thickness

http://www.engineersedge.com/gauge.htm

How do you judge the i.d of a pipe?

3" o.d = 2.87" diam. inside

2.75 o.d = 2.62"diam. inside

2.5 o.d = 2.37" diam. inside

2.25 o.d = 2.12" diam. inside

theres THREE distinct areas of pressure/velocity

(1)

gases in the cylinders and header primary tubes as the exhaust exits the cylinders

(2)

gases in the header primary tubes and header primary tubes as the exhaust exits the header COLLECTORS

(3) the exhaust system past the collectors

(1) and (2) must be calculated to match the intended displacement ,cam timing and intended rpm range

(3) (traditional back pressure ) should be MINIMIZED

keep in mind installing an (X) almost increases the effective cross sectional area, of the dual exhaust ,or collector cross sectional area to double what it had been behind a single header collector, by doubling the area that the exhaust flow sees, dropping the restriction to flow almost in half

looking thru an (X) pipe

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/auto.html

PRIMARY PIPE LENGTH

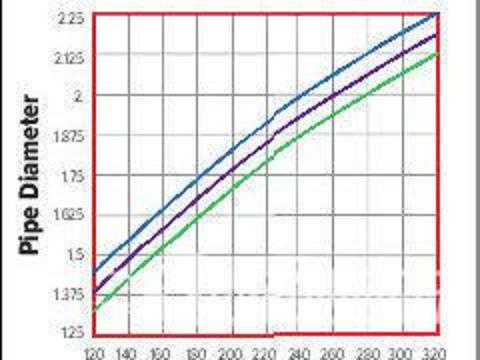

"The overall length of the primary header pipe is governed almost exclusively by the target engine's rpm range, and displacement which is dependent upon wave tuning. Typically, a lower engine rpm range likes a longer primary pipe, while a high rpm engine prefers a shorter primary."

SECONDARY PIPE DIAMETER (collector length in a 4 into one design)

While typical off-the-shelf street 4-into-1 headers do not have true secondary pipes, Burns' research has proven repeatedly that his Tri-Y designs make more overall power over a broader rpm range. While traditional lines of thought have street enthusiasts knowing Tri-Y pipes make more bottom-end torque, further research by Burns into the design have resulted in headers making more power all across the rpm range. With more components as part of the Tri-Y design, more tuning possibilities exist, and therefore more potential lives within.

"The secondary pipe diameter is determined by considering both pressure waves and reflective waves throughout the system. Since the pipes are paired according to the firing order, these waves can work together or against each other. Naturally, our designs work with the waves to increase the efficiency of the header, using the wave pulses to help pull gases from the engine.

"There are two basic kinds of waves we're dealing with. First, there are pressure waves. The pressure wave travels the length of the primary pipe in a 4-into-1 header, then is reflected from the collector where the area changes from the small-diameter primary into the larger-area collector. A reflection of negative pressure goes back up the primary pipe.

"In a Tri-Y design, the pressure of additional area changes (where the primary pipes become secondary pipes) produces additional reflections, so the Tri-Y must be designed in a different manner with respect to wave control. Given this, the area of the Tri-Y header between the first and second collectors becomes critical, and tuneable. The entire header is affected by this crucial length of pipe, and can be fine-tuned accordingly through proper sizing for optimal broad-range performance.

"The 4-into-1 pipe is also affected by altering pipe lengths, of course. But, without these secondary pipes it is impossible to tune with the same level of precision as with the Tri-Y headers. It's for this reason we prefer the Tri-Y design in most applications. The tuneability is so much more accurate, we're able to find more power over a broader rpm range. This is especially critical in engines expected to work well over a wide rpm range, like street machines."

Another huge reason for the move to Tri-Y headers is weight savings. Burn's claims most of their Tri-Y headers weigh in at about _ the weight of comparable 4-into-1 pipes for the same application, due to the smaller pipe diameters used throughout similar applications. Also, with less internal volume than comparable 4-into-1 headers, the Tri-Y equipped engine is typically more responsive. Tri-Y designs require physically smaller collectors as well, contributing further to space and fit concerns, and adding further to crisp engine responsiveness.

COLLECTORS

"There is much power to be found in researching collector design and size. The optimal collector is determined by several variables, and it's engineering interacts with the entire exhaust system. The internal volume, the outlet size diameter, and the angles at which the pipes come together within the collector are all factors that must be maximized for the header to perform to its full potential."

1 - Primary Pipe Entry Size

"Our computer model design program determines many of these hard dimensions based on data gathered over many years, including the length and diameter of the primary or secondary pipe entering the collector."

2- PRIMARY PIPE ENTRY ANGLE

"The pipe entry angle is typically between 10-20 degrees, with most pipes being right at 15 degrees. The cone (or goilet) formed between the pipes as they transition from primary to collector is formed as a consequence of these angles, nothing more. The mass of gases moving through the pipe does not want to change direction, so keeping these "pyramid" cones true to the pipe entry angle helps smooth the transition from the relatively small volume of the feed pipe to the larger volume of the collector."

3 - COLLECTOR OUTLET DIAMETER

"The collector outlet diameter is the most critical dimension in the header. It's what makes the merged collector work the way it does. Each collector we sell is custom-sized to each customer's engine, and there's no real 'formula' to get a broad-based general determination for street machines. As a rule, the overwhelming majority of aftermarket headers designed for the street market have way too big of a collector outlet diameter. Most street guys are losing power because of badly designed, manufactured, or engineered street headers. There is much room for improvement here."

4 - OVERALL COLLECTOR LENGTH

"Overall collector length is not critical. Once the other variables in the header design have been determined, the collector ends up being as long as it needs to be. We've found no benefit in lengthening or minimizing this dimension. It's more important to properly engineer what's going on inside the merged collector, and let the length determine itself once all the other important factors are optimized."

AFT OF THE COLLECTOR

One of the growing areas of research at Burns is the critical area just aft of the all-important collector outlet. Burns' dyno research led him to begin experimenting with interchangeable venturis, which slip into receivers just aft of the collector. While these prototype dyno parts were initially crafted to assist Jack in determining the critical overall collector diameter size, he soon realized they could be a marketable product. His initial "DynoSYS" product for dyno research evolved into a line of interchangeable sleeves called the Burns Tuneable Exhaust Collector, or BTEC for short.

The BTEC system has shown capability to alter the entire power curve of the engine. By changing only the insert, racers can change the entire tune on their engines to fine-tune for track conditions, weather, or driver preferences. Mostly used by drag racers, many in Pro Stock, the BTEC system offers enthusiasts a glimpse into the future of header design. While the drag racers have already embraced the benefits of BTEC, a number of road racers are beginning to experiment with the system as well.

X-PIPES

One area street machine enthusiasts are aware of is the evolution of the X-pipe. Early on, connecting the left and right halves of a true-dual exhaust system with an H-pipe resulted in measurable benefits. This theory evolved into the X-pipe, which allowed both left and right portions of the exhaust system to share some common flow area and resulted in even greater gains in power with a notable reduction in exhaust noise.

placing two x pipes in sequence seems to work well at both mellowing the exhaust note, and increasing the exhaust scavenging of the cylinders as it blends and smooths out the exhaust flow by allowing the individual cylinder pulse strength to dissipate rapidly, the first (x) reduces flow restriction, the second allows the exhaust pulse to run into itself further disrupting the individual pulse strength

http://www.bgsoflex.com/auto.html

http://www.engr.colostate.edu/~allan/fl ... /pipe.html

http://www.bgsoflex.com/bestheader.html

http://www.engr.colostate.edu/~allan/fl ... age7f.html

very short version on header design

exhaust gases have a known mass, temp range,expanded volume and velocity,

the engines cylinder volume, ignition timing, combustion burn times,

and fuel/air mixture are variables, everything is always a compromise in some area.

but the calcs are generally assumed all those to be close to optimal

at the generally accepted power band for a 383 sbc thats from about 4300 rpm to about 6300 rpm

remember piston speeds must remain under critical stress levels (think red-line)

the max negative pressure at the exhaust valve in that rpm range and its timing can be calculated.

read the links it should help

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/x-or-h-pipe.1503/

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/bestheader.html

https://www.musclecardiy.com/perfor...t-system-math-build-high-performance-engines/

https://www.centuryperformance.com/exhaust-header-tube-sizing-and-length.html

https://www.sandersonheaders.com/lets-get-technical.html

https://www.hotrod.com/articles/proper-exhaust-header-collector-volume-vs-engine-size/

https://www.centuryperformance.com/exhaust-header-tube-sizing-and-length.html

http://www.headerdesign.com/extras/engine.asp

at lower engine rpms less ignition advance is needed because theres more time available, between ignition and cylinder pressure building , over the piston ,as the flame crosses the cylinder, so most of the pressure occurs after the cranks rod journal passes TDC, at lower rpms this burn & pressure build can take 50 thousands of a second, as rpms increase the time available is much shorter requiring a longer lead time or a greater "ADVANCE" but as rpms further increase ,turbulence caused by rapid compression increasingly speeds burn times

http://www.carcraft.com/techarticles/he ... index.html

http://victorylibrary.com/mopar/header-tech-c.htm

http://www.headerdesign.com/

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/bestheader.html

http://www.porcupinepress.com/_bending/segmentbends.htm

http://www.pontiacracing.net/js_header_length1.ht

http://www.hotrod.com/news/1402-new-products/

http://racingarticles.com/blog/2008/02/ ... aders.html

Id really appreciate your input on this question gentlemen

Id like to replace the TIG welder I was forced to sell in my move from FLA to TX. last year, I want to purchase a AC/DC pulse TIG with a 200-250 AMP rating, I kept the fluid torch, fluid pump and foot petal , and shield gas gauge set, assembly from the old miller TIG, so I may not need those...

garage.grumpysperformance.com

http://garage.grumpysperformance.co...oughts-on-a-welder-purchase.15648/#post-93766

http://garage.grumpysperformance.com/index.php?threads/tips-on-mig-welding.14225/

http://garage.grumpysperformance.com/index.php?threads/bits-of-tig-welding-info.295/

http://garage.grumpysperformance.com/index.php?threads/most-versital-shop-welder.1594/

http://garage.grumpysperformance.com/index.php?threads/shield-gas-selection-for-welding.1108/

http://garage.grumpysperformance.co...-t-do-stupid-stuff-get-decent-equipment.1669/

http://garage.grumpysperformance.co...azed-at-the-price-increases-on-welders.15497/

Last edited by a moderator: