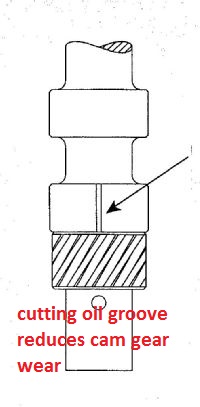

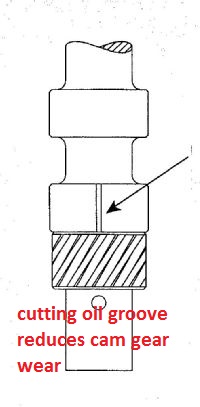

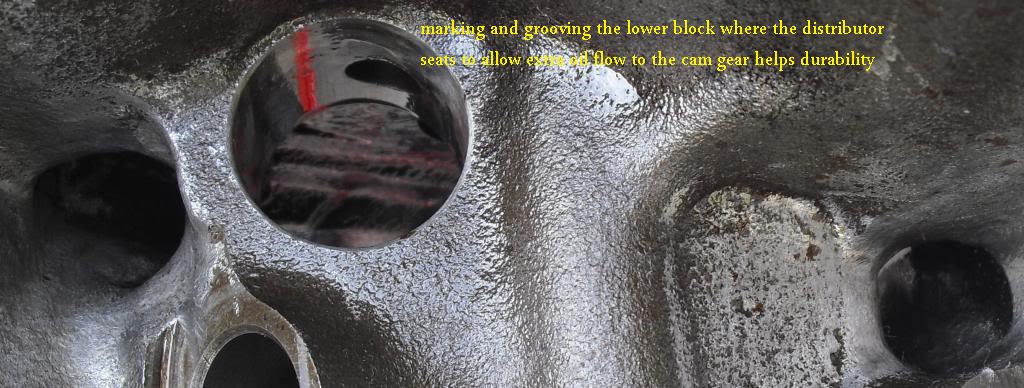

as a general tip, marking the distributor shaft so the oil sprays on the cam gear/distributor gear mesh/contact area helps,

durability, if its correctly located and its not too large,

but that depends to some extent to be helpful on getting the oil flow groove correctly indexed,

and that might be screwed up a bit if its not placed correctly , now obviously if the engines in the car and assembled its not a good idea to start doing this,,

it helps during the initial engine assembly if you put some thought into the build before you get too far into the build,

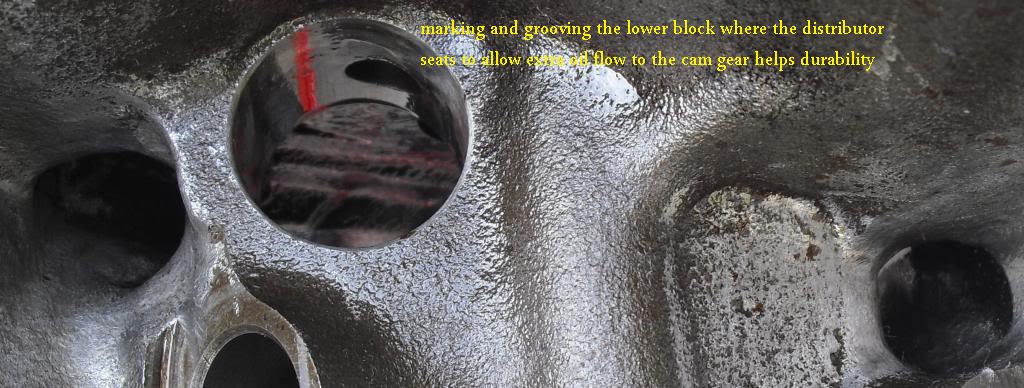

if you have the bare block at some point to groove the area in the block where the distributor seats,

just a bit with a very small second groove as the picture indicate,

as that ill always be in the correct location and does not depend on the distributors position in the block.

don't get carried away a groove about .008 x.008 (eight thousand's deep x eight thousand's wide in the correct location,) is all that's necessary

so grooving the lower oil band directly above the point where the gears start to mesh helps spray extra oil on the distributor/cam gears contact area, and yes that changes with distributor position so most guys cut a small fine groove in both the lower block wall and the distributor lower section above that location to assure a constant oil mist spray into the meshing gears

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

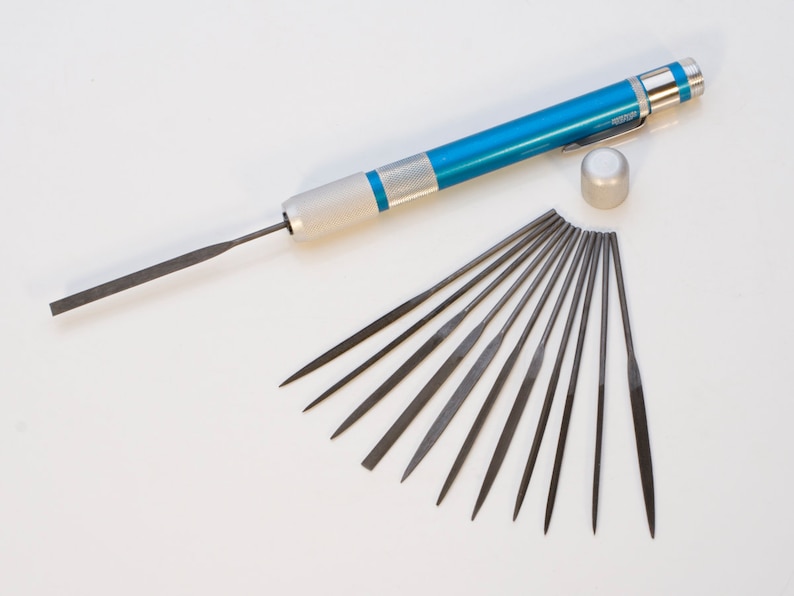

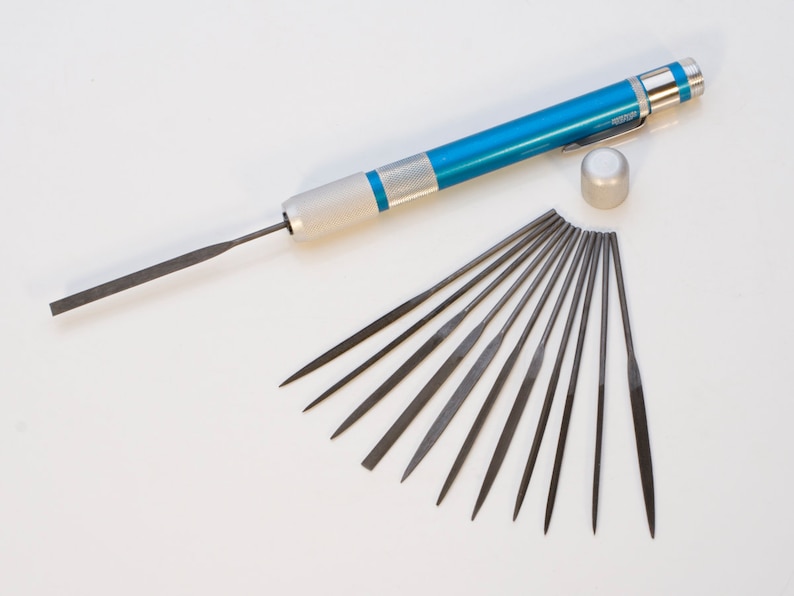

owning a set of jeweler's files certainly won't hurt any engine shop

and thats $20 well spent

https://www.etsy.com/listing/628075...2663&msclkid=7f4f3c79f79518b7c26c5c5b97776f4e

durability, if its correctly located and its not too large,

but that depends to some extent to be helpful on getting the oil flow groove correctly indexed,

and that might be screwed up a bit if its not placed correctly , now obviously if the engines in the car and assembled its not a good idea to start doing this,,

it helps during the initial engine assembly if you put some thought into the build before you get too far into the build,

if you have the bare block at some point to groove the area in the block where the distributor seats,

just a bit with a very small second groove as the picture indicate,

as that ill always be in the correct location and does not depend on the distributors position in the block.

don't get carried away a groove about .008 x.008 (eight thousand's deep x eight thousand's wide in the correct location,) is all that's necessary

so grooving the lower oil band directly above the point where the gears start to mesh helps spray extra oil on the distributor/cam gears contact area, and yes that changes with distributor position so most guys cut a small fine groove in both the lower block wall and the distributor lower section above that location to assure a constant oil mist spray into the meshing gears

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

owning a set of jeweler's files certainly won't hurt any engine shop

and thats $20 well spent

https://www.etsy.com/listing/628075...2663&msclkid=7f4f3c79f79518b7c26c5c5b97776f4e

Last edited: