read thru these FOUR threads and links BELOW SEVERAL TIMES

http://www.jegs.com/InstallationInstruc ... 119661.pdf

read THESE links

http://garage.grumpysperformance.com/index.php?threads/timing-chains-stretch.5734/#post-17492

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-67562

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.co...nter-1-for-timing-ignition-cam.966/#post-1682

http://garage.grumpysperformance.co...e-train-clearances-and-problems.528/#post-668

http://garage.grumpysperformance.co...king-piston-to-valve-clearances.399/#post-488

http://www.competitionproducts.com/Camshaft-Degreeing-and-Cam-Measuring-Tools/products/1387/

OK lets go thru the basics ,

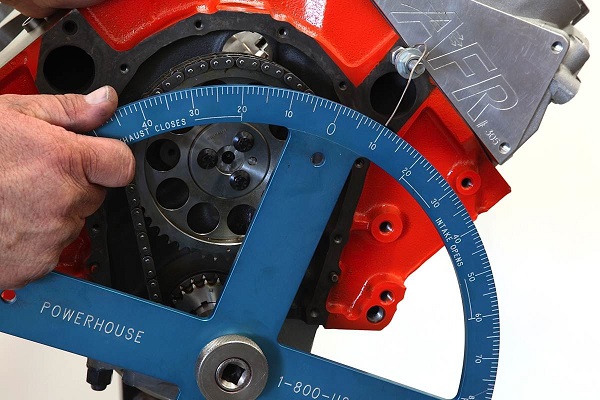

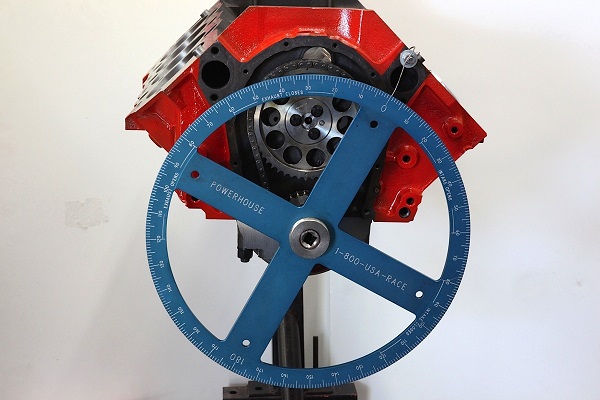

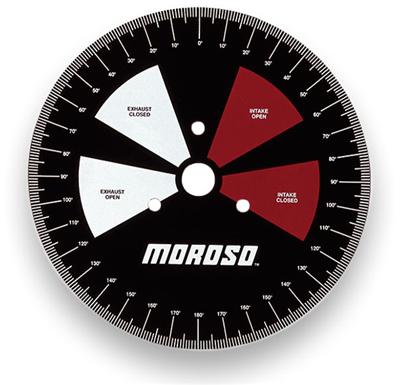

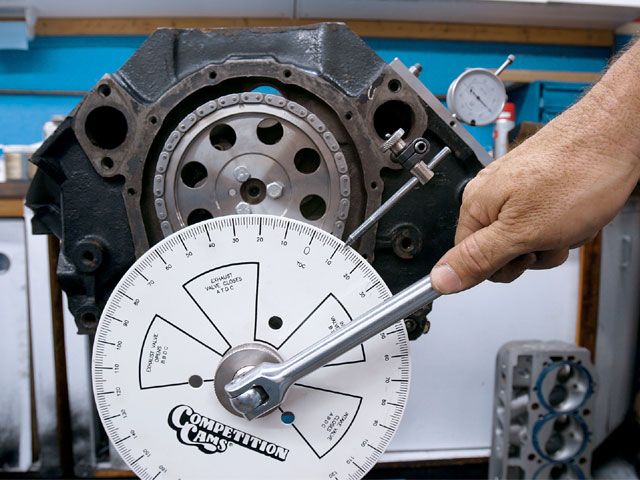

you need an accurate degree wheel,

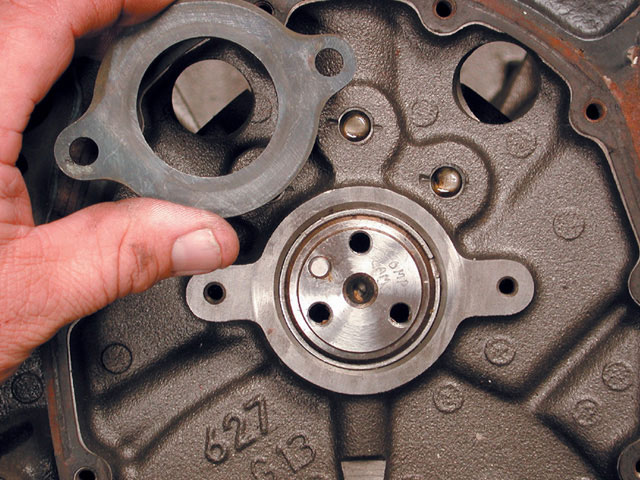

this adapter comes in really handy to mount the degree wheel and spin the crank,

http://www.summitracing.com/parts/cca-4793

a long bendable stiff wire, like tig welding rod or a heavy gauge coat hanger, to use as a pointer for the degree wheel.

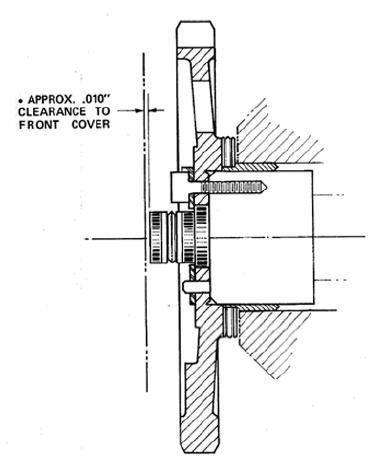

and a piston stop to locate TDC,

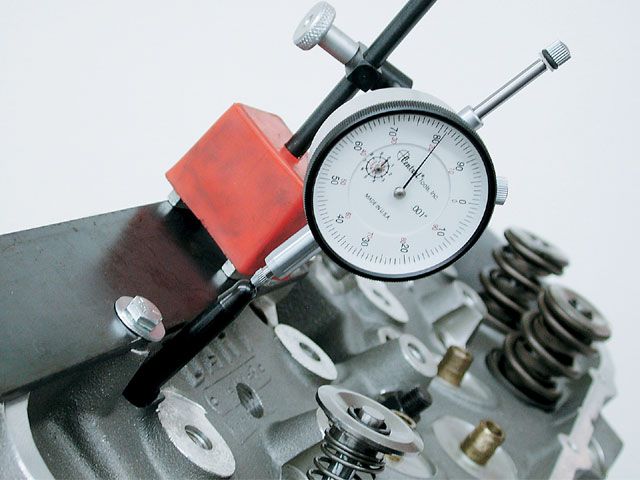

a couple lifters, you can epoxy together to use for the dial indicator to read off or ideally this tool

http://store.summitracing.com/partdetai ... toview=sku

naturally the dial indicator and a decent magnetic stand will help

youll need a easy way to turn the crank, and the instructions on how to do the process correctly

I generally prefer to start with cams installed STRAIT UP, SPLIT OVERLAP

http://store.summitracing.com/partdetai ... toview=sku

summitracing sells these kits for about $86

https://www.summitracing.com/parts/pow-pow101600

if you plan on graphing the lift vs cam lobe rotation per degree of rotation, you can safely ignore, totally the lifter seat being held up on a running engine, when your using a lifter and push rod too move, and verify a dial indicator reading, (keep in mind the cam rotates at 1/2 the crank rotation speed.)

when checking the cam lobe lift and duration.as the cam rotates it compresses the lifter seat as the lobe acceleration ramp, or start of the lifter movement upwards in its lifter bore occurs.

this is how the oil is forced up the push rod to cool the rocker and valve springs and at low rotational rpm's the push-rod lifter seat bottoms out in the lifter well before max lift on the push-rod even gets close,

thus theres a minor delay in the lifter movement as the engine oil is forced up the push rod as the cam lobe rotates under the lifter base but this has very little effect on duration and almost zero on total lift.

these threads and the sub linked info should help

viewtopic.php?f=52&t=90

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=974&p=1699&hilit=+degree+wheel#p1699

http://www.summitracing.com/parts/sum-g1056

youll need one bushing kit to make corrections

http://www.summitracing.com/parts/cca-4760

YOULL WANT THESE TOOLS LISTED BELOW ALSO[/color]

Ive used mine only a few dozen times but its well worth the money (I previously used two solid lifters I epoxied together on hydraulic or solid lifter flat tappet cams OR a pair of solid roller lifters Id brazed dimes into to measure from on roller cams)

the first time you degree in a cam, you wonder how difficult this COMPLEX PROCEDURE will be, but after doing it MANY DOZENS of TIMES it amazes you that you worried about it the first few times.

http://www.summitracing.com/parts/cca-4925

http://store.summitracing.com/partdetai ... toview=sku

http://www.summitracing.com/parts/sum-900134

http://store.summitracing.com/partdetai ... =PRO-66830

http://store.summitracing.com/partdetai ... =MOR-61755

http://www.summitracing.com/parts/MOR-61755/

http://www.summitracing.com/parts/MOR-62191/

THE LONGER I USE THE MOROSO DEGREE WHEEL AND BBC CRANK SOCKET THE MORE IVE COME TO APPRECIATE THEM,, BTW the COMP CAMS SBC VERSION IS BELOW

http://www.summitracing.com/parts/CCA-4 ... refilter=1

http://store.summitracing.com/partdetai ... toview=sku