before, you start reading through the thread and links below,

Ill point out that I've done the forensics on quite a few failed cams over the years,

that guys have brought to my shop and Id say about

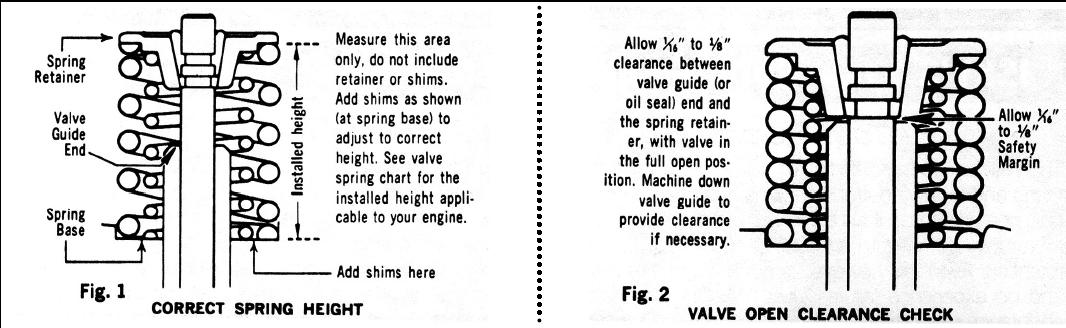

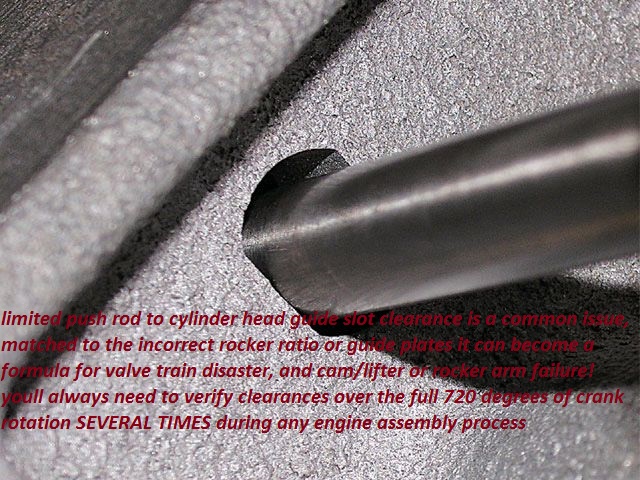

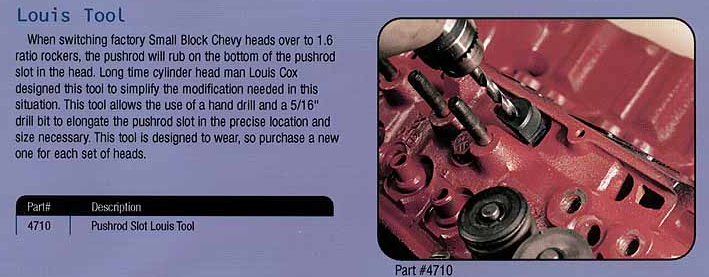

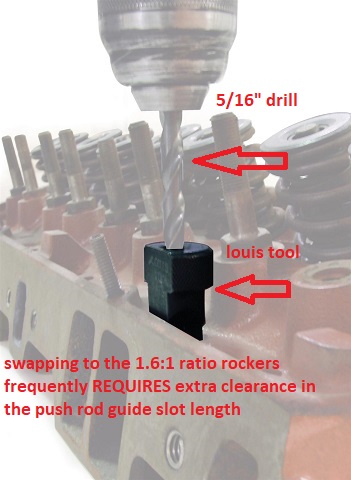

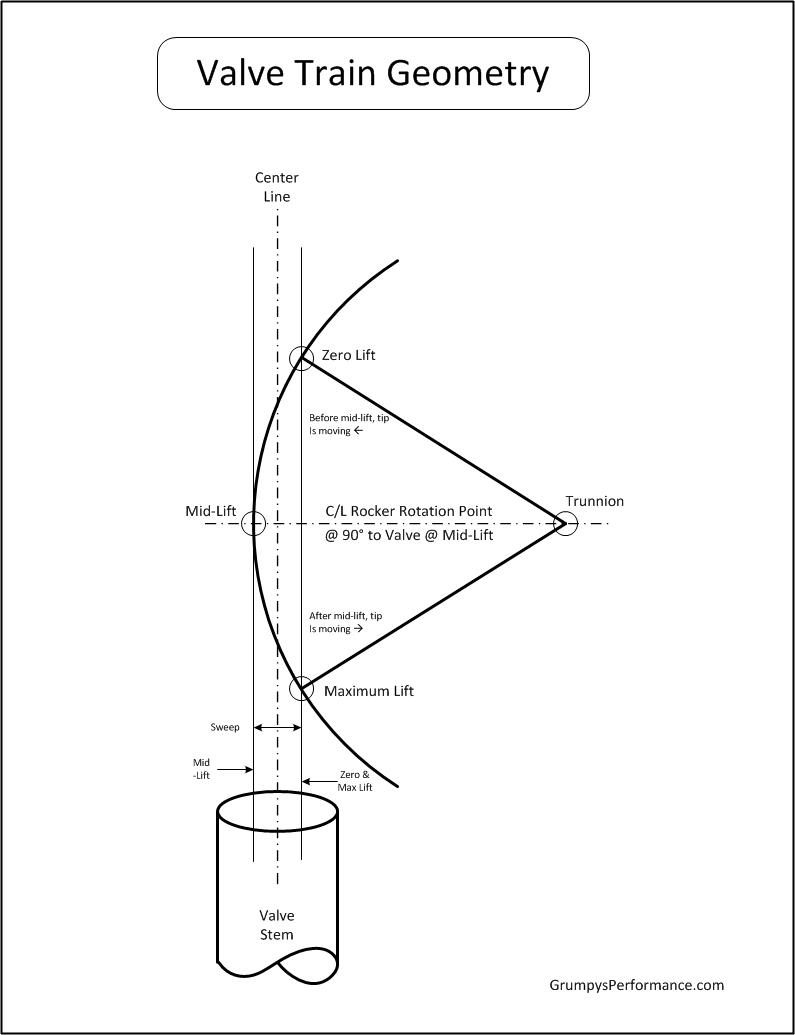

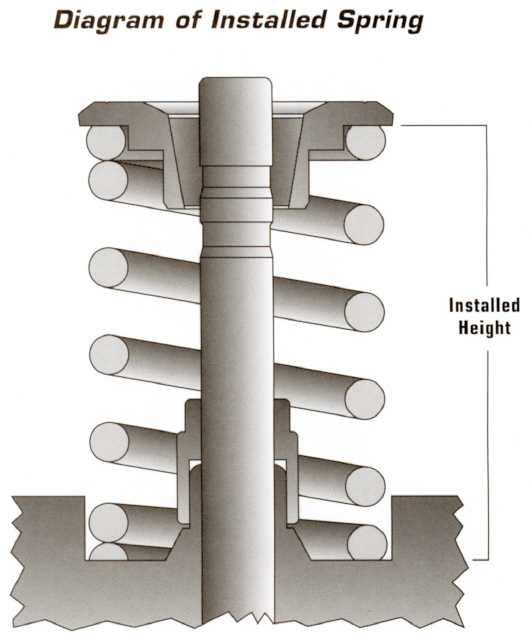

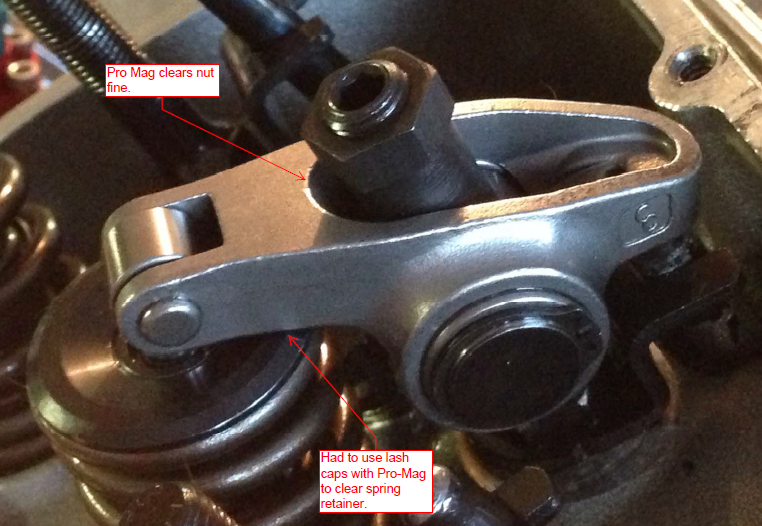

60% of the failed cam lobe & lifter problems were traced to a failure to check clearances or correct valve train geometry issues , like coil bind, rocker to rocker stud, or rocker to adjustment nut clearance, retainer to valve seal, clearances or rocker geometry, use of the wrong spring load rates for the application ,or failure to check valve train or push rods binding issues like rocker to retainer, push rods binding on guide plates or heads, etc. before they became an issue.

about

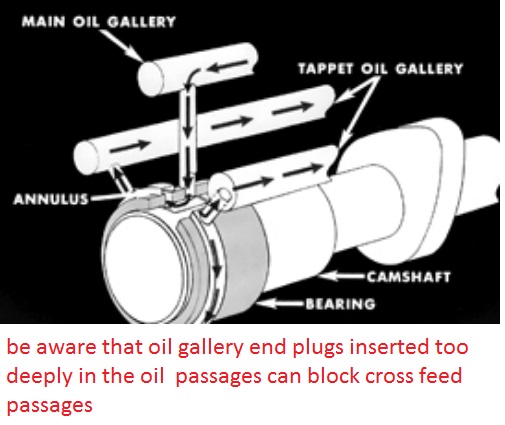

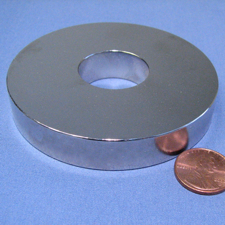

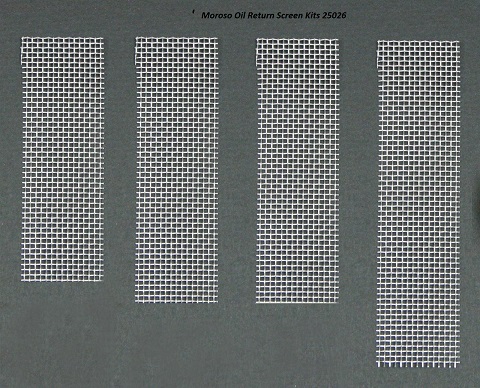

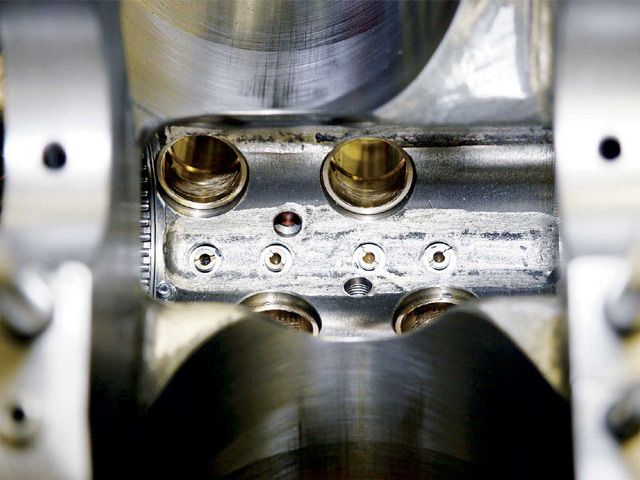

10% were traced to failure to remove metallic or other trash, generated by a previous cam failing from the engines internal oil passages, or failure to carefully clean the engine before installing the new cam, and components, ( use of shrapnel screens and magnets help a great deal in this but can,t remove all trash as some is non-magnetic)

5% to low quality components, or miss matched parts, like the wrong spring load rates for the application, and perhaps

15% of the failures due to using the wrong lubricants , or not nearly enough moly cam lube on the lobes and lifter bases or setting up the oil supply system correctly, or use of a high quality oil and filter, and a failure to change that oil and filter regularly after the first few hundred miles , the remaining

10% were from unknown causes but more than likely due to a failure to correctly break in the cam, or properly adjust the valves before the engine break-in process or carefully check and re-adjust the lifters rapidly during the break-in process

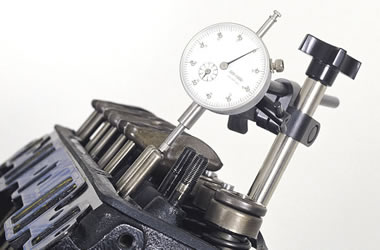

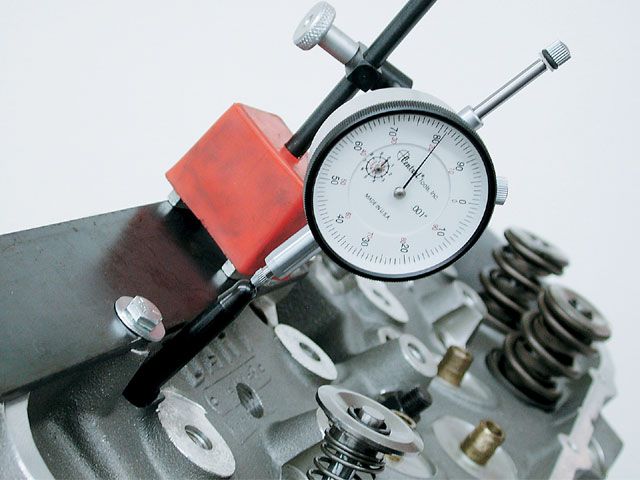

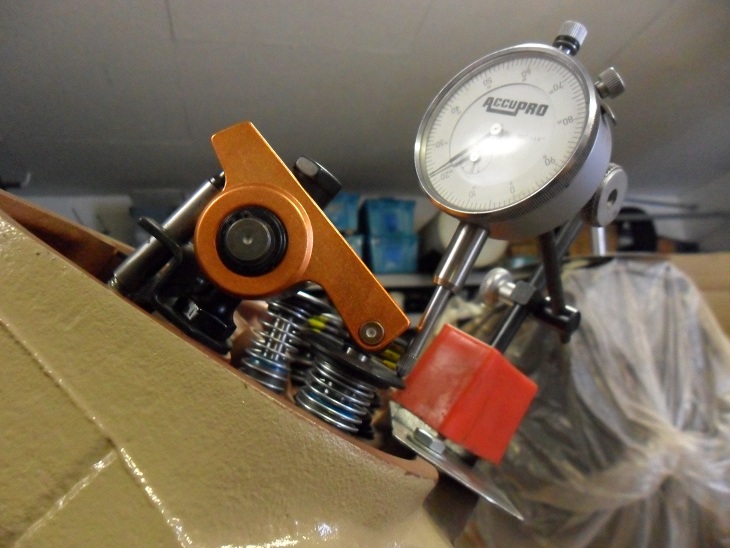

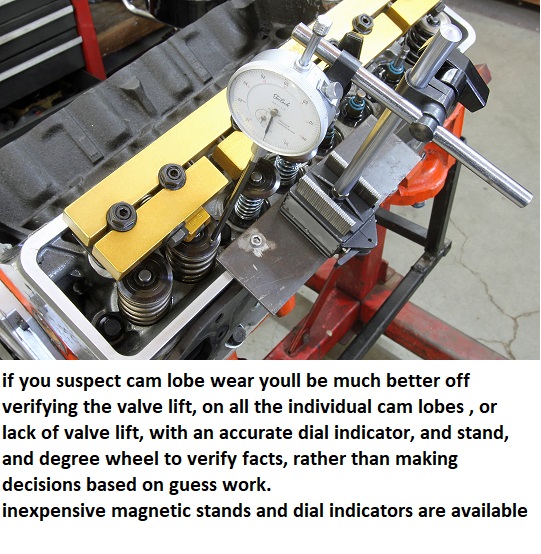

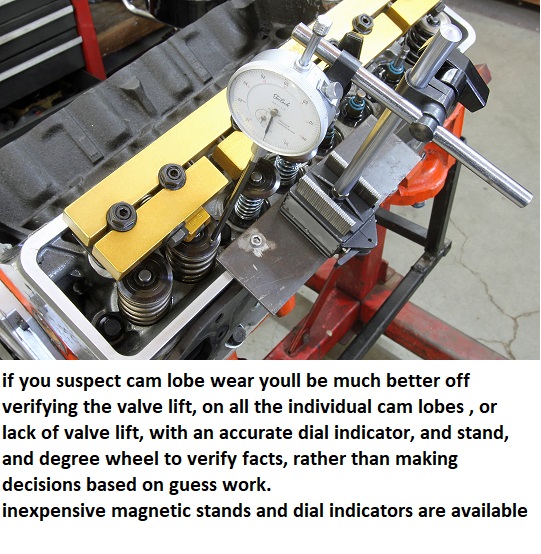

If you suspect a worn cam lobe, checking the cams lobe lift with a dial indicator on the valve spring retainer vs the other lobes would certainly provide useful related info.

knowing vs guessing helps in making decisions wisely

http://www.summitracing.com/parts/pro-66830/overview/

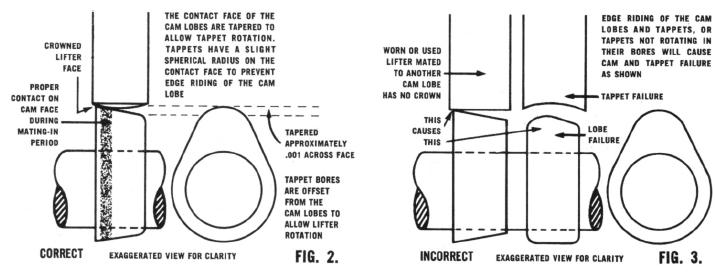

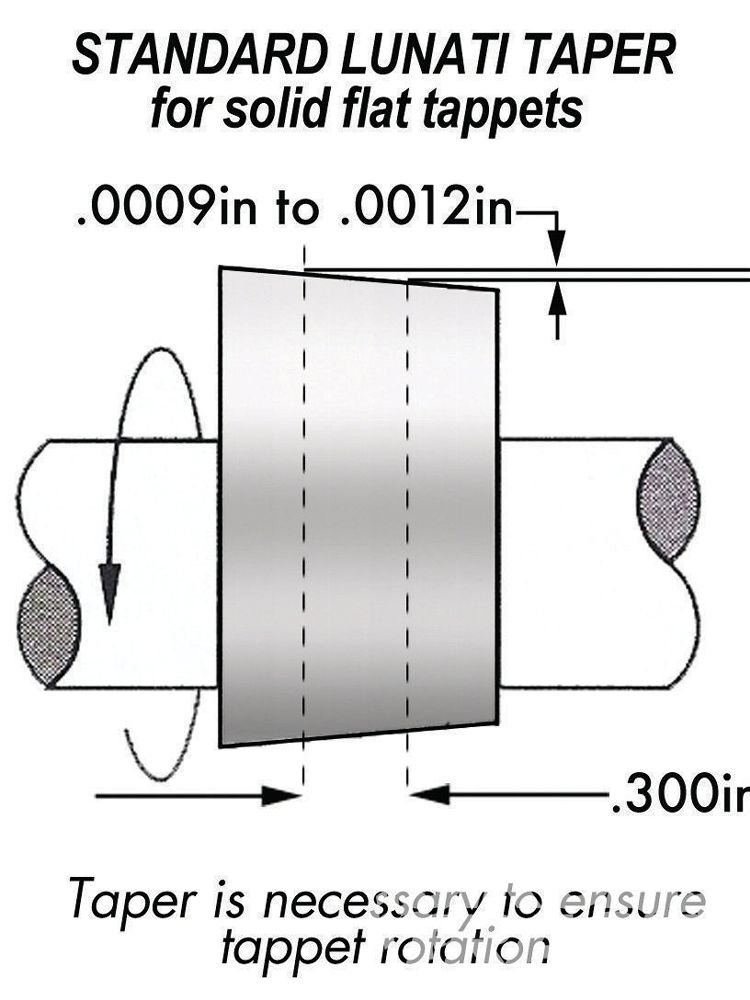

It is when they stop spinning that the camshaft and lifters fail and become a lathe.

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=indicator+stand

read this thread also

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

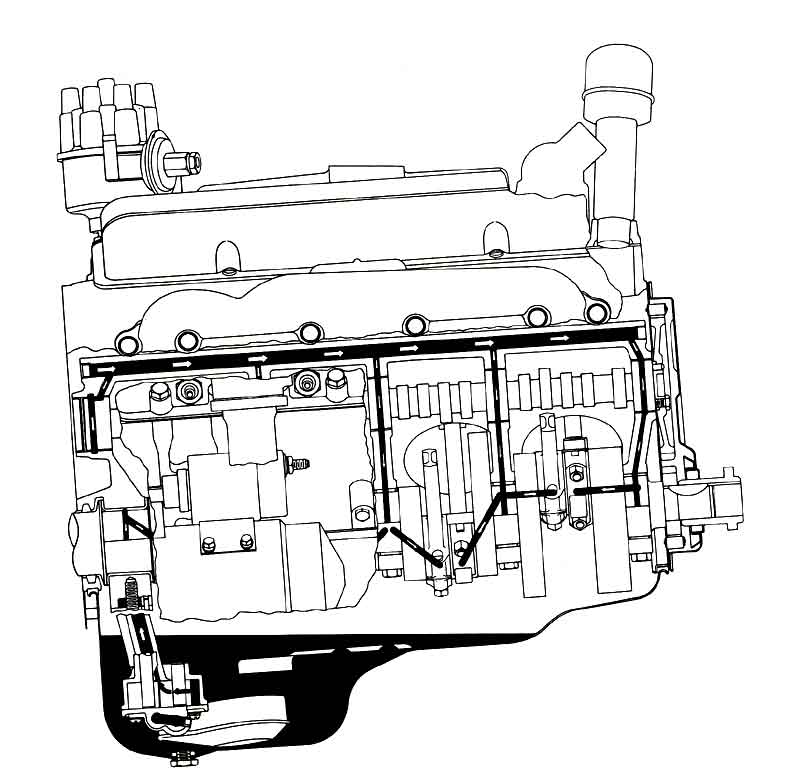

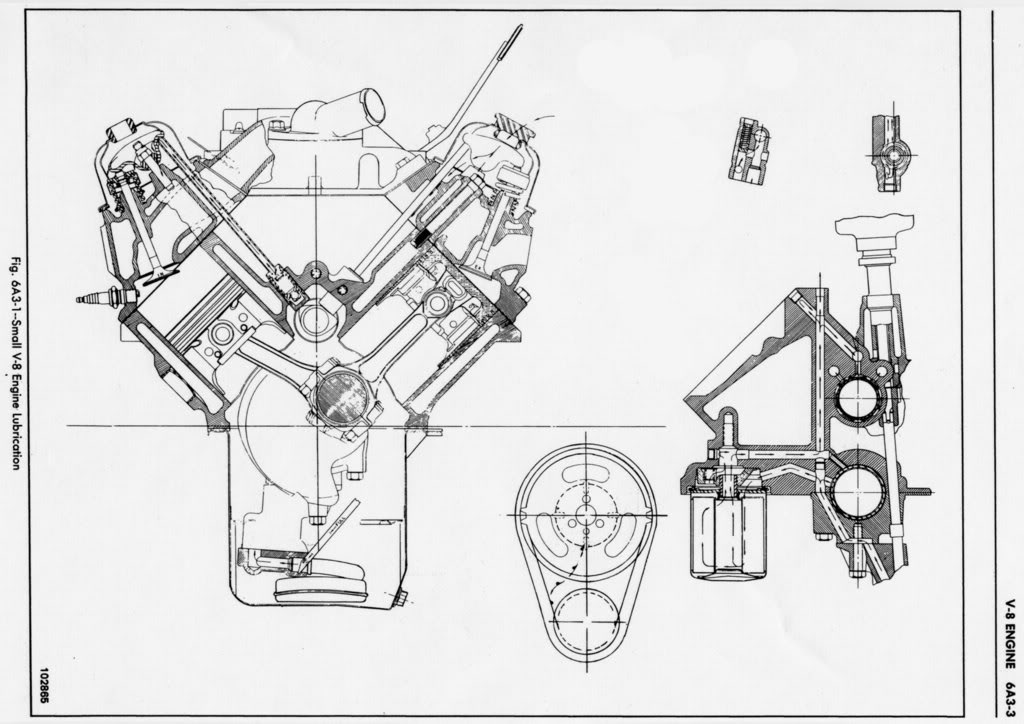

the rotating assembly bearings ,wrist pins and complete valve train,valve springs, lifters, valves and valve guides and the pistons and rings are where a great deal of the engine heat is generated, and those components are initially cooled with oil flow that absorbs and transfers the heat collected , and transported from those components to the block and coolant, so having a constant flow of pressurized oil flow over those parts are mandatory for maximum durability.thus adding a larger capacity baffled oil pan and an oil cooler will generally enhance and extend an engines life span. Its a good idea TOO ALWAYS ask detailed questions as to the best , and most durable parts combination they have available, for your intended application, from your cam suppliers tech department

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...ck-chevy-gen-v-vi-to-adjustable-rockers.4564/

links worth reading thru

BEFORE TRYING TO BREAK IN YOUR CAM!

http://www.cranecams.com/pdf-tech-tips/cam_failure811.pdf

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://www.drivenracingoil.com/news/dro/training-center/articles/zinc-in-motor-oil/

http://johncalliesinc.com/morel_products.php

http://www.hotrod.com/how-to/engine/ctr ... ubricants/

btw the best deal I found lately on basic hydraulic flat tappet lifters

http://www.summitracing.com/parts/sum-ht817/overview/

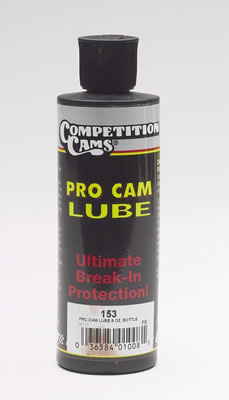

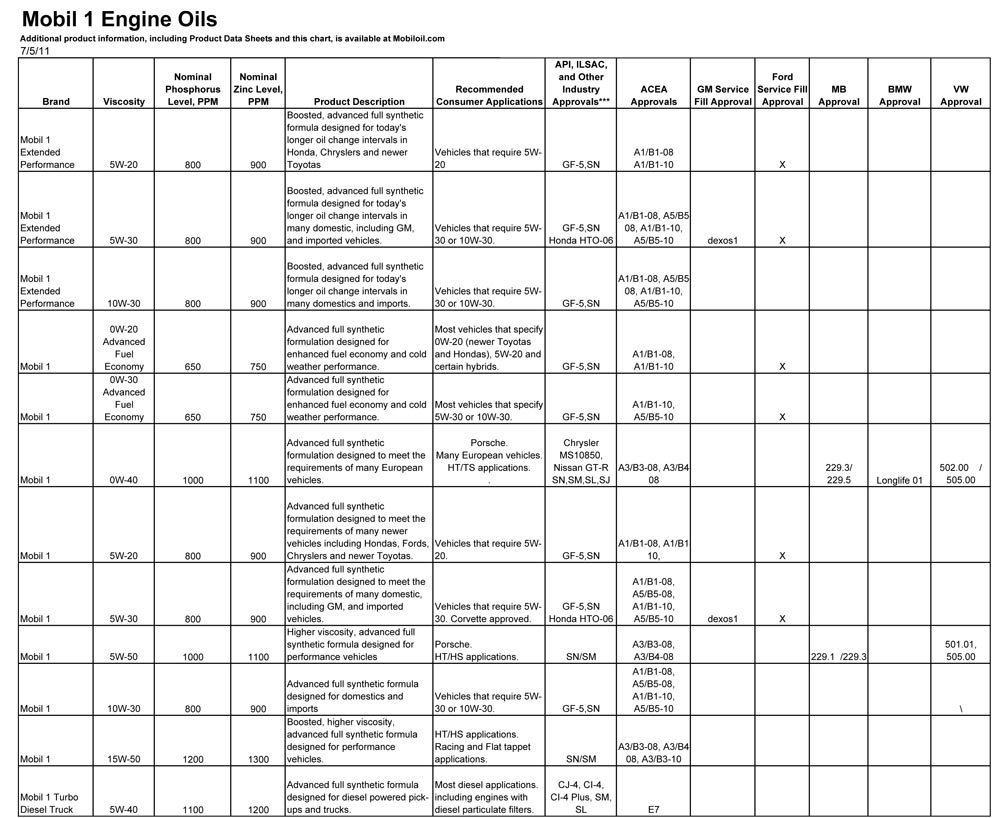

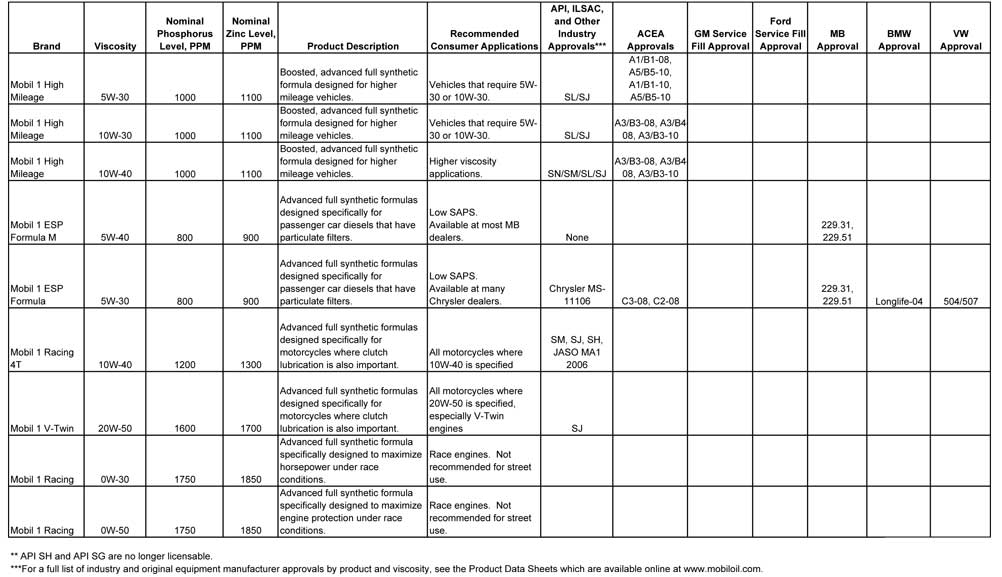

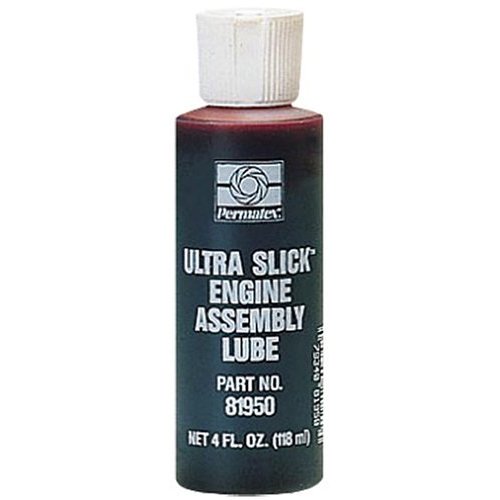

HERES A FEW OF THE OILS I TRUST, coat flat tappet lifters and cam lobes with crane moly assembly paste lube

I usually use 6-7 quarts of oil and 1 quart of marvel mystery oil added in my oil pan 11 quart oil pan and oil cooler system capacity

10W30 Valvoline VR1 Conventional Racing Oil

10W30 Valvoline NSL

10w30 Castrol GTX conventional,

10w30 mobile 1

10w30 KENDAL racing oil

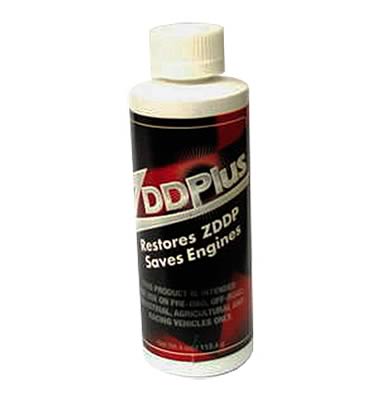

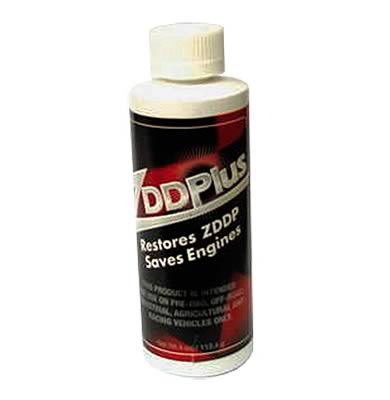

and heres a good break in additive for flat tappet lifter cams

http://www.summitracing.com/parts/CRO-86092

http://www.acdelco.com/auto-parts/v...engine-oil-supplement-assembly-lubricant.html

READ THRU THESE LINKS

http://garage.grumpysperformance.co...il-properties-related-to-zddp-detergent.4793/

http://garage.grumpysperformance.co...h-the-oil-when-a-cam-failed.11542/#post-53323

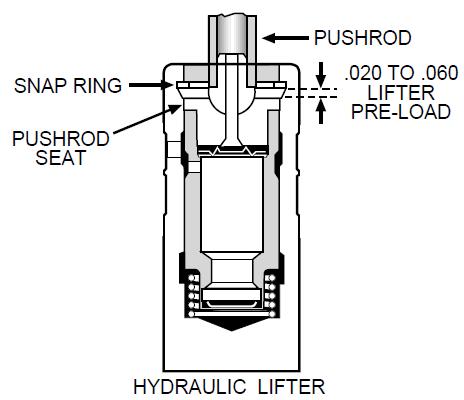

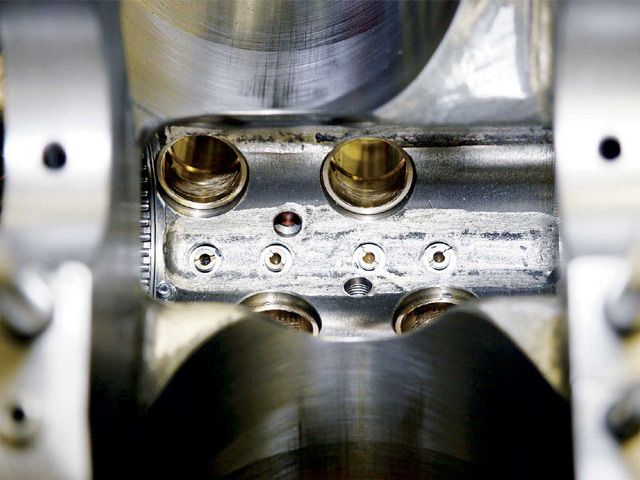

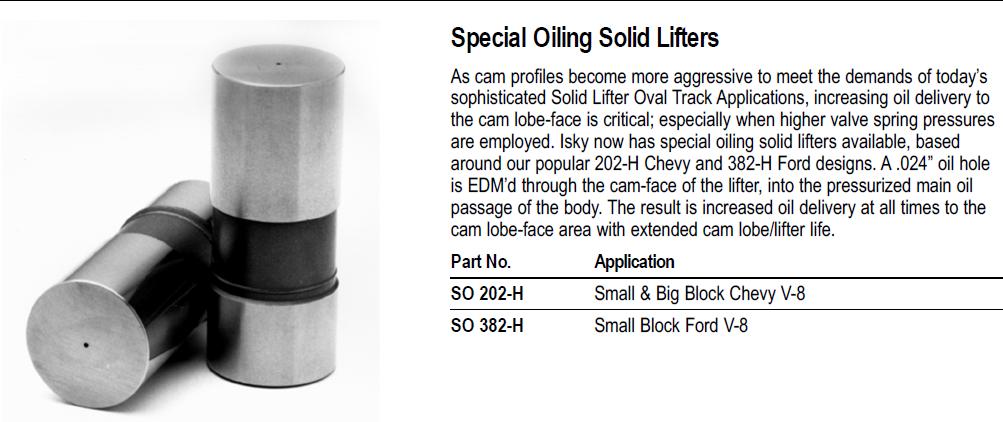

the better quality hydraulic and solid flat tappet lifters have hardened bases

it only takes a few seconds running a new engine for an improperly installed cam , lifters and valve train, during the break-in process to generate teaspoons of metallic trash that ,once in the engine oil flow ,rapidly destroys bearings if the clearances ,spring load rates or valve train geometry is wrong

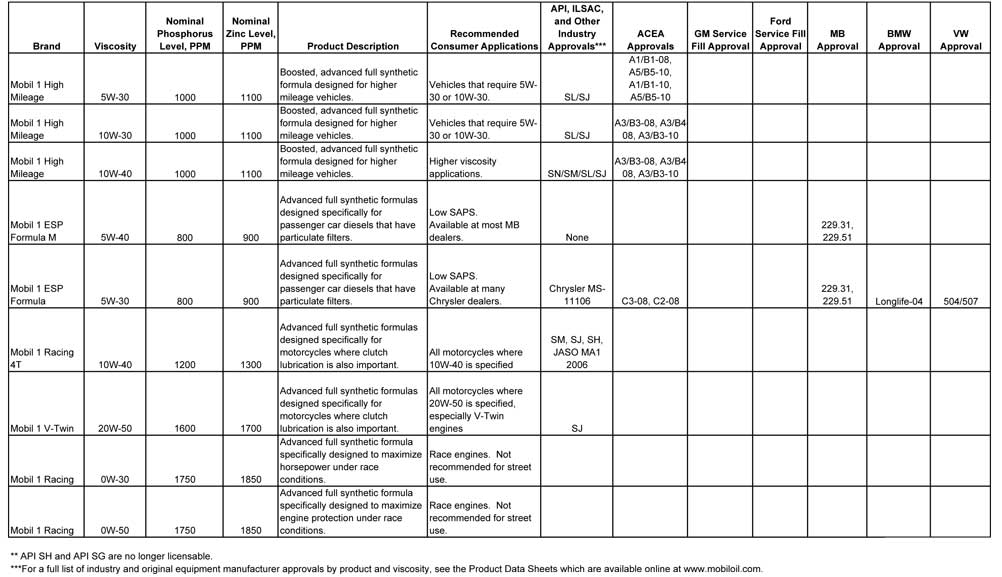

If your not getting oil flow, at the rockers,youll still need to verify the oil feed holes line up and are not blocked and the rockers adjusted correctly, try backing off on the adjustment nut as the engine idles to the point the rocker clicks noticeably then slowly tighten just to the point the noise stops , then add only a 1/4 turn, and see if that doesn,t cure the oil feed issue

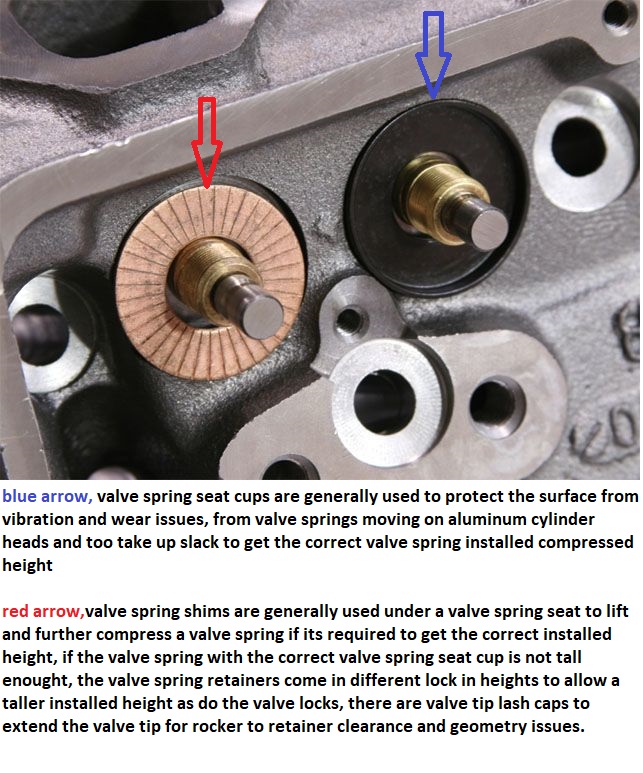

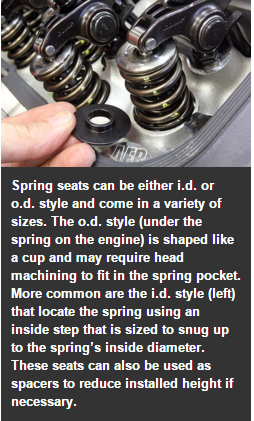

Id also point out that youll want to lubricate any valve you install in a valve guide and verify the valve train clearances very carefully, and use the correct valve springs and add the correct valve seals installed

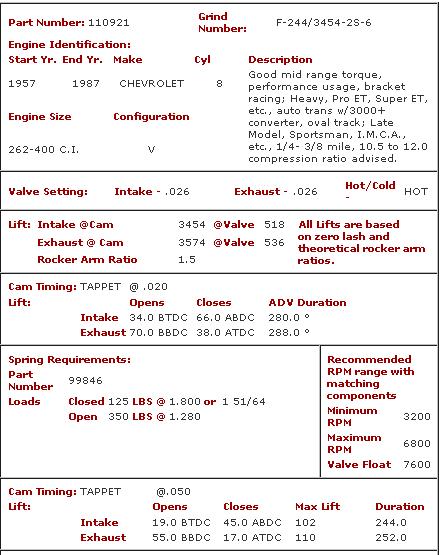

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

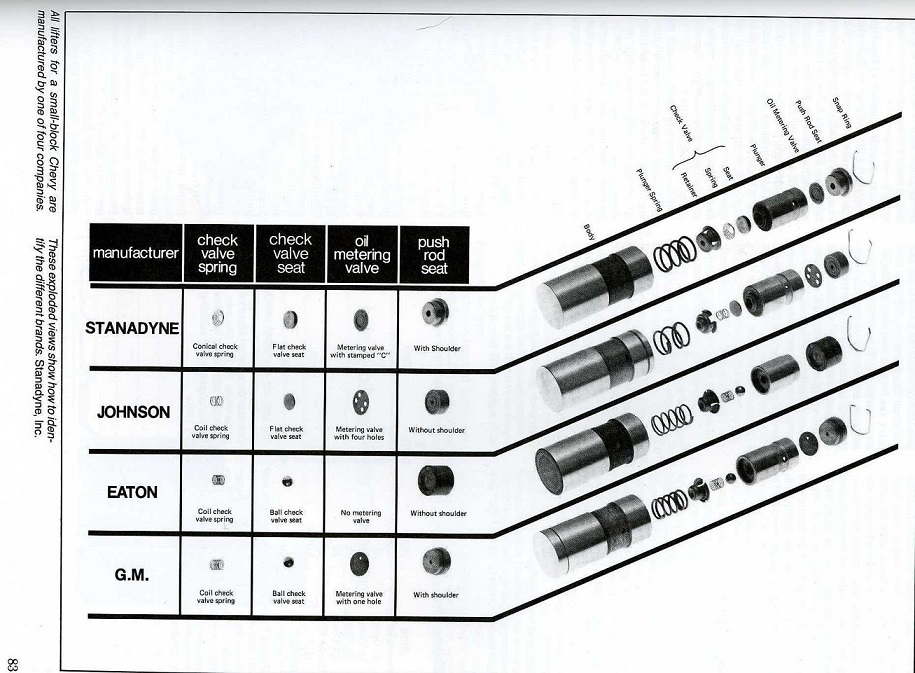

generally its best to purchase all the listed components in a cam installation kit (cam, lifters,valve springs, etc. ) from a single manufacturer as mixing parts, sources or brands,

allows the cam manufacturer to void the warranty, even if the parts in the kit they sell are either identical or inferior to,

the individually purchased components you individually sourced. keep in mind most manufacturers will have tested parts compatibility ,

so they are reasonably sure the components they sell in the kit will work, that can,t be always assumed,

with randomly matched parts even if those parts are good quality.

READ THIS THREAD

http://www.nitemareperformance.150m.com/ZDDP.html

http://s572.photobucket.com/albums/ss16 ... mpCams.flv

http://www.circletrack.com/techarticles ... index.html

adding e.o.s. to your oil is beneficial during the cam break-in, but it tends to leave deposits that can cause detonation over time in the combustion chambers

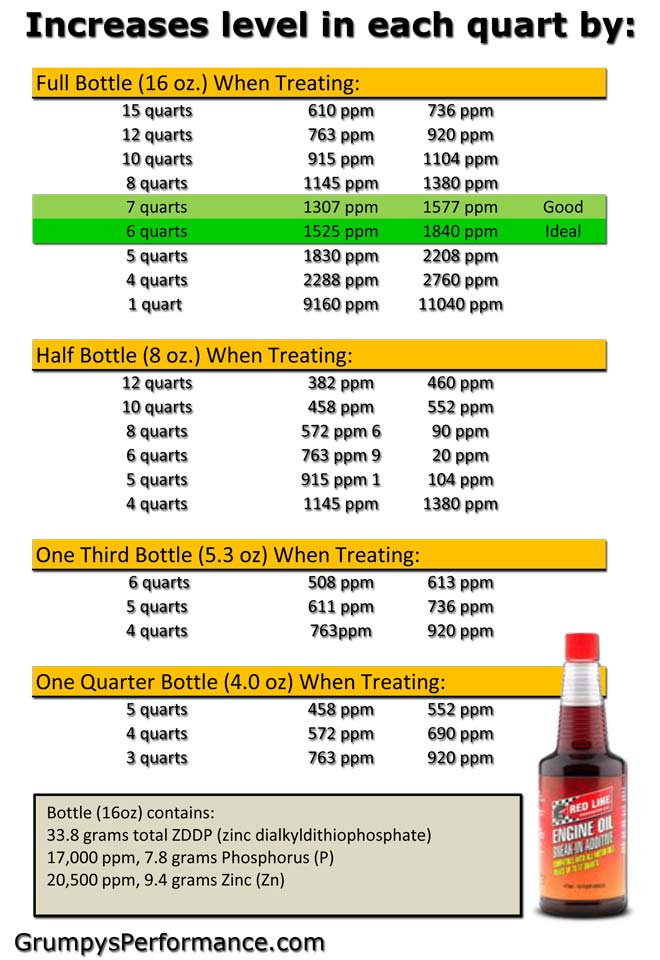

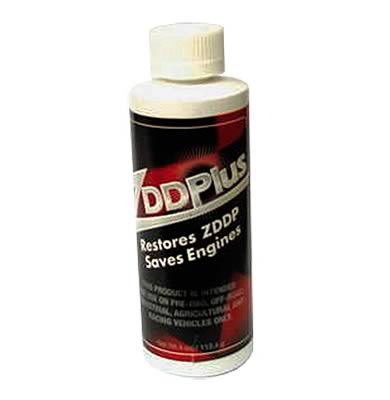

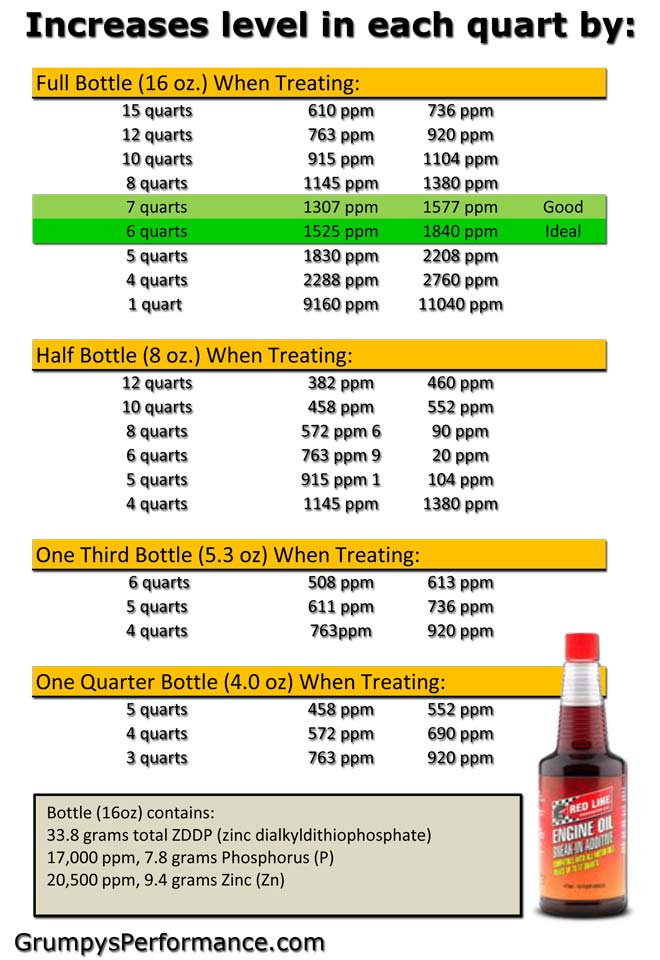

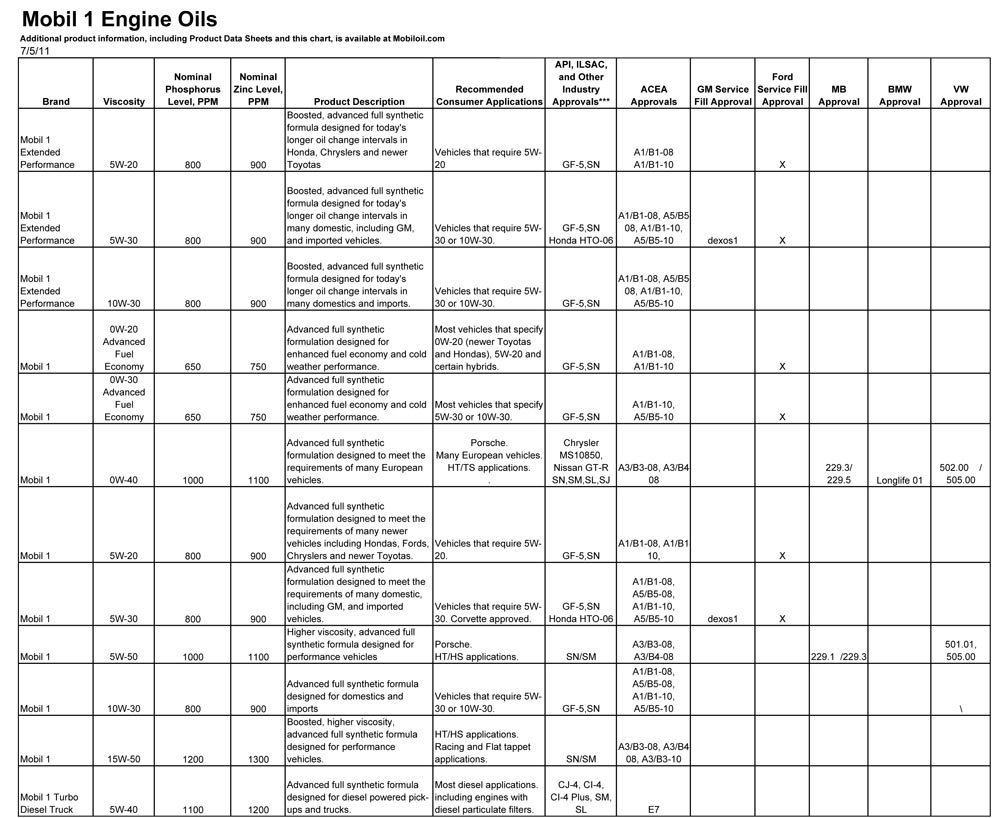

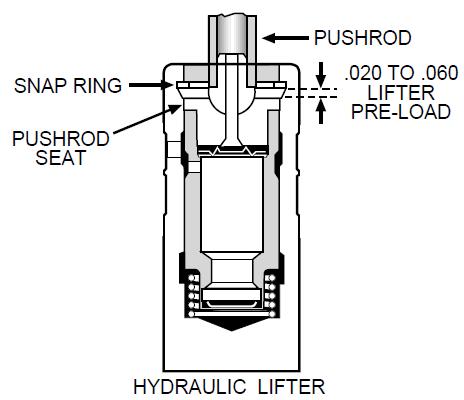

NOTE:1200PPM-1400PPM ZDDP IS THE GENERAL RECOMMENDED MINIMUM ZDDP LEVEL FOR FLAT TAPPET CAMS WITH THE HOT CAMS WITH HI SPRING RATES BEING AT THE HIGHER 1350-1400PPM

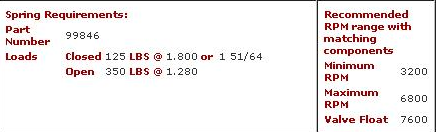

CAST CAM CORES ARE NOT DESIGNED TO HANDLE OVER ABOUT 130lbs SEAT and 400lbs OPEN SPRING LOADS YOU NEED A BILLET CAM CORE FOR DURABILITY IF THOSE LIMITS ARE EXCEEDED

ID suggest you read these links

http://www.enginebuildermag.com/Article ... fters.aspx

http://automotivemileposts.com/zddp.html

http://zddppluscentral.com/

http://www.crower.com/misc/product/dl/ZDDP_clr.pdf

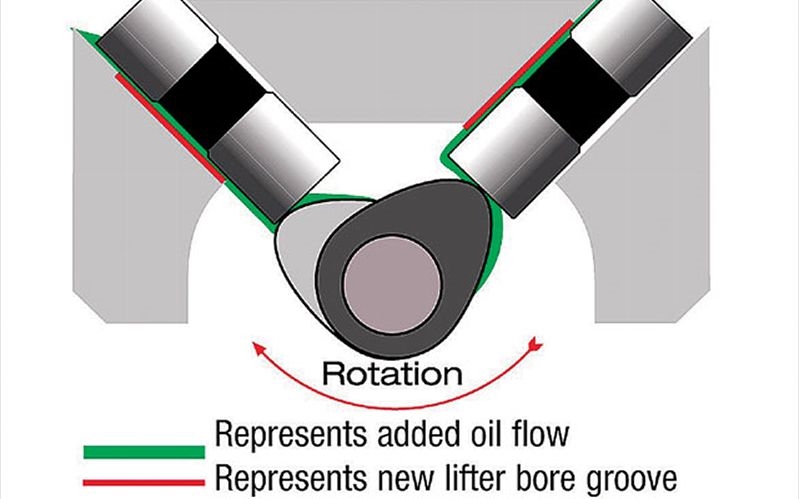

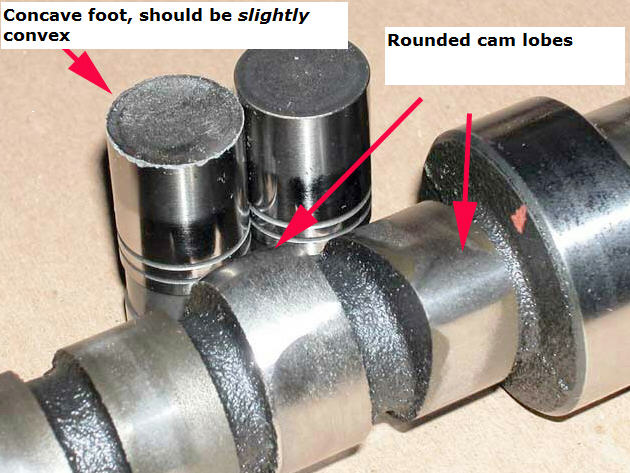

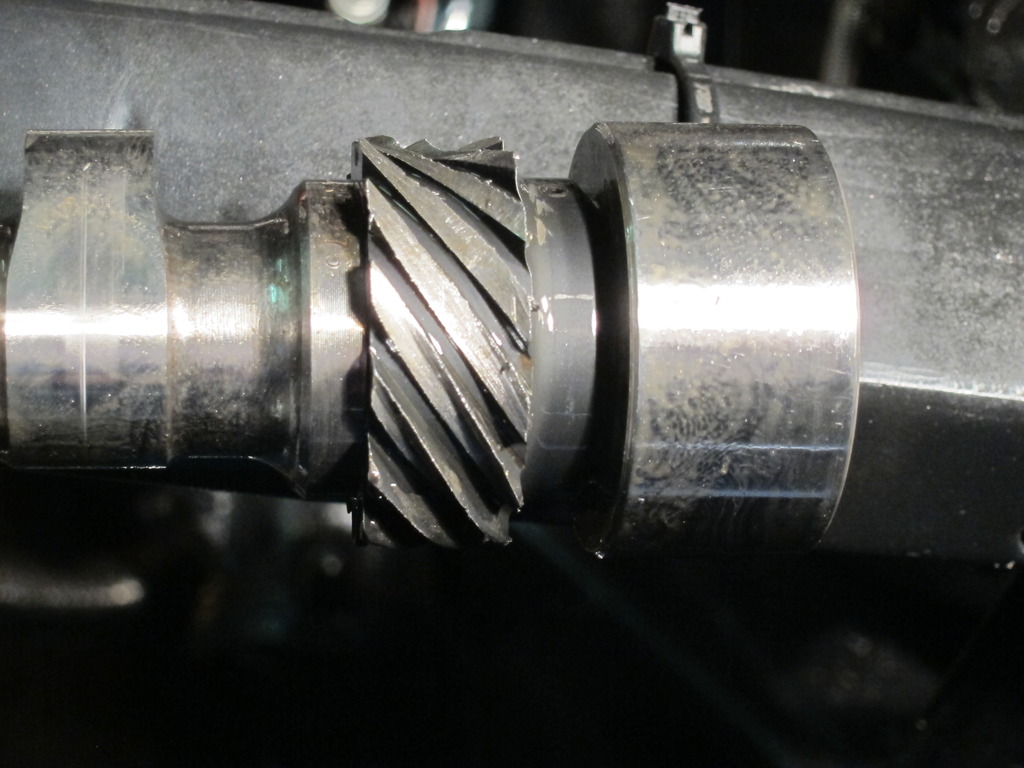

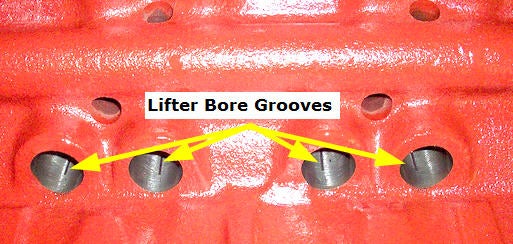

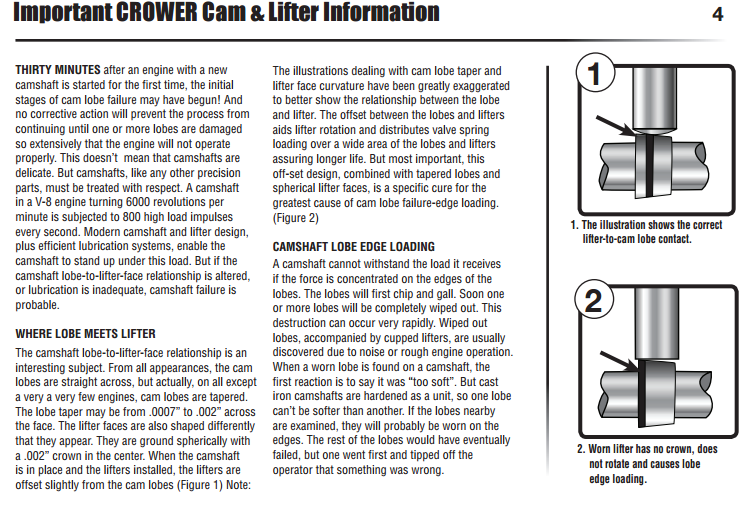

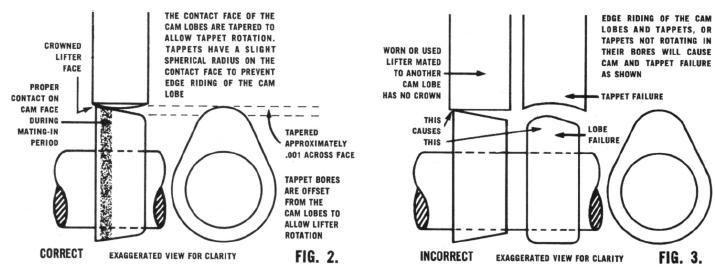

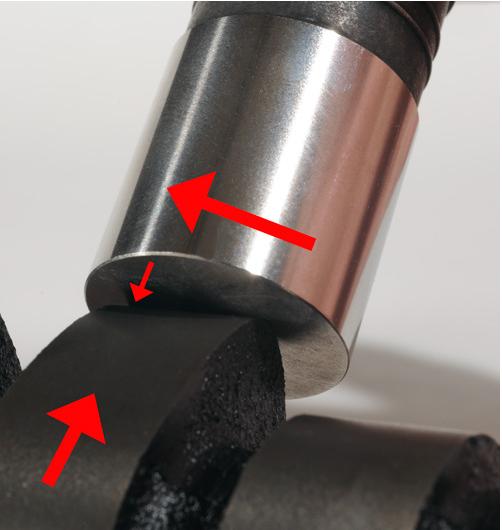

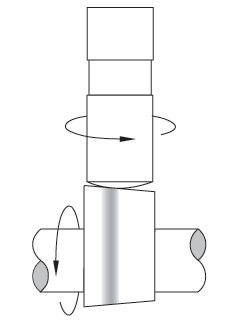

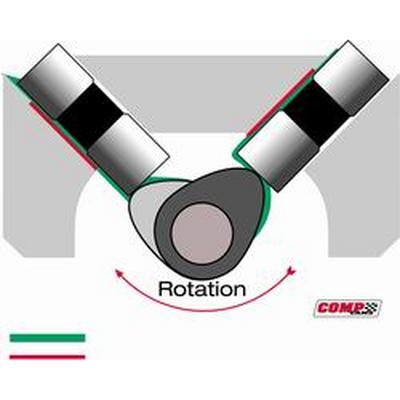

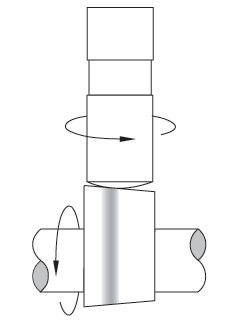

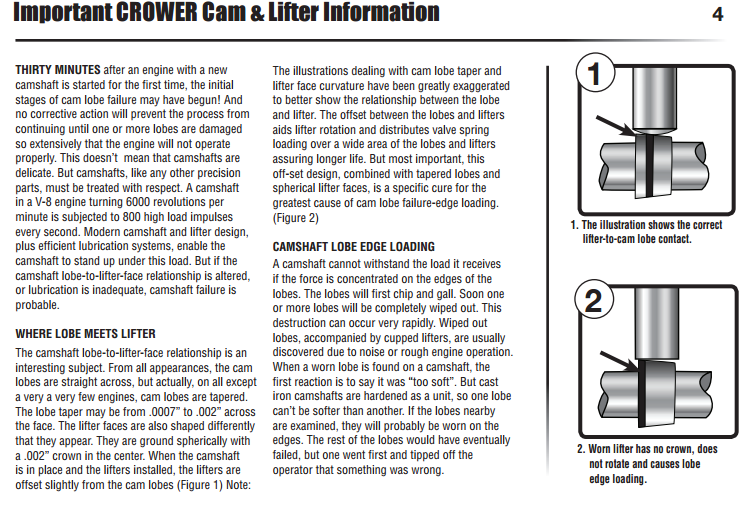

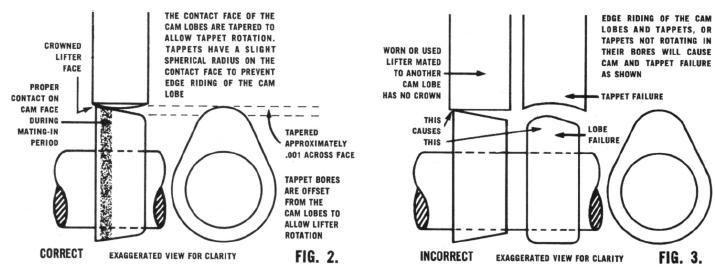

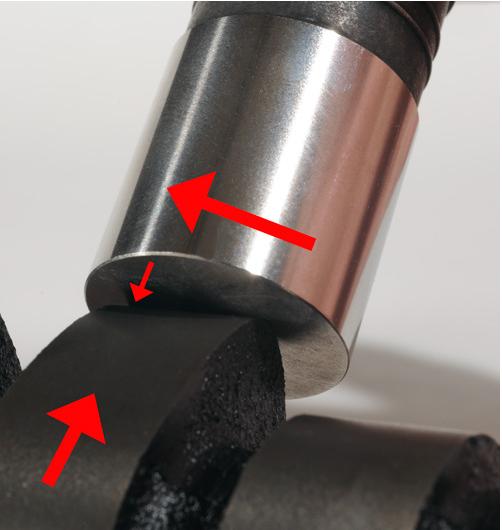

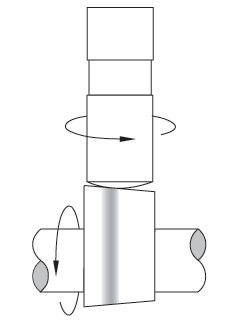

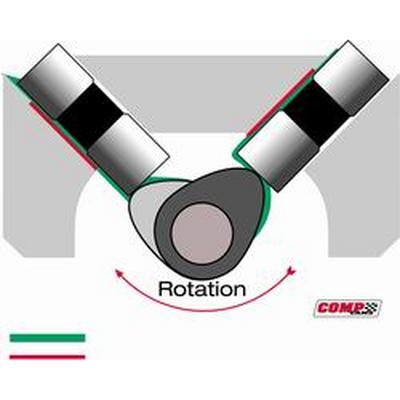

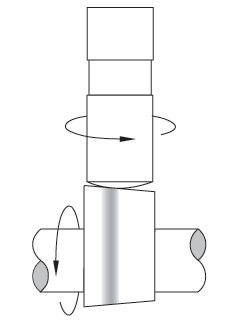

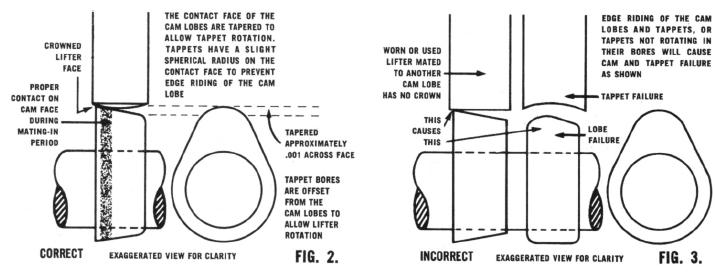

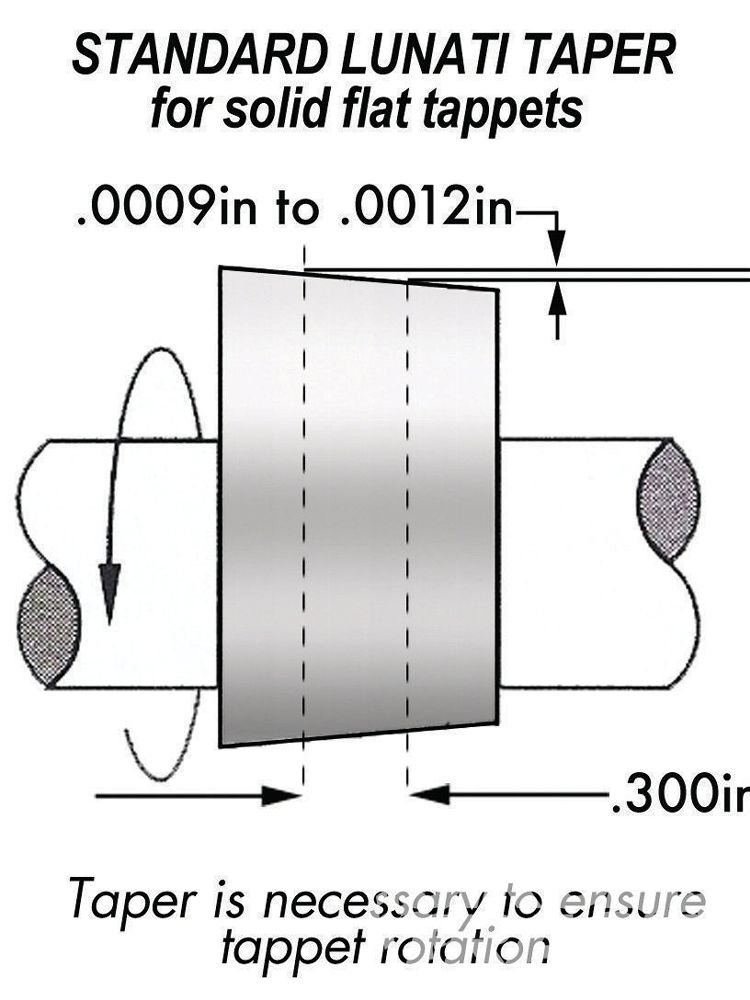

the slight bevel on the cam lobe and the slight convex surface on the lifter base in combination with the lobe center-line being slightly offset from the blocks lifter bore results in the lifter rotating in its bores as the lobe rotates under the lifter base

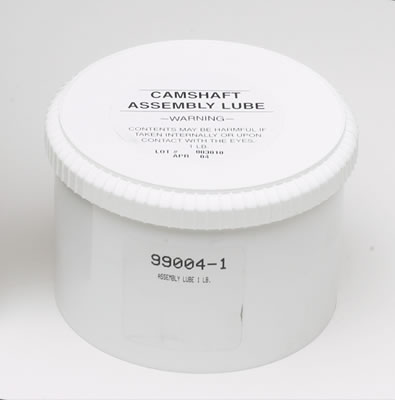

https://www.summitracing.com/parts/crn-99004-1

very good

very very good

pre-spraying all bearing and valve train components with a moly based spray, helps embed micro moly lubricants in the metallic surface micro fissures , a good paste lube like cranes assembly lube over the spray surface helps insure a good lubricant surface coating, that is far stronger than just the ZINC and PHOSPHATES in oil

read this

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out

http://streetmuscleaction.com/wp-conten ... reakin.pdf

spraying the cam surface with moly and then coating it with moly assembly lube before installation tends to help.

http://www.globalindustrial.com/gcs/pro ... paignId=WZ

http://www.circletrack.com/enginetech/c ... index.html

http://www.circletrack.com/enginetech/c ... index.html

http://www.compcams.com/Community/Artic ... 1578676008

http://www.circletrack.com/enginetech/c ... index.html

http://www.corvetteactioncenter.com/tech/oil/index.html

http://www.rehermorrison.com/techtalk/47.htm

http://www.cam-shield.com/index.html

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

http://www.hotrod.com/techarticles/cams ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

the assembly lube, oil and clearances are critical to durability

you might want to read thru this

preventing cam & lifter break-in failures

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

http://www.corvetteactioncenter.com/tech/oil/index.html

OPTIONS

it should be rather obvious that theres options, cam failures are usually the result of incorrect CLEARANCES or too much SPRING PRESSURE or LACK of ADEQUATE LUBRICATION,USE DECENT MOLY CAM LUBE, and decent quality oil, adding MAGNETS to trap metallic CRUD HELPS, be sure to change your oil filter and oil after the first 3-4 hours or 100 miles as theres bound to be crud and assembly lube trapped in the oil and filter

the old familiar stuffs Part #1052367 is getting hard to find

E.O.S. was discontinued but.....

http://www.sdparts.com/product/1052367/GMEngineOilSupplimentEOS16ozBottle.aspx

the new stuff...

http://www.acdelco.com/html/pi_vehcare_lub.htm

(use the drop down menu)

Part 10-106

12371532

E.O.S. Assembly Lubricant (1 pint)

its still available if you know where to look, most but not all parts counter guys will know this but youll run into a few who just insist its not available

http://www.cranecams.com/?show=promo&id=48

btw MOLY base lubes are your first and best break-in lube during the first few minutes

http://www.cranecams.com/index.php?show=browseParts&lvl=2&prt=15

http://www.cranecams.com/pdf/548e.pdf

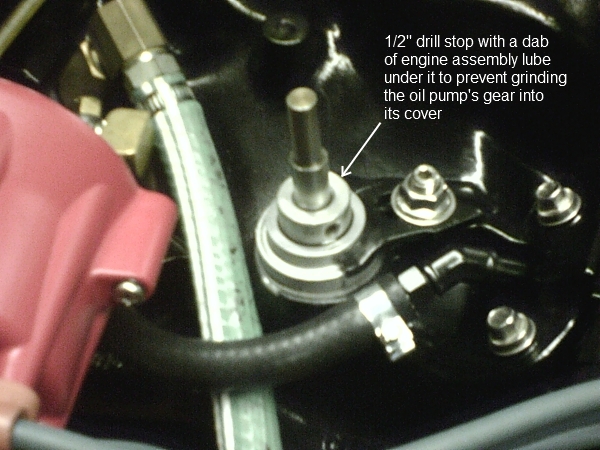

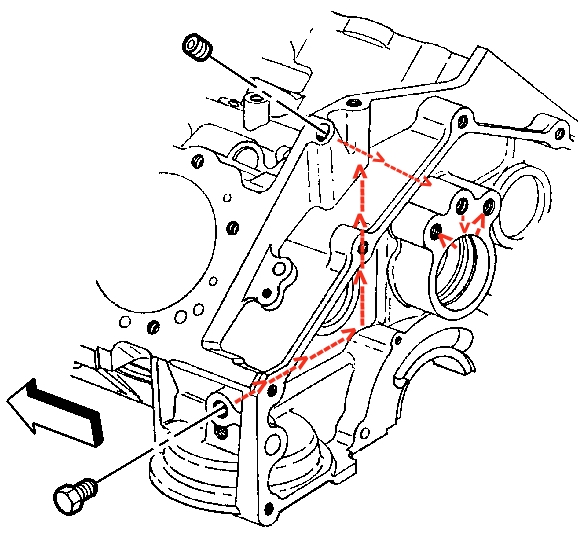

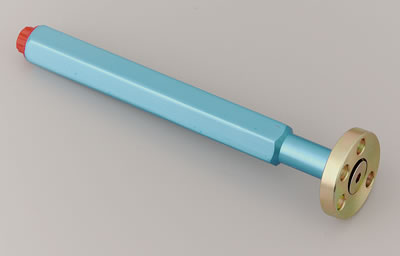

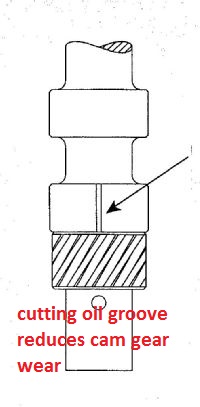

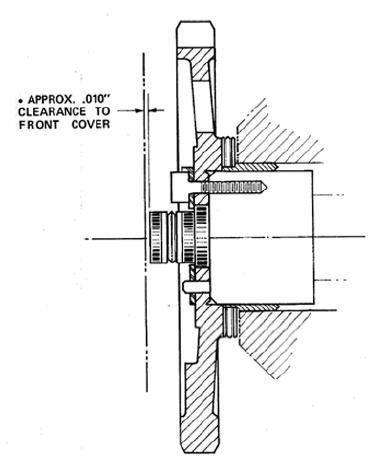

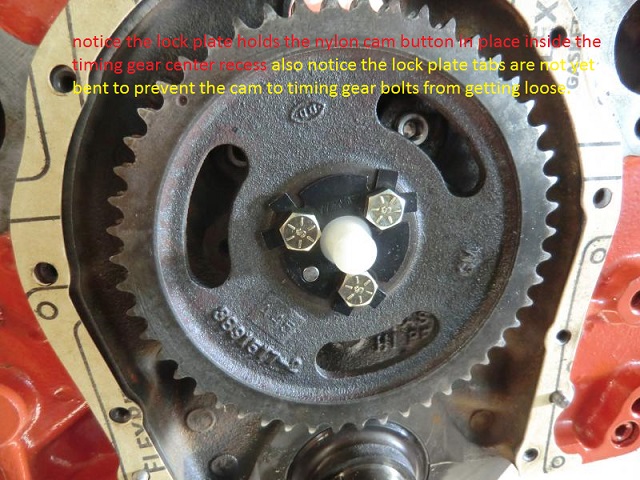

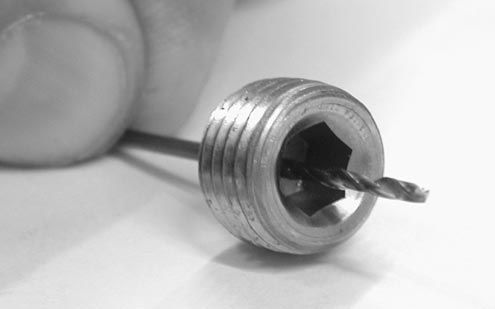

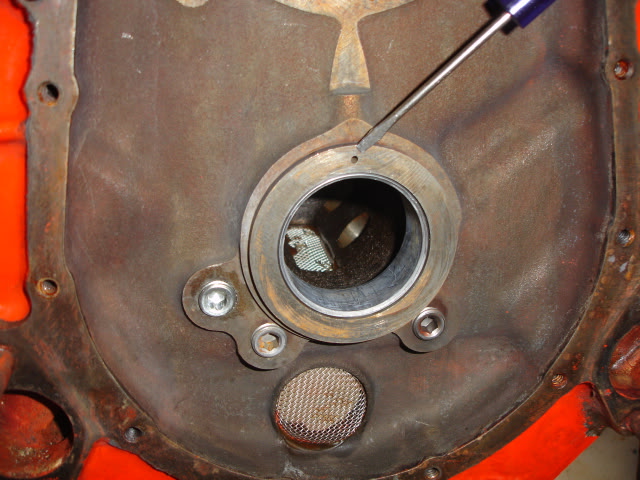

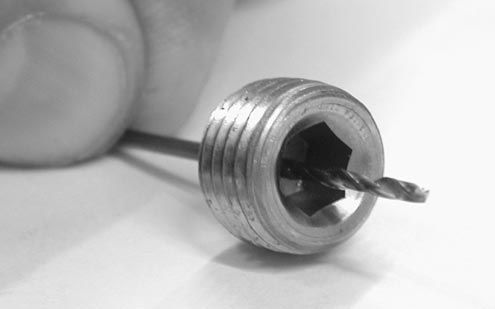

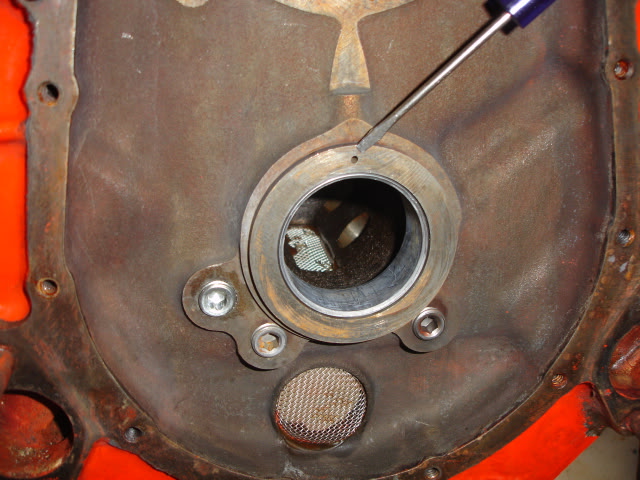

its also a real good idea to drill the pass side oil plug under the timing cover with a .030-.035 drill so oil constantly sprays on the timing chain during use,and while IM discussing cam timing sets Id say that about 90% of the time a good CLOYES timing chain set should be used on street cars vs a gear drive if that's one option your thinking about.

drilling the pass side oil passage plug with a 1/32" bit so oil constantly sprays on the timing gears helps extend chain and gear life.

CRANES Super Lube Break-In Concentrate is an anti-wear additive formulated with a high concentration of special zinc dithiophosphate to provide sustained protection against cam lobe and lifter scuffing and wear. This oil supplement is to be added to the engine oil for the initial break-in period after the installation of a new camshaft and lifters.

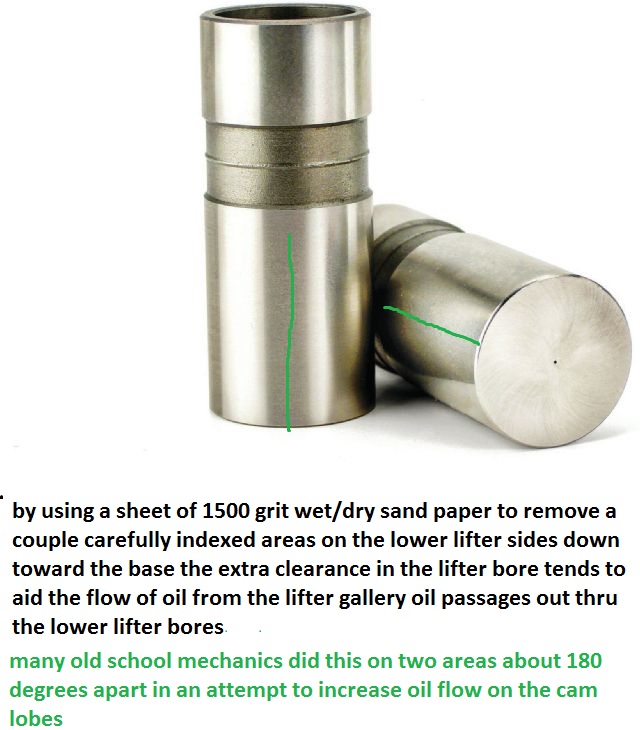

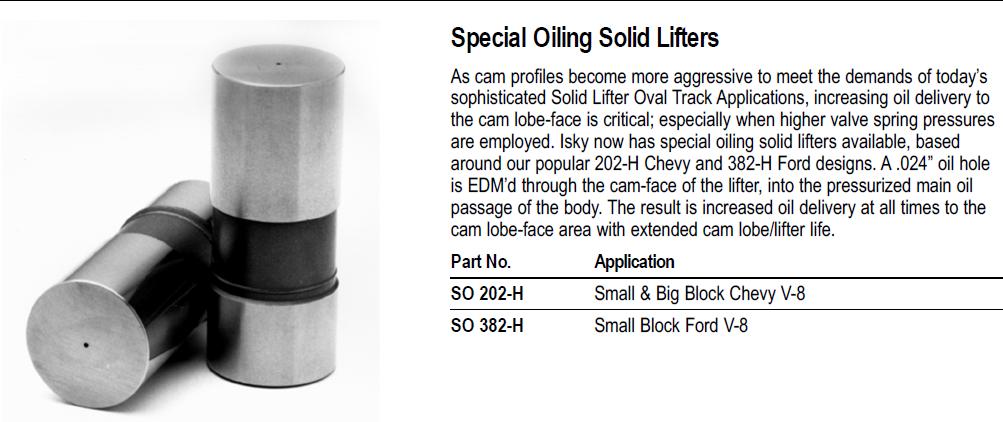

Now it should be obvious that reducing the pressure at the contact point between the lifter and the cam lobe will tend to reduce the tendency for lifter & lobe wear, and increasing the coolant flow at that point helps, so its generally a good idea to remove the INNER spring on DUAL spring valve trains during the break -in process, to reduce pressures while the parts lap in, and a few minutes with some 1000grit sand paper to remove burrs from the lifter edge sure helps in most cases

Part No. 99003-1 -- 8-ounce container

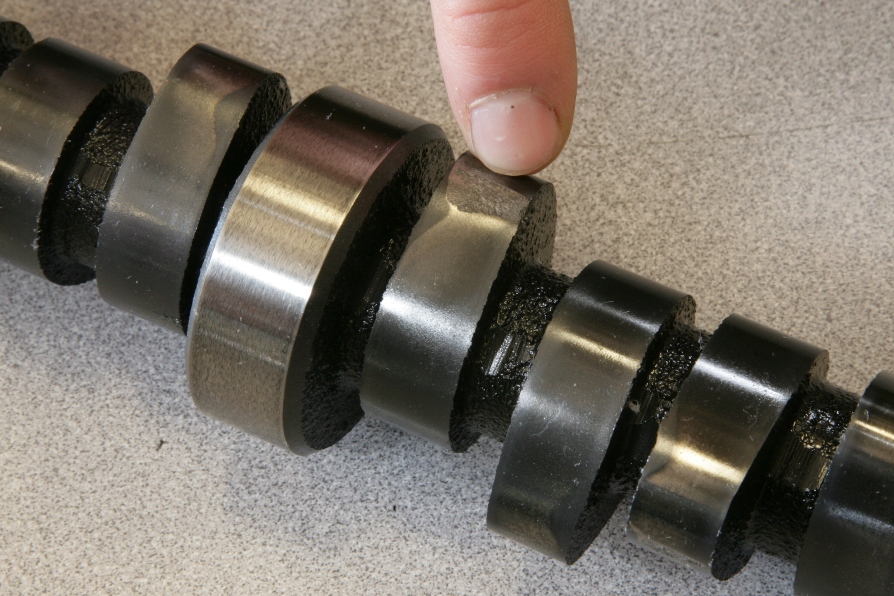

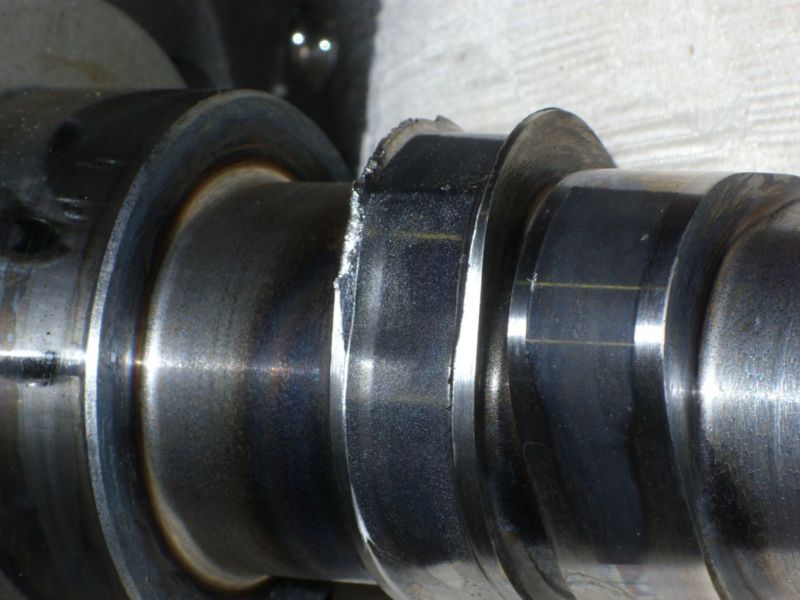

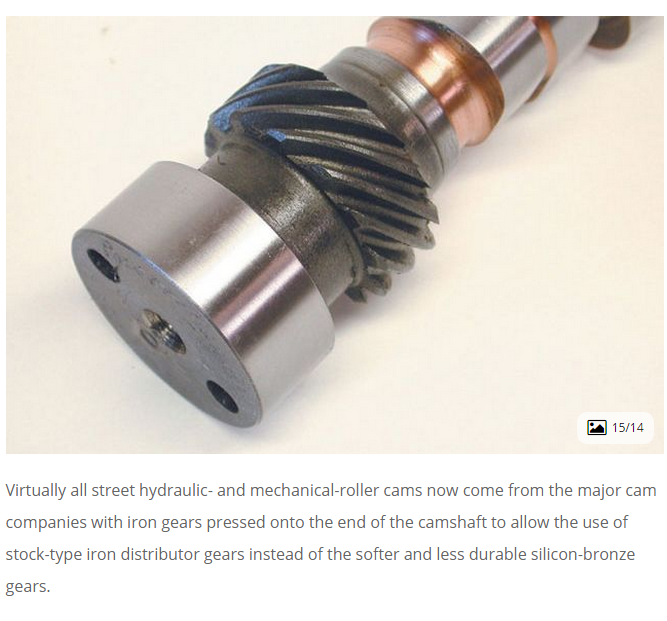

a decent BILLET cam core and quality roller lifters will prevent a great deal of cam lobe wear issues

even roller cams can wipe out lobes if the valve train components or valve train lubrication, geometry is not set up correctly

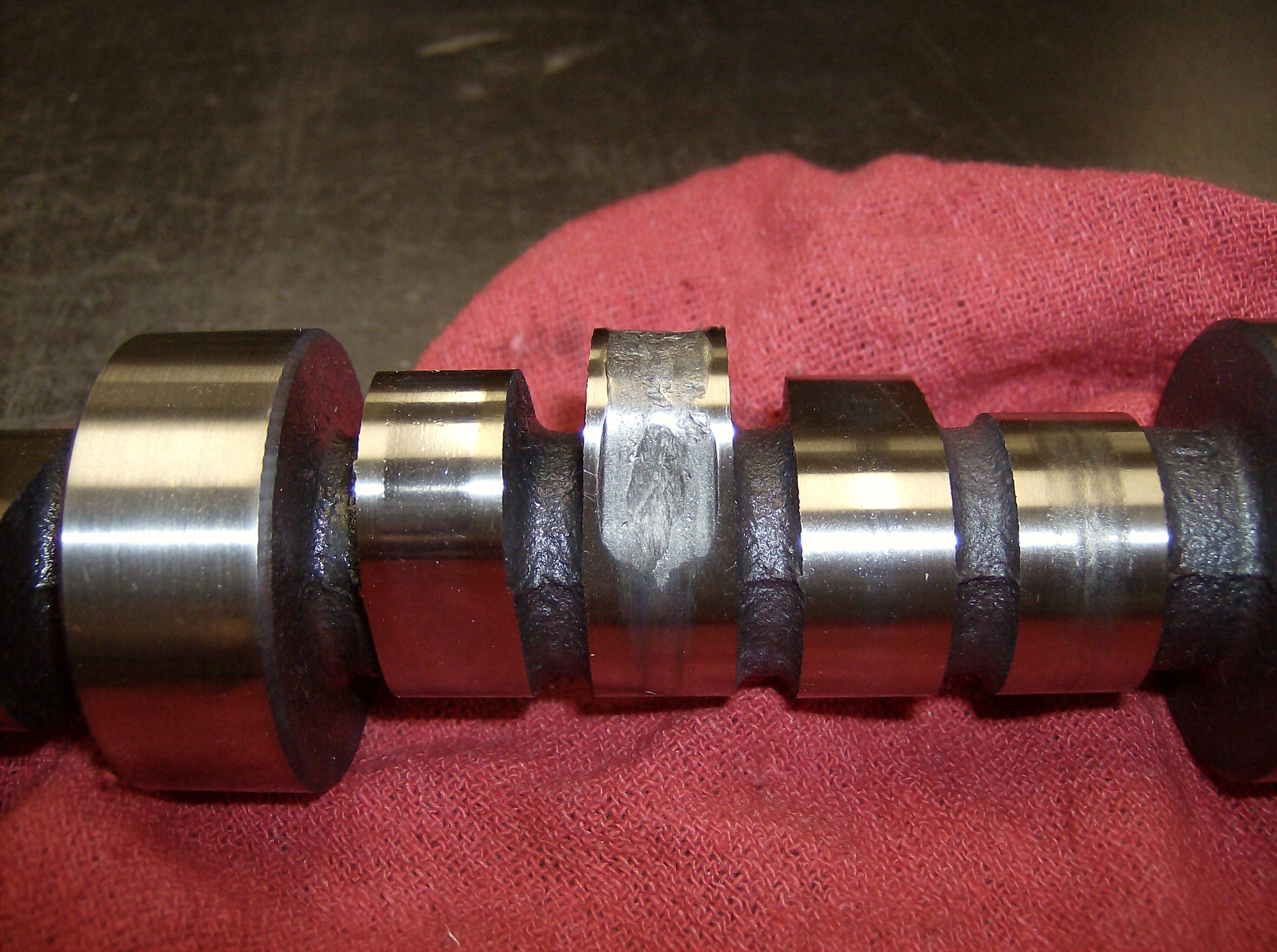

IF youve ever wondered what happens in SECONDS to a cam lobe if the roller lifter turns sideways in its bore if it has the dog bone or link break...

a small hole 1/16" intersecting the oil feed passage to provide pressurized oil to the rear of the timing gear won,t hurt, and tends to reduce block wear

OBVIOUSLY YOULL WANT THE CORRECT VALVE SPRINGS

http://www.competitionproducts.com/1500-1585-OD-Valve-Springs/products/2631/1/0

https://www.summitracing.com/search/part-type/valve-springs

https://www.iskycams.com/cart/valve-springs-c-99.html

http://www.cranecams.com/userfiles/file/334-343.pdf

https://www.racingsprings.com/Valve-Spring/Store/13

http://www.lunatipower.com/Category.aspx?id=23

http://www.pspring.com/products/engine-valve-springs/

http://www.competitionproducts.com/Valve-Springs/departments/49/

http://psisprings.com/products/

http://www.compcams.com/Products/CC-'Valve Springs By Usage'-0.aspx

http://www.racingsprings.com/Beehive-Valve-Springs

https://www.supertechperformance.com/valve-springs-p109

http://www.cvproducts.com/index.php/psi-springs/

or if your into serious mods

have you seen this

http://www.summitracing.com/parts/CRO-86092

BEEHIVE SPRINGS and FORGED STEEL ROCKERS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

BTW BEFORE SOMEONE ASKE'S, YOU CAN NOT USE A ROLLER TAPPET ON A FLAT TAPPET CAM OR A FLAT TAPPET LIFTER ON A ROLLER CAM< BECAUSE...of several reasons, the main one is that, flat tappet cams have BEVELED LOBES, roller cams have PARALLEL LOBE RAMPS, you can NOT mix and match, the lobe on either cam will quickly DESTROY the other type of lifter design, if its mistakenly installed

USED LIFTERS TEND TO BE A BAD BET ON CAM DURABILITY

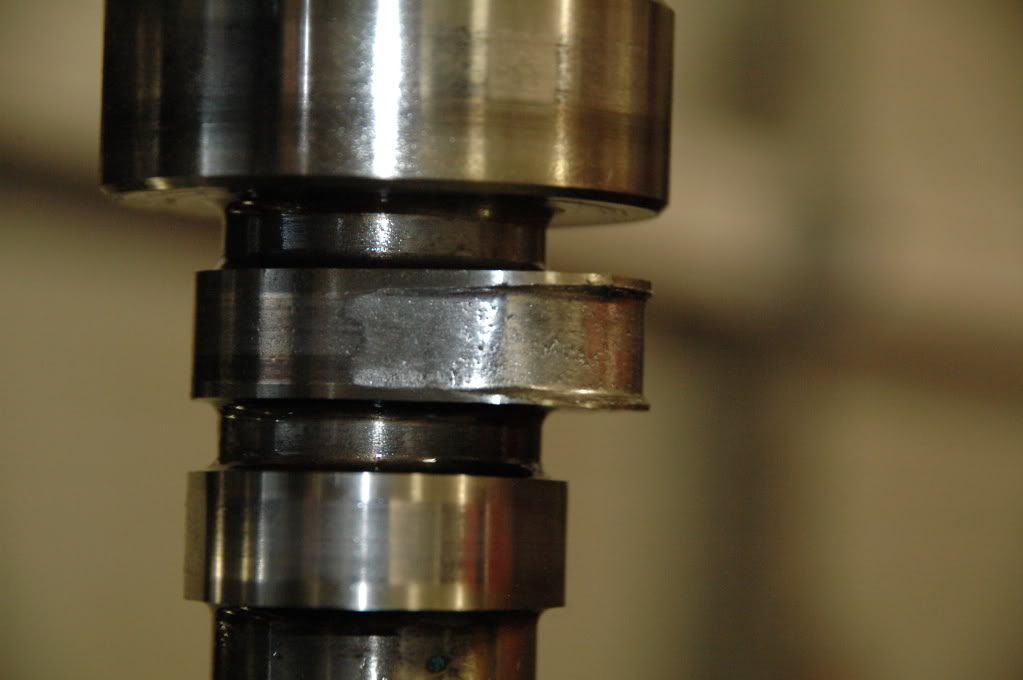

FLAT TAPPET

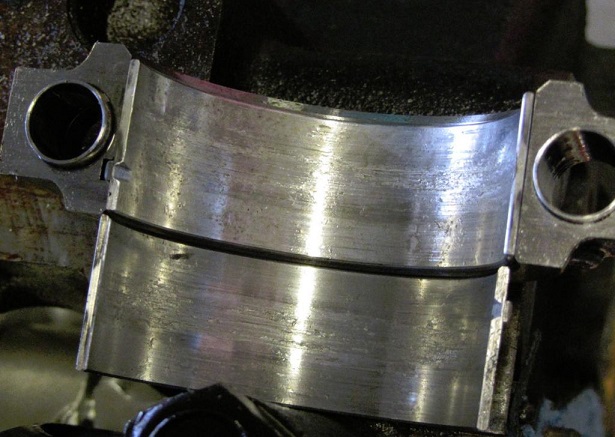

a quality hardened cam with proper lube won,t wear like this first two picture's, but notice the lifter stayed on track

hardened cam lobes and high quality hardened roller lifter wheels have very low rotational friction,

and as long as the valve train stays in its designed limitations and the inertial loads don,t over come the valve springs ability to maintain constant lifter to lobe contact,

and theres a constant bath of cooling oil flowing over the contact areas,

rates of lifter to lobe contact and wear are minimal or basically non-existent over any reasonable time frame

ROLLER CAM

use of the best friction reducing MOLY assembly lube plus the better oils, helps reduce cam lobe wear issues

proper clearances ARE MANDATORY

Moly Basics

Molybdenum Disulfide

posting.php?mode=edit&f=52&p=34840

BRAKE IN LUBE

http://www.summitracing.com/parts/CRO-86092

Molybdenum is a very hard metal with a number of industrial uses.

It is combined with chromium in steel to make the steel harder and more resistant to bending. Most of the bicycle frames produced today use chromium and molybdenum steel. Because the steel is so much harder, the manufacturers can use less, thereby making the frame lighter.

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts.

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out.

Eventually, there is metal to metal contact, which damages these moving parts and creates large amounts of heat. Fortunately, this is not the case with some lubricants.The layer of moly that forms on these moving surfaces can withstand pressures of 500,000 psi, without being squeezed out.

Engineers and scientists have tried for years to use Moly in motor oils but they had been unsuccessful because they could not find a way to keep Moly in suspension. Once Moly was put into suspension it would gradually settle out. It was easy to see it come out of suspension because a black sludge would collect on the bottom of the oil containers. In engines it would settle to the bottom of the crankcase or clog oil pathways and filters.

Engineers have overcome these obstacles. They have developed a process that keeps Moly in suspension and isn’t filtered out. Since that time the product has undergone extensive independent testing in labs and in the field for many years to insure that the product stands up to the rigorous needs of today’s engines. With the plating action of Moly reducing friction which reduces heat, this helps keep rings free from carbon buildup, prevents blow-by, decreases emission, and extends oil life.

ASSEMBLY LUBE USED ON CAMS AND LIFTERS ROCKERS< BEARINGS ETC. like CRANE CAM LUBE, has molybdenum disulfide in assembly lube, that helps maintain a strong heat resistant high pressure lubricating support film on sliding surfaces, BUT assembly lube is NOT INTERCHANGEABLE WITH MOLY AXLE GREASE

which has other ADDITIVES, in some cases its mixed with non-compatible lithium grease base,

you must use a moly based assembly lube thats designed to mix with automotive oil to provide a strong surface film on sliding surfaces

http://en.wikipedia.org/wiki/Lithium-based_grease

Ill point out that I've done the forensics on quite a few failed cams over the years,

that guys have brought to my shop and Id say about

60% of the failed cam lobe & lifter problems were traced to a failure to check clearances or correct valve train geometry issues , like coil bind, rocker to rocker stud, or rocker to adjustment nut clearance, retainer to valve seal, clearances or rocker geometry, use of the wrong spring load rates for the application ,or failure to check valve train or push rods binding issues like rocker to retainer, push rods binding on guide plates or heads, etc. before they became an issue.

about

10% were traced to failure to remove metallic or other trash, generated by a previous cam failing from the engines internal oil passages, or failure to carefully clean the engine before installing the new cam, and components, ( use of shrapnel screens and magnets help a great deal in this but can,t remove all trash as some is non-magnetic)

5% to low quality components, or miss matched parts, like the wrong spring load rates for the application, and perhaps

15% of the failures due to using the wrong lubricants , or not nearly enough moly cam lube on the lobes and lifter bases or setting up the oil supply system correctly, or use of a high quality oil and filter, and a failure to change that oil and filter regularly after the first few hundred miles , the remaining

10% were from unknown causes but more than likely due to a failure to correctly break in the cam, or properly adjust the valves before the engine break-in process or carefully check and re-adjust the lifters rapidly during the break-in process

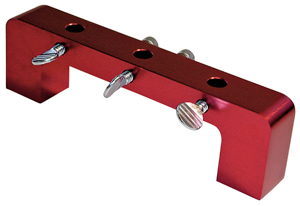

If you suspect a worn cam lobe, checking the cams lobe lift with a dial indicator on the valve spring retainer vs the other lobes would certainly provide useful related info.

knowing vs guessing helps in making decisions wisely

http://www.summitracing.com/parts/pro-66830/overview/

It is when they stop spinning that the camshaft and lifters fail and become a lathe.

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=indicator+stand

read this thread also

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

the rotating assembly bearings ,wrist pins and complete valve train,valve springs, lifters, valves and valve guides and the pistons and rings are where a great deal of the engine heat is generated, and those components are initially cooled with oil flow that absorbs and transfers the heat collected , and transported from those components to the block and coolant, so having a constant flow of pressurized oil flow over those parts are mandatory for maximum durability.thus adding a larger capacity baffled oil pan and an oil cooler will generally enhance and extend an engines life span. Its a good idea TOO ALWAYS ask detailed questions as to the best , and most durable parts combination they have available, for your intended application, from your cam suppliers tech department

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...sion-and-oil-cooler-increases-durability.176/

http://garage.grumpysperformance.co...ck-chevy-gen-v-vi-to-adjustable-rockers.4564/

links worth reading thru

BEFORE TRYING TO BREAK IN YOUR CAM!

http://www.cranecams.com/pdf-tech-tips/cam_failure811.pdf

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://www.drivenracingoil.com/news/dro/training-center/articles/zinc-in-motor-oil/

http://johncalliesinc.com/morel_products.php

http://www.hotrod.com/how-to/engine/ctr ... ubricants/

btw the best deal I found lately on basic hydraulic flat tappet lifters

http://www.summitracing.com/parts/sum-ht817/overview/

HERES A FEW OF THE OILS I TRUST, coat flat tappet lifters and cam lobes with crane moly assembly paste lube

I usually use 6-7 quarts of oil and 1 quart of marvel mystery oil added in my oil pan 11 quart oil pan and oil cooler system capacity

10W30 Valvoline VR1 Conventional Racing Oil

10W30 Valvoline NSL

10w30 Castrol GTX conventional,

10w30 mobile 1

10w30 KENDAL racing oil

and heres a good break in additive for flat tappet lifter cams

http://www.summitracing.com/parts/CRO-86092

http://www.acdelco.com/auto-parts/v...engine-oil-supplement-assembly-lubricant.html

READ THRU THESE LINKS

http://garage.grumpysperformance.co...il-properties-related-to-zddp-detergent.4793/

http://garage.grumpysperformance.co...h-the-oil-when-a-cam-failed.11542/#post-53323

the better quality hydraulic and solid flat tappet lifters have hardened bases

it only takes a few seconds running a new engine for an improperly installed cam , lifters and valve train, during the break-in process to generate teaspoons of metallic trash that ,once in the engine oil flow ,rapidly destroys bearings if the clearances ,spring load rates or valve train geometry is wrong

If your not getting oil flow, at the rockers,youll still need to verify the oil feed holes line up and are not blocked and the rockers adjusted correctly, try backing off on the adjustment nut as the engine idles to the point the rocker clicks noticeably then slowly tighten just to the point the noise stops , then add only a 1/4 turn, and see if that doesn,t cure the oil feed issue

Id also point out that youll want to lubricate any valve you install in a valve guide and verify the valve train clearances very carefully, and use the correct valve springs and add the correct valve seals installed

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

generally its best to purchase all the listed components in a cam installation kit (cam, lifters,valve springs, etc. ) from a single manufacturer as mixing parts, sources or brands,

allows the cam manufacturer to void the warranty, even if the parts in the kit they sell are either identical or inferior to,

the individually purchased components you individually sourced. keep in mind most manufacturers will have tested parts compatibility ,

so they are reasonably sure the components they sell in the kit will work, that can,t be always assumed,

with randomly matched parts even if those parts are good quality.

READ THIS THREAD

http://www.nitemareperformance.150m.com/ZDDP.html

http://s572.photobucket.com/albums/ss16 ... mpCams.flv

http://www.circletrack.com/techarticles ... index.html

adding e.o.s. to your oil is beneficial during the cam break-in, but it tends to leave deposits that can cause detonation over time in the combustion chambers

NOTE:1200PPM-1400PPM ZDDP IS THE GENERAL RECOMMENDED MINIMUM ZDDP LEVEL FOR FLAT TAPPET CAMS WITH THE HOT CAMS WITH HI SPRING RATES BEING AT THE HIGHER 1350-1400PPM

CAST CAM CORES ARE NOT DESIGNED TO HANDLE OVER ABOUT 130lbs SEAT and 400lbs OPEN SPRING LOADS YOU NEED A BILLET CAM CORE FOR DURABILITY IF THOSE LIMITS ARE EXCEEDED

ID suggest you read these links

http://www.enginebuildermag.com/Article ... fters.aspx

http://automotivemileposts.com/zddp.html

http://zddppluscentral.com/

http://www.crower.com/misc/product/dl/ZDDP_clr.pdf

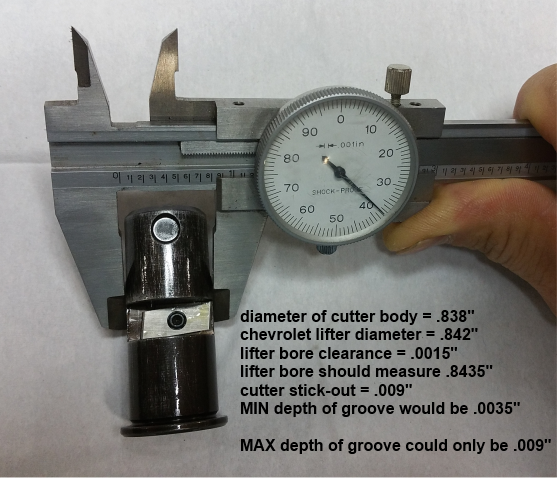

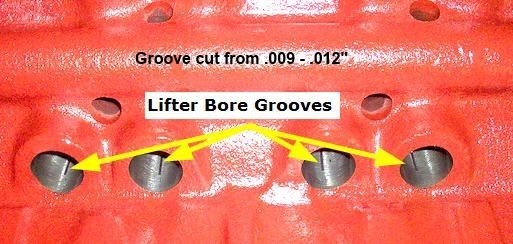

the slight bevel on the cam lobe and the slight convex surface on the lifter base in combination with the lobe center-line being slightly offset from the blocks lifter bore results in the lifter rotating in its bores as the lobe rotates under the lifter base

https://www.summitracing.com/parts/crn-99004-1

very good

very very good

pre-spraying all bearing and valve train components with a moly based spray, helps embed micro moly lubricants in the metallic surface micro fissures , a good paste lube like cranes assembly lube over the spray surface helps insure a good lubricant surface coating, that is far stronger than just the ZINC and PHOSPHATES in oil

read this

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out

http://streetmuscleaction.com/wp-conten ... reakin.pdf

spraying the cam surface with moly and then coating it with moly assembly lube before installation tends to help.

http://www.globalindustrial.com/gcs/pro ... paignId=WZ

http://www.compcams.com/Community/Artic ... 1578676008

http://www.circletrack.com/enginetech/c ... index.html

http://www.corvetteactioncenter.com/tech/oil/index.html

http://www.rehermorrison.com/techtalk/47.htm

http://www.cam-shield.com/index.html

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

http://www.hotrod.com/techarticles/cams ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

the assembly lube, oil and clearances are critical to durability

you might want to read thru this

preventing cam & lifter break-in failures

http://www.pbm-erson.com/uploads/cat%5B ... CEDURE.pdf

http://www.corvetteactioncenter.com/tech/oil/index.html

OPTIONS

it should be rather obvious that theres options, cam failures are usually the result of incorrect CLEARANCES or too much SPRING PRESSURE or LACK of ADEQUATE LUBRICATION,USE DECENT MOLY CAM LUBE, and decent quality oil, adding MAGNETS to trap metallic CRUD HELPS, be sure to change your oil filter and oil after the first 3-4 hours or 100 miles as theres bound to be crud and assembly lube trapped in the oil and filter

the old familiar stuffs Part #1052367 is getting hard to find

E.O.S. was discontinued but.....

http://www.sdparts.com/product/1052367/GMEngineOilSupplimentEOS16ozBottle.aspx

the new stuff...

http://www.acdelco.com/html/pi_vehcare_lub.htm

(use the drop down menu)

Part 10-106

12371532

E.O.S. Assembly Lubricant (1 pint)

its still available if you know where to look, most but not all parts counter guys will know this but youll run into a few who just insist its not available

http://www.cranecams.com/?show=promo&id=48

btw MOLY base lubes are your first and best break-in lube during the first few minutes

http://www.cranecams.com/index.php?show=browseParts&lvl=2&prt=15

http://www.cranecams.com/pdf/548e.pdf

its also a real good idea to drill the pass side oil plug under the timing cover with a .030-.035 drill so oil constantly sprays on the timing chain during use,and while IM discussing cam timing sets Id say that about 90% of the time a good CLOYES timing chain set should be used on street cars vs a gear drive if that's one option your thinking about.

drilling the pass side oil passage plug with a 1/32" bit so oil constantly sprays on the timing gears helps extend chain and gear life.

CRANES Super Lube Break-In Concentrate is an anti-wear additive formulated with a high concentration of special zinc dithiophosphate to provide sustained protection against cam lobe and lifter scuffing and wear. This oil supplement is to be added to the engine oil for the initial break-in period after the installation of a new camshaft and lifters.

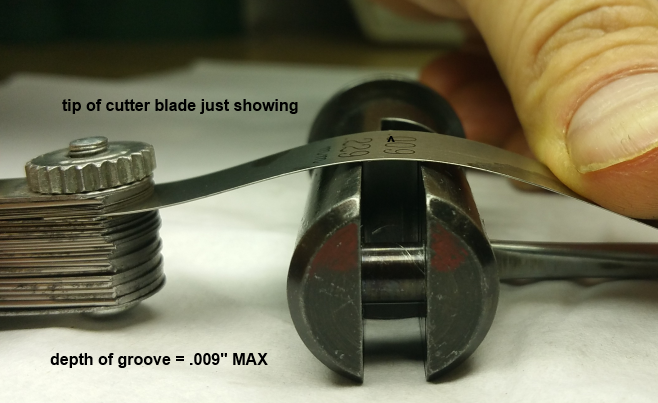

Now it should be obvious that reducing the pressure at the contact point between the lifter and the cam lobe will tend to reduce the tendency for lifter & lobe wear, and increasing the coolant flow at that point helps, so its generally a good idea to remove the INNER spring on DUAL spring valve trains during the break -in process, to reduce pressures while the parts lap in, and a few minutes with some 1000grit sand paper to remove burrs from the lifter edge sure helps in most cases

Part No. 99003-1 -- 8-ounce container

a decent BILLET cam core and quality roller lifters will prevent a great deal of cam lobe wear issues

even roller cams can wipe out lobes if the valve train components or valve train lubrication, geometry is not set up correctly

IF youve ever wondered what happens in SECONDS to a cam lobe if the roller lifter turns sideways in its bore if it has the dog bone or link break...

a small hole 1/16" intersecting the oil feed passage to provide pressurized oil to the rear of the timing gear won,t hurt, and tends to reduce block wear

OBVIOUSLY YOULL WANT THE CORRECT VALVE SPRINGS

http://www.competitionproducts.com/1500-1585-OD-Valve-Springs/products/2631/1/0

https://www.summitracing.com/search/part-type/valve-springs

https://www.iskycams.com/cart/valve-springs-c-99.html

http://www.cranecams.com/userfiles/file/334-343.pdf

https://www.racingsprings.com/Valve-Spring/Store/13

http://www.lunatipower.com/Category.aspx?id=23

http://www.pspring.com/products/engine-valve-springs/

http://www.competitionproducts.com/Valve-Springs/departments/49/

http://psisprings.com/products/

http://www.compcams.com/Products/CC-'Valve Springs By Usage'-0.aspx

http://www.racingsprings.com/Beehive-Valve-Springs

https://www.supertechperformance.com/valve-springs-p109

http://www.cvproducts.com/index.php/psi-springs/

or if your into serious mods

have you seen this

http://www.summitracing.com/parts/CRO-86092

BEEHIVE SPRINGS and FORGED STEEL ROCKERS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

BTW BEFORE SOMEONE ASKE'S, YOU CAN NOT USE A ROLLER TAPPET ON A FLAT TAPPET CAM OR A FLAT TAPPET LIFTER ON A ROLLER CAM< BECAUSE...of several reasons, the main one is that, flat tappet cams have BEVELED LOBES, roller cams have PARALLEL LOBE RAMPS, you can NOT mix and match, the lobe on either cam will quickly DESTROY the other type of lifter design, if its mistakenly installed

USED LIFTERS TEND TO BE A BAD BET ON CAM DURABILITY

FLAT TAPPET

a quality hardened cam with proper lube won,t wear like this first two picture's, but notice the lifter stayed on track

hardened cam lobes and high quality hardened roller lifter wheels have very low rotational friction,

and as long as the valve train stays in its designed limitations and the inertial loads don,t over come the valve springs ability to maintain constant lifter to lobe contact,

and theres a constant bath of cooling oil flowing over the contact areas,

rates of lifter to lobe contact and wear are minimal or basically non-existent over any reasonable time frame

ROLLER CAM

use of the best friction reducing MOLY assembly lube plus the better oils, helps reduce cam lobe wear issues

proper clearances ARE MANDATORY

Moly Basics

Molybdenum Disulfide

posting.php?mode=edit&f=52&p=34840

BRAKE IN LUBE

http://www.summitracing.com/parts/CRO-86092

Molybdenum is a very hard metal with a number of industrial uses.

It is combined with chromium in steel to make the steel harder and more resistant to bending. Most of the bicycle frames produced today use chromium and molybdenum steel. Because the steel is so much harder, the manufacturers can use less, thereby making the frame lighter.

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts.

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out.

Eventually, there is metal to metal contact, which damages these moving parts and creates large amounts of heat. Fortunately, this is not the case with some lubricants.The layer of moly that forms on these moving surfaces can withstand pressures of 500,000 psi, without being squeezed out.

Engineers and scientists have tried for years to use Moly in motor oils but they had been unsuccessful because they could not find a way to keep Moly in suspension. Once Moly was put into suspension it would gradually settle out. It was easy to see it come out of suspension because a black sludge would collect on the bottom of the oil containers. In engines it would settle to the bottom of the crankcase or clog oil pathways and filters.

Engineers have overcome these obstacles. They have developed a process that keeps Moly in suspension and isn’t filtered out. Since that time the product has undergone extensive independent testing in labs and in the field for many years to insure that the product stands up to the rigorous needs of today’s engines. With the plating action of Moly reducing friction which reduces heat, this helps keep rings free from carbon buildup, prevents blow-by, decreases emission, and extends oil life.

ASSEMBLY LUBE USED ON CAMS AND LIFTERS ROCKERS< BEARINGS ETC. like CRANE CAM LUBE, has molybdenum disulfide in assembly lube, that helps maintain a strong heat resistant high pressure lubricating support film on sliding surfaces, BUT assembly lube is NOT INTERCHANGEABLE WITH MOLY AXLE GREASE

which has other ADDITIVES, in some cases its mixed with non-compatible lithium grease base,

you must use a moly based assembly lube thats designed to mix with automotive oil to provide a strong surface film on sliding surfaces

http://en.wikipedia.org/wiki/Lithium-based_grease

Last edited by a moderator: